Professional Documents

Culture Documents

Seal Installation Instructions

Uploaded by

ZakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seal Installation Instructions

Uploaded by

ZakCopyright:

Available Formats

SEAL INSTALLATION INSTRUCTIONS

1. Disassemble pump cavity to expose existing seal.

Removal of old seal and assembly of new seal

requires careful operations and precautions.

CAUTION: Lapped and polished faces of new seals

are easily scratched and damaged. PROTECT FROM

DAMAGE, DIRT, AND FINGERPRINTS.

2. Carefully remove old seal head and seat (note where

and how it was installed) taking care not to scratch

shaft or seat counterbore.

3. Clean shaft and counterbore surfaces using fine

emery cloth or equivalent. Remove rust, burrs and

wipe clean.

4. Before installing the new seal be sure to check seal

surfaces to insure they are free of any dirt, grit or

lubricants. An alcohol wipe may be used to clean the

seal face before final installation.

5. Press seal seat firmly into counterbore, be sure it

is bottomed square. SLIDE SEAL HEAD ALONG

SHAFT MAKING SURE THE SPRING IS CORRECTLY

ENGAGED INTO SEAL.

6. Re-assemble pump and remember that trouble free

operation of a pump includes making a correct seal

installation.

7. Flood the pump with water before starting. NEVER

RUN THE PUMP DRY! This damages the seal.

3/4” socket

or pipe

Mechanical seal

rotating half

Polished

surface

Rubber

o

Mechanical seal Turn ver surface

stationary half

A-Seal removal-rotating half

Seal Plate

B-Seal removal-stationary half C-Stationary half installation

Shaft

shoulder

Rubber drive

ring

Sealing

face

Impeller

D-Rotating half installation

You might also like

- Audi A4 (B6, B7) Repair Manual: 2002-2008 - ExcerptDocument6 pagesAudi A4 (B6, B7) Repair Manual: 2002-2008 - ExcerptBentley Publishers44% (57)

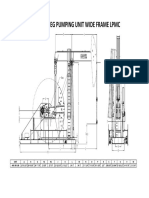

- Eg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726Document45 pagesEg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726ZakNo ratings yet

- Wärtsilä Pulse Lubricating System To CompleteDocument23 pagesWärtsilä Pulse Lubricating System To Completekasibhatta100% (9)

- Ford 1998 4.0 Intake Gasket ReplacementDocument10 pagesFord 1998 4.0 Intake Gasket Replacementmarvstewart100% (1)

- Piezo InjectorDocument24 pagesPiezo InjectorJozsi Szabo100% (9)

- Manual Woodward PGG-200 PDFDocument42 pagesManual Woodward PGG-200 PDFkamporrobles100% (1)

- VOITH Torque ConverterDocument22 pagesVOITH Torque ConverterLTE002100% (1)

- Mechanical Seal IOMDocument2 pagesMechanical Seal IOMEduardo SolisNo ratings yet

- Automatic Transmission A442F RM314E-1995-SupplementDocument21 pagesAutomatic Transmission A442F RM314E-1995-Supplementcarlos100% (1)

- Mechanical Seal Presentation (2009)Document28 pagesMechanical Seal Presentation (2009)LelosPinelos123100% (5)

- 40 90 Mechanical Seal Kits SWIDocument2 pages40 90 Mechanical Seal Kits SWIWong DaNo ratings yet

- Montaje de Sello SLCDocument35 pagesMontaje de Sello SLCChristianReinosoNo ratings yet

- API GuideDocument41 pagesAPI GuideJulivan SouzaNo ratings yet

- Operation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsDocument4 pagesOperation Instructions Seal Replacement: Vil 4300 - 20×20×19 Installation and Operating InstructionsDiego ArmandoNo ratings yet

- Instruction Manual: Internal Gear PumpDocument16 pagesInstruction Manual: Internal Gear PumpGrosu DanutNo ratings yet

- FCV PlugValve 5000RDocument12 pagesFCV PlugValve 5000RtestNo ratings yet

- 2005 - 2009 Water Leak RepairsDocument5 pages2005 - 2009 Water Leak RepairsJuan CandiaNo ratings yet

- Eaton: Hydraulic MotorDocument4 pagesEaton: Hydraulic MotorRidha AbbassiNo ratings yet

- MMBK8FDocument4 pagesMMBK8FAnond UseryNo ratings yet

- AquaBoost Install 0217Document2 pagesAquaBoost Install 0217Luke Haoqi WuNo ratings yet

- Disc BrakesDocument17 pagesDisc BrakesBenz Aio Calachua AraujoNo ratings yet

- Enfield Bullet Workshop Manual 2000 2 PDFDocument53 pagesEnfield Bullet Workshop Manual 2000 2 PDFsivakumar natarajanNo ratings yet

- 101-0850!63!0 - DSD Mechanical Seal ReplacementDocument3 pages101-0850!63!0 - DSD Mechanical Seal ReplacementHamza Bin MasoodNo ratings yet

- Before Removal: Special Tools Description Part No. QtyDocument6 pagesBefore Removal: Special Tools Description Part No. QtyPhomma KhinphommavongNo ratings yet

- PB PDFDocument10 pagesPB PDFAlexanderNo ratings yet

- TM 9-1245 37-MM Gun, M3, and Carriage, M4-1941Document54 pagesTM 9-1245 37-MM Gun, M3, and Carriage, M4-1941ferdockmNo ratings yet

- Angst+Pfister Rotating Seals Technical CatalogueDocument54 pagesAngst+Pfister Rotating Seals Technical CatalogueDanieleNo ratings yet

- 03 Cabezales de SujeciónDocument4 pages03 Cabezales de SujeciónCicero MelloNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoNo ratings yet

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- Volume 2 Design and Manufacturing of Hydraulic CylindersDocument53 pagesVolume 2 Design and Manufacturing of Hydraulic CylindersFarooq NaregalNo ratings yet

- Install Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Document13 pagesInstall Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Mauriece CarrilloNo ratings yet

- One Touch Hydraulic Punch Clamp Operator's ManualDocument21 pagesOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNo ratings yet

- Introduct Tion: Me Installa Grasso GL Echanical Shaf Ation Procedu Series Compre FT Seal Ure For EssorsDocument2 pagesIntroduct Tion: Me Installa Grasso GL Echanical Shaf Ation Procedu Series Compre FT Seal Ure For EssorsjorgeNo ratings yet

- 04 - Clutch - Gearshift Linkage - Kick Starter - AbwtDocument8 pages04 - Clutch - Gearshift Linkage - Kick Starter - Abwtcarlos melendez morenoNo ratings yet

- Sealing Flange and Flywheel/drive Plate, Removing and InstallingDocument11 pagesSealing Flange and Flywheel/drive Plate, Removing and InstallingPionir PionirNo ratings yet

- Octavia Manual Running Gear Part4Document136 pagesOctavia Manual Running Gear Part4Mihai IordacheNo ratings yet

- 2 - Top Cover OverhaulDocument7 pages2 - Top Cover OverhaulyilmazeviinNo ratings yet

- CM M 09 Mechanical SealDocument109 pagesCM M 09 Mechanical SealAuthers Raj4No ratings yet

- 35-1 Input Shaft AssemblyDocument12 pages35-1 Input Shaft Assemblymefisto06cNo ratings yet

- Construction Maintenance Department: Mechanical Technician Qualification ModuleDocument109 pagesConstruction Maintenance Department: Mechanical Technician Qualification ModuleAndinata Sitepu100% (1)

- Seals101 GrundfosWebinarDocument48 pagesSeals101 GrundfosWebinarmoh saeedNo ratings yet

- 39-1 Final Drive Flange SealDocument3 pages39-1 Final Drive Flange SealNilson BarbosaNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document2 pagesPressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoskiNo ratings yet

- Fis122 Cartridge InstallDocument4 pagesFis122 Cartridge InstalllubangjarumNo ratings yet

- Fis122 Cartridge Install PDFDocument4 pagesFis122 Cartridge Install PDFPdm BadakNo ratings yet

- 13-79 Pistons and Connecting Rods Assembly PDFDocument8 pages13-79 Pistons and Connecting Rods Assembly PDFmefisto06cNo ratings yet

- 06 1955 CAD-Chassis SuspensionDocument4 pages06 1955 CAD-Chassis SuspensionLuis Fernando ZampieriNo ratings yet

- Presentación 21kDocument36 pagesPresentación 21kCamilo MendozaNo ratings yet

- Fundamentalsofmechanicalseals 150318230522 Conversion Gate01Document37 pagesFundamentalsofmechanicalseals 150318230522 Conversion Gate01Jesús Manuel ManriqueNo ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Oil Seal Service BulletinDocument11 pagesOil Seal Service BulletinjisuuuNo ratings yet

- 12 - Cast Iron Tapping MachinesDocument14 pages12 - Cast Iron Tapping MachinesaurabloodNo ratings yet

- 2531Document5 pages2531sangkil05No ratings yet

- Mechanical SealDocument15 pagesMechanical SealTinu Paul Jepin100% (2)

- Drum Section: (Removal and Assembly)Document15 pagesDrum Section: (Removal and Assembly)Thinkplus TradingNo ratings yet

- Air BrakeDocument65 pagesAir BrakeThabo NgidiNo ratings yet

- HCP Type f-2f4b2-2584 1167Document3 pagesHCP Type f-2f4b2-2584 1167Hamdi NaufelNo ratings yet

- 3902 Maintenance Instruction: Build-Up QF Traction Motor Mounting AssemblyDocument8 pages3902 Maintenance Instruction: Build-Up QF Traction Motor Mounting Assemblyemmsh71No ratings yet

- 3 21010001 GA 12 31 r0 SignedDocument1 page3 21010001 GA 12 31 r0 SignedBhadresh KumbhaniNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- OverhaulforgentwoDocument4 pagesOverhaulforgentwoZakNo ratings yet

- Agua Pura Destilador Labtech LWD 3004 3008 3012 EngDocument20 pagesAgua Pura Destilador Labtech LWD 3004 3008 3012 EngZakNo ratings yet

- 98183327623Document2 pages98183327623ZakNo ratings yet

- EG640-365-168 WIDE FRAME LPMC Catalog View 20220701Document1 pageEG640-365-168 WIDE FRAME LPMC Catalog View 20220701ZakNo ratings yet

- Chemistry CatalogueDocument1 pageChemistry CatalogueZakNo ratings yet

- Ashirwad EnterprisesDocument22 pagesAshirwad EnterprisesZakNo ratings yet

- QTN No 213469Document4 pagesQTN No 213469ZakNo ratings yet

- QTN No 213470Document2 pagesQTN No 213470ZakNo ratings yet

- Hot Plate & StirrerDocument1 pageHot Plate & StirrerZakNo ratings yet

- Adjusting Downstroke On A LFL - AaDocument2 pagesAdjusting Downstroke On A LFL - AaZakNo ratings yet

- Hpu Commissioning A Gas Driven LFL - AaDocument6 pagesHpu Commissioning A Gas Driven LFL - AaZakNo ratings yet

- Hpu Installation of A Bottom Plate - AaDocument2 pagesHpu Installation of A Bottom Plate - AaZakNo ratings yet

- Hpu Bypassing Presco Shutdown - AaDocument3 pagesHpu Bypassing Presco Shutdown - AaZakNo ratings yet

- KUDU HPU Well Manager Hardware ManualDocument58 pagesKUDU HPU Well Manager Hardware ManualZakNo ratings yet

- Hpu Configuring KWM With H30-144 - AaDocument6 pagesHpu Configuring KWM With H30-144 - AaZakNo ratings yet

- KUDU HPU Well Manager Configuration ManualDocument235 pagesKUDU HPU Well Manager Configuration ManualZakNo ratings yet

- Xyl0100 Largepumps Flygt3001 Cooling Leaflet 180214-FinalDocument2 pagesXyl0100 Largepumps Flygt3001 Cooling Leaflet 180214-FinalZakNo ratings yet

- Oil Lift Driveheads - 9.25.19 - DigitalDocument2 pagesOil Lift Driveheads - 9.25.19 - DigitalZakNo ratings yet

- Annexure - IDocument4 pagesAnnexure - IZakNo ratings yet

- 2019 Overhaul BrochureDocument10 pages2019 Overhaul BrochureZakNo ratings yet

- ML11215A009Document9 pagesML11215A009ZakNo ratings yet

- QuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualDocument16 pagesQuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualZakNo ratings yet

- General Purpose 3 Phase Motors E2 Efficiency: Nical Ca Talog UeDocument12 pagesGeneral Purpose 3 Phase Motors E2 Efficiency: Nical Ca Talog UeZakNo ratings yet

- Pistion and Connetion Rod removeSMCS - 1225 - 011Document2 pagesPistion and Connetion Rod removeSMCS - 1225 - 011ZakNo ratings yet

- Vintrol Valve - A - B - Float - BVDocument8 pagesVintrol Valve - A - B - Float - BVZakNo ratings yet

- Technical Specs ValveDocument3 pagesTechnical Specs ValveZakNo ratings yet

- Introduction, 1: Chapter - OneDocument12 pagesIntroduction, 1: Chapter - OneZakNo ratings yet

- Valves: Technical Industrial InstituteDocument31 pagesValves: Technical Industrial InstituteZakNo ratings yet

- OmniSeal EPV Brochure R6.1Document30 pagesOmniSeal EPV Brochure R6.1ZakNo ratings yet

- f20 Manual Feb 2000 - Rev. 1Document20 pagesf20 Manual Feb 2000 - Rev. 1Larry JorgensonNo ratings yet

- Pump JTN B1Document8 pagesPump JTN B1Patricia J ÁngelesNo ratings yet

- Inductotherm Product PortfolioDocument16 pagesInductotherm Product PortfoliofvwcomprasNo ratings yet

- Catalogue: Racing Ahead 2017Document186 pagesCatalogue: Racing Ahead 2017Manuel Alejandro Pontio RamirezNo ratings yet

- DS LR20 30110 0 IsopurLR20 BrochureDocument2 pagesDS LR20 30110 0 IsopurLR20 BrochureJuan Alejandro Cañas ColoradoNo ratings yet

- 7540Document10 pages7540pruebaNo ratings yet

- Complaint CodesDocument35 pagesComplaint CodesRajneesh JaswalNo ratings yet

- Grouting TAMDocument42 pagesGrouting TAMPinoyini100% (2)

- STC350TDocument12 pagesSTC350TLantis PNo ratings yet

- CF PumpsDocument133 pagesCF PumpsNilesh GohelNo ratings yet

- Effect of Bearing Housing On Centrifugal Pump RotordynamicDocument6 pagesEffect of Bearing Housing On Centrifugal Pump Rotordynamicmsh16000No ratings yet

- Engineering ServicesDocument2 pagesEngineering ServiceszeeNo ratings yet

- Lecture 4 TBT 2 Hoisting Systems and Pipe Handling SystemsDocument109 pagesLecture 4 TBT 2 Hoisting Systems and Pipe Handling SystemsTyo DekaNo ratings yet

- Sludge Pump ManualDocument55 pagesSludge Pump Manualm s sankar raoNo ratings yet

- SERV1852 - TXT3 Controles y Bombas Hidraulicas PrincipalesDocument35 pagesSERV1852 - TXT3 Controles y Bombas Hidraulicas PrincipalesDiego Alonso Huaraca Baleriano100% (2)

- Sabp L 005Document13 pagesSabp L 005Li Peng100% (1)

- G Series - ENG.MRISDocument4 pagesG Series - ENG.MRISMatsumura SokonNo ratings yet

- S34xen Schwing Pump PDFDocument2 pagesS34xen Schwing Pump PDFAmin KmiNo ratings yet

- Operating Manual Winch SystemDocument152 pagesOperating Manual Winch SystemmujeebtalibNo ratings yet

- Dt002gb000-Ir 01Document33 pagesDt002gb000-Ir 01LorenzoNo ratings yet

- NewHolland M160 Hydraulic Variable PumpDocument39 pagesNewHolland M160 Hydraulic Variable PumpElena DNo ratings yet

- BS en Iso 9908-1998Document24 pagesBS en Iso 9908-1998Tasawwur Tahir100% (1)

- Fuel Injection Nozzle - Test: Testing and AdjustingDocument13 pagesFuel Injection Nozzle - Test: Testing and AdjustingTri WahyuningsihNo ratings yet

- Kip KIPDocument28 pagesKip KIPAndrijana MajoNo ratings yet

- 059 Vacuum Truck SafetyDocument6 pages059 Vacuum Truck Safetyichal_zaidanNo ratings yet

- Engine Engine: /contDocument6 pagesEngine Engine: /contyadav.adarsh099No ratings yet