Professional Documents

Culture Documents

Toyota: How To Find Toyota Ignition System Faults Fast!

Uploaded by

Akram SiddigOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toyota: How To Find Toyota Ignition System Faults Fast!

Uploaded by

Akram SiddigCopyright:

Available Formats

July 2021

TOYOTAtech

An AutomotiveTechInfo.com publication ToyotaTech.net

How to Find Toyota Ignition

System Faults Fast!

Dotting the IGFs and Crossing the IGTs

Ignition Boot Spark Leakage

from Carbon Tracking

Dotting the IGFs and Crossing the IGTs

The world’s greatest fictional detective, Sherlock

Holmes referred to electricity as “the high

priest of false security.” Thankfully, electrical

devices are much more reliable now than they

were during the late 1800s in Victorian London.

These days, electrical systems are very reliable + -

indeed, and this is demonstrated by how well

they hold up under very demanding conditions

in today’s automobiles.

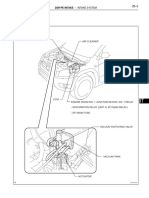

Take an engine’s ignition system for example.

IGNITER

A six-cylinder engine turning at 4000 RPM

has 12,000 ignition firings per minute. That’s DISTRIBUTOR

B

B-R

B-W

B-Y

200 sparks every single second. A 10-year-old

ignition coil will likely have somewhere around

B

3 billion cycles on its clock! It’s amazing how To Tachometer

reliable these parts are. However, no matter how

well engineered and how well a thing is made,

nothing lasts forever.

To EFI Computer

This article will focus on Toyota’s ignition

system. We’ll cover system operation, the best

testing methods, and typical failures. We’ll be B-W

focusing on Toyota’s Direct Ignition System (DIS), IGT

B-Y

EFI ECU

sometimes referred to as Coil On Plug (COP), IGF From Ignitor

since that’s what you’ll find on the majority of B-R

NE

Toyota cars currently.

B KNOCK

KNK

Key Players SENSOR

Toyota has built their reputation on consistency.

Distributor Ignition System 1988 Pickup 2.4L 22R-E

A key part of the Toyota

Way doctrine is to use

standards whenever

possible, in part to

create that consistency.

This makes learning

about Toyota ignition

systems easy; the signal

and part names have

remained consistent

since Toyota’s early

electronic ignition

systems all the way

through to the latest

model years.

The following is a

list of the key input Direct Ignition System

2020 Sienna 3.5L 2GR-FKS

and output signals

in Toyota’s ignition

TOYOTAtech July 2021 | 2

Dotting the IGFs and Crossing the IGTs

system. Once you learn these, you’ll be able to quickly located on an intake camshaft. On V6 and V8 engines,

understand any Toyota ignition system with a quick one bank may not be monitored and the ECM assumes

read over the information on Toyota’s Technical that the cam timing is correct. Newer engines have a

Information System (TIS). cam position sensor for each camshaft.

NE +/NE – (Crankshaft Position Sensor Signal) There are two styles of cam position sensor. Older

The NE signal holds information about crankshaft cars have a VR sensor, just like the sensor used to

speed and position. It can be produced using different create the NE signal. Newer cars use a 3-wire Hall

sensor designs and distributed with different circuit effect sensor, which produces a digital signal, typically

layouts, but it’s used for the same purposes, such a 5V square wave. Once again, TIS has example

as ignition timing, misfire detection, transmission waveforms for you to compare.

operation, or any other system that needs crankshaft

speed and position data. KNK (Knock Sensor Signal)

The knock sensor is another important input for the

Toyota favors variable reluctance (VR) sensors for ignition system. Four-cylinder engines usually have

their crankshaft position sensors on both older a single knock sensor. V6 and V8 engines have one

and newer vehicles. The VR sensor consists of two sensor for each bank. The ECM continuously monitors

components: a reluctor and a pickup. The reluctor the knock sensor signal. If the ECM detects knocking,

looks a bit like a gear, with protruding teeth, and it will retard the ignition timing until the knock is no

it’s connected to the crankshaft. The pickup is a longer present or its adjustment limit is reached.

stationary two wire sensor and is mounted to the

block. When a reluctor tooth passes the pickup, the IGT (Ignition Timing Signal)

pickup generates an AC voltage. The ECM monitors IGT is the ignition timing signal. It’s a 5V square wave

the changes in voltage to determine the speed and pulse generated by the ECM and sent to the igniters.

position of the crankshaft. Modern Toyota vehicles have one ignition coil for each

cylinder. Each coil has an integral igniter.

Toyota recommends using an oscilloscope to test the

crankshaft sensor. Connect the oscilloscope’s positive Every time the ECM sends an IGT pulse to an igniter,

lead to NE+ and the negative lead to NE-. The signal the igniter opens the ignition coil primary circuit, and

should be measured as close to the ECM as possible, the ignition coil produces a spark for the spark plug.

so the entire circuit is tested, not just the sensor. The ECM can control the ignition timing by controlling

However, this may not always be practical, depending the IGT pulse.

on ECM location. Toyota includes waveform examples

on TIS, which you can use to compare against your IGF (Ignition Confirmation Signal)

own measurements. The ECM uses the IGF signal to confirm each ignition

coil has fired after it sends an IGT pulse. The ECM

G/VVT (Camshaft Position Sensor Signal) supplies a 5V reference voltage on the IGF circuit

The G or VVT signal provides camshaft position shared by all coils. Each time a coil fires, its igniter

information to the ECM. The ECM uses this signal in pulls the IGF 5V reference voltage to ground.

conjunction with the NE signal to determine which

cylinder is at TDC on the compression stroke. On If the ECM doesn’t receive an IGF pulse in response to

older cars without variable valve timing, the service an IGT command, a P035x ignition coil code will set for

manual calls it the G signal. On newer cars with VVT, the cylinder with the missing IGF pulse. The ECM will

the service manual calls it VVT. This data is critical to also likely turn off the fuel injector for that cylinder to

determining camshaft angle, ignition timing and fuel prevent damage to the catalytic converter.

injection timing.

Testing Methods

The camshaft position sensor generates the G signal. The best non-intrusive method of testing a Toyota

Older engines may only have one cam position sensor, Direct Ignition System requires a lab scope with at

TOYOTAtech July 2021 | 3

Dotting the IGFs and Crossing the IGTs

least three channels. (See “IGT & IGF Signals with Coil 3. Amp Clamp on power or ground feed to the

Current.”) The three channels should be connected to ignition coils.

the vehicle as follows:

1. IGT signal at an ignition coil, preferably the This testing method gives a bird’s eye view of the

suspect cylinder. ignition system and will allow all ignition coil current

2. IGF signal at any coil because they share a ramps and IGF signals to be monitored. Fuel injector

common circuit. current can often be viewed during this test as well, if

IGF Signal

IGT Signal

Ignition Coil Current

IGT & IGF Signals with Coil Current

IGT IGF Testing Under hood fuse IG2 with Amp Clamp

TOYOTAtech July 2021 | 4

Dotting the IGFs and Crossing the IGTs

the fuel injectors are powered by the same fuse as the tracking, or a faulty spark plug. Areas that are prone

ignition coils. to rodents getting under the hood of vehicles may

also see wiring damage to the ignition coil circuits. The

This method is not possible on all vehicles, however. symptoms of these failures can range from a single

Certain models and years don’t use a dedicated fuse cylinder misfire to a no start condition, or various

for the ignition coil power feed. If the power feed drivability and performance concerns.

circuit can’t be accessed easily, it may be possible to

connect the amp clamp to the ground side of the coils Input Failure Example

at a common ground location. One example of an input failure is from the following

2009 Tacoma with a 1GR-FE 4.0-liter engine. The

The primary windings cannot be directly accessed for

testing due to the igniter being part of the circuitry

inside the DIS ignition coil, so the only option for

primary ignition testing is ignition coil current with an

amp clamp.

The secondary ignition can be tested intrusively using

a spark tester or secondary lead extension. However,

these methods disturb the components and removing

an ignition coil to install a spark tester or secondary

lead extension could temporarily ‘fix’ a spark leakage

issue. A non-intrusive option to test the secondary

ignition would be an inductive pickup wand like

PicoScope’s COP wand.

Types of Failures

Ignition system failures can be grouped in two basic

categories: input failures and output failures. Input

failures can come in a variety of sensor or wiring

Cam gear with

problems. Input problems can also be a result of broken tone ring

incorrect repair

or inadvertent

damage during

engine repairs.

For example,

damaging the

reluctor teeth

on a crankshaft

sprocket during Two teeth missing from Bank 1 Camshaft tone ring

a timing belt

replacement.

Output failures

are typically

either an

ignition coil

failure, a spark

leakage issue

due to carbon 2009 Tacoma Cam - Crank Waveform

TOYOTAtech July 2021 | 5

Dotting the IGFs and Crossing the IGTs

symptoms for this truck were the check engine light Carbon Tracking

being illuminated and an extended cranking time. on Spark Plug

Hooking up a lab scope to the crankshaft sensor and

both camshaft sensors resulted in the “2009 Tacoma

Cam - Crank Waveform” shown on the previous page.

The variable reluctance crankshaft sensor is shown

with the blue trace and the Hall effect camshaft

sensors are shown by the green and gold traces. The

capture clearly shows two missing pulses from the

green camshaft sensor trace.

The magnet on the camshaft sprocket originally had

three protrusions. Two had broken off (see “Cam

gear with broken tone ring” on previous page), which

explained the two missing pulses in the waveform.

This signal is used for injector timing and ignition

timing. The truck was able to start without a proper

signal, but it caused an extended crank while the

ECU searched for the expected sensor output, and

of course a trouble code once it realized the sensor

output was incorrect.

Output Failure Example

The image on page one (“Ignition Boot Spark

Leakage...”) and the carbon tracking on the spark

plug (right) are examples of an output failure. These

components were taken from the same cylinder on an

engine that would misfire under a load.

Vehicle Case Studies Sienna With a Bad Coil

This first

vehicle

study is

taken from a

No IGF Signal

2006 Sienna

with a 3.3L

V6 3MZ-FE

engine. This

vehicle had

a single

cylinder Disabled

misfire and Fuel

the check Injector

engine light

was flashing.

The faults Shorted Coil

present were

a P0305 and Sienna 3MZ-FE Shorted Ignition Coil

TOYOTAtech July 2021 | 6

Dotting the IGFs and Crossing the IGTs

P0355 for a Cylinder 5 Misfire and Cylinder 5 Primary/ idle. A fault scan using Techstream revealed a P0354

Secondary Circuit. In this transversely mounted V6 Cylinder 4 Primary/Secondary fault, but it also showed

engine, cylinder 5 is on the rear bank covered by the individual misfire faults pending for all six cylinders.

intake plenum.

Using the same testing method of an amp clamp on

With the preferred testing method of using three the ignition coil fuse and two channels on the IGT

channels of a lab scope the problem can quickly and IGF signal wires, the following waveform was

and easily be identified. There is no need to swap captured. The image shows the cylinder 4 ignition coil

components to a different cylinder to see if the fault current-limiting ability has failed. The coil is drawing

will follow. The waveform clearly shows that Cylinder 14 amps of current, when all the others are at 12

5 ignition coil is completely shorted, with no gradual amps or less. This excessive current affects the IGF

ramp up to

the current

flow. The

shorted coil

has resulted

in no IGF

confirmation

signal. The

ECM then sets

the P0355

Primary

fault and

shuts down

fuel injector

operation for

that cylinder.

RAV4 Coil

Refuses to 2007 RAV4 Fault Codes

Confirm

The final

vehicle study

comes from

a 2007 RAV4

with the

2GR-FE V6

engine. The

owner of this

vehicle was

concerned

that the

check engine

light was

on and the

engine was

intermittently

running a

rough at Ignition Coil with Excessive Current

TOYOTAtech July 2021 | 7

Dotting the IGFs and Crossing the IGTs

confirmation signal

for this coil, keeping in

mind that the IGF signal

Noise in the IGF signal

is created by circuitry causing the Primary/

inside the ignition coil. Secondary Circuit fault

Zooming in on one of

the Cylinder 4 ignition

event shows the IGF

signal breaking down.

Ultimately, the real

cause of the misfire

on this vehicle was

the IGF circuit inside

the cylinder 4 ignition

coil. The excessive coil Faulty IGF Signal

current caused the

IGF signal to break down which the ECM interpreted the remaining misfires were sympathetic faults flagged

as an ignition failure and disabled the fuel injector incorrectly and will not return.

resulting in the intermittent rough running this RAV4

was experiencing. Given the increased reliability of electronics, and logical

methods of deduction available to today’s technicians,

The misfire detection system often flags misfires for We think that Mr. Holmes surely would have changed

several cylinders, or even all the cylinders, when a his mind about electricity. He may have even traded

primary circuit fault code is present. The best practice in his trademark pipe and hat for an oscilloscope! And if

this situation is to focus testing and repair efforts toward asked what he thought of electricity, his response just

the cylinder with the primary fault code. In most cases, might be, “Elementary, my dear Watson!” n

TOYOTAtech

July 2021

Publisher

Tamra Ayers Banz

An AutomotiveTechInfo.com publication tbanz@automotivedatamedia.com

Editorial Director

Paul Cortes

pcortes@automotivedatamedia.com

Technical Writers

TOYOTAtech is written by professional automotive

Scott Brown, Ken Coleman, Jordan Hill,

aftermarket technicians for professional Chris Ligocki, Gary Smith, Frank Walker

automotive aftermarket technicians. TOYOTAtech

is a publication of Automotive Tech Info (ATI).

No part of this newsletter may be reproduced

Creative Director

Christopher Ayers III

without the express written permission of ATI.

ayersc3@automotivedatamedia.com

Group Publisher

Christopher M. Ayers Jr.

cayers@automotivedatamedia.com

CAUTION: Vehicle servicing performed by untrained persons could result in serious injury to those

persons or others. Information contained in this publication is intended for use by trained, professional

auto repair technicians ONLY. This information is provided to inform these technicians of conditions which Editorial and Circulation Offices:

may occur in some vehicles or to provide information which may assist them in proper servicing of these 134B River Road

vehicles. Properly trained technicians have the equipment, tools, safety instructions, and know-how Montague, NJ 07827

to perform repairs correctly and safely. If a condition is described, DO NOT assume that a topic Phone: 330.620.3929

covered in these pages automatically applies to your vehicle or that your vehicle has that condition.

AutomotiveTechInfo.com

TOYOTAtech

You might also like

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- DI121Document6 pagesDI121Erln LimaNo ratings yet

- Steering Column Switch PDFDocument26 pagesSteering Column Switch PDFDaniel OlariNo ratings yet

- Engine Oil Change Reminder Light: 2005 Toyota RAV4 2005 Toyota RAV4Document70 pagesEngine Oil Change Reminder Light: 2005 Toyota RAV4 2005 Toyota RAV4Sonny RaymundoNo ratings yet

- A Report On Industrial Work ExperienceDocument20 pagesA Report On Industrial Work ExperienceAgusiobo Anthony ChukwudiNo ratings yet

- Foxwell NT301 OBD OBD2 Engine Universal Car Code Reader Scanner Diagnostic ToolDocument3 pagesFoxwell NT301 OBD OBD2 Engine Universal Car Code Reader Scanner Diagnostic ToolD JocelynNo ratings yet

- General Motors Regular Production Options (Rpo) CodesDocument58 pagesGeneral Motors Regular Production Options (Rpo) CodeskallekuhlaNo ratings yet

- ECM/PCM Input and Output TestsDocument2 pagesECM/PCM Input and Output TestsDhami NongNo ratings yet

- GM ChargingDocument20 pagesGM ChargingMihai TacheNo ratings yet

- 556U Immobolizer InterfaceDocument9 pages556U Immobolizer InterfaceLuis Perez100% (1)

- VgrsDocument6 pagesVgrsAnon JansabNo ratings yet

- DODGE Dart Ground...Document5 pagesDODGE Dart Ground...miguelNo ratings yet

- CR-Pro 0020 User 0027 S 0020 Manual 0020 V2 002E 8Document93 pagesCR-Pro 0020 User 0027 S 0020 Manual 0020 V2 002E 8Pili MaoNo ratings yet

- DIY Electronic Trunk Release - Toyota Yaris Forums - Ultimate Yaris Enthusiast Site PDFDocument9 pagesDIY Electronic Trunk Release - Toyota Yaris Forums - Ultimate Yaris Enthusiast Site PDFMarwan MaqtaryNo ratings yet

- Advanced Electrical SystemsDocument386 pagesAdvanced Electrical SystemsAlberto LandaburuNo ratings yet

- Z TT Plus ManualDocument44 pagesZ TT Plus ManualHerbert Frota CuradoNo ratings yet

- Mazda Carburetor Manual 1979-1985Document133 pagesMazda Carburetor Manual 1979-1985PIlkadutNo ratings yet

- Wiring Diagrams - Reading PDFDocument7 pagesWiring Diagrams - Reading PDFthu vuNo ratings yet

- Wotbox Instructions 2010mustangDocument14 pagesWotbox Instructions 2010mustangAlejandro Da CostaNo ratings yet

- EEC IV Self Test - Ford Fuel Injection and EEC IV Electronic Engine Control - EEC 4Document9 pagesEEC IV Self Test - Ford Fuel Injection and EEC IV Electronic Engine Control - EEC 4Juan Pablo Rey BravoNo ratings yet

- Illuminated Wrench Light-Diagnostic TSB 13-3-19 Trouble Code (DTC) B1029:11-With or Without Lack of PerformanceDocument2 pagesIlluminated Wrench Light-Diagnostic TSB 13-3-19 Trouble Code (DTC) B1029:11-With or Without Lack of PerformanceEvertonReis100% (1)

- 2014 Toyota Tundra - Terminals of ECUDocument6 pages2014 Toyota Tundra - Terminals of ECURocky VergaraNo ratings yet

- Acura RL ManualDocument394 pagesAcura RL ManualrosanateamoNo ratings yet

- Model Indentifiction For Cars TestsDocument454 pagesModel Indentifiction For Cars TestsRichard Thodé JrNo ratings yet

- Rs Wiring DiagramDocument594 pagesRs Wiring DiagramRuben Castro100% (1)

- 2012 Mazda 6 Factory Service ManualDocument13,696 pages2012 Mazda 6 Factory Service ManualRafael OlaveNo ratings yet

- 2011 Fusion Hybrid MKZDocument12 pages2011 Fusion Hybrid MKZTung NguyenNo ratings yet

- HyundaiDocument14 pagesHyundaimohhizbarNo ratings yet

- Mitsubishi Eclipse Spyder 3.0LDocument97 pagesMitsubishi Eclipse Spyder 3.0LrobertoNo ratings yet

- 2005 Chevrolet Tahoe/Suburban Owner ManualDocument530 pages2005 Chevrolet Tahoe/Suburban Owner ManualClaudio Hernández PobleteNo ratings yet

- Vehicle Sensors WiringDocument8 pagesVehicle Sensors WiringAudrick RussellNo ratings yet

- Immobilizer and Smart Key Reset: Vehicle Interior Theft Deterrent/Keyless Entry USADocument23 pagesImmobilizer and Smart Key Reset: Vehicle Interior Theft Deterrent/Keyless Entry USATeddy KhantNo ratings yet

- Workshop Manual: Mazda3 Mazdaspeed3Document11 pagesWorkshop Manual: Mazda3 Mazdaspeed3CiaranNo ratings yet

- 06SkiNautique196 206Document184 pages06SkiNautique196 206Gustavo Flores MorenoNo ratings yet

- 4runner 1998Document350 pages4runner 1998Felix SimãoNo ratings yet

- Most Complete List For Chevy Check Engine Light CodesDocument14 pagesMost Complete List For Chevy Check Engine Light CodesMassango J JuniorNo ratings yet

- 34d04 TRC and VSC PDFDocument14 pages34d04 TRC and VSC PDFMelvin Mhds100% (1)

- ToyodaDocument4 pagesToyodaCloud SkyNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts TroubleshootingDocument4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts TroubleshootingDaniel GarciaNo ratings yet

- Map Sensor Diagnosis by Pierburg PDFDocument4 pagesMap Sensor Diagnosis by Pierburg PDFIonut-alexandru IordacheNo ratings yet

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Document6 pagesIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064No ratings yet

- Symbols and Circuit DiagramsDocument31 pagesSymbols and Circuit DiagramsSourabh SamantaNo ratings yet

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDocument54 pagesIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNo ratings yet

- In This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceDocument40 pagesIn This Issue: Brake System Service Toyota's Hybrid Vehicle Continuously Variable Transmission Power Steering ServiceDilan SenarathneNo ratings yet

- sb0341t09 PDFDocument7 pagessb0341t09 PDFZool Car زول كارNo ratings yet

- 2005 Nissan FrontierDocument336 pages2005 Nissan FrontierMerlin Meléndez RodríguezNo ratings yet

- Ford-F-150 2009 EN-US US 058dce541bDocument405 pagesFord-F-150 2009 EN-US US 058dce541bJuan Daniel Resendiz EscobarNo ratings yet

- 2013 Honda Accord Coupe Owner's ManualDocument554 pages2013 Honda Accord Coupe Owner's Manualred eagle winsNo ratings yet

- Ford CrownVic 1998 ManualDocument160 pagesFord CrownVic 1998 ManualNasir AyubNo ratings yet

- 1995 To 1999 Toyota Avalon Keyless Remote TSBDocument4 pages1995 To 1999 Toyota Avalon Keyless Remote TSBerjenkins1No ratings yet

- 02 WgetDocument260 pages02 WgetesquisofNo ratings yet

- E4OD/4R100 Technical Information: ST ND RD THDocument3 pagesE4OD/4R100 Technical Information: ST ND RD THgreybinjosueNo ratings yet

- FMP User GuideDocument24 pagesFMP User Guidekamaleon doradoNo ratings yet

- Alternator Regulator TroubleshootingDocument2 pagesAlternator Regulator Troubleshootingsheba1023No ratings yet

- Toyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemDocument13 pagesToyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemJulius ThomasNo ratings yet

- IDS WebdownloadDocument25 pagesIDS WebdownloadObdvietnam ServiceNo ratings yet

- Ford 2011 ObdDocument251 pagesFord 2011 ObdschraeubleNo ratings yet

- TK Prog Master v5.0 Smart Key Solution: Quick Start GuideDocument2 pagesTK Prog Master v5.0 Smart Key Solution: Quick Start GuideKey ChipNo ratings yet

- PATS Key Type: All Keys Are 8-Cut Unless Otherwise NotedDocument2 pagesPATS Key Type: All Keys Are 8-Cut Unless Otherwise NotedAlbertNo ratings yet

- Sistem PengapianDocument16 pagesSistem PengapianArdianto BahtiarNo ratings yet

- Scan Tool Basics: Front Door Vs Back Door DiagnosticsDocument8 pagesScan Tool Basics: Front Door Vs Back Door DiagnosticsAkram SiddigNo ratings yet

- Shim Catalogue To PrintDocument32 pagesShim Catalogue To PrintAkram SiddigNo ratings yet

- Effects of Ethanol Added Fuel On Exhaust EmissionsDocument11 pagesEffects of Ethanol Added Fuel On Exhaust EmissionsAkram SiddigNo ratings yet

- Below Is An Overview of Fuel System OperationDocument5 pagesBelow Is An Overview of Fuel System OperationAkram SiddigNo ratings yet

- Tiggo 5 t21Document253 pagesTiggo 5 t21Akram SiddigNo ratings yet

- Release NoteDocument14 pagesRelease NoteAmanda GrantNo ratings yet

- Grundfos RSI: Renewable Solar Inverter For Pump Control 1.5 - 250 KWDocument20 pagesGrundfos RSI: Renewable Solar Inverter For Pump Control 1.5 - 250 KWJa AcostaNo ratings yet

- CMMP AS M0 HW - 2015 07b - 8046779g1Document122 pagesCMMP AS M0 HW - 2015 07b - 8046779g1Bruno Eduardo Tumbaco ToalaNo ratings yet

- Selection Guide Fluid Coupling NewDocument34 pagesSelection Guide Fluid Coupling NewIsaac Montero Barrera100% (1)

- Iia Module Iii PDFDocument13 pagesIia Module Iii PDFgayathri vishnuNo ratings yet

- IEC 60708 SummaryDocument6 pagesIEC 60708 SummaryAdnan Khan0% (1)

- 15EGSADocument1 page15EGSAmandahandriNo ratings yet

- CEMU Game CompatabilityDocument140 pagesCEMU Game CompatabilityJohnny OrdoñezNo ratings yet

- Sony KDL - 52s5100 Chasis Exr2Document104 pagesSony KDL - 52s5100 Chasis Exr2Alejandra Maria ManriqueNo ratings yet

- RFSoC Evaluation Tool User GuideDocument71 pagesRFSoC Evaluation Tool User GuideBismillah Nasir IshfaqNo ratings yet

- VTX A8 Specsheet - 5108391-00CDocument3 pagesVTX A8 Specsheet - 5108391-00CIvan UzunovNo ratings yet

- A Survey On Slip Power Recovery DrivesDocument9 pagesA Survey On Slip Power Recovery Drivesesaivanan1150% (2)

- List of Figures: Pin Type Insulator 11Document46 pagesList of Figures: Pin Type Insulator 11Shivlal MohalNo ratings yet

- Iec 60076 24 2020Document11 pagesIec 60076 24 2020Fardhani RozakNo ratings yet

- 6 16Document2 pages6 16Indira KarimovaNo ratings yet

- Real-Time Environment Monitoring System Using ESP8266 and ThingSpeak On Internet of Things PlatformDocument5 pagesReal-Time Environment Monitoring System Using ESP8266 and ThingSpeak On Internet of Things PlatformMichelle LlamatumbiNo ratings yet

- Intake System: Parts LocationDocument7 pagesIntake System: Parts LocationMenzie Peter RefolNo ratings yet

- CMOS Three Axis Hall Sensor and Joystick Application Schott3axisJoystickDocument4 pagesCMOS Three Axis Hall Sensor and Joystick Application Schott3axisJoystickbesttv046936No ratings yet

- FCR GoDocument3 pagesFCR Gom_rebelo5808No ratings yet

- Factors The Insulation: InfluencingDocument6 pagesFactors The Insulation: InfluencinggiovanipifferNo ratings yet

- DDS238-2 ZN/S TYPE Single Phase Energy Meter 5 (65) A User ManualDocument4 pagesDDS238-2 ZN/S TYPE Single Phase Energy Meter 5 (65) A User ManualMauroFariasNo ratings yet

- Paket 6 Product InformationDocument4 pagesPaket 6 Product InformationRiskyNo ratings yet

- T4 F Electric CircuitDocument9 pagesT4 F Electric CircuitNowNo ratings yet

- Unit 3 PLC PDFDocument15 pagesUnit 3 PLC PDFMahesh ShendeNo ratings yet

- 1VAL088301-TG RevB ReliaGearSB TechGuide DigitalDocument72 pages1VAL088301-TG RevB ReliaGearSB TechGuide DigitalsimonNo ratings yet

- LogDocument8 pagesLogJonas Honorato0% (1)

- ATR Tech WebDocument3 pagesATR Tech WebAudioDuck22No ratings yet

- BTE Student Performance Checklist by Courses - UpdatedDocument2 pagesBTE Student Performance Checklist by Courses - UpdatedazizNo ratings yet

- 012 Goppit PE File Format RevEngineering View Goppit CBJ-2005-74 PDFDocument100 pages012 Goppit PE File Format RevEngineering View Goppit CBJ-2005-74 PDFz4rm4r100% (1)

- Chapter 11 AC ResonanceDocument20 pagesChapter 11 AC ResonanceErin LoveNo ratings yet