Professional Documents

Culture Documents

And Good:: ,,::1 ,,+i. A-.: .: ..,.i.:: I - '::.. .

Uploaded by

Sudipta GangopadhyayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

And Good:: ,,::1 ,,+i. A-.: .: ..,.i.:: I - '::.. .

Uploaded by

Sudipta GangopadhyayCopyright:

Available Formats

: ,,::1 ,,+i. a-.: .: .

.*ij ..:-.. I ii$ ::i

.1 ,, ' . ji::: '

..,.i.::=i; . '::..*. : : :

<,: .:: " ::, ':: t: i:.ji ..i:

,.f

-- SL '":, '

..!* ..

j.;

.'i:::* i:'.

'!t i,

w'-'

ls.l s

=-'*

iil.!r:!'. q ':

. * ' lt

,

r i !gat.-l

,::. '{3: t'

r.. j

:,1 r"

The production of M-Sand or fectively used in making con-

Manufactured Sand generally crete which provides adequate

involves Crushing, Screening strength and durability for

and possibly Washing. sepa- the concrete. Having cubical

ration into discrete f ractions, shape, it effectively provides

recombining and blending good bonding in concrete.

At the beginning M-sand pro- Crading of manufactured sand

duced (by Jaw crusher, cone can be controlled i.e. required

crusher, roll crusher, hammer zone of sand can be obtained.

mill etc.) contains flaky ard l'.'an-lactured sand can be

elongated particles. Fo n e. =- c.cC uced ,'vith zero f ines.

when manufactured sa no s

Rajesh Jha,

(Managing Director)

produced from V.S.l (vert c: -s ::r cesn'r contain silt and

shaft impactor) it becomes : ^'a^^rties of

Y Vvve ce-

Aggregate Innovations Pvt. Ltd. suitable and viable s-bsr ., -:

to river sand and cou d b: :'- t : =: .: .. - e'e larqe quantity

Crushing & Quarrying World I June 2019 | 16

Expert's opinion

\

cf aggregate is required, plants the two words - Manufactured Market name for Manu-

are established near the site so sand and Crushed dust. The factured sand.

:hat the cost of transportation actual meaning is given below

which illustrates that the two It is being called in the market

:an be reduced. with different names like

-he sand should be of proper are entirely different.

gradation (i.e. should have par- Crushed dust is the waste

. Artificial sand (as it is artifi-

:icles from 15Op to 4.75 mm in product produced from the cially produced )

3roper proportion). When fine stone quarries. The main .

3articles are in Proper Propor- Robo sand (as it produced

-- cn, the sand will have less

aim of the stone quarry is to irst bythe company named

f

produce coarse aggregate Robosilicon Pvt. Ltd.)

.cids. The cement required (BOmm-4.75mm according to

,',ill be less when there will be lS 3831997). The waste from . Crushed sand (as it is Pro-

:ss void in sand. Such sand will these plants contain lot of duced from crushing),

:e more economical. There is f ines (passing through 75t-t)

=:andard specif ication for Fipe along with flat<y and elongat- . Rock sand (as the origin is

(Sand). lt is divided ed particles of size ranging rock).

=Jgregates

^ four gradations. CenerallY from 4.75mm to 75pr. lf prop-

- ^ cwn as Zone l, Zone ll, Zone

erly treated this can be used Types of M Sand

and Zone lV. There is sieve for producing Manufactured Concrete M Sand, M Sand for

::signation for each grade. sand. Brick & Block work and Plas-

,'adation is made as per the tering M Sand are the types

-.= of the sand. V.S.l can pro- Manufactured sand on the of M Sand available. Concrete

: -ce any zone of sand. other hand is purposefullY M Sand for all concreting Pur-

made from parent rock but it poses, Brickl Block M Sand is

Difference between doesn't contain fines (silt, clay) for laying bricks & block I t"ta'

manufactured sand and instead it contains uniformlY sonry Work and Plastering M

crushed dust: graded cubical particles of size sand for External and lnternal

--:'e ranging f rom 4.75mm-15opt. plastering.

is an ambiguity between

The production of M-Sand or Manufactured Sand erickl Block Work M

Eenerally involves Crushing, Screening and pos- Sand

slbly Washing, separation into discrete fractions,

recombining and blending Plastering M Sand

. M-SAND - Sand Cranule

Thickness -'l5omicron - 4.75

ffi mm; Usage - RCC, Block

works flooring/Til i ng; Qua n-

tity per metric ton 0O0O

kgs) - 21.5 cftlmetric ton

::.,,:::a a

. P-SAND - Sand Cranule

Thickness - l5Omicron - 2.36

a:,.a:-a,aa,a:: :..a ::

mm; Usage - lnternal and

External Plastering; Quanti-

ty per metric ton (1OOO kgs)

- 22 cftl metric ton

Sand is generally mixed with

cement and water to form

concrete. These sand particles

should be hard and inert with

respect to cement. Continuous

usage of river sand from river

beds is day by day deteriorat-

ing and threatening environ-

mental disaster. This situation

has forced various state gov-

ernments in lndia to ban sand

Crushing & Quarrying World I June 2Ol9 | 17

ool"l::

ll - '*l:1"

salt, the sedimentarY rocks

parttcularlY medium grain size

Limestone and Sandstone are

perfectly suitable as safe sand

substitute. Sandstone con-

taining SYPSUm' however is

to be ignored. The metamor-

phic ro-ks like slates, quartzite

and marbles are satisfactory

for sand substitutes. Cneisses

rocks are generallYtouch dura-

ble rocks with low PorositY and

are therefore satisfactorY as

aggregate materials. Quartz-

it6-cornposed dominantly of

quartz grains are generally

dente and tough with so low

a porosltY that they make verY

satisfactorY sand substitutes'

This is a suPerior substitute of

river sand.

The metamorPhic rock could

be an ideal choice against

granite rock in substituting

Ihe river sand. lgneous rocks

contains lot of deleterious ma-

terials and moreover it is high-

mining in manY rivers and kers to adulterate river sand ly porous hence more water

also to enforce stringent re- with cheaP sea sand

and sell and greater sklll are needed to

strictions wherever it is still in at high Price. Thus the short oreoire concrete mlx or Plas-

supplies of sand couPled with ier'mix and this high addition

vogue. This action has resulted

in deficlencies in sand suPPlY poor qualitY and also the high of water will in turn affect the

nationwide. The booming con- price have forced the crusher strength of the concreting' lt is

struction industrY is in a con- industry to Produce a

suitable therefore ProPosed to set uP a

stant state offlutter these daYs su bstitute. Quartz stone crushing unit in-

and this scarcitY has forced Apart from Cranite and Ba- stead of igneous rocks'

the profit motivated sand bro-

Provisional registration, Project report preparation

Ac-

quisition of Quarry lease and Crusher land /shed and

loan application

Procurement of machinery & equipments' and installa- 4

tion

ma-

Recruitment of Man power and Procurement of raw

terials

produc-

Trial production, streamlining and Commercial

tion

Crushing & Quarrying World I June 2O19 | l8

Expert's Opinion '',

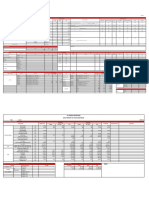

l-r"t m lAOa/o lOOo/o 100% laOo/o

90%-100% 9OYo-1OOo/n 9Oo/o-1OOo/o 95o/o-1OOo/o

;-:Er" rn 600/o-95o/o 75o/o-fOOo/o 85o/o-1OOo/o 9Sok-laOo/o

:-- 3Oo/o-7O%o 55%o-9Oo/o 75o/o-1OOo/o 90%-100%

ffiti.nicrons 15%-34% 35o/o-59o/o 60%o-79o/o BOo/o-1OOo/o

O5o/o-2Oo/o OBo/o-3Oo/o 12o/o-4Oo/o 15%-50%

5C :-rcrons A%o-lao/o ao/o-1O%o Oo/o-1Oo/o Oo/o-15o/o

irl: : - lradation of river/crushessand as required 5u, rg l,,J3RTH

Crushing & euarrying World I June 2O19 | 19

ll -Exolrt's.oo1ion

****.*. :"*;;;::-. *

Table 2 suggests the grada-

tion configuration required for

fine aggregates. While most

of the sand sourced from the

river banks do qualifY for zone

j r.

:

'::.. ! -.1 j,.: i ., 1 & 2, natural qualification of

crushed sand under zone I &

2 is diff icult due to the reason

that in case of crushed sand,

the rock mass is Pulverized

into fines, first bY aPPlication

Market Potential ent u nsaturated market. of chemical energY in form of

Due to the increase of PoPu- It is possible to imPlement this explosives, and then mechani-

lation & living standards, the project within B months. The cal energy in form of crushing,

dernand for M-Sand is multi- following is the tentative time which both reduce the aver-

plying every year. The Present schedule required for imPle- age grain size of sand' ln order

supply of production is meet- mentation. to transform crushed sand of

ing only about 20% of the de- zone 3 I 4 qualification into ac-

mand. Even if all the available Technically, a naturallY occur- ceptable qualitY range of zone

crusher units start manufac- ring or manufactured stone 1 or 2, it becomes imPerative

turing M-Sand as an addition- product bearing size of less to take out the fines from it

al venture then also it could than 4.75mm (S.Omm in some by means of air classification.

meet only about 50- 60l of the cases), is called fine aggre- This air classification can be

requirement. Looking into the gates or sand or stone dust. done by both drY Process and

stringent state government Both lS and MoRTH define wet process. While, wet classi-

policy on sand excavalicn and detailed gradation criteria for fication is more effective than

the constant fluttering state f ine aggregates to be used in dry classif ication, it Poses chal-

of construction industries intermediate gradation bands lenges in terms of enormous

and short suPPlY of \'- Sard it between 4.75mm/5mm and water requirement and also,

would be highlY 3oc'lc' .:e ro Omm, which is as Per the table disposal of the Process residue

set up sand units - :^3 c'?s- 2. which is normallY in slurrY'

Crushing & Quarrying ",'..' tr J-.e 2019 l20

You might also like

- Tippett - Songs For ArielDocument7 pagesTippett - Songs For ArielPierre F.No ratings yet

- Blind Melon NoRainDocument6 pagesBlind Melon NoRainMarioNo ratings yet

- The Liquefaction Susceptibility, Resistance and Response of Silty ClayDocument272 pagesThe Liquefaction Susceptibility, Resistance and Response of Silty ClaySajjad AnwarNo ratings yet

- Tybms Sem5 SM Nov19Document2 pagesTybms Sem5 SM Nov19chirag guptaNo ratings yet

- Andhra Pradesh Records of Rights in Land and Pattadar Pass Books PDFDocument15 pagesAndhra Pradesh Records of Rights in Land and Pattadar Pass Books PDFLatest Laws TeamNo ratings yet

- ... - :... ,.,'.bucureqti: Affz ' .: KciilxafitaDocument1 page... - :... ,.,'.bucureqti: Affz ' .: KciilxafitaMunteanu FlaviaNo ratings yet

- Last Year Question PapersDocument4 pagesLast Year Question PapersharshajitiyaNo ratings yet

- Bowles - Foundation Analysis and Design 5th EditionDocument57 pagesBowles - Foundation Analysis and Design 5th EditionTapu mojumder0% (1)

- Lucas MDB Running Instructions 1929Document30 pagesLucas MDB Running Instructions 1929Wilhelm MüllnerNo ratings yet

- Society For American ArchaeologyDocument12 pagesSociety For American ArchaeologymilesNo ratings yet

- DesignOfRectangularStorageTanks 18.06.11Document71 pagesDesignOfRectangularStorageTanks 18.06.11vinay1999No ratings yet

- New England Geological Guide 1992: January 1992Document100 pagesNew England Geological Guide 1992: January 1992JoshLeighNo ratings yet

- 21 Sensational Patchwork BagsDocument119 pages21 Sensational Patchwork BagsAriel Garcia100% (3)

- Department Order) ) ) ) : Office of The SecretaryDocument5 pagesDepartment Order) ) ) ) : Office of The SecretaryPaulo BesaNo ratings yet

- Force-Vector Diagrams: Static 2. Static 3. StaticDocument2 pagesForce-Vector Diagrams: Static 2. Static 3. Staticsvenkatk737No ratings yet

- AC Circuits - 1Document25 pagesAC Circuits - 1Shivam AggarwalNo ratings yet

- IMG - 0128 4 DC Circuit Refresher DF 1Document1 pageIMG - 0128 4 DC Circuit Refresher DF 1ricky fluor50No ratings yet

- Rules and Regulation Governing Licensing of ConstructorsDocument62 pagesRules and Regulation Governing Licensing of ConstructorsZhenwei LiNo ratings yet

- The Devils PulpitDocument368 pagesThe Devils PulpitDusty MonroeNo ratings yet

- Tamil Nadu Urban Land Tax Act, 1966 PDFDocument58 pagesTamil Nadu Urban Land Tax Act, 1966 PDFLatest Laws TeamNo ratings yet

- Finite Element Analysis - 16-5-18Document2 pagesFinite Element Analysis - 16-5-18NISAR SHAIKHNo ratings yet

- Tamil Nadu Urban Land Tax Act, 1966Document58 pagesTamil Nadu Urban Land Tax Act, 1966Latest Laws TeamNo ratings yet

- L/epubltr of TF, JC: !ourtDocument15 pagesL/epubltr of TF, JC: !ourtBong MarcosNo ratings yet

- ,/' I Ffivnticl: I - C R: R O R C In:P,:Rta'T - Tirc Pro 1 ' PRRRT (,S: . (6) What Do - You Under:Iiancl BF S.$R"GG - F.:Egs - $3!Ult.V ? Librv Is Ihc Process Mil"Uriiill-AnDocument4 pages,/' I Ffivnticl: I - C R: R O R C In:P,:Rta'T - Tirc Pro 1 ' PRRRT (,S: . (6) What Do - You Under:Iiancl BF S.$R"GG - F.:Egs - $3!Ult.V ? Librv Is Ihc Process Mil"Uriiill-AnMeenu GuptaNo ratings yet

- Form B - Buii Qing Massa - Chusetts Historical Co?' 1missro:.Document31 pagesForm B - Buii Qing Massa - Chusetts Historical Co?' 1missro:.Lee WrightNo ratings yet

- Iiroouc1S - : Itp Building WorksDocument1 pageIiroouc1S - : Itp Building WorksDido BenaliNo ratings yet

- ,F Ffi: T.R-R IrDocument15 pages,F Ffi: T.R-R IrAhmedMahirNo ratings yet

- Pages From 2010 EW Certs Brady To CaoDocument56 pagesPages From 2010 EW Certs Brady To CaoJoshtaxpayerNo ratings yet

- Monogram US Navy Marine Corps Aircraft Color Guide Vol-4 1960-1993Document205 pagesMonogram US Navy Marine Corps Aircraft Color Guide Vol-4 1960-1993JeanAker100% (4)

- Tybms Sem5 LSCM Nov19Document3 pagesTybms Sem5 LSCM Nov19Kanaiyalal ThakkarNo ratings yet

- Jan-Feb2023 18Document1 pageJan-Feb2023 18Umera AhmedNo ratings yet

- Our Town June 13, 1946Document6 pagesOur Town June 13, 1946narberthcivicNo ratings yet

- Betty Schrampfer Azar BASIC ENGLISH GRAM 2 p044Document1 pageBetty Schrampfer Azar BASIC ENGLISH GRAM 2 p044sandi irawanNo ratings yet

- ProjectDocument10 pagesProjectManishNo ratings yet

- (Form F) SESE (Science)Document39 pages(Form F) SESE (Science)omercomsatNo ratings yet

- Liabl E: r',FIEDocument6 pagesLiabl E: r',FIESAO SAMONNo ratings yet

- Machine FoundationDocument84 pagesMachine Foundationbonifaceyambala.byNo ratings yet

- Continjent Bil FormDocument2 pagesContinjent Bil Formsreelaks;hmiNo ratings yet

- More Steps in Chinese Cooking PDFDocument106 pagesMore Steps in Chinese Cooking PDFwarnerNo ratings yet

- Analysis of Casing Failures of Deep Geothermal Wells in GreeceDocument11 pagesAnalysis of Casing Failures of Deep Geothermal Wells in GreeceAhmed GalalNo ratings yet

- Majestic Revelations PDFDocument64 pagesMajestic Revelations PDFJake KernNo ratings yet

- 111/Llllllhhllllllhlll: The of Pseudo-GeberDocument415 pages111/Llllllhhllllllhlll: The of Pseudo-GeberНикола НаковNo ratings yet

- Augustan Gates at Torino and SpelloDocument12 pagesAugustan Gates at Torino and SpelloxyzNo ratings yet

- Ca3 Sem5 CBCGS Baf Commerce Nov19Document4 pagesCa3 Sem5 CBCGS Baf Commerce Nov19Hasan ShahNo ratings yet

- Prospect HillDocument29 pagesProspect HillLee WrightNo ratings yet

- Water Tank Made of FerrocementDocument120 pagesWater Tank Made of Ferrocementsuherlan endan100% (1)

- Tamil Nadu Land Reforms (Fixation of Ceiling On Land) Act, 1986Document9 pagesTamil Nadu Land Reforms (Fixation of Ceiling On Land) Act, 1986Latest Laws TeamNo ratings yet

- A Meeting With The UniverseDocument233 pagesA Meeting With The UniverseBob AndrepontNo ratings yet

- The Andhra Pradesh Records of Rights in Land and Pattadar Pass Books (Amendment) Act, 1989Document15 pagesThe Andhra Pradesh Records of Rights in Land and Pattadar Pass Books (Amendment) Act, 1989Shanta Linga SwamijiNo ratings yet

- Pl-311 Instalasi Plumbing Air Kotor & Bekas Lantai 27 (Refuge)Document6 pagesPl-311 Instalasi Plumbing Air Kotor & Bekas Lantai 27 (Refuge)Fathur RozyNo ratings yet

- Engineering Physics Local AuthorDocument514 pagesEngineering Physics Local AuthorFUN TIMENo ratings yet

- High Speed Displacement Vessel Parametric Studies and Calm Water ResistanceDocument72 pagesHigh Speed Displacement Vessel Parametric Studies and Calm Water ResistanceasdalfNo ratings yet

- Rose Ring or His Tor 00 ThacDocument202 pagesRose Ring or His Tor 00 Thacxuji2027No ratings yet

- F-Till:. 111111 WE MT! Am: Effect of Dynamic Bit Forces On Bit Bearing LifeDocument5 pagesF-Till:. 111111 WE MT! Am: Effect of Dynamic Bit Forces On Bit Bearing LifependexxNo ratings yet

- Rate Analysis Norms - DOIDocument118 pagesRate Analysis Norms - DOIMWIDD 01100% (1)

- Book of Kami PDFDocument30 pagesBook of Kami PDFJohn Frangos50% (2)

- Deed of RaghvenkDocument4 pagesDeed of RaghvenkParameshwaran NanjundanNo ratings yet

- 4 - Sediment Transport and Design of Irrigation ChannelsDocument88 pages4 - Sediment Transport and Design of Irrigation ChannelsBhaskar JoshiNo ratings yet

- Eeeeceete,, - o 0 0 - Tie Ce OnDocument68 pagesEeeeceete,, - o 0 0 - Tie Ce OnAl KNo ratings yet

- Ge - 1 MCQDocument20 pagesGe - 1 MCQlakshmidileepNo ratings yet

- Virgin Islands Rain Gardens: StormwaterManagement in Your BackyardDocument31 pagesVirgin Islands Rain Gardens: StormwaterManagement in Your BackyardFree Rain Garden ManualsNo ratings yet

- Water Cycle OutlineDocument3 pagesWater Cycle Outlinemgarcia5No ratings yet

- IrrigationDocument2 pagesIrrigationAjitpal SinghNo ratings yet

- Soil Report Karanja GhadgeDocument19 pagesSoil Report Karanja Ghadgekumawat.sunilNo ratings yet

- Science 4: Soil and Its CharacteristicsDocument5 pagesScience 4: Soil and Its CharacteristicsJohn Paul MedranoNo ratings yet

- Git 2011Document150 pagesGit 2011khushbooNo ratings yet

- Berroco Rooibos v2Document7 pagesBerroco Rooibos v2Melanie ManriquezNo ratings yet

- Soil Mechanics Module 1Document7 pagesSoil Mechanics Module 1Aljon AvilaNo ratings yet

- The Advantages and Disadvantages of Particle BoardDocument2 pagesThe Advantages and Disadvantages of Particle Boardpoosa annupriyaNo ratings yet

- Explanation Text HMDocument7 pagesExplanation Text HMI Gede Gegiranang Wiryadi50% (2)

- Rocks Revision Worksheet PDFDocument6 pagesRocks Revision Worksheet PDFnoeme tolentinoNo ratings yet

- An Introduction To Geology and Hard Rock MiningDocument76 pagesAn Introduction To Geology and Hard Rock MiningcharlescastleNo ratings yet

- Types of Stones Used in ConstructionDocument2 pagesTypes of Stones Used in ConstructionPranav PandeyNo ratings yet

- 48BDocument5 pages48BJamie SchultzNo ratings yet

- Webinar Series 1B Hutama Karya Masyhur Permasalahan Geoteknik TanahDocument31 pagesWebinar Series 1B Hutama Karya Masyhur Permasalahan Geoteknik Tanahantonius satrioNo ratings yet

- EXPERIMENT FOUR Abe 323Document9 pagesEXPERIMENT FOUR Abe 323Carpenter BreadNo ratings yet

- Drilling and BlastingDocument49 pagesDrilling and BlastingSri KanthNo ratings yet

- Effect of RBI-81 On CBR and Swell Behaviour of Expansive SoilDocument4 pagesEffect of RBI-81 On CBR and Swell Behaviour of Expansive SoilAndrea DeleonNo ratings yet

- Foundation NBCDocument61 pagesFoundation NBCrangarajanNo ratings yet

- Daily Prod Report SGB 01 - 07 - 2022Document2 pagesDaily Prod Report SGB 01 - 07 - 2022Said PrayogiNo ratings yet

- The Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsDocument13 pagesThe Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsVetriselvan ArumugamNo ratings yet

- 76 PDFDocument4 pages76 PDFmaran2326No ratings yet

- Gold SilverDocument2 pagesGold SilverAnonymous O27ezjcNo ratings yet

- Wasteland Management 426Document11 pagesWasteland Management 426Gurpreet Bedi0% (1)

- ﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘDocument8 pagesﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘdadaNo ratings yet

- Lorpen Winter16 En-FrDocument72 pagesLorpen Winter16 En-FrJulioNo ratings yet

- ConMatTechIVNotes2011 PDFDocument117 pagesConMatTechIVNotes2011 PDFBaatseba ChaukeNo ratings yet

- Geology Semester 1Document57 pagesGeology Semester 1La PremiereNo ratings yet