Professional Documents

Culture Documents

Approved MS For Welding

Approved MS For Welding

Uploaded by

Sagar Sharma0 ratings0% found this document useful (0 votes)

11 views5 pagesOriginal Title

Approved MS for welding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views5 pagesApproved MS For Welding

Approved MS For Welding

Uploaded by

Sagar SharmaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

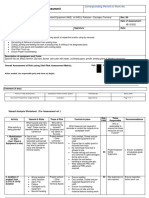

~ L, = — ~~ Corresponding Permit to Work No. °229-00-395776"

Risk Assessment

Risk Assessment of: Welding of Lifting Eyes on SKP-06

‘Assessor(s): Sagar Sharma, Sheeraz Ahmed, Mirza Muhammad Anwar

Ei 3

Responsible Supervisor: Sheeraz Ahmed, Mirza Anwar Signature di CL Date: |

Description of activity: er

1 pment and manpower on site

2 ide from main hole and gas testing before stating hot work

3. ‘welding of eyes on roof for access and anchor point reference permit number (P289-00-3945560)

4 0p side

5. Perform DPT.

6. Housekeeping

Description of equipment and Tools:

Welding Plant, DPT Set(Cleaner, Penetrate & Developer), Full body Harness, and other general hand tools.

Overall Assessment of Risk (using Shell Risk Assessment Matrix): High ‘Medium i Low

Action needed: (inc responsible party and close out target)

X Ems Paepor Acces Sheultl be Provrled yo. Acess'75 ov Koy or [nspetar

4 Pr Sisalig g Het Werle ges fethy rlsl be Pojews by AGT

Comment (if any): a emf fe 7 civ pretties OCB

Hazard Analysis Worksheet (For Assessment ref :) v

rf

\ NO

q 2\ ot » ws -

Form G — Risk “ae Distribution Permit to Work System Reviewed by: 777 zoos

S

BS)

‘Document Prepared by! (Sagar Sharma) Custodian: ‘Approved by: \ 7 Page tof 5

Activity Hazards.& Risks | Those at Risk Controls in place Bek | pesneSinle | Recommendations

| What hazards andrisks | Who willbe sna

are associated with the | affected by the | what measures are required to responsible to

What activity is task? These must be hazards? ‘ t atin

What sc | igenthied befor te jb ic | Employees and | elitinte or cotral the hazards fo an ensure that these

edad wy arens'e acceptable level? measures are put

~ the area. in place?

4. Mobilization | + Use of non- Project workers: © Only certified, Tested and pre-

on Site: recommended, self- 1 Other inspected Equipment to be

(Tool / Plant & fabricated and banned contractor / used.

Equipment to site) oe plant ! equipment Terminal Assets + Ensure that no safety guard is

may lead to personal removed from tools.

injury and damage to + No homemade hand tool is ,

terminal assets. allowed at site. Project Engineer | « Ensure availability

+ Provide red tag and remove 2c | Safety of industrial grade

any hand tool if it gets damaged ‘Supervisor hand tools.

during work at site.

* Access the load before

handling to ensure safe grip.

* Wear adequate PPEs and

additional PPEs where

required,

2.Visual Inspection | « Flammable material Project workers |» Ensure Visual inspection of 2B | Project Engineer | inspection should be

of internal side * Hydrocarbons 1 Other internal side from top side main Safety done before starting

it a | ° Slug contractor / hole Supervisor work

a oie fectone, * Toxic gases Terminal Assets | + Ensure gas testing by

aes sere fe authorized gas tester

stating hot work ‘+ Ensure no flammable material

inside tank or near hot work

N activity

Form G = Risk ma Z| —Disrbuton Permit to Work System Reviewed by arch 2006

+ Dosument Prepared by: (SagakSnaim’) Custodian ‘Approved by. Page 2of 6

sfxtend * Fall from height Project workers | Ensure double Layardharness | 3C | Project Engineer | Ensure Pre

‘scaffolding © Slip & trip / Other belt during working at height Safety Inspection of Harness

platform for Contractor / «Ensure 100% tie off ‘Supervisor before Each use

welding of eyes on Terminal Assets | During erection and dismantling

aot foreccess and only scaffolders are allowed

anchor poi 5 Ensure no lp and ip materia

reference permit Shee ore

before st rk

number (P289-00- ae

3945560)

4. Welding = of © Hot work Project workers: © Ensure gas testing ‘3C | Project Engineer © Use of

Lifting Eyes on © Presence of gases Other * Ensure fire blanket Safety appropriate

SKP-06 top side © Un-trained, or contractor / Ensure fire extinguisher on site ‘Supervisor PPE’s (face

inexperienced Terminal Assets | Ensure all the workers are

workers trained to perform the activity

‘Fall from height + Welding plant should be third

© Fatigue party Certified plugs =)

© Heat stroke + Ensure All tools are inspected Seer

‘© Drop Object and colour coded unauthorised

© Unskilled + Ensure Suitable anchor point personnel

welder/grinder + Ensure Fully body harness movement

a Sat lao 100% Tie Off © Ensure proper

: © Ensure proper rest breaks fixing of dise

Uninspected tools Ensure cool drinking water on

site

. ‘© Ensure job rotation

© Sharp edges © Ensure Toe Boards

= Bpkvebon © Ensure area barricade

a Ensure drop object zone are

Lane barricade and no personal in

© Work near live line of fre

areas ‘© Scaffolding should be

dismantled in reverse order of

Use of non- erection ( from top to bottom)

recommended, self-

‘© Skilled & trained personnel to

fabricated and banned perform hot job

=a ANE ana TT aoe 1

| Becument Prepared by: (Sagar Sarma) Custodian: ‘Approved by: Page 3 of 5

[tools /plant / equipment ‘© Use of appropriate PPE’s for

may lead to personal the job

injury and damage to aces oft A

pected & right tools

terminal assets. for the job

«Ensure that leads/cables are

proper with no damage

‘* Proper cable/leads management

to avoid tripping hazards

Stop hot job if conditions are

abnormal,

‘© Ensure proper housekeeping of

area

«Sharp edges of steel bars should

be properly grinded

* Use of proper canopy to avoid

naked sparks and flame

3. Perform DPT Project workers | Ensure proper face mask, 2B | Project Engineer | + Ensure area

1 Other goggles and gloves Safety barricade

contractor / ‘+ Ensure proper rest breaks ‘Supervisor + Ensure PPESs

Terminal Assets | + Ensure housekeeping suitable with

« Fatigue + Ensure Nitrile gloves the task

«Report yourself if you are

suffering from fatigue

6. Housekeeping * Dust effect Project workers |» Ensure proper face mask 2B | ProjectEngineer [+ Plan

workers working in | /other + Ensure water cooler on site Safety maximum

area contractor! «Ensure proper rest breaks Supervisor work in the

+ Heat stress terminal assets / Ensure reporting if you are coolest part of

(Fatigue visitors suffering from fatigue day

‘+ Ensure ORS on site (to avoid Ensure

. Proper

dehydration) rest breaks

‘+ Ensure Housekeeping

Don't left tools unintended/ on

\ =

_{\

Form G — Risk Assessm| Distribution Permit to Work System Reviewed by: = ‘March 2006

4 a

a red by: (Sagar Custodian: “Approved by: : : Page 40f 5

fan ae L site |

_|__+ Ensure Proper rest breaks I

exhaustive list of hazard categories

When conducting a risk assessment:

“The assessment should be carried out in good time prior to the relevant decision being made

When a specific assessment is needed then such an assessment, rather than a generic assessment should be made

“The risk from each activity should be considered

‘Ateam of people or employees with practical knowledge of the process/activity being assessed should be used as appropriate

Consultants should be used where necessary

All the hazards associated with a particular activity should be considered

Hazards and risk controls should be linked

The results of the assessment should be properly used.

‘Assessment should be revised when change in condition, tool, task or methodology or when new technology is introduced.

INCREASING LIKELIHOOD

ry

Environment

SEVERITY

People

March 206

{

1 = Fre hasseesnaret fp Lif tyattention Perret to Work Systern Reeeewed by.

sagen ty (pe Cantos

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D ShackleDocument1 pageD ShackleSagar SharmaNo ratings yet

- B ShackleDocument1 pageB ShackleSagar SharmaNo ratings yet

- Permit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnDocument53 pagesPermit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnDocument47 pagesPermit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Permit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Document4 pagesPermit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Sagar SharmaNo ratings yet

- Angle Grinder BG-01Document1 pageAngle Grinder BG-01Sagar SharmaNo ratings yet

- Method StatementDocument3 pagesMethod StatementSagar SharmaNo ratings yet

- Manual Lifting PlanDocument2 pagesManual Lifting PlanSagar SharmaNo ratings yet

- Chain Block CB NS.010 2T - 2Document1 pageChain Block CB NS.010 2T - 2Sagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- New EntryDocument1 pageNew EntrySagar SharmaNo ratings yet

- Progress Report 32Document2 pagesProgress Report 32Sagar SharmaNo ratings yet

- Ilovepdf MergedDocument8 pagesIlovepdf MergedSagar SharmaNo ratings yet

- JSA For NSE ProjectDocument7 pagesJSA For NSE ProjectSagar SharmaNo ratings yet

- Progress Report 33Document2 pagesProgress Report 33Sagar SharmaNo ratings yet

- Risk Assessment: Corresponding Permit To Work NoDocument4 pagesRisk Assessment: Corresponding Permit To Work NoSagar SharmaNo ratings yet

- Rescue Plan Working at HeightDocument2 pagesRescue Plan Working at HeightSagar SharmaNo ratings yet

- Emergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelDocument1 pageEmergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelSagar SharmaNo ratings yet

- Progress Report 31Document2 pagesProgress Report 31Sagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- SHELL SMEP Lifting and Hoisting Manual Rev 1 0Document349 pagesSHELL SMEP Lifting and Hoisting Manual Rev 1 0Sagar SharmaNo ratings yet

- Work at Height Rescue PlanDocument1 pageWork at Height Rescue PlanSagar SharmaNo ratings yet

- Key Performance Indicator Naseem & SonDocument1 pageKey Performance Indicator Naseem & SonSagar SharmaNo ratings yet

- Rescue Plan For HeightDocument2 pagesRescue Plan For HeightSagar SharmaNo ratings yet

- Naseem & Son: Report of Internal AuditDocument5 pagesNaseem & Son: Report of Internal AuditSagar SharmaNo ratings yet

- Assessment Report Naseem & SonDocument2 pagesAssessment Report Naseem & SonSagar SharmaNo ratings yet

- Safety Walk Report by ClientDocument3 pagesSafety Walk Report by ClientSagar SharmaNo ratings yet

- Naseem & Son: Emergency Response PlanDocument7 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- SSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckDocument4 pagesSSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksDocument2 pagesMethod Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksSagar SharmaNo ratings yet