Professional Documents

Culture Documents

Lipped channel compression members: Effective width method for local and global buckling

Uploaded by

amokeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lipped channel compression members: Effective width method for local and global buckling

Uploaded by

amokeCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/334603567

EFFECTIVE WIDTH METHOD FOR LIPPED CHANNEL COMPRESSION MEMBER

UNDERGOING LOCAL AND GLOBAL BUCKLING INTERACTION

Conference Paper · December 2018

CITATIONS READS

0 154

2 authors, including:

Aayillia K Jayasidhan

Indian Institute of Technology Palakkad

3 PUBLICATIONS 1 CITATION

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

POST-GLOBAL BUCKLING STRENGTH OF CFS COMPRESSION MEMBERS View project

All content following this page was uploaded by Aayillia K Jayasidhan on 23 July 2019.

The user has requested enhancement of the downloaded file.

SEC18: Proceedings of the 11th Structural Engineering Convention - 2018

Jadavpur University, Kolkata, India, December 19 - 21, 2018

Paper No. 20180358_1

EFFECTIVE WIDTH METHOD FOR LIPPED CHANNEL

COMPRESSION MEMBER UNDERGOING LOCAL AND GLOBAL

BUCKLING INTERACTION

Aayillia K Jayasidhan1 and M V Anil Kumar2

1, 2

Department of Civil Engineering, Indian Institute of Technology Palakkad, Kerala, India

E-mail: 101704001@smail.iitpkd.ac.in, anil@iitpkd.ac.in

ABSTRACT

Cold-formed steel (CFS) compression members may undergo local buckling (L), distortional buckling

(D), global/Euler’s buckling (E) or interaction between these modes such as local-distortional (LD),

local-global (LE), distortional-global (DE) or local-distortional-global (LDE) before failure.The

strength of such members may be calculated using the traditional effective width method (EWM) or

the recent direct strength method (DSM). LE interaction accounted for both EWM and DSM is by

replacing yield strength, fy in the local buckling strength equation with global buckling strength, fn. In

this paper, the adequacy of EWM in estimating the ultimate strength of lipped channel compression

members undergoing independent local buckling or LE interaction before failure was evaluated. Finite

element analysis results available in the literature are used for this study. Even though EWM predicts

strength of lipped channel due to local buckling accurately, it gives very conservative results for LE

interaction especially when the global buckling mode is flexural-torsional.

Keywords: Cold-formed steel, Compression member, Effective Width Method, LE interaction

NOMENCLATURE Pule=Ultimate strength under local-global(LE)

Interaction (N)

beff =Effective width of plate element(mm)

1. INTRODUCTION

b= Width of plate element(mm)

Cold-formed steel (CFS) members are used as

load bearing members in lightweight structures

=non-dimensional slenderness ratio due to its high strength to weight ratio. CFS

members are fabricated from thin steel plates

fy=yield stress of material (N/mm2) (thickness ranging from 0.6mm to 3mm) as

strength relies more on the shape than the

=Critical local buckling stress thickness of the plate elements. The thin plate

elements leads to different buckling modes such

k = Plate buckling coefficient as local buckling (L), distortional buckling (D),

global/Euler’s buckling (E) or interaction

= Youngs modulus(N/mm2) between these buckling modes such as local-

distortional (LD), local-global (LE),

=Poison’s ratio distortional-global (DE), or local-distortional-

global (LDE) before material yielding(Y). The

Pu-FEA= Ultimate strength from Finite Element strength of thin-walled CFS members is

Analysis(FEA) calculated by effective width method (EWM) or

direct strength method (DSM).

Pul=Ultimate strength under local buckling (N)

EWM [NAS(2016), EN 1993-1-3(2004),

IS801(1975), AS/NZS2005] uses the reduced

SEC18:Paper No. 20180358_1

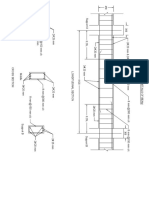

width(effective width, beff) of different plate The FE model used by Kumar and

elements (eg: web, flanges, lips etc.) to account Kalyanaraman (2012) for generating data for

for local buckling and effective area obtained independent local buckling strength is shown in

from the reduced section properties are used for Fig.1. The translational restraints at corners 1

member strength calculation. DSM and 3 (Fig.1) eliminates global buckling without

[NAS(2016), Schafer and Pekö z (1998b), restraining the Poisson’s expansion of the plate

Hancock et. al. (1994), Schafer (2002), and elements. Multi-point constraints (Fig.1)

Schafer(2008)] considers buckling of the ensuring the out of plane translation of the

member(local, distortional and global) as a flange at flange-lip juncture equal to that at

whole and ultimate strength is calculated from web-flange juncture eliminates the out of plane

elastic buckling loads using empirical equations. movement of flange-lip assembly. i.e., MPC

The concept of the effective width of eliminates the distortional buckling mode.

compressed plate elements simply supported

along both longitudinal edges was originally

proposed by Von Karman (1932) and

subsequently calibrated for imperfection by

Winter (1968). Effective width formula

proposed by Winter (1968), is given in Eq.[1].

( . / )

= ≥ 0.673 (1)

1 < 0.673

Fig.1: FEA model for independent local

buckling [Kumar(2012)]

If the member is slender, it may undergo global

member buckling in addition to local buckling The FE model used by Kumar and

of the plate elements. The local-global (LE) Kalyanaraman (2018) for generating data for

buckling interaction is accounted for in both strength of the specimen failed in LE interaction

EWM and DSM by replacing yield stress, fy, in shown in Fig.2. The distortional buckling mode

the local buckling strength (fcr) equation [Eq.(1)] is eliminated from the FE model by using an

with global buckling strength, fn. This procedure artificial constraint, known as distortional

is justified as the maximum stress in the cross buckling constraint (DBC). DBC consists of

section of the long compression member is beam elements connecting four corners to the

equal to global buckling strength, fn. shear centre (SC) as shown in Fig.2. The in-

plane hinges (H1) are provided at end of the

This paper evaluates the accuracy of EWM for beam to avoid rotational restraint offered to

estimating the strength of CFS lipped channel plate elements by the beams. This will ensure

compression member with fully stiffened that local buckling deformations are not affected

flanges under independent local buckling and by DBC. The torsional rigidity remains

LE interaction. The finite element analysis unaffected as the beam elements meets at shear

(FEA) results of lipped channel compression centre. The out of plane hinge (H2) at the shear

members undergoing LE interaction reported in centre end ensures that warping behavior is

Kumar and Kalyanaraman(2012,2018) are used unaffected.

for this study.

2. FINITE ELEMENT ANALYSIS

The details of the finite element (FE) model and

its validation with the test results are reported in

Kumar and Kalyanaraman (2012, 2018).

Statistical summary of FEA validation is shown

in Table 1. Constraints are used in such a way

that the failure of the specimen is either due to

independent local buckling or due to LE Fig.2: FEA model for LE interaction

interaction. [Kumar(2018)]

SEC18:Paper No. 20180358_1

3. EVALUATION OF EFFECTIVE partial rotational restraint offered by the

WIDTH METHOD adjoining element to buckling element)

is ignored in the elastic buckling load

3.1. Local Buckling calculation.

The adequacy of EWM for estimating the local 3.2. LE Interaction

buckling strength of CFS lipped channel

compression members with fully stiffened LE interaction is accounted for in EWM is by

flanges is evaluated using test and FEA results replacing the yield stress, fy by global buckling

of specimens failed due to independent local strength, fn in Eq.(1).The ratio of the ultimate

buckling. strength from FEA to that obtained from EWM

(Pule-FEA /Pule-EWM), is plotted against non-

The ratio of ultimate strength from either tests dimensional slenderness λLE [√(fn/fcrl)] in Fig.4

or FEA to that obtained from EWM (Pul-FEA/Pul- for different web height to flange width, h/b,

EWM) is plotted with respect to non-dimensional ratios. The statistics of Pule-FEA/Pule-EWM are given

local buckling slenderness of cross section in Table 2.

λL[√(fy/fcrl)] in (Fig.3). The statistics of

comparison (Sample size (n), mean ( ), 2.5

h/b=2

standard deviation ( ), maximum value (Max) h/b=1.5

2 h/b=1

and minimum value (Min)) are given in Table 1. h/b=0.6

2

Pule-FEA/Pule-EWM

1.5

1.75

1.5 1

Pul-FEA/Pul-EWM

1.25

0.5

1

0.75 0

0 1 2 3

0.5 λLE

0.25 Fig.4: Pule-FEA/Pule-EWM vs λLE for LE interaction

0

Table.2: Statistical summary of Pule-FEA/Pule-EWM

0 1

λL 2 3 4

Fig. 3: Pul-FEA/Pul-EWM vs λL

h/b n Max. Min.

Table.1: Statistical summary of Pu-FEA /Pul-EWM

2 15 1.058 0.084 1.205 0.939

Reference n Max. Min. 1.5 24 1.2 0.201 1.503 0.780

1 24 1.312 0.245 1.837 0.967

Kumar

32 1.078 0.071 1.238 0.944 0.6 17 1.331 0.252 1.633 0.752

(2012)

FEA . 80 1.235 0.231 1.837 0.752

10 0.974 0.048 1.051 0.903

Validation

Following observations are made from Fig.3 Observations based on Fig.4 and Table 2 are

and Table-1. listed below;

The statistical parameters (μ =1.078, The statistical parameters (μ =1.23, and

and σ =0.071) of (Pul-FEA/Pul-EWM) shows σ =0.231) of (Pule-FEA/Pul-EWM) shows that

that EWM predicts the strength of EWM gives very conservative strength

lipped channel compression members estimates for specimens failing due to

accurately. LE interaction.

For larger values of λL the EWM The maximum conservative prediction

predictions are conservative. This may is around 83%. This shows that there is

be because the element interaction (the scope of improving the LE interaction

procedure adopted by EWM

SEC18:Paper No. 20180358_1

The EWM predictions corresponding to Euler Buckling of Thin-Walled Columns",

interaction of local and flexural Journal of Structural Engineering, ASCE,128,

buckling (h/b=2) are less conservative pp.128:3(289), 2002.

compared to predictions corresponding

to local and flexural torsional buckling [5] Desmond T. P., Pekoz, T. and Winter., “Edge

(h/b =0.6, 1 and 1.5). Stiffeners for Cold-formed Steel Members”, -

4th International Specialty Conference on Cold-

4. CONCLUSIONS Formed Steel Structures, Missouri University of

Science and Technology, 1978.

In this paper, the accuracy of EWM to calculate

the strength of compression members under [6] Gregory J. Hancock, Thomas Murray, Duane

local buckling and LE interaction was studied S. Ellifrit., Cold-Formed Steel Structures to the

using FEA results available in literature. AISI Specifications, New York, CRC Press

Following are the conclusions made based on

this study [7] Kumar, M. V. A. and V. Kalyanaraman,

"Design Strength of Locally Buckling Stub-

1. EWM accurately predicts the strength of Lipped Channel Columns", Journal of

short compression members undergoing Structural Engineering, ASCE,.pp. 1291-1299,

only local buckling before failure. As non- 2012

dimensional slenderness increases EWM

[8] Kumar, M. V. A, Interaction of local,

predictions are slightly conservative

distortional and overall buckling in cold formed

(almost 15 to 20%). This may be because steel lipped channel compression members,

the element interaction is not considered in Ph.D. thesis, IIT Madras, Chennai, India, 2012

the elastic buckling calculations.

2. In general, the strength of the lipped [9] Kumar, M. V. A. and V. Kalyanaraman,

channel compression members obtained "Interaction of Local, Distortional, and Global

from EWM undergoing LE interaction is Buckling in CFS Lipped Channel Compression

Members", Journal of Structural Engineering,

conservative.

ASCE, 2017

3. As web height to flange width ratio, h/b,

decreases, the strength estimate by EWM [10] Timoshenko. S and Gere,J. M, Theory of

becomes more conservative. i.e., as global elastic stability, McGraw-Hill book company,

buckling is flexural-torsional in nature, the In., NewYork, 1961.

strength estimates are conservative.

[11] Young B. and Kim J. R. Rasmussen, "Tests

of Fixed-Ended Plain Channel Columns",

REFERENCES

Journal of Structural Engineering, ASCE, pp.

131-139, 1998

[1] American Iron and Steel Institute (AISI),

North American specification for the design of

[12] Young B. and Kim J. R. Rasmussen,

cold-formed steel structural members, AISI

"Design of Lipped Channel Columns", Journal

S100, Washington, 2007

of Structural Engineering, ASCE, pp. 140-148,

1998

[2] European Committee for Standardization

(CEN), Design of steel structures, Part1.3:

[13] Young B. and Kim J. R. Rasmussen, "Shift

Supplementary rules for cold-formed members

of Effective Centroid of Channel Columns",

and sheeting, ENV 1993-1-3, Brussels, 2004.

Journal of Structural Engineering, ASCE, pp.

524-531, 1999

[3] B.W. Schafer, "Review: The Direct Strength

Method of cold-formed steel member design",

[14] Young B. and Kim J.R. Rasmussen,

Journal of Constructional Steel Research,

"Behaviour of Cold-Formed Singly Symmetric

ELSEVIER 64, pp. 766–778, 2008

Columns", Thin-Walled Structures 33,

ELSEVIER, pp. 83–102, 1999

[4] B.W. Schafer, "Local, Distortional, and

View publication stats

You might also like

- Interaction of Stiffened and Unstiffened Element Buckling Modes in CFS Plain Channel Compression Members - Kalam Aswathy and Anil Kumar 2021Document7 pagesInteraction of Stiffened and Unstiffened Element Buckling Modes in CFS Plain Channel Compression Members - Kalam Aswathy and Anil Kumar 2021amokeNo ratings yet

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainFrom EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainNo ratings yet

- Video PDFDocument8 pagesVideo PDFAhmed Ali TahaNo ratings yet

- Compression Members - Local Buckling and Section Classification PDFDocument15 pagesCompression Members - Local Buckling and Section Classification PDFAnonymous lswzqloNo ratings yet

- Effect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DDocument10 pagesEffect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DSubhash NaiduNo ratings yet

- Jse1999 Schafer Pekoz Beams PaperDocument10 pagesJse1999 Schafer Pekoz Beams Paperclam2014No ratings yet

- Failure Assessment Diagram (FAD) Analysis of Fatigue Test Results For X65 Welded JointsDocument6 pagesFailure Assessment Diagram (FAD) Analysis of Fatigue Test Results For X65 Welded JointsMeliha MaslesaNo ratings yet

- AISC Effect of Compound Buckling On Compression Strength of Built-Up MembersDocument8 pagesAISC Effect of Compound Buckling On Compression Strength of Built-Up Memberssebastian9033No ratings yet

- The Effects of Geometric Nonlinearity and Cracking On Concrete Planar FramesDocument10 pagesThe Effects of Geometric Nonlinearity and Cracking On Concrete Planar FramesAtiq R RafiNo ratings yet

- Chapter 12 PDFDocument17 pagesChapter 12 PDFAdolfo ElizondoNo ratings yet

- Finite element analysis of eccentrically loaded steel anglesDocument8 pagesFinite element analysis of eccentrically loaded steel anglesIftesham BasharNo ratings yet

- End Restraints in Single - and Double - Bolted AngDocument7 pagesEnd Restraints in Single - and Double - Bolted AngJonatan ViloriaNo ratings yet

- Competitive Analysis Solutions for Flat Slabs and Slab with Beams Deformability and CostDocument10 pagesCompetitive Analysis Solutions for Flat Slabs and Slab with Beams Deformability and CostMariana MercadoNo ratings yet

- Analysis of R.C Deep Beam by Finite Element Method: B.R. Niranjan, S.S.PatilDocument4 pagesAnalysis of R.C Deep Beam by Finite Element Method: B.R. Niranjan, S.S.PatilIJMERNo ratings yet

- If emDocument13 pagesIf emglassw380No ratings yet

- (2008) Chan and Gradner EHSDocument11 pages(2008) Chan and Gradner EHSRaees MazharNo ratings yet

- Behaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingDocument12 pagesBehaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingKLNo ratings yet

- P 12-16 PRIYANKA Finite Element Analysis of Internally Ply Drop-Off Composite LaminatesDocument5 pagesP 12-16 PRIYANKA Finite Element Analysis of Internally Ply Drop-Off Composite LaminatesEditorijer IjerNo ratings yet

- FEA - Flange JointDocument5 pagesFEA - Flange JointkisshokNo ratings yet

- An Insight Into Slope Stability Using Strength Reduction TechniqueDocument5 pagesAn Insight Into Slope Stability Using Strength Reduction Techniquerafael souzaNo ratings yet

- Progressive Collapse Material Cost SavingsDocument17 pagesProgressive Collapse Material Cost SavingsBandula PrasadNo ratings yet

- Finite Element Simulation of Low Velocity Impact Damage in Composite LaminatesDocument6 pagesFinite Element Simulation of Low Velocity Impact Damage in Composite LaminatesRodrigo MaiaNo ratings yet

- Coneccion Ansys DisipadorDocument8 pagesConeccion Ansys DisipadorHectoreRodriguezlNo ratings yet

- (Kiot) : Design of Steel and Timber StructureDocument53 pages(Kiot) : Design of Steel and Timber Structurebini1221No ratings yet

- Probabilistic Assessment of Fracture Mechanics of Low Pressure Turbine Disk KeywayDocument8 pagesProbabilistic Assessment of Fracture Mechanics of Low Pressure Turbine Disk KeywayManoj Paul JohnNo ratings yet

- An Assessment of The Eurocode 3 Provisions For Lateral-Torsional Buckling of I-Sections Under Uniaxial and Biaxial BendingDocument18 pagesAn Assessment of The Eurocode 3 Provisions For Lateral-Torsional Buckling of I-Sections Under Uniaxial and Biaxial Bendingjackcan501No ratings yet

- Effect of Compound Buckling On Compression Strength of Built-Up MembersDocument9 pagesEffect of Compound Buckling On Compression Strength of Built-Up MembersFishatsion AsgelelewNo ratings yet

- Chapter 3 - Tension Members: A Beginner's Guide To The Steel Construction ManualDocument4 pagesChapter 3 - Tension Members: A Beginner's Guide To The Steel Construction Manualedn_mj1645No ratings yet

- Analysis of Buckling Strength of Inner WindingsDocument5 pagesAnalysis of Buckling Strength of Inner Windingsalex696No ratings yet

- Verification of CLT-plates Under Loads in PlaneDocument10 pagesVerification of CLT-plates Under Loads in Planenodas2No ratings yet

- (2002) DUBINA e UNGUREANU - Effect of Imperfections On Numerical Simulation of Instability Behaviour of Cold-Formed Steel MembersDocument24 pages(2002) DUBINA e UNGUREANU - Effect of Imperfections On Numerical Simulation of Instability Behaviour of Cold-Formed Steel MembersOtávio Teixeira DiasNo ratings yet

- Bolts and ConnectionsDocument11 pagesBolts and ConnectionsSafrul EfendiNo ratings yet

- Dr. R.N. Review Article On: Plastic Flow and Fracture in Incremental Sheet Metal FormingDocument17 pagesDr. R.N. Review Article On: Plastic Flow and Fracture in Incremental Sheet Metal FormingVigneshwaran Soundararaja Perumal100% (1)

- Matecconf Iceta2015 04028Document5 pagesMatecconf Iceta2015 04028john wickNo ratings yet

- Analysis of Continuous Beams With Joint SlipDocument19 pagesAnalysis of Continuous Beams With Joint SliprayNo ratings yet

- Strength Reduction and Step Loading Finite Element Approaches in Geotechnical EngineeringDocument10 pagesStrength Reduction and Step Loading Finite Element Approaches in Geotechnical EngineeringPabloNo ratings yet

- Chapter-3 Design For Compression Member - StrutDocument16 pagesChapter-3 Design For Compression Member - Strutzakai zakiNo ratings yet

- Rationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsDocument20 pagesRationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsmirzaNo ratings yet

- Stiffness Properties in Timber Structure Analysis and DesignDocument8 pagesStiffness Properties in Timber Structure Analysis and DesignNick CuiNo ratings yet

- Earthquake Resistant Design of Steel StructuresDocument12 pagesEarthquake Resistant Design of Steel StructuresFranklin GarciaNo ratings yet

- Structural Elements in FLAC 3DDocument186 pagesStructural Elements in FLAC 3DSergio Andres ZerreitugNo ratings yet

- Interaction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018Document9 pagesInteraction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018amokeNo ratings yet

- Khalfallah-Guerdouh2014 Article TensionStiffeningApproachInCon PDFDocument6 pagesKhalfallah-Guerdouh2014 Article TensionStiffeningApproachInCon PDFyanimuhammadNo ratings yet

- WidthThicknessRequirements McCormick 14jul14 FinalDocument4 pagesWidthThicknessRequirements McCormick 14jul14 Finaleuric82No ratings yet

- Applsci 11 11428Document13 pagesApplsci 11 11428AakashRanjanNo ratings yet

- 5502-Article Text PDF-9260-1-10-20130718Document13 pages5502-Article Text PDF-9260-1-10-20130718Yadava JaffaNo ratings yet

- Modelling Structural ResistanceDocument6 pagesModelling Structural Resistanceconsultor9010No ratings yet

- Blast Resistant Building DesignDocument10 pagesBlast Resistant Building DesignStephen KokoNo ratings yet

- Dependence of Ultimate Bending Moment of Box Girders On Panel's SlendernessDocument4 pagesDependence of Ultimate Bending Moment of Box Girders On Panel's SlendernessJosé Manuel Antunes Mendes GordoNo ratings yet

- Local buckling of thin steel platesDocument15 pagesLocal buckling of thin steel platesLakshmanan SreenivasanNo ratings yet

- Progress Report on Developing Weight Functions and Computer Integration Procedures for Calculating Stress Intensity FactorsDocument108 pagesProgress Report on Developing Weight Functions and Computer Integration Procedures for Calculating Stress Intensity FactorsOth ManNo ratings yet

- Fundamentals of Seismic Base Isolation: January 2002Document11 pagesFundamentals of Seismic Base Isolation: January 2002rmanuel30100% (1)

- Lecture 8 - 2 - Behaviour and Design of Unstiffened PlatesDocument34 pagesLecture 8 - 2 - Behaviour and Design of Unstiffened PlatesNurali MamenNo ratings yet

- Tabeshpour A 10 57 1 77f3196Document9 pagesTabeshpour A 10 57 1 77f3196Irfan KhanNo ratings yet

- The Continuous Strength Method: Structures & Buildings January 2008Document25 pagesThe Continuous Strength Method: Structures & Buildings January 2008Mazin MohammedNo ratings yet

- FLAC2 DDocument180 pagesFLAC2 DMohamed A. El-BadawiNo ratings yet

- Shear-Lag Versus Finite Element Models For Stress Transfer in Fiber-Reinforced CompositesDocument9 pagesShear-Lag Versus Finite Element Models For Stress Transfer in Fiber-Reinforced CompositesDavid AcostaNo ratings yet

- Estimation Method For The Fatigue Limit of Case Hardened SteelsDocument6 pagesEstimation Method For The Fatigue Limit of Case Hardened SteelssauravNo ratings yet

- Interface Elements Modelling DelaminationDocument11 pagesInterface Elements Modelling DelaminationPeter DudasNo ratings yet

- Design Strength of Locally Buckling Stub-Lipped Channel Columns 2012Document9 pagesDesign Strength of Locally Buckling Stub-Lipped Channel Columns 2012amokeNo ratings yet

- Interaction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018Document9 pagesInteraction of Local, Distortional, and Global Buckling - Anil Kumar, Kalyanaraman 2018amokeNo ratings yet

- Laterally Braced Cold-Formed Steel Flexural Members With Edge Stiffened Flangesn - Schafer, PekozDocument10 pagesLaterally Braced Cold-Formed Steel Flexural Members With Edge Stiffened Flangesn - Schafer, PekozamokeNo ratings yet

- Hancock, Gregory J. (1985) - Distortional Buckling of Steel Storage Rack ColumnsDocument14 pagesHancock, Gregory J. (1985) - Distortional Buckling of Steel Storage Rack ColumnsamokeNo ratings yet

- Evaluation of Direct Strength Method For CFS Compression Members Without Stiffeners 2010Document7 pagesEvaluation of Direct Strength Method For CFS Compression Members Without Stiffeners 2010amokeNo ratings yet

- Ajeesh S S, Arul Jayachandran S, A Constrained Spline Finite Strip MethodDocument11 pagesAjeesh S S, Arul Jayachandran S, A Constrained Spline Finite Strip MethodamokeNo ratings yet

- Design of Thin-Walled Columns With Unstiffened Flanges: KeywordsDocument10 pagesDesign of Thin-Walled Columns With Unstiffened Flanges: KeywordsamokeNo ratings yet

- Unstiffened Elements As Limiting Case of Distortional Buckling of Partially Stiffened Elements - Kalam Aswathy and Anil Kumar 2020Document11 pagesUnstiffened Elements As Limiting Case of Distortional Buckling of Partially Stiffened Elements - Kalam Aswathy and Anil Kumar 2020amokeNo ratings yet

- Distortional Buckling of CFS Stiffened Lipped Channel Compression Members - Anil Kumar, Kalyanaraman 2014Document14 pagesDistortional Buckling of CFS Stiffened Lipped Channel Compression Members - Anil Kumar, Kalyanaraman 2014amokeNo ratings yet

- Methods of Testing Cement - Part 5: Pozzolanicity Test For Pozzolanic CementDocument7 pagesMethods of Testing Cement - Part 5: Pozzolanicity Test For Pozzolanic CementamokeNo ratings yet

- Tests Coarse AggregatesDocument47 pagesTests Coarse AggregatesamokeNo ratings yet

- Cad Beam DetailDocument1 pageCad Beam DetailamokeNo ratings yet

- Design of Angle Columns With Locally Unstable Legs: Kim J. R. RasmussenDocument8 pagesDesign of Angle Columns With Locally Unstable Legs: Kim J. R. RasmussenamokeNo ratings yet

- Uses of Steel in ConstructionDocument29 pagesUses of Steel in ConstructionAditya RajNo ratings yet

- 450 8 MM Dia at 180 MM C/C Spacing: Reinforcement Details of FootingDocument1 page450 8 MM Dia at 180 MM C/C Spacing: Reinforcement Details of FootingamokeNo ratings yet

- Floods in India - WikipediaDocument10 pagesFloods in India - WikipediaamokeNo ratings yet

- Practical Exercises ManualDocument40 pagesPractical Exercises ManualamokeNo ratings yet

- Experimental Investigation On Beams Partial Replacement Below The Neutral AxisDocument4 pagesExperimental Investigation On Beams Partial Replacement Below The Neutral AxisamokeNo ratings yet

- To Whomsoever It May ConcernDocument1 pageTo Whomsoever It May ConcernZaki SiddiquiNo ratings yet

- Cad RCC Column MarkingDocument1 pageCad RCC Column MarkingamokeNo ratings yet

- Droughts in India - WikipediaDocument8 pagesDroughts in India - WikipediaamokeNo ratings yet

- Literature Review: 2.1 PreambleDocument26 pagesLiterature Review: 2.1 PreambleamokeNo ratings yet

- List of Earthquakes in India - WikipediaDocument7 pagesList of Earthquakes in India - WikipediaamokeNo ratings yet

- Testing and Design of Gravity-Loaded Steel Purlins Restrained by SheetingDocument10 pagesTesting and Design of Gravity-Loaded Steel Purlins Restrained by SheetingamokeNo ratings yet

- Analysis of Cold-Formed Zed-Purlins Partially Restrained by Steel SheetingDocument9 pagesAnalysis of Cold-Formed Zed-Purlins Partially Restrained by Steel SheetingamokeNo ratings yet

- NHAI Internship Scheme for Academic Year 2019-2020Document1 pageNHAI Internship Scheme for Academic Year 2019-2020SubhashNo ratings yet

- Journal of Constructional Steel Research: Chong Ren, Long-Yuan Li, Jian YangDocument7 pagesJournal of Constructional Steel Research: Chong Ren, Long-Yuan Li, Jian YangamokeNo ratings yet

- Cold-Formed Steel Channel Sections With Web Stiffeners SubjectedDocument15 pagesCold-Formed Steel Channel Sections With Web Stiffeners Subjectedviveksp99No ratings yet

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Diplomawork MarsimoyiTerefeBangoF8EE3C BME 2019Document116 pagesDiplomawork MarsimoyiTerefeBangoF8EE3C BME 2019Milkeessaa TarrafeeNo ratings yet

- Mr. Rai Site Assessment ReportDocument6 pagesMr. Rai Site Assessment ReportRachit SharmaNo ratings yet

- CPM Rumah ContohDocument3 pagesCPM Rumah Contohq upeehNo ratings yet

- General Arrangement of PilingDocument8 pagesGeneral Arrangement of PilingPNo ratings yet

- Loading CalculationDocument13 pagesLoading CalculationGlyra RosalemNo ratings yet

- Case Study - Ellwood No 18Document10 pagesCase Study - Ellwood No 18Antônio CarotiniNo ratings yet

- Design Criteria For Concrete Foundations & Structures 2Document24 pagesDesign Criteria For Concrete Foundations & Structures 2Chetan ToliaNo ratings yet

- ColumnsDocument16 pagesColumnsrohiniNo ratings yet

- Construction Labor Rate-CostsDocument7 pagesConstruction Labor Rate-Costsljcme100% (2)

- Holcim CementDocument3 pagesHolcim CementTito GarciaNo ratings yet

- Defence Research Proposal Slide PresentationDocument25 pagesDefence Research Proposal Slide PresentationAmira DzulkifliNo ratings yet

- Types of Bitumen Mixes and Their Applications in Road Pavement ConstructionDocument13 pagesTypes of Bitumen Mixes and Their Applications in Road Pavement Constructionsreenath0% (1)

- Design Criteria and Loadings SummaryDocument2 pagesDesign Criteria and Loadings SummaryJems MansuetoNo ratings yet

- Labour Output Constants for Excavation, Concrete, Mortar and FormworkDocument2 pagesLabour Output Constants for Excavation, Concrete, Mortar and FormworkR L Rao100% (1)

- Admixtures For ConcreteDocument5 pagesAdmixtures For ConcreteShahril ZainulNo ratings yet

- E TN SWD Csa A23 3 94 009 PDFDocument5 pagesE TN SWD Csa A23 3 94 009 PDFRazvan RobertNo ratings yet

- Connection Details-ModelDocument1 pageConnection Details-Modelkhem thapaNo ratings yet

- Evaluation of Damping Modification FactorsDocument15 pagesEvaluation of Damping Modification FactorselbinclusolNo ratings yet

- MDOT-Material Source Guide Qualified Products 84764 7 - 12.2015Document22 pagesMDOT-Material Source Guide Qualified Products 84764 7 - 12.2015houstonhimselfNo ratings yet

- Sadeer Pre Qualification DocumentDocument62 pagesSadeer Pre Qualification DocumentChristine JoyNo ratings yet

- Concrete Pouring LogDocument537 pagesConcrete Pouring Logakram husseinNo ratings yet

- Analysis of Combined Axial and Bending Loads On Columns: CE 537, Spring 2011 1 / 8Document8 pagesAnalysis of Combined Axial and Bending Loads On Columns: CE 537, Spring 2011 1 / 8Jirard Elmo Sto TomasNo ratings yet

- Acpa Early Cracking of Concrete Pavement-Causes and RepairsDocument24 pagesAcpa Early Cracking of Concrete Pavement-Causes and RepairsLydia100% (1)

- LGU-Inventory-RoadsDocument4 pagesLGU-Inventory-RoadsgreteNo ratings yet

- UPV Testing Results for Ruko Pronto Building in Bintaro JayaDocument16 pagesUPV Testing Results for Ruko Pronto Building in Bintaro JayaCihuy RahmatNo ratings yet

- Boundary Wall Plan and Sections for Housing AuthorityDocument1 pageBoundary Wall Plan and Sections for Housing AuthorityMian M KhurramNo ratings yet

- Types of Philippine School Buildings ExplainedDocument71 pagesTypes of Philippine School Buildings ExplainedMichael Ervin GuerzonNo ratings yet

- BRE - Design of Normal Concrete MixesDocument47 pagesBRE - Design of Normal Concrete MixesJay Musa100% (2)

- ns24 Lecture4 2perDocument45 pagesns24 Lecture4 2perLuis CortesNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Learning Robotics, with Robotics, by Robotics: Educational RoboticsFrom EverandLearning Robotics, with Robotics, by Robotics: Educational RoboticsNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- Artificial Intelligence: Data Analytics and Innovation for BeginnersFrom EverandArtificial Intelligence: Data Analytics and Innovation for BeginnersRating: 5 out of 5 stars5/5 (3)

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet