Professional Documents

Culture Documents

98183327623

Uploaded by

ZakOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

98183327623

Uploaded by

ZakCopyright:

Available Formats

Cmp

blow moulding machine manual

Cmp blow moulding machine price list. Cmp description. Cmp instructions. Cmp examples.

When it comes to extrusion blow molding capability, most people think of standard plastic bottles, tight-head containers, jars, and larger water containers. However, the extrusion blow molding process can do much more.

In fact, when using a technologically advanced extrusion blow molding machine, it can produce finished products with complicated shapes, and in varying sizes. Understanding the Extrusion […] Multiple industries and outside manufacturing companies depend on advanced extrusion blow moulding machinery. Without the right machine, there would

be no way to produce superior quality products and we, at CMP, provide quality over quantity.

Let us go through the advantages you will get for using CMP’s machine. ADVANCE PLCIn a continuous process of improvement, we have developed PLC with brands like Beckhoff & BNR which helps to monitor energy consumption along with total and phase-wise power. Upgrading our system has many other advantages. With this, you will be able to

save approximate 2% on electricity which is very important for product cost reduction. We use the highest quality PLC which has a complete touch screen. LANAnother advantage of using CMP blow moulding machines is that you can operate the machine from remote places without hassle. You can monitor machine activity through LAN connection

sitting conveniently in your office same way it helps to overcome all most all the problems arising on the machine. Yes, this is possible with a proper internet connection.

We have developed a new program having In/ Out swapping facility. It eliminates machine breakdown due to card failure. This will also help reduce your inventory. GEARBOXCMP blow moulding machines core strength is its sturdy and robust gearbox. With our aim to provide the best to the customer we provide a gearbox from Shanthi gearbox which

is made with the highest precision. These are ISO standard cases hardened to 58-62 HRC hardness.

These gearboxes are custom made to our requirements. These are class 5 gearboxes that indicate the highest quality and performance. QUALITY & SERVICECMP blow moulding machines have set the example of quality and service provided. We have spares on the shelf to overcome any difficult situation and all the critical parts can be made

available with minimum lead time. Our machines are one-time investment products because of less wear and tear of the products as major of our products are multinational company’s products such as Yuken, Festo, Moog etc. Our machines prove stability, rigidity, productivity and best at power consumption as compared to other manufacturers. The

quality of the machine is proving to be stronger and stronger as most of the parts are being manufactured under our roof under strict quality control. In addition time to time, we provide software updates at no additional cost. Our motto is customer satisfaction to the core. ONLINE SERVICEThis is one of the best advantages of the CMP blow

moulding machine. longnecker anesthesiology 3rd edition pdf free download Using advanced PLC technology, we can check the machines online during your breakdown.

This helps to reduce customers’ breakdown time. With this feature, we can start and run the machine overseas without any physical presence VALUE FOR MONEYAs CMP blow moulding machines are designed using the best product, the running maintenance cost of the machine is too low. As per our survey, there are CMP blow moulding machines

in working condition which were manufactured in 1990. This is how we give huge savings to our customers.

The power consumption of our machines is low as compared to other make blow moulding machines. The per-unit cost of CMP blow moulding machines is less and helps the customers to save on electric expenses GOOD PRODUCTIVITYLess cycle time and higher production are the major components playing a role in the competition. We at CMP have

been constantly working to optimize the combination of both time and production. Our blow moulding machines are designed in such a way which fulfils both the requirements of customers. affine transformation 3d python We have been continuously working on the best engineering technology available around the globe to optimize time and increase

productivity. 422095254.pdf COMPACT DESIGNThis is another good feature of CMP blow moulding machines.

Our structural designs are compact and space-saving. CMP blow moulding machines save your floor space as compared to other blow moulding machines. Hence once again it helps customers save on the per/sq.ft cost of industrial units. ENERGY SAVINGWith an advanced energy module, it is possible to control the temperature with accuracy up to

+/-0.5 degrees compare to +/-2 degrees on machines supplied by other manufacturers. There are two aspects of extrusion blow moulding machine energy savings. Including the power part and heating part.Energy savings for power part:Adopt inverter. The energy savings way is to save the residual energy of the motor, and the frequency converter is

to change the power output of the motor to achieve an energy; savings effect.Energy savings for heating part:The energy savings of the heating part is mostly energy savings by introducing heaters, and the energy savings rate is about 30% – 70% of the old resistance coil.Our machines give 15% addition power saving factor with the addition of IE4

grade motor developed by us. Which is proven at our end.

Skip to content Central Machinery & Plastic Products – Blow Moulding Machines – India error: Sorry Not Allowed !!

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- Blow Molding MachineDocument16 pagesBlow Molding MachineAksMast0% (1)

- Eg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726Document45 pagesEg 640-365-168 WFLPMC Llii640.16.15.01j-00 20220726ZakNo ratings yet

- SIEMENS. Chloropac Operations & Maintenance ManualDocument172 pagesSIEMENS. Chloropac Operations & Maintenance ManualRômulo CarriçoNo ratings yet

- Selectomat PL: Always Two Steps AheadDocument6 pagesSelectomat PL: Always Two Steps AheadArt7i ::No ratings yet

- Research Paper On Frictionless CompressorDocument4 pagesResearch Paper On Frictionless Compressoregwv92v7100% (1)

- WWW Bma Worldwide Com Products Automation Centrifugal ControDocument3 pagesWWW Bma Worldwide Com Products Automation Centrifugal ContromanfenixNo ratings yet

- CG Pumps: Product CatalogueDocument88 pagesCG Pumps: Product CatalogueAnimesh SahaNo ratings yet

- Thermoforming Systems Gain Upgrades, Features - Technology - Plastics MachineryDocument4 pagesThermoforming Systems Gain Upgrades, Features - Technology - Plastics MachineryChandan S GanigNo ratings yet

- Siempelkamp Metalforming Presses-EngDocument9 pagesSiempelkamp Metalforming Presses-EngAbdulsalamNo ratings yet

- 6 CNC Theory - GeneralDocument20 pages6 CNC Theory - GeneralManojAnandNo ratings yet

- Types of Production Systems and Their AutomationDocument15 pagesTypes of Production Systems and Their AutomationRoHan ShaRmaNo ratings yet

- Chemical Engineering Magazine Abril 2009 PDFDocument108 pagesChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- 04 CCM DMK-CMDocument6 pages04 CCM DMK-CMJason XueNo ratings yet

- Chamunda Pharma MachineryDocument10 pagesChamunda Pharma MachinerychamundapharmaNo ratings yet

- DVM Catalogue (080108 Ver3)Document62 pagesDVM Catalogue (080108 Ver3)Razvan HuzlauNo ratings yet

- PDF CompAir OilFree PDFDocument16 pagesPDF CompAir OilFree PDFMilenko Eduardo Yáñez RojasNo ratings yet

- SML Technology Report 2. Edition 2010 Druckversion v. 12.10.10 SaveDocument0 pagesSML Technology Report 2. Edition 2010 Druckversion v. 12.10.10 SaveMarcWorldNo ratings yet

- JIP Compressor FoulingDocument3 pagesJIP Compressor FoulinglvicencioaNo ratings yet

- CNC Machine Research PaperDocument7 pagesCNC Machine Research Paperafeawldza100% (1)

- FINAL 120 BPM CSD Filling Line NewDocument14 pagesFINAL 120 BPM CSD Filling Line NewOMKAR JADHAVNo ratings yet

- Grundfosliterature 5188176Document3 pagesGrundfosliterature 5188176eddy1588No ratings yet

- American MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFDocument50 pagesAmerican MFG Co Oilfield Products and Capabilities Blue Eagle Valves and Pistons PDFsitaNo ratings yet

- Eta SeriesDocument16 pagesEta SeriesjoejumbooNo ratings yet

- DVM CatalogDocument62 pagesDVM CatalogNguyễn Lê ViệtNo ratings yet

- CPP Cast Film Production LineDocument9 pagesCPP Cast Film Production LineZaheer AbbasNo ratings yet

- Prospekt Venture 13 15 GB 14540Document16 pagesProspekt Venture 13 15 GB 14540Pat MontalbanoNo ratings yet

- Somar Integra - Intelligent Motor ControlDocument6 pagesSomar Integra - Intelligent Motor Controlvanessa_cornelia0% (1)

- 60 BPM CSD For 250 ML Arvind AquaDocument17 pages60 BPM CSD For 250 ML Arvind AquaOMKAR JADHAVNo ratings yet

- 1Document11 pages1Kotadia ShivamNo ratings yet

- Commissioning Commercial KitchensDocument3 pagesCommissioning Commercial KitchensMoh'd KhadNo ratings yet

- Accspro - E50001 g520 A393 X 4a00enlrfinalDocument2 pagesAccspro - E50001 g520 A393 X 4a00enlrfinalandy175No ratings yet

- EpL Blowers Katalog2009 enDocument120 pagesEpL Blowers Katalog2009 enHesham SharakyNo ratings yet

- Matchless With Uncompromising: Pricing QualityDocument4 pagesMatchless With Uncompromising: Pricing QualityAmmar AlaghbariNo ratings yet

- Centrifugal Aftermarket Solutions BrochureDocument8 pagesCentrifugal Aftermarket Solutions BrochureJose Renato MendesNo ratings yet

- BlowersDocument120 pagesBlowersAriana Ribeiro Lameirinhas0% (1)

- CP BourgDocument20 pagesCP BourgJimmy Coto ANo ratings yet

- Name: Athrava Savalekar Subject: Business To Business Communication Roll No: 20MBAMKT079 Marketing-BDocument4 pagesName: Athrava Savalekar Subject: Business To Business Communication Roll No: 20MBAMKT079 Marketing-BPratik PatilNo ratings yet

- 2935 0969 40 GV18-300Document6 pages2935 0969 40 GV18-300Yacine CherifiNo ratings yet

- Upvc CrusherDocument28 pagesUpvc Crushermaes fakeNo ratings yet

- KYMC Coating and LaminatingDocument6 pagesKYMC Coating and LaminatingValli MuthuNo ratings yet

- Company Profile Alternative Energy New PDFDocument8 pagesCompany Profile Alternative Energy New PDFIqra AngelsNo ratings yet

- Literature Review On Air CompressorDocument7 pagesLiterature Review On Air Compressorofahxdcnd100% (1)

- BLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFDocument6 pagesBLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFJoenetDarmawanNo ratings yet

- Chemical Engineering 12 2012Document70 pagesChemical Engineering 12 2012Leonardo Ramos100% (1)

- ABB-EOW-Education and Proposals OptDocument155 pagesABB-EOW-Education and Proposals OptŽeljko Posavec100% (1)

- BORSIG Germany - ZM - Reciprocating - CompressorsDocument16 pagesBORSIG Germany - ZM - Reciprocating - CompressorsMuhammad ImranNo ratings yet

- EDGESPEAK7Document8 pagesEDGESPEAK7QwanBlueNo ratings yet

- P Series: Fette CompactingDocument14 pagesP Series: Fette Compactingmohammad pirayeshNo ratings yet

- 10 Compressed Air Saving Tips: Easy Insight Into Energy Flows™Document2 pages10 Compressed Air Saving Tips: Easy Insight Into Energy Flows™tilkifoxNo ratings yet

- CPM BrochureDocument4 pagesCPM BrochureAlexandru IonescuNo ratings yet

- AMP ProjectDocument11 pagesAMP Projectomkarkadam50351No ratings yet

- Usaid Bin Arshad Bba 182023: ConsDocument3 pagesUsaid Bin Arshad Bba 182023: ConsUsaid SiddiqueNo ratings yet

- Buyers Guide Air CompressorsDocument9 pagesBuyers Guide Air Compressorstasiosvas100% (1)

- Integrated Gas Turbine Control Capabilities MS68Document3 pagesIntegrated Gas Turbine Control Capabilities MS68Ko ThihaNo ratings yet

- Marine Pumps: Grundfos Industrial Solutions MarineDocument7 pagesMarine Pumps: Grundfos Industrial Solutions MarineGrundfosEgypt100% (1)

- GA 11+-30/GA 15-30 VSD: Oil-Injected Rotary Screw Compressors, 11-30 KW / 15-40 HPDocument3 pagesGA 11+-30/GA 15-30 VSD: Oil-Injected Rotary Screw Compressors, 11-30 KW / 15-40 HPdragosh27No ratings yet

- D. Y. Patil College of Engineering & Technology, KolhapurDocument62 pagesD. Y. Patil College of Engineering & Technology, KolhapurTushar KhorateNo ratings yet

- TPM - A Route to World Class Performance: A Route to World Class PerformanceFrom EverandTPM - A Route to World Class Performance: A Route to World Class PerformanceRating: 4 out of 5 stars4/5 (5)

- Pioneering Views: Pushing the Limits of Your C/ETRM - Volume 2From EverandPioneering Views: Pushing the Limits of Your C/ETRM - Volume 2No ratings yet

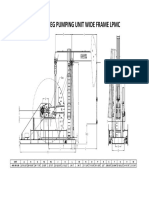

- EG640-365-168 WIDE FRAME LPMC Catalog View 20220701Document1 pageEG640-365-168 WIDE FRAME LPMC Catalog View 20220701ZakNo ratings yet

- QTN No 213470Document2 pagesQTN No 213470ZakNo ratings yet

- Agua Pura Destilador Labtech LWD 3004 3008 3012 EngDocument20 pagesAgua Pura Destilador Labtech LWD 3004 3008 3012 EngZakNo ratings yet

- Ashirwad EnterprisesDocument22 pagesAshirwad EnterprisesZakNo ratings yet

- Hpu Configuring KWM With H30-144 - AaDocument6 pagesHpu Configuring KWM With H30-144 - AaZakNo ratings yet

- Hpu Commissioning A Gas Driven LFL - AaDocument6 pagesHpu Commissioning A Gas Driven LFL - AaZakNo ratings yet

- 2019 Overhaul BrochureDocument10 pages2019 Overhaul BrochureZakNo ratings yet

- Chemistry CatalogueDocument1 pageChemistry CatalogueZakNo ratings yet

- Hpu Installation of A Bottom Plate - AaDocument2 pagesHpu Installation of A Bottom Plate - AaZakNo ratings yet

- Hpu Bypassing Presco Shutdown - AaDocument3 pagesHpu Bypassing Presco Shutdown - AaZakNo ratings yet

- KUDU HPU Well Manager Hardware ManualDocument58 pagesKUDU HPU Well Manager Hardware ManualZakNo ratings yet

- Adjusting Downstroke On A LFL - AaDocument2 pagesAdjusting Downstroke On A LFL - AaZakNo ratings yet

- OverhaulforgentwoDocument4 pagesOverhaulforgentwoZakNo ratings yet

- KUDU HPU Well Manager Configuration ManualDocument235 pagesKUDU HPU Well Manager Configuration ManualZakNo ratings yet

- Annexure - IDocument4 pagesAnnexure - IZakNo ratings yet

- Xyl0100 Largepumps Flygt3001 Cooling Leaflet 180214-FinalDocument2 pagesXyl0100 Largepumps Flygt3001 Cooling Leaflet 180214-FinalZakNo ratings yet

- Pistion and Connetion Rod removeSMCS - 1225 - 011Document2 pagesPistion and Connetion Rod removeSMCS - 1225 - 011ZakNo ratings yet

- OmniSeal EPV Brochure R6.1Document30 pagesOmniSeal EPV Brochure R6.1ZakNo ratings yet

- QuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualDocument16 pagesQuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualZakNo ratings yet

- Introduction, 1: Chapter - OneDocument12 pagesIntroduction, 1: Chapter - OneZakNo ratings yet

- STEEL SHIMS PRICE LIST - Standard Types "A", "B", "C" & "D": Alignment Tools LTDDocument1 pageSTEEL SHIMS PRICE LIST - Standard Types "A", "B", "C" & "D": Alignment Tools LTDZakNo ratings yet

- General Purpose 3 Phase Motors E2 Efficiency: Nical Ca Talog UeDocument12 pagesGeneral Purpose 3 Phase Motors E2 Efficiency: Nical Ca Talog UeZakNo ratings yet

- Vintrol Valve - A - B - Float - BVDocument8 pagesVintrol Valve - A - B - Float - BVZakNo ratings yet

- Valves: Technical Industrial InstituteDocument31 pagesValves: Technical Industrial InstituteZakNo ratings yet

- 25 Mechanical Seal Fitting InstructionsDocument2 pages25 Mechanical Seal Fitting InstructionsZakNo ratings yet

- Installing A Mechanical Seal 1Document9 pagesInstalling A Mechanical Seal 1ZakNo ratings yet

- Seal Installation InstructionsDocument2 pagesSeal Installation InstructionsZakNo ratings yet

- Technical Specs ValveDocument3 pagesTechnical Specs ValveZakNo ratings yet

- Rotalign: Why Not Use A 10" Diameter in The Coupling Mode?Document1 pageRotalign: Why Not Use A 10" Diameter in The Coupling Mode?ZakNo ratings yet

- Primary Current Injection Test System: Oden atDocument7 pagesPrimary Current Injection Test System: Oden atvladaemsNo ratings yet

- A3930 1 Datasheet PDFDocument21 pagesA3930 1 Datasheet PDFKaan GünayNo ratings yet

- Engine Control PDFDocument53 pagesEngine Control PDFRamon CasillasNo ratings yet

- 1.eti-Psi-137 LaDocument30 pages1.eti-Psi-137 LaTarun BhatejaNo ratings yet

- FP06P Data SheetDocument1 pageFP06P Data Sheetcuatrillizos2015No ratings yet

- Introduction To VHDL: Dr. Adnan ShaoutDocument32 pagesIntroduction To VHDL: Dr. Adnan ShaoutBhargav ShahNo ratings yet

- BEEE215L - Module-3 - Lecture-19 - Testing of DC Motor - Swinburne'sDocument16 pagesBEEE215L - Module-3 - Lecture-19 - Testing of DC Motor - Swinburne'sBelwin EdwardNo ratings yet

- SGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Document2 pagesSGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Adam SamyNo ratings yet

- Bluetooth and NFC Enabled Contactless Access Control SystemDocument28 pagesBluetooth and NFC Enabled Contactless Access Control SystemkaushiksamNo ratings yet

- Ece V Digital Signal Processing (10ec52) NotesDocument161 pagesEce V Digital Signal Processing (10ec52) NotesrafeshNo ratings yet

- Structure of Bipolar Junction TransistorDocument10 pagesStructure of Bipolar Junction TransistorNitishNo ratings yet

- AMSC Brochure PDFDocument16 pagesAMSC Brochure PDFAnta MasimmoNo ratings yet

- 4bit Ripple CounterDocument1 page4bit Ripple CounterAdnan JanwariNo ratings yet

- SolarDocument10 pagesSolarsunilNo ratings yet

- Manual ArduBoxDocument21 pagesManual ArduBoxEmilio BonnetNo ratings yet

- Vinegar BatteryDocument28 pagesVinegar Batterykmata092006No ratings yet

- 2019-April-UG-Rules+Policies+Curriculum+Syllabi-of-Courses 15 April 2019Document394 pages2019-April-UG-Rules+Policies+Curriculum+Syllabi-of-Courses 15 April 2019Prajwal MahajanNo ratings yet

- Rohde-Schwarz - Mustreads - Emc (2020 - 07 - 08 11 - 09 - 15 UTC)Document37 pagesRohde-Schwarz - Mustreads - Emc (2020 - 07 - 08 11 - 09 - 15 UTC)konradNo ratings yet

- Degine of 2 Stage CMOs Opamp......Document14 pagesDegine of 2 Stage CMOs Opamp......Vinay MishraNo ratings yet

- DSE3110 Wiring DiagramDocument2 pagesDSE3110 Wiring DiagrammetanirvanaNo ratings yet

- Lab ManualDocument87 pagesLab ManualSrividya KondaguntaNo ratings yet

- Bms 4592nd T.dataDocument1 pageBms 4592nd T.datammNo ratings yet

- 590G-V2 in A4 CatalogueDocument6 pages590G-V2 in A4 CatalogueMATIAS_CNo ratings yet

- Comf2167 Pss en - IdDocument9 pagesComf2167 Pss en - IdMuhammad Nur RokimNo ratings yet

- Atoll NB IoTDocument3 pagesAtoll NB IoTDenmark Wilson100% (1)

- IBC MonoSol 305 ZX5 Black - Data Sheet Europe Japan - ENDocument2 pagesIBC MonoSol 305 ZX5 Black - Data Sheet Europe Japan - ENCarlos CastilloNo ratings yet

- Microwave Journal-March 2021Document168 pagesMicrowave Journal-March 2021Petros TsenesNo ratings yet

- Social InternshipDocument12 pagesSocial InternshipRishabh NiketaNo ratings yet