Professional Documents

Culture Documents

1.0 Design Criteria - Rev 1

Uploaded by

Ramesh-NairCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.0 Design Criteria - Rev 1

Uploaded by

Ramesh-NairCopyright:

Available Formats

Cambodia Leader Energy 1x150MW CFB Plant

1.0 Design Criteria

The following conditions have been considered in the Plant design to meet the

performance requirements.

1.1 Site Conditions

Parameter Unit Minimum Guarantee Maximum

Point

Ambient Air Temperature °C 21 28 40

Ambient Air Pressure mbar 970 1013 1030

Power Factor (Lagging) - 0.85

Relative Humidity % 76 80 98

Annual Rainfall (mean) mm - 3200

24 Hours Rainfall mm - 136.4

Site Grade Elevation (above m - - 10

mean sea level)

Wind Speed Average m/s - 3~6

Seismic Design Condition - U.B.C. Zone 1

according to US Uniform

Building Code (UBC 1997)

Cooling water temperature degC 28 30 32

(Sea water)

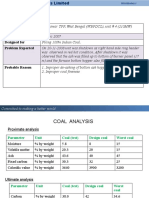

1.2 Fuel Analysis (Coal)

Following Coal Analysis has been considered for the Plant Design (the fuel

analysis is same as being fired in the existing Plant):

Unit Minimum Maximum

Proximate Analysis

Total Moisture (% a.r) 7.5 35

Calorific value (HHV) Kcal/kg 4975 6900

(a.d)

Ash (% a.d) 4 15

Volatile Matter (% a.d) 25.5 47

Jurong Engineering Limited

Rev 1

Page 1 of 9

Cambodia Leader Energy 1x150MW CFB Plant

Fixed Carbon (% a.d) 30 57

Inherent Moisture (% a.d) 2.5 25

Sulphur (S) (% a.d) 0.05 1.2

Hardgrove Index (HGI) 38

Ultimate Analysis

Carbon (C) (%d.a.f 60 88.5

)

Hydrogen (H) (%d.a.f 3 10

)

Nitrogen (N) (%d.a.f 0.5 2.0

)

Oxygen (O) (%d.a.f 5.0 27.5

)

Ash Analysis (dry basis)

SiO2 % 42.0 71.5

Al2O3 % 21.0 18.2

Fe2O3 % 16.0 2.8

CaO % 7.0 1.50

MgO % 3.0 0.50

Na2O % 0.30 0.60

K2O % 1.0 1.80

SO3 % 8.0 0.70

Mn3O4 % 0.30 0.4

TiO2 % 0.5 1.1

P2O5 % 0.08 0.11

Ash Fusion Temperatures

(reducing atmosphere)

Initial deformation temp degC 1100 1555

Hemispherical degC 1130 1625

Fluid degC 1170 1625

The following Fuel Analysis considered for Plant Guarantees:

Description Unit For

Guarantee

Proximate Analysis

Total Moisture (% a.r) 20.6

Calorific value (HHV) Kcal/kg 5193

(a.r)

Ash (% a.d) 8.16

Volatile Matter (% a.d) 38.17

Fixed Carbon (% a.d) 41.26

Jurong Engineering Limited

Rev 1

Page 2 of 9

Cambodia Leader Energy 1x150MW CFB Plant

Inherent Moisture (% a.d) 12.4

Sulphur (S) (% a.d) 0.375

Hardgrove Index (HGI) 46

Ultimate Analysis (as received)

Carbon (C) % 54.07

Hydrogen (H) % 3.96

Nitrogen (N) % 1.07

Sulphur (S) % 0.34

Oxygen (O) % 12.56

Total Moisture % 20.6

Ash % 7.4

Calorific value (HHV) Kcal/kg 5193

Calorific value (LHV) Kcal/kg 4867

Ash Analysis (dry basis)

SiO2 % 54.72

Al2O3 % 22.47

Fe2O3 % 7.65

CaO % 3.51

MgO % 2.01

Na2O % 1.30

K2O % 1.55

SO3 % 5.04

Mn3O4 % 0.05

TiO2 % 0.89

P2O5 % 0.37

Ash Fusion Temperatures

(reducing atmosphere)

Initial deformation temp degC 1180

Hemispherical degC 1270

Fluid degC 1320

Note: We refer to the Ash Analysis provided in Exhibit A of the Term Sheet.

While the individual constituents “minimum” and “maximum” limits are specified,

this does not provide the actual “Ash Composition” with the total leading upto

100%. In order to understand the ash characteristics and the corresponding coal

behaviour, it is necessary to have the correct ash composition totalling to 100%. As

the basis of our proposal, we have provided in this Design Criteria the typical “Ash

Composition” considered for the boiler design.

Fuel Sizing - Coal

Jurong Engineering Limited

Rev 1

Page 3 of 9

Cambodia Leader Energy 1x150MW CFB Plant

For Boiler performance 100% less

than 6 mm.

Less than

1mm

around 30%

For Boiler operation 100% less

than 6 mm.

Less than

1mm

around 40%

Start up Fuel Analysis – LDO

Ultimate Analysis (as received)

Carbon (C) % 85.50

Hydrogen (H) % 11.50

Nitrogen (N) % 0

Sulphur (S) % 3.00

Oxygen (O) % 0

Total Moisture % 0

Ash % 0

Calorific Value (HHV) Kcal/kg 10700

Limestone composition % by wt

Calcium carbonate % 95

Magnesium carbonate % 1.5

Inert / SiO2 % 3.25

Moisture % 0.25

Limestone properties

Reactivity >3.3

Attrition Index <2.6

Nature Soft,

powdery

Bulk Density Kg/m3 1100 - 1300

Limestone size (Indicative, to be confirmed)

US Mesh Microns % passing

18 1000 100

20 840 96 – 100

30 590 85 – 95

50 300 65 – 85

70 210 25 – 55

100 150 10 – 30

Jurong Engineering Limited

Rev 1

Page 4 of 9

Cambodia Leader Energy 1x150MW CFB Plant

140 100 10 – 15

200 75 0

Bed Material composition

Analysis Unit Range

Silica % 68

Al2O3 % 28

FeO % 1.05

TiO2 % 1.67

MnO % Traces

CaO % 0.54

MgO % 0.23

P2O5 % 0.08

Na2O % 0.22

K2O % 0.45

Bed material physical properties

Bulk Density Kg/m3 1000 - 1100

Fusion temperature degC >1250

Nature and condition Dry

Hardness mohs 6.8 – 7.2

Sphericity 0.75 – 0.9

During normal operation, considering low ash fuel, continuous addition of bed

material / limestone is required to maintain the bed inventory.

Bed Material size (Indicative, to be confirmed)

Size in Microns Unit % passing

< 500 % 100

< 400 % 90

< 300 % 60 – 80

< 250 % 10

< 140 % 0

1.3 Electric Power Supply

Volt Phase Frequency

Generator Terminal voltage 11,500 3 50 Hz

Medium high voltage 6,600 3 50 Hz

consumers (160kW & above)

Low voltage consumers 400 3 50Hz

Jurong Engineering Limited

Rev 1

Page 5 of 9

Cambodia Leader Energy 1x150MW CFB Plant

( below 160 kW)

Lighting 400/230 3/1 50 Hz

Instruments 230 1 50 z

1.4 Demineralized Water Quality (Outlet of Existing Demin Plant)

The following DM water quality shall be supplied from the existing Plant:

Parameter Quality

pH 7.0 – 7.5

Dissolved Organic Carbon (DOC) 200 µg/kg max

Total Suspended Solids Nil

Hardness Nil

Conductivity @ 25degC 0.1 µS/cm max

Silica (SiO2) 0.01 mg/l max

Total Iron (Fe) 0.01 mg/l max

Total Copper (Cu) 0.003 mg/l max

Sodium (Na) 0.01 mg/l max

Oil Nil

The above quality of DM water meets the requirements of

Boiler and Steam Turbine manufacturers.

1.5 Filtered Water Quality (Outlet of Pre-treatment Plant)

The following filtered water quality is anticipated at the outlet of pre-treatment

Plant:

pH value 8 ~ 10

Turbidity, NTU 3 max

Hardness, mg/L as CaCO3 48 ~108

TDS, mg/L 100

Iron, Fe, mg/L <0.3

Residual Chlorine, mg/l <0.5

O&G, mg/l <2

The filtered water is stored in the existing Service water cum

Jurong Engineering Limited

Rev 1

Page 6 of 9

Cambodia Leader Energy 1x150MW CFB Plant

Fire water storage tank and this will be used for the following

applications:

1. To supply Service water to various user points

2. To supply fire water, for 2 hours, for any plant fire emergency

Filtered water quality shall meet industry service water quality

and the fire water quality as required and no additional treatment

is expected.

1.6 Instrument Air (from outlet of existing dryer)

Quality To meet Instrument air quality as per ISO

Pressure barg 9.0

Temperature C 50-55 Deg C

Pressure Dew point C -40 Deg C

Mechanical design pressure barg 12

Mechanical design temperature C 60

1.7 Plant Air (from existing Plant)

Pressure barg 8.0

Temperature C 50-55 Deg C

Dew point C saturated

Mechanical design pressure barg 12

Mechanical design temperature C 60

1.8 Environmental Considerations

1.8.1 Noise Emissions

The facility, under scope of supply, will be designed and constructed to meet the

noise emission limit of 85 dB (A) at normal, continuous and stable operating

conditions, under 100% base load operation, measured in accordance with DIN

45635 and ISO 3746, at a distance of 1 meter from each equipment / enclosure

surface, and height of 1.5 meter above the ground level. During abnormal

operation cases, such as opening of safety valves / start-up vent, turbine bypass

operation, start up and shut down, EDG and diesel fire pump operation, the noise

Jurong Engineering Limited

Rev 1

Page 7 of 9

Cambodia Leader Energy 1x150MW CFB Plant

levels will be higher (about 115dBA), but such operations are expected to be only

for a short duration.

The back ground noise level is assumed to be zero for such guarantees.

1.8.2 Air Emissions (Stack Emissions)

Emissions at 100% BMCR with HP Heater in service and while firing

performance fuel and corrected 1013 mbar a and 6% O2 (dry) will not exceed

the values specified below:

Dust (PM10) <50 mg/Nm3

SOx TBA

NOx TBA

Ambient air quality is clean and no contaminants shall be present.

Conditions for normal cubic meters (Nm3) are 0 degC and 760mm of Hga.

Conditions for standard cubic feet (SCF) are 15degC and 760mm of Hga

The SOx emissions will depend on the sulphur content in the fuel.

1.9 Codes and Standards

The Facility will be designed in accordance with the following list of codes and

standards. The Facility must also comply with Cambodia national standards as may be

approved by Ministry (or any other approved Governmental Authority) from time to time.

The codes and standards utilized will be the latest editions in effect on the date of

this proposal.

In the event these codes and standards are subsequently modified by their issuing

agency, and should such modifications be required to be incorporated into the

Facility, then any resulting additional cost, project delays, changes in

performance guarantees, etc., will be considered as a change in the work scope.

ACI American Concrete Institute

AISC American Institute of Steel Construction

AISI American Iron and Steel Institute

ANSI American National Standards Institute

API American Petroleum Institute

ASHRAE American Society of Heating, Refrigeration & Air Conditioning Engineers

ASME American Society of Mechanical Engineers

ASTM American Society for Testing and Materials

AWS American Welding Society

AWWA American Water Works Association

BS British Standards Institution

Jurong Engineering Limited

Rev 1

Page 8 of 9

Cambodia Leader Energy 1x150MW CFB Plant

CEN European Committee for Standardization

CENELEC European Committee for Electrotechnical Standardization

DIN German Standardization Institute

EHS World Bank EHS Guidelines

HEI Heat Exchange Institute

HIS Hydraulic Institute Standard

IBC I nternational Building Codes

IEC International Electrotechnical Commission

IEE Institute of Electrical Engineers

IEEE Institute of Electrical and Electronics Engineers

IETE Institution of Engineering and Technology in UK

IFC PS IFC Performance Standards

ISO International Standards Organization

JIS Japanese Industrial Standards

MSS Manufacturer’s Standardization Society

NEMA National Electrical Manufacturers Association

NFPA National Fire Protection Association

PIANC Permanent International Association of Navigation Congresses

SSPC Steel Structures Painting Council.

TEMA Tubular Exchanger Manufacturers Association

TRD Technical Rules for Steam Generators

VDI Association of German Engineers

VGB Society of large utility owners

UBC Uniform Building Codes

For packaged equipment supplies, the manufacturer’s codes and standards, as per

their standard engineering practices, will be followed. The surface preparation

and painting for such equipment shall follow their recommended procedures.

Jurong Engineering Limited

Rev 1

Page 9 of 9

You might also like

- 1.0 Design Criteria - Rev 1Document9 pages1.0 Design Criteria - Rev 1Ramesh-NairNo ratings yet

- Russian Hard Coking Coal AnalysisDocument1 pageRussian Hard Coking Coal Analysisnaresh adusumilliNo ratings yet

- MABU - HCC 2022-SpecDocument2 pagesMABU - HCC 2022-SpecDUANJUNXINo ratings yet

- Lee2014 Ie500110v Si 001Document3 pagesLee2014 Ie500110v Si 001Bidesh M KirtaniaNo ratings yet

- Fuel Analysis: A H C N O S M QDocument10 pagesFuel Analysis: A H C N O S M QThaigroup CementNo ratings yet

- Coal ConversionDocument3 pagesCoal ConversionIrfan AhmedNo ratings yet

- 1 Dolochar Including Char Lump Sample and Char Fines Sample: E C C CDocument5 pages1 Dolochar Including Char Lump Sample and Char Fines Sample: E C C CJKKNo ratings yet

- MLV - HCC SpecV1-2022Document1 pageMLV - HCC SpecV1-2022DUANJUNXINo ratings yet

- Black Hill Coking CoalDocument1 pageBlack Hill Coking Coalnaresh adusumilliNo ratings yet

- Main design and auxiliary units of steam generation processDocument18 pagesMain design and auxiliary units of steam generation processMustafa MohamedNo ratings yet

- China Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsDocument32 pagesChina Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsJawad HussainNo ratings yet

- Coal Fuel Analyses and Mass BalanceDocument2 pagesCoal Fuel Analyses and Mass Balancemohamed ElsayedNo ratings yet

- Design Criteria 1 PDFDocument17 pagesDesign Criteria 1 PDFAnonymous ahdhFMaNo ratings yet

- Agbami 2012 03Document5 pagesAgbami 2012 03eke23No ratings yet

- Statoil Eagle Ford Gen Grade 2017 07Document5 pagesStatoil Eagle Ford Gen Grade 2017 07AhmedAlhosaniNo ratings yet

- Gas ValueDocument3 pagesGas Valuemahi_kotaNo ratings yet

- Boiler performance calculation using Hottel's methodDocument18 pagesBoiler performance calculation using Hottel's methodXamir Suarez AlejandroNo ratings yet

- Eff FormulaDocument59 pagesEff FormulaVenkateswara Rao DoodalaNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- Atlas Copco-Basic Product TrainingDocument42 pagesAtlas Copco-Basic Product TrainingArstNo ratings yet

- Coal Analysis + Price AdjusmentDocument46 pagesCoal Analysis + Price AdjusmentWahyoedyNo ratings yet

- Typical Specification - Russian PCI Coal - KravaskyDocument1 pageTypical Specification - Russian PCI Coal - Kravaskynaresh adusumilliNo ratings yet

- Garbage IncineratorDocument59 pagesGarbage IncineratorgsdaundhNo ratings yet

- GNFC 18 MW CCPP Fuel and Ash AnalysisDocument3 pagesGNFC 18 MW CCPP Fuel and Ash AnalysisashokNo ratings yet

- Ch140: Chemical Process Industries Case StudyDocument4 pagesCh140: Chemical Process Industries Case StudymarkkkkkNo ratings yet

- Crude Summary Report: Reference: KRKUK359 Crude: KirkukDocument5 pagesCrude Summary Report: Reference: KRKUK359 Crude: Kirkukasad razaNo ratings yet

- METROPOLITAN HARD COKING COAL SPECIFICATIONDocument1 pageMETROPOLITAN HARD COKING COAL SPECIFICATIONnaresh adusumilliNo ratings yet

- Report On Combustion Test Gramtech, TeamDocument26 pagesReport On Combustion Test Gramtech, TeamYousufNo ratings yet

- ISP - Trial of Russian Kiyzassky MV PCI CoalDocument6 pagesISP - Trial of Russian Kiyzassky MV PCI CoalbfispoperationsNo ratings yet

- Sepco Erosion Prediction: R M R R R R R RDocument7 pagesSepco Erosion Prediction: R M R R R R R RMohamed HashemNo ratings yet

- Fertial Arzew Plant2Document5 pagesFertial Arzew Plant2Azee TitouNo ratings yet

- Analysis of Indian Coal (F Grade)Document3 pagesAnalysis of Indian Coal (F Grade)JKKNo ratings yet

- Sponge Iron Heat & Mass BalanceDocument33 pagesSponge Iron Heat & Mass BalanceNILESH JAIN100% (1)

- Alvheim Blend 2013 09Document5 pagesAlvheim Blend 2013 09Tree SilviaNo ratings yet

- Raw Materials Burnability Testing Reports, Port Daniel Cement Plant ProjectDocument48 pagesRaw Materials Burnability Testing Reports, Port Daniel Cement Plant ProjectNihar Ranjan TripathyNo ratings yet

- Fuel Ash Analysis ReportsDocument1 pageFuel Ash Analysis Reportsmohan babuNo ratings yet

- Metro ViewerDocument5 pagesMetro ViewerSteve WanNo ratings yet

- Project DescriptionDocument32 pagesProject Descriptionxiangjintao50% (2)

- Pilot Species Temp Boundary Conditions Mean Values Reacting Non-ReactingDocument1 pagePilot Species Temp Boundary Conditions Mean Values Reacting Non-ReactingSouhardya BanerjeeNo ratings yet

- Pretreatment design for FABA and WWTP waste streamsDocument2 pagesPretreatment design for FABA and WWTP waste streamsalwi sahabNo ratings yet

- Georgia Gulf Chemicals and Vinyls furnace emissions testing resultsDocument10 pagesGeorgia Gulf Chemicals and Vinyls furnace emissions testing resultsAris StarsNo ratings yet

- Data Reference: Merk: FG-Wilson, Model: P700-1, 2014 Fuel ConsumptionDocument22 pagesData Reference: Merk: FG-Wilson, Model: P700-1, 2014 Fuel ConsumptionIrene 'septiriana'No ratings yet

- Azeri BTC 2015 10Document5 pagesAzeri BTC 2015 10Faisal SiagianNo ratings yet

- Russian Prime PCI - Bachatsky - April, 2019Document1 pageRussian Prime PCI - Bachatsky - April, 2019naresh adusumilliNo ratings yet

- Mass Balance (Final)Document26 pagesMass Balance (Final)Adeel AhmedNo ratings yet

- Allowable DischargeDocument3 pagesAllowable DischargeTiago PhillipeNo ratings yet

- Deepika(Ammonia)Document2 pagesDeepika(Ammonia)suhailkpuaeNo ratings yet

- HW MgoDocument5 pagesHW MgotauqeerNo ratings yet

- Thermophysical PropertiesDocument7 pagesThermophysical PropertiesWei JianNo ratings yet

- Material Balance - Reactor 1Document29 pagesMaterial Balance - Reactor 1Xy karNo ratings yet

- Analytical Report - Lot 1 (800MT)Document1 pageAnalytical Report - Lot 1 (800MT)FLOWSYSNo ratings yet

- Eor AnalysisDocument60 pagesEor AnalysisDiego Armando HerreraNo ratings yet

- Specific Gas Ratio - SwapnilDocument33 pagesSpecific Gas Ratio - SwapnilYhane100% (1)

- Ten Blend 2019Document4 pagesTen Blend 2019Para DiseNo ratings yet

- PROCESS DESCRIPTION AND LCA ICA PresentationDocument15 pagesPROCESS DESCRIPTION AND LCA ICA PresentationTehmasipNo ratings yet

- Comparative Study For Hydrodesulphurization (HDS) and Hydrogenation of The Constituent Elements in Lacustrine Oil Shale Deposit at Timahdit (Morocco)Document13 pagesComparative Study For Hydrodesulphurization (HDS) and Hydrogenation of The Constituent Elements in Lacustrine Oil Shale Deposit at Timahdit (Morocco)IJAR JOURNALNo ratings yet

- Boiler-1 Aditya Cement Works Sept 21Document7 pagesBoiler-1 Aditya Cement Works Sept 21ameer meerNo ratings yet

- Case Study:: Project Synchronized On Designed For Problem ReportedDocument18 pagesCase Study:: Project Synchronized On Designed For Problem ReportedSanajy TyagiNo ratings yet

- Case Study 3Document49 pagesCase Study 3eze_atn_vNo ratings yet

- The Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationFrom EverandThe Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationShulamith SchlickNo ratings yet

- HRSG-Forum-Presentation-LCRI-9-24-21-1Document12 pagesHRSG-Forum-Presentation-LCRI-9-24-21-1Ramesh-NairNo ratings yet

- KPP-000-XA96-702-ADocument39 pagesKPP-000-XA96-702-ARamesh-NairNo ratings yet

- KPP-000-XA96-700-ADocument246 pagesKPP-000-XA96-700-ARamesh-NairNo ratings yet

- 2023-10-Elder-Manual-sfl - E - Shepherd The Flock of GodDocument290 pages2023-10-Elder-Manual-sfl - E - Shepherd The Flock of GodRamesh-NairNo ratings yet

- Steam Turbine O&M ManualDocument183 pagesSteam Turbine O&M ManualErin Ward100% (9)

- Annexure 4Document1 pageAnnexure 4Ramesh-NairNo ratings yet

- Advert - Assistant Project ManagerDocument2 pagesAdvert - Assistant Project ManagerRamesh-NairNo ratings yet

- gb-electricity-market-implementation-planDocument39 pagesgb-electricity-market-implementation-planRamesh-NairNo ratings yet

- Annexure 10Document10 pagesAnnexure 10Ramesh-NairNo ratings yet

- EDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Document3 pagesEDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Ramesh-NairNo ratings yet

- MOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Document2 pagesMOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Ramesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument65 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- Annexure 2Document27 pagesAnnexure 2Ramesh-NairNo ratings yet

- JusMundi PDF Heirs To The Sultanate of Sulu V Malaysia Final AwardDocument124 pagesJusMundi PDF Heirs To The Sultanate of Sulu V Malaysia Final AwardRamesh-NairNo ratings yet

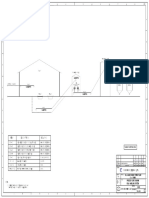

- Attachment 4 - PFD Coal Handling SystemDocument1 pageAttachment 4 - PFD Coal Handling SystemRamesh-NairNo ratings yet

- Attachment 4 - Sketch For New Plant and Shared Facilities - CEL FinalDocument1 pageAttachment 4 - Sketch For New Plant and Shared Facilities - CEL FinalRamesh-NairNo ratings yet

- Ash Handling Technical SpecificationDocument13 pagesAsh Handling Technical SpecificationRamesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument11 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- An Introduction To CEEQUAL May 2018Document16 pagesAn Introduction To CEEQUAL May 2018Ramesh-NairNo ratings yet

- Cambodian Energy Employers RequirementsDocument62 pagesCambodian Energy Employers RequirementsRamesh-NairNo ratings yet

- Routine Performance Test Guidelines For Steam TurbinesDocument40 pagesRoutine Performance Test Guidelines For Steam TurbinesRamesh-Nair100% (1)

- Us 20120067568Document30 pagesUs 20120067568Ramesh-NairNo ratings yet

- Workplace Safety Health RegulationsDocument76 pagesWorkplace Safety Health RegulationsRamesh-NairNo ratings yet

- Fire Fighting System - Spec - Rev0Document14 pagesFire Fighting System - Spec - Rev0Ramesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument5 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- Executive Summary - Hydrogen Cofiring Demonstration at New York Power Authority - S Brentwood Site - GE LM6000 Gas TurbineDocument8 pagesExecutive Summary - Hydrogen Cofiring Demonstration at New York Power Authority - S Brentwood Site - GE LM6000 Gas TurbineRamesh-NairNo ratings yet

- Newspaper Article - STRAITS SETTLEMENTS CIVIL SERVICEDocument5 pagesNewspaper Article - STRAITS SETTLEMENTS CIVIL SERVICERamesh-NairNo ratings yet

- Newspaper Article - NO COMPROMISE ON DUAL CITIZENSHIPDocument2 pagesNewspaper Article - NO COMPROMISE ON DUAL CITIZENSHIPRamesh-NairNo ratings yet

- Pressure Equipment Material AppraisalDocument1 pagePressure Equipment Material AppraisalRamesh-NairNo ratings yet

- Steam Turbine Performance Engineers GuideDocument142 pagesSteam Turbine Performance Engineers GuideRamesh-Nair100% (1)

- Switching & Controlling - PricelistDocument72 pagesSwitching & Controlling - Pricelistsaurabhrai85No ratings yet

- Machinery Space Operations Record ExamplesDocument6 pagesMachinery Space Operations Record ExamplesRosario SisniegasNo ratings yet

- Physics 2023 Matriculation Examination Pilot TestDocument2 pagesPhysics 2023 Matriculation Examination Pilot TestEainDra SoeNo ratings yet

- DEWA Substation CT TestingDocument38 pagesDEWA Substation CT TestingMohammed SameeNo ratings yet

- Peraturan Dan Undang-Undang Alam Sekitar (Rcra)Document7 pagesPeraturan Dan Undang-Undang Alam Sekitar (Rcra)Iser100% (1)

- Region I - Tourist SpotsDocument1 pageRegion I - Tourist SpotsRG GarvinNo ratings yet

- KASCO Large-Diameter Seamless Pipe Manufacturer ProfileDocument44 pagesKASCO Large-Diameter Seamless Pipe Manufacturer ProfileKristen NguyenNo ratings yet

- Q400 - 12. PropellersDocument14 pagesQ400 - 12. PropellersDavid Owen100% (1)

- Fire-Extinguisher-Safety-PPT_LightDocument25 pagesFire-Extinguisher-Safety-PPT_Lightashok sanghviNo ratings yet

- Page 47-54 Immobiliser and DiagnosisDocument13 pagesPage 47-54 Immobiliser and DiagnosisDaniel Mamani Paredez100% (1)

- Photovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerDocument12 pagesPhotovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerHocine AbdelhakNo ratings yet

- Portable Compressors (Diesel) MDVN RangeDocument29 pagesPortable Compressors (Diesel) MDVN RangeRotair spaNo ratings yet

- Final Project Report SubmisssionDocument56 pagesFinal Project Report SubmisssionShreyash KaleNo ratings yet

- 8587ctts 330v 2i 1178 182Document5 pages8587ctts 330v 2i 1178 182Haresh RaisinghaniNo ratings yet

- Design and Implementation of Solar Powered Mobile Phone Charging Station For Public PlacesDocument1 pageDesign and Implementation of Solar Powered Mobile Phone Charging Station For Public Placesmarchanalzandra2No ratings yet

- Physics of VLSI Devices (ECE5018) - CAT-2 Solutions: Dr. Rajan Pandey Associate Professor, SENSEDocument16 pagesPhysics of VLSI Devices (ECE5018) - CAT-2 Solutions: Dr. Rajan Pandey Associate Professor, SENSEVibha M VNo ratings yet

- Board Exam 2011 Part 1Document5 pagesBoard Exam 2011 Part 1JC YabisNo ratings yet

- Catalog D-1 Reg Sol and 3-Way Heat Reclaim ValvesDocument60 pagesCatalog D-1 Reg Sol and 3-Way Heat Reclaim ValvesviniciusschwabNo ratings yet

- Planuri MentenantaDocument9 pagesPlanuri MentenantaBogdan PoantăNo ratings yet

- Routine Test Reports for DisconnectorsDocument5 pagesRoutine Test Reports for Disconnectorsgrigore mircea100% (1)

- Mga Sagot Ni Ashe Montage Gen Physics1Document4 pagesMga Sagot Ni Ashe Montage Gen Physics1Valencia AngieNo ratings yet

- Power Sector Economics and PlanningDocument123 pagesPower Sector Economics and Planningsundaram upadhyayNo ratings yet

- KSSR Science Year 4Document36 pagesKSSR Science Year 4farahNo ratings yet

- AnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622Document6 pagesAnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622rotimi olalekan fataiNo ratings yet

- Gölcük VET Scenario - Oil Tempereture HighDocument1 pageGölcük VET Scenario - Oil Tempereture HighCantekin CeNo ratings yet

- Manual Wind Controller 2Document12 pagesManual Wind Controller 2Kazedr 15No ratings yet

- Addendum 5. December 2019 Changed Pages OnlyDocument210 pagesAddendum 5. December 2019 Changed Pages OnlyMelele MuNo ratings yet

- Ritschard Case Study Combustion EngineeringDocument6 pagesRitschard Case Study Combustion Engineeringvikubhardwaj9224No ratings yet

- Modular FURNACE INSULATION THKNESS CALDocument2 pagesModular FURNACE INSULATION THKNESS CALRamachandra Bhat HireNo ratings yet

- Optimate 32L: FR NLDocument24 pagesOptimate 32L: FR NLmanuren9_471188952No ratings yet