Professional Documents

Culture Documents

LAVOCE Sistema N123.14N SuggDes RevB.A

Uploaded by

RoshanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAVOCE Sistema N123.14N SuggDes RevB.A

Uploaded by

RoshanCopyright:

Available Formats

SUGGESTED DESIGN SISTEMA N123.

14N

1 X 12” FULL RANGE CABINET

WAN123.00 DN14.25T HD1403

500 W AES 80 W AES 80° X 60°

WWW.LAVOCESPEAKERS.COM Lavoce Italiana

support@lavocespeakers.com

CABINET CONSTRUCTION

OVERVIEW

- NET CABINET VOLUME l (ft3): 50,2 (1.77)

- SUGGESTED TYPE OF WOOD: BALTIC BIRCH PLYWOOD (18mm thickness)

- OTHER CONSTRUCTION DETAILS (CONNECTORS , HANDLING, WHEELS,…)

ARE USER’S CHOICE

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 1 / 21

CABINET CONSTRUCTION

EXPLODED VIEW

4

7

9

11

5

3

12

6

1

10 2

8

NOTE: the project has been conceived to ITEM N° QTY DESCRIPTION PAGE

maximize the performance of the cabinet, 1 1 FRONT BAFFLE 3

therefore the coupling of the panels is

2 1 FRONT STIFFENER 4

made by milling. If a different coupling

method is used, the size of the internal 3 1 SIDE PANEL - RIGHT 5

panels must be recalculated. 4 1 BACK PANEL A 6

5 1 BACK PANEL B 7

6 1 SIDE PANEL - LEFT 8

7 1 TOP PANEL 9

8 1 BOTTOM PANEL 10

9 2 VERTICAL DUCT 11

10 1 BRACKET 12

11 1 HORIZONTAL DUCT A 13

12 1 HORIZONTAL DUCT B 14

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 2 / 21

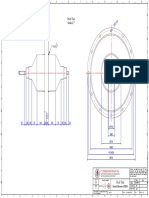

CABINET CONSTRUCTION

ITEM 1 - FRONT BAFFLE

43,0 [1,69] 280 [11,02]

313,5 [12,34]

52,5 [2,07]

18 [0,71]

14 [0,55]

588,0 [23,15]

538,0 [21,18]

108,0 [4,25]

258,0 [10,16]

DRILL FOR WOODEN 35]

[ R0 ,

THREADED INSERT M6 R9

388,0 [15,28]

606 [23,86]

577 [22,72]

338,0 [13,31]

300,7 [11,84]

410 [16,14]

n287 [n11,30]

n317 [n12,48]

350 [13,76]

220,0 [8,66] 246 [9,69]

163,0 [6,42]

106,0 [4,17]

25,3 [1,00]

126 [4,96]

240 [9,45]

320,7 [12,62]

183 [7,20]

45,3 [1,79]

366 [14,41]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 3 / 21

CABINET CONSTRUCTION

ITEM 2 - FRONT STIFFENER

321 [12,62]

18 [0,71]

126 [4,96]

183 [7,20]

240 [9,45]

45 [1,79]

15 [0,59]

301 [11,84]

18 [0,71]

°

45

220 [8,66]

328 [12,91]

163 [6,42]

n7 [n0,28]

106 [4,17]

25 [1,00]

n287 [n11,30]

366 [14,41]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 4 / 21

CABINET CONSTRUCTION

ITEM 3 - SIDE PANEL - RIGHT

606 [23,86]

310 [12,20] 18 [0,71]

]

,35

[ R0

R9 °

213 [8,37]

65

36 [1,42]

R9

[R

120 [4,72] 0,3

392 [15,43] 18 [0,71] 5]

18 [0,71]

15 [0,59]

18 [0,71]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 5 / 21

CABINET CONSTRUCTION

ITEM 4 - BACK PANEL A

606 [23,86] 18 [0,71]

278 [10,94] 18 [0,71] 15 [0,59]

°

65

231 [9,08]

55

°

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 6 / 21

CABINET CONSTRUCTION

ITEM 5 - BACK PANEL B

606 [23,86] 18 [0,71]

310 [12,20] 18 [0,71] 15 [0,59]

°

60

253 [9,97]

55

°

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 7 / 21

CABINET CONSTRUCTION

ITEM 6 - SIDE PANEL - LEFT

606 [23,86] 18 [0,71]

18 [0,71] 310 [12,20] 15 [0,59]

R9

[R °

0,3 60

5

234 [9,23]

36 [1,42]

120 [4,72]

R9

[R

0 ,3

5]

18 [0,71]

18 [0,71] 392 [15,43]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 8 / 21

CABINET CONSTRUCTION

ITEM 7 - TOP PANEL

396 [15,59]

,3 7 ]

19,8 [0,78]

58 [2,28] 244 [9,61] 58 [2,28]

R3 9

18 [0,71] 18 [0,71]

00 [

R1 0

120 [4,72]

18 [0,71]

213 [8,37]

234 [9,23]

R9

380,7 [14,99]

[R

361 [14,21]

0,

35

°

]

130

12

° 0

18 [0,71] 110° 18 [0,71]

15 [0,59]

219 [8,63]

18 [0,71]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 9 / 21

CABINET CONSTRUCTION

ITEM 8 - BOTTOM PANEL

396 [15,59] 18 [0,71]

219 [8,63] 15 [0,59]

]

71

,

[0

18 [0,71]

18

110°

0°

381 [14,99]

12

130

°

234 [9,23]

213 [8,37]

36 [1,42]

R 10 0 0

19,8 [0,78]

[ R 3 9,3

7]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 10 / 21

CABINET CONSTRUCTION

ITEM 9 - VERTICAL DUCT

5 ]

196 [7,72] ,3

[ R0

R9

102 [4,02]

18 [0,71]

QTY: 2 OFF

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 11 / 21

CABINET CONSTRUCTION

ITEM 10 - BRACKET

203 [7,98] 18 [0,71]

]

,30

[1

33

110°

310 [12,19]

0°

130

12

193 [7,58]

]

°

24

173 [6,80]

R 0,

[

R6

33 [1,30] 300 [11,81]

366 [14,41]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 12 / 21

CABINET CONSTRUCTION

ITEM 11 - HORIZONTAL DUCT A

]

,35

5

0,3

0

[R

[R

R9

R9

102 [4,02]

18 [0,71] 61 [2,40]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 13 / 21

CABINET CONSTRUCTION

ITEM 12 - HORIZONTAL DUCT B

R9

R9

[R

[R

0,3

0 ,3

5

5]

]

102 [4,02]

61 [2,40] 18 [0,71]

7

9 11

4

3

5

2

12 1

6 10 8

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 14 / 21

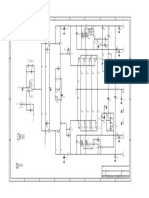

CABINET CONSTRUCTION

FRONT VIEW

396 [15,59]

360 [14,17]

40 [1,57]

193 [7,60]

275 [10,83]

600 [23,62]

636 [25,04]

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 15 / 21

CABINET CONSTRUCTION

SIDE & TOP SECTION VIEW

381 [14,99]

343 [13,50] 38 [1,49]

186 [7,33]

102 [4,02] 381 [14,99]

193 [7,60]

A A

275 [10,83]

396 [15,59]

600 [23,62]

636 [25,04]

A-A

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 16 / 21

CABINET CONSTRUCTION

DAMPING MATERIAL

NOTE: Damping material needs to be fixed DAMPING MATERIAL SPECIFICATIONS

to the cabinet, in a way that it always keeps

SYMBOL WIDTH HEIGHT THICKNESS NOTE

enough distance from the X-over PCB

P1 600 mm 240 mm 25 mm Polyester wool 500 g/m^2

and the magnet systems of the speakers. P2 600 mm 750 mm 25 mm Polyester wool 500 g/m^2

Distance from the magnets has to be at P3 600 mm 750 mm 25 mm Polyester wool 500 g/m^2

least 20mm to avoid over-heating of the

motors and reduce risk of fire. The X-over

PCB should be mounted into an open steel

housing to always keep the safety distance

from the damping material.

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 17 / 21

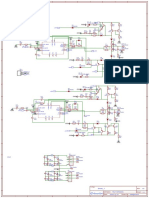

FILTER CONSTRUCTION

SCHEMATIC

PTC1 C2 C3

R1

HF+

3.75 A 5Ω

3.9 µF 12.2 µF R2 9Ω R3 3.4 Ω

L4 0.47 mH L5 0.33 mH

L2 0.68 mH L3 0.68 mH

C4 4.7 µF C5 0.47 µF

HF−

L1

IN+ LF+

1.8 mH

C1 33 µF

IN− LF−

BILL OF MATERIALS

RESISTORS

SYMBOL VALUE POWER TOLERANCE NOTE

R1 5 Ohm 60 W 5% Resistance can be split over parallel resistor to get the desired power rating

R2 9 Ohm 50 W 5% Resistance can be split over parallel resistor to get the desired power rating

R3 3.4 Ohm 50 W 5% Resistance can be split over parallel resistor to get the desired power rating

CAPACITORS

SYMBOL VALUE VOLTAGE TYPE TOLERANCE NOTE

C1 33 uF 400 V MKP 5% Metallized Plastic Polypropylene Capacitor. High current/low loss

C2 3.9 uF 250 V MKT 5% Metallized Plastic Polyester Capacitor

C3 12.2 uF 250 V MKT 5% Metallized Plastic Polyester Capacitor. Capacitance can be split over two

parallel capacitors (10 uF and 2,2 uF)

C4 4.7 uF 250 V MKT 5% Metallized Plastic Polyester Capacitor

C5 0.47 uF 250 V MKP 5% Metallized Plastic Polypropylene Capacitor

INDUCTORS

SYMBOL VALUE WIRE DIAMETER TYPE TOLERANCE MAX RESISTANCE NOTE

L1 1.8 mH 1.4 mm IRON CORE 5% 0.3 Ohm High temperature coil body with core required

L2 0.68 mH 1 mm AIR CORE 3% 0.5 Ohm -

L3 0.68 mH 1 mm AIR CORE 3% 0.5 Ohm -

L4 0.47 mH 1 mm AIR CORE 3% 0.4 Ohm -

L5 0.33 mH 1 mm AIR CORE 3% 0.3 Ohm -

POSITIVE TEMPERATURE COEFFICIENT THERMISTOR

SYMBOL HOLD CURRENT MAXIMUM NOTE

VOLTAGE

PTC1 3.75 A 60 V Protection for compression driver DN14.25T

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 18 / 21

PERFORMANCE

HF HORN

DN14.25T HD1403

LF

WAN123.00

FREQUENCY RESPONCE

110

100

@ Znom

90

@ 1W/1m

80

1W/1m

(dB)

70

SPL(dB)

SPL

60

50

40

20 100 500 1000 10000 20000

Frequency

Frequency(Hz)

(Hz)

Measurement hardware: Four Audio ROBO3 with WinMF software.

Smoothing 1/6 oct.

TOTAL HARMONIC DISTORTION

110 SPL 1W

THD 1W

100 THD 100W

(dB)

@ 10% THD

90

Distortion

80

Max SPL (dB)

Total Harmonic

70

60

50

40

20 100 500 1000 10000 20000

Frequency

Frequency(Hz)

(Hz)

Measurement hardware: Four Audio ROBO3 with WinMF software.

Crown IT12000 amplifier.

All measurements in class 1 semi-anechoic chamber using ground plane

technique, with microphone placed on-axis at 4m distance; measurements are

then normalized to 1w/1m in free-field condition.

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 19 / 21

PERFORMANCE

HF HORN

DN14.25T HD1403

LF

WAN123.00

IMPEDANCE

60

@ Znom

40

Impedance

SPL (Ohm)

(dB) 1W/1m

20

0

10 100 500 1000 10000 20000

Frequency (Hz)

Frequency (Hz)

Measurement hardware: Four Audio ROBO3 with WinMF software.

Smoothing 1/6 oct.

MAX SPL

140

135

- Znom - 10% THD

130

SPL (dB) @ 10% THD

125

120

115

1000W

110

SPL (dB) @Max

105

100

95

90

50 100 500 1000 10000

Frequency (Hz)

Frequency (Hz)

Measurement hardware: Four Audio ROBO3 with WinMF software.

Crown IT12000 amplifier

All measurements in class 1 semi-anechoic chamber using ground plane

technique, with microphone placed on-axis at 4m distance.

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 20 / 21

PERFORMANCE

HF HORN

DN14.25T HD1403

LF

WAN123.00

HORIZONTAL PLANE

POLAR PLOT DIRECTIVITY CONTOUR PLOT

0

30 330

0

60 −10 300

−20

90 270

−30

120 240

150 210

180

500 Hz 1 kHz 5 kHz 10 kHz 20 kHz

Measurement hardware: Four Audio ROBO3 with WinMF software.

VERTICAL PLANE

POLAR PLOT DIRECTIVITY CONTOUR PLOT

0

30 330

0

60 300

−10

−20

90 270

−30

120 240

150 210

180

500 Hz 1 kHz 5 kHz 10 kHz 20 kHz

Measurement hardware: Four Audio ROBO3 with WinMF software.

All measurements in class 1 semi-anechoic chamber; measurements are then

normalized with respect to on axis values. Smoothing 1/12 oct.

rev_B.a

SUGGESTED DESIGN SISTEMA N123.14N 21 / 21

WWW.LAVOCESPEAKERS.COM

International sales dept - Italy - T +39 0733 870 840 - M +39 349 4760452 - F +39 0733 870 880 - sales@lavocespeakers.com

Sales office - China - T +86 573 8910 5856 - M +86 186 2181 7905 - F +86 573 8910 5859 - sales.cn@lavocespeakers.com

info@lavocespeakers.com

You might also like

- Strategic Asset Allocation in Fixed Income Markets: A Matlab Based User's GuideFrom EverandStrategic Asset Allocation in Fixed Income Markets: A Matlab Based User's GuideNo ratings yet

- Skema Box Speaker LAVOCE - Sistema-F153.14NDocument23 pagesSkema Box Speaker LAVOCE - Sistema-F153.14NZaid DenieNo ratings yet

- LAVOCE Sistema F153.10N SuggDes RevB.ADocument23 pagesLAVOCE Sistema F153.10N SuggDes RevB.ARoshanNo ratings yet

- 21” Bass Reflex Cabinet Construction GuideDocument18 pages21” Bass Reflex Cabinet Construction GuideZaid Denie100% (1)

- Lavoce Bassline 118rDocument23 pagesLavoce Bassline 118rGiovanni VirdisNo ratings yet

- 113300023-VTP-Drawing (General Arrangement)Document2 pages113300023-VTP-Drawing (General Arrangement)pochoNo ratings yet

- Drill holes with skipped obstacles in two partsDocument1 pageDrill holes with skipped obstacles in two partsDavid BumbaloughNo ratings yet

- Chapter 7 Line Models Flexible Gripper 3D Truss Two-Story BuildingDocument8 pagesChapter 7 Line Models Flexible Gripper 3D Truss Two-Story BuildingAlvaro Fernandez VillarNo ratings yet

- 3641 42 r6 0706Document4 pages3641 42 r6 0706riviera_co2477No ratings yet

- Current Revision Approved: USE AWS E309-17/E309L-17 CONSUMABLE Weld NoteDocument1 pageCurrent Revision Approved: USE AWS E309-17/E309L-17 CONSUMABLE Weld NoteRigobrertoNo ratings yet

- KIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsDocument121 pagesKIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsjoeNo ratings yet

- Product Datasheet Velux Heritage Conservation GCLDocument8 pagesProduct Datasheet Velux Heritage Conservation GCLSammy ChanNo ratings yet

- Auxiliary Water Pump Belt Tensioner Retrofit Parts KitDocument1 pageAuxiliary Water Pump Belt Tensioner Retrofit Parts KitMuhammad AsadNo ratings yet

- Assembly of V Belt, Pully & GearDocument1 pageAssembly of V Belt, Pully & GearPriyam SrivastavaNo ratings yet

- Parts Bulletin for TVS Motorcycle Covers Frame Head Assembly, Headlamp Assembly, and Pillion Footrest AssemblyDocument12 pagesParts Bulletin for TVS Motorcycle Covers Frame Head Assembly, Headlamp Assembly, and Pillion Footrest AssemblyRama ChandranNo ratings yet

- B 2458 S - Drawing PDFDocument1 pageB 2458 S - Drawing PDFhugoheloNo ratings yet

- Drawing - Hub Tension Ring 67BE08Document3 pagesDrawing - Hub Tension Ring 67BE08Rizki MWNo ratings yet

- Exo Slide 60Document1 pageExo Slide 60ramakeredwinNo ratings yet

- UntitledDocument12 pagesUntitledAdar OsNo ratings yet

- Douglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Document6 pagesDouglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Luis Omar AmundarayNo ratings yet

- PB 92202 006Document4 pagesPB 92202 006Rafael Dutil LucianaNo ratings yet

- ID10134834 Type GGL-B en-HQ WWDocument7 pagesID10134834 Type GGL-B en-HQ WWDaniel MoisésNo ratings yet

- Detail C-C Scale 2: 1: Cpu CardDocument1 pageDetail C-C Scale 2: 1: Cpu CardAhmed ShawkiNo ratings yet

- FC Installation SheetDocument4 pagesFC Installation SheetSamuel Lopez BenitesNo ratings yet

- Cart 1Document13 pagesCart 1api-388397199No ratings yet

- S02 Rock DrillDocument22 pagesS02 Rock DrillEver Jhonatan Mellisho CanoNo ratings yet

- Hydraulic Rock Drill HLX 5 Water FlushinDocument19 pagesHydraulic Rock Drill HLX 5 Water FlushinSales Aydinkaya100% (1)

- CIVE 6338 - Sectional AnalysisDocument12 pagesCIVE 6338 - Sectional AnalysissatyaNo ratings yet

- 31-10-2012 - Correction To 1kd-Ftv Water Pump Remove & Install ProcedureDocument5 pages31-10-2012 - Correction To 1kd-Ftv Water Pump Remove & Install ProcedureMaster XeotoNo ratings yet

- Chapter 7 Line Models 1Document8 pagesChapter 7 Line Models 1Darshan SoniNo ratings yet

- Ati Agp r300 128mb Bga Dvii Vga Vo Rev 11 SCHDocument31 pagesAti Agp r300 128mb Bga Dvii Vga Vo Rev 11 SCHGuga BomfimNo ratings yet

- Painting List Elnusa Samudra 7Document5 pagesPainting List Elnusa Samudra 7Muhammmad IhsannNo ratings yet

- Product Overview: Features: Applications: Also AvailableDocument2 pagesProduct Overview: Features: Applications: Also AvailableMAZM17No ratings yet

- H12092021-004 CIW Drilling Choke GADocument1 pageH12092021-004 CIW Drilling Choke GAJitendra BhosaleNo ratings yet

- 04 150 211 DTR.L Mat Fa10Document1 page04 150 211 DTR.L Mat Fa10ClarkFedele27No ratings yet

- Ue1006a11 2Document1 pageUe1006a11 2MARTIN GONZALEZNo ratings yet

- ILLUSTRATED PARTS LIST FOR TRACTOR MODEL TC 142Document20 pagesILLUSTRATED PARTS LIST FOR TRACTOR MODEL TC 142Alejandro Frasica MNo ratings yet

- GE Renewal Parts: Lube Oil Relief ValveDocument4 pagesGE Renewal Parts: Lube Oil Relief ValveRafael Dutil LucianaNo ratings yet

- Ezcarry Adjustable Horizontal High Performance Back-To-Back Siphon Jet No-Hub Water Closet Carrier SystemDocument1 pageEzcarry Adjustable Horizontal High Performance Back-To-Back Siphon Jet No-Hub Water Closet Carrier SystemAndres Coronado RuizNo ratings yet

- Goodwin ValvesDocument1 pageGoodwin ValvesAnderson SiqueiraNo ratings yet

- Base Plate DimensionsDocument1 pageBase Plate DimensionsKevin VoNo ratings yet

- Training Center Material Take-OffDocument6 pagesTraining Center Material Take-Offmajmor-1No ratings yet

- Illustrated Parts List MFG. ID NO. 96051011000 Customer Catalog No. CTH 224tfi PRODUCT NO. 960 51 01-10Document13 pagesIllustrated Parts List MFG. ID NO. 96051011000 Customer Catalog No. CTH 224tfi PRODUCT NO. 960 51 01-10ar dseNo ratings yet

- CBQ 22ADocument7 pagesCBQ 22AJonathan ORotNo ratings yet

- Espaçador PCIDocument1 pageEspaçador PCIRodrigo BonfanteNo ratings yet

- AF5457 - Transformador LLCDocument1 pageAF5457 - Transformador LLCJuan Carlos ColqueNo ratings yet

- Developing a ConeDocument11 pagesDeveloping a ConeK C Tharun KumarNo ratings yet

- 60G Paper Roll ClampDocument15 pages60G Paper Roll ClampÁrgyó András-BotondNo ratings yet

- Valve Parts ListDocument1 pageValve Parts ListhugoheloNo ratings yet

- PTC Creo Parametric generator base dimensionsDocument2 pagesPTC Creo Parametric generator base dimensionsmahranNo ratings yet

- Illustrated Parts List MFG. ID NO. 96051004100 Customer Catalog No. M155-107Hrb PRODUCT NO. 960 51 00-41Document20 pagesIllustrated Parts List MFG. ID NO. 96051004100 Customer Catalog No. M155-107Hrb PRODUCT NO. 960 51 00-41ludi CovjekNo ratings yet

- S02 Rock DrillDocument60 pagesS02 Rock DrillAlejandro LazzariniNo ratings yet

- IPL, YTH2754 T, 96041006203, 2010-04 Spare Parts ListDocument18 pagesIPL, YTH2754 T, 96041006203, 2010-04 Spare Parts ListJhonatan ComakNo ratings yet

- Rebuild Valve Kit Parts List Ariel Spare Parts WebsiteDocument1 pageRebuild Valve Kit Parts List Ariel Spare Parts WebsitehugoheloNo ratings yet

- The Gorman-Rupp Co.: T6AS-B T6BS-B T6Csc-B T6DS-B T6Esc-B T6Fsc-BDocument1 pageThe Gorman-Rupp Co.: T6AS-B T6BS-B T6Csc-B T6DS-B T6Esc-B T6Fsc-BFranco bucciarelliNo ratings yet

- TE-24200 Drawing PackageDocument32 pagesTE-24200 Drawing Packageayberkyurtsever22No ratings yet

- Quick Change System: Robot Clamp BaseDocument3 pagesQuick Change System: Robot Clamp BaseRoboToolNo ratings yet

- Guia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraDocument2 pagesGuia Práctica de Interpretacià N de La Resolucià N SRT 9002015 Protocolo de Medicià N de Puesta A TierraSergio Fabian VasicekNo ratings yet

- FB MaintSheet LA125 42 deckLawnTractorDocument1 pageFB MaintSheet LA125 42 deckLawnTractorAssassin 117No ratings yet

- PCB and Parts Price ListDocument1 pagePCB and Parts Price ListRoshanNo ratings yet

- Matrix Ceiling Prices by SizeDocument1 pageMatrix Ceiling Prices by SizeRoshanNo ratings yet

- 20x60 5feetDocument1 page20x60 5feetRoshanNo ratings yet

- Bridge Modul and Balance InputDocument5 pagesBridge Modul and Balance InputRoshanNo ratings yet

- 16x48 4 FeetDocument1 page16x48 4 FeetRoshanNo ratings yet

- Regulated Input Buffer TopDocument1 pageRegulated Input Buffer TopRoshanNo ratings yet

- Master 3600 LayoutDocument1 pageMaster 3600 LayoutRoshanNo ratings yet

- PICKIT2Document3 pagesPICKIT2Roshan100% (1)

- Plusinfo - LK 111187698403742Document4 pagesPlusinfo - LK 111187698403742RoshanNo ratings yet

- Schematic - TDA7394 High Efficient - 2021-02-28Document1 pageSchematic - TDA7394 High Efficient - 2021-02-28RoshanNo ratings yet

- Introduction To InternetDocument24 pagesIntroduction To InternetRoshanNo ratings yet

- Protel SchematicDocument1 pageProtel SchematicRoshanNo ratings yet

- Instrt 400 XDocument1 pageInstrt 400 XRoshanNo ratings yet

- Introduction To EmailDocument23 pagesIntroduction To EmailRoshanNo ratings yet

- JBL Srx718S: Technical ManualDocument2 pagesJBL Srx718S: Technical ManualRoshanNo ratings yet

- Hydraulic System.Document95 pagesHydraulic System.zae nurdinNo ratings yet

- Simplicity SE Controls - 5127914-UTG-A-0515Document61 pagesSimplicity SE Controls - 5127914-UTG-A-0515Mario LozanoNo ratings yet

- Job Posting - Lead Rotating Equipment EngineerDocument3 pagesJob Posting - Lead Rotating Equipment EngineerKlizman AmineNo ratings yet

- Dell Premium DES-4121 by - VCEplus 60q-DEMO PDFDocument19 pagesDell Premium DES-4121 by - VCEplus 60q-DEMO PDFDinaj AttanayakaNo ratings yet

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- Scribd For IphoneDocument3 pagesScribd For IphoneScribd50% (2)

- Shell Sort Algorithm Explained in DetailDocument8 pagesShell Sort Algorithm Explained in DetailLovely BeatsNo ratings yet

- Merge PDF Files Online. Free Service To Merge PDF - IlovepdfDocument3 pagesMerge PDF Files Online. Free Service To Merge PDF - IlovepdfAMIR RAZANo ratings yet

- A Report On Industrial VisitDocument15 pagesA Report On Industrial VisitChandni Bhagchandani100% (1)

- 06.01.2021.warehouse ManagementDocument29 pages06.01.2021.warehouse ManagementArham OrbNo ratings yet

- AutoLaser UM enDocument151 pagesAutoLaser UM enCristian LopezNo ratings yet

- Major Project SynopsisDocument11 pagesMajor Project SynopsisSankalp VarshneyNo ratings yet

- 4 Special Fire Hazards and PreventionDocument22 pages4 Special Fire Hazards and Preventiondroffilcz27100% (1)

- Grade 8 Term 1 Pretechnical Schemes MentorDocument9 pagesGrade 8 Term 1 Pretechnical Schemes MentorBENARD LUKIBIANo ratings yet

- XPAIB006EN I RefGuide InstrSW WebDocument41 pagesXPAIB006EN I RefGuide InstrSW WebXavier ArévaloNo ratings yet

- KDS 330 Built for Today, Ready for TomorrowDocument2 pagesKDS 330 Built for Today, Ready for TomorrowBill GetsNo ratings yet

- Oferta Bodor: Model (E) Pret ( Fara TVA) Garantie Modele CO2Document3 pagesOferta Bodor: Model (E) Pret ( Fara TVA) Garantie Modele CO2Librarie PapetarieNo ratings yet

- N210 - Computer Practice N4 QP Nov 2019Document21 pagesN210 - Computer Practice N4 QP Nov 2019Pollen SilindaNo ratings yet

- Image Stitching Using Matlab PDFDocument5 pagesImage Stitching Using Matlab PDFnikil chinnaNo ratings yet

- Wiley CIA P1 MCQsDocument240 pagesWiley CIA P1 MCQsSameh Saber80% (5)

- A Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictDocument11 pagesA Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictNithishNo ratings yet

- My Live Official ScreenshotDocument8 pagesMy Live Official ScreenshotCava TorohNo ratings yet

- Boiler Feed Water PumpDocument7 pagesBoiler Feed Water PumphadijawaidNo ratings yet

- Classifying Websites as Static or DynamicDocument2 pagesClassifying Websites as Static or DynamicStephanie AquinoNo ratings yet

- VB Programs BCA 4th SemDocument58 pagesVB Programs BCA 4th SemadarshNo ratings yet

- Elonex 10inch Etouch 1000ET UserGuideDocument31 pagesElonex 10inch Etouch 1000ET UserGuideroadrash100No ratings yet

- Lte Performance Analysis On 800 and 1800 MHZ BandsDocument96 pagesLte Performance Analysis On 800 and 1800 MHZ BandsAttila KovácsNo ratings yet

- Arduino Nano Propeller LEDAnalog Clock 20190403 ADocument4 pagesArduino Nano Propeller LEDAnalog Clock 20190403 AJeng RaffaNo ratings yet

- Financial Reporting Case Writing ConsiderationsDocument2 pagesFinancial Reporting Case Writing ConsiderationsIrina KasymovaNo ratings yet

- Assignment 2 SMN3043 A211Document4 pagesAssignment 2 SMN3043 A211ChimChim UrkNo ratings yet