Professional Documents

Culture Documents

Method Statement For Site Preparation, Excavation & Backfilling Works

Uploaded by

Naveen GladsonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Site Preparation, Excavation & Backfilling Works

Uploaded by

Naveen GladsonCopyright:

Available Formats

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

SUDAIR ONE RENEWABLE ENERGY COMPANY

Project Company SUDAIR ONE RENEWABLE ENERGY COMPANY

Main Contractor LARSEN & TOUBRO SAUDI ARABIA LLC

Discipline Civil

Document Name/No. METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION

& BACKFILL (Site Grading )

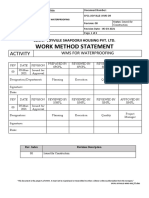

DATE REV REVISION DESCRIPTION PREAPARED BY CHECKED BY APPROVED BY

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

TABLE OF CONTENTS

1.0 SCOPE

Page 3

2.0 REFERENCE

Page 3

3.0 ABBREVATION & DEFINATION

Page 3

4.0 GENERAL & SAFETY REQUIREMENTS

Page 3-4

5.0 RESPONSIBILITIES

Page 4, 5 & 6

6.0 TOOLS & EQUIPMENT

Page 6

7.0 WORK PROCEDURE

Page 6, 7 & 8

Page 2 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION & 1.0

BACKFILL 1.0

SCOPE

The scope of work covered under this contract shall comprise of supplying qualified manpower, field and

laboratory equipment, instruments and facilities to conduct and report on the physical and geotechnical

characteristics of the soil and ground water conditions in the plant area. The investigation scheme shall

also consist of laboratory analysis of samples of soil and rock collected from designated locations in this

site as per specification detailed in the document.

The Project is located in the area controlled by the Saudi Industrial Property Authority (MODON) in the

Sudair Industrial City, south of the city of Majmaah in the Riyadh Province. The Site’s altitude is

approximately 700-750 meters above sea level. The location of the site is indicated in the map below:

2.0 REFERENCES

2.1 Approved IFC Drawing

2.2 Project Quality Plan

2.3 Safety and Medical Plan

2.4 Project Specification & Standards

2.4.1 Site Preparation Specification

2.4.2 Excavation & Backfilling Specification

3.0 ABBREVIATIONS & DEFINITIONS

3.1 MS Method Statement

3.2 Client ACWA

3.2 HSE Health Safety and Environment

3.3 QA-QC Quality Assurance / Quality Control

3.4 ASTM American Standard for Testing and Materials

3.5 PS Pooling Station

3.6 OHTL Over Head Tower Line

Page 3 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION & 4.0

BACKFILL 4.0

GENERAL AND SAFETY REQUIREMENTS

Risk Assessment shall be prepared including mitigation measures, and responsibility for

implementation. This shall be coordinated with site Safety In-charge and attach to this method

statement.

Before commencing any work, all permits shall be checked and ensured that they are valid until

completion of activity.

All works shall be referred to the Drawings and specifications.

All staff and workmen shall wear Personnel Protective Equipment (PPE).

All personnel shall be cautioned while working near live lines and other services.

It shall be ensured that all men working in high-level are wearing necessary safety harness

complying with the safety requirements and following precautionary measures on safety

aspects.

All equipment shall be calibrated and accompanied by the competent operators prior to

commencement of any works.

In case of any emergency please contact the following:

5.0 RESPONSIBILITIES

Below mentioned personnel with the responsibilities entrusted to them shall be responsible for carrying

out below mentioned works. In addition to their roles and responsibilities disseminated in the Project

Quality & EHS Plans and the following specific activity functions shall be carried out:

5.1 Construction Manager

Reporting to the Project Manager and assisted by construction team as indicated in the project

organization chart.

Ensure that method statement is prepared, established & control measures taken before starting the

work and guiding the team for implementation.

Follow-up & coordinate with design engineering team for preparation of Coordinates drawing Layout.

Conduct training and awareness program for all personnel deployed for the activity.

5.2 Site Engineer

Directly reporting to the Construction Manager.

Prepare method statement, take approval, and implement.

Execute works according latest method statement, Coordinates drawing Layout, and contract

specifications.

Orient/train the team to implement the method statements effectively.

Maintain related records.

Page 4 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

Coordinate with Surveyor for survey works

5.3 Civil Foreman

Directly reporting to the Site Engineer.

Responsible on his own discipline for direct execution of works according to the plan.

Directly control and instruct to the working personnel.

Ensure that works are performed with proper tool, equipment, and PPE’s.

Ensure regular housekeeping of the entire work area.

5.4 Surveyor

Study drawing and establish control points as per plot plan / approved drawing.

Acquire information from reference station/s & datum level provided by client; establish new control

points at site & cross verify with reference station/s and datum level.

Conduct survey, prepare survey report, and maintain records.

Provide route markings and obtain approvals.

Ensure calibration of survey equipment and its maintenance

5.5 QA/QC Engineer

Quality In-charge shall review the method statements and ensure all requirements are included.

Schedule inspection of works in coordination with Site Engineer.

Prepare and maintain inspection logs, records, and obtain approval from client.

Inspecting the calibration certificates of measuring tools.

Maintain third party testing reports.

Review Quality Control records and ensure correctness.

5.6 Safety In-charge and requirements

Disseminate HSE requirements specific to the activities involved and facilitate implementation.

Prepare and coordinate the implementation of Risk Assessment plan.

Ensure that work is carried out in safe manner in coordination with Site Engineer, sub-contractors,

etc.

All concerned parties shall be exposed to the method statements applicable to their working scope

and must attend a safety briefing prior to carrying out any works on site.

All personnel shall ensure safe working conditions prior to the start of work.

Great emphasis shall be made on all matters of health, safety, and environmental both in the

workplace, and to the public during the execution of works.

Page 5 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

Personal Protective Equipment (PPE) shall be issued to all employees and visitors. PPE includes

reflective vest, safety shoes, hard hat, gloves and safety goggles (if required). The usage of proper

PPE is mandatory for all personnel at all times they are on site.

Dusk masks and eye goggles shall be used in windy weather.

The drill rig should be certified and safe for usage on site. Certification should be with the operator at

all times.

Boreholes locations shall be clearly marked and barricaded after the boreholes are dug to avoid

falling hazards.

Manual pit at a suitable depth shall be conducted under the boreholes location to ensure that the site

is clear from underground utilities.

Do not drive the drill rig from hole to hole with the mast (derrick) in the raised position.

Instruct all drill rig personnel and visitors to "stand clear" of the drill rig immediately prior to starting

the engine.

Only certified drill rig personnel are allowed to operate the drill rig. Visitors must stand clear of the

drill rig at all times.

6.0 TOOLS AND EQUIPMENTS

The following are the tools and tackles and Equipment identified for the scope of the work and shall

be deployed as per the requirements:

Crow Bar

Shovel & other Hand Tools for manual excavation

Pay Loader

Backhoe

Dump Truck

Jack Hammer

Road Roller

Water Truck

Wheel Borrow

Bob Cat

Plate / Jumping Jack Compactor

GPS

Dumpy Level

Measuring tape

Marking pegs

Warning tape

7.0 WORK METHODOLOGY

7.1 Grading & Excavation:

Page 6 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

Prior to elevate the site to required level, the existing soil shall be excavated if required

as per drawing to 200 mm deep. Following sequence of works shall be carried under this

activity.

a) Prepare all required permits and keep such documents at site always for the

verification by any authorized personnel at any time.

b) Prior to start any excavation works the surveyor shall be establishing, mark and

monument all required levels and co-ordinates for easy access and reference and

furnish a contour drawing showing contour levels at five-meter (5 Meter) intervals.

c) Prepare warning sign boards showing the classification of excavation such as

“shallow’’ or ‘’deep excavation’’ and ‘’Men at work’’ etc.

d) Prepare warning tapes and safety barricades as wide as required in the excavation

areas.

e) Check and assure the accessibility of equipment to be entered at site without causing

any damaged to any of the permanent or temporary properties present at site.

f) Cleaning, grubbing all the desert bushes and its roots shall be removed from the site

and disposed at designated area.

g) The excavated soil shall be safely removed and dumped at temporary dumping area

for final disposal or using for backfilling (After 3rd party testing approved)

h) The excavated bed shall be properly levelled and graded before compaction.

i) Finally, the excavated bed shall be compacted to achieve relative density required as

per project specification.

j) The sub-grade shall be compacted to required density 85% of consolidation and

tested through approved third-party testing agency, witnessed by the owner and

certified by third party inspection team.

k) The excavated sub-grade shall be compacted to required density of consolidation as

per project specification and tested through approved third-party testing agency.

Witnessed by the owner and certified by third party inspection team.

7.2 Backfilling:

Following to the compaction of sub-grade compaction, backfilling and grading shall be

carried out in the following sequence of works

a) Prior to start any backfilling works, it is necessary to prepare all fill materials approved and

mark readily available at site.

b) Fill and backfill materials shall be from on-site excavation, designated borrow areas or off

site sources conforming to the following criteria or as recommended by a geotechnical

report.

c) Submittal for fill material shall be prepared in advance and submit to the owner along with

all required all laboratory analysis reports.

Page 7 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

d) Fill or backfill materials shall meet the requirements as per specifications.

e) The backfilling materials shall pass the required testing by approved 3rd party laboratory

and approved by Owner representative.

f) The areas to received fill shall be clear from roots, logs, standing water & foreign objects,

etc.

g) All observed soft spots or loose zones shall be compacted in place or excavated to firm soil

and replace with properly compacted fill.

h) Compacting of materials shall begin only if the fill or backfill has been properly placed and

the material to be compacted is at the proper moisture content.

i) Fill materials shall be placed in lifts not exceeding to 200 mm in loose depth if using heavy

compactor to achieve maximum density of 95% as per ASTM D 1557.

j) The moisture content of the material to be compacted shall be between (+/- 2) as per ASTM

D 2216.

k) The compacted surface of fill and backfill shall be finish graded to the cross section, lines,

grades and elevation as indicated on IFC drawing.

l) Availability of fill material in sufficient quantity shall be assured in site and requirements

during backfilling and grading process in turn.

m) Backfilling shall be carried out in layers as specified in the project specification, i.e. it should

be maximum thickness of 150 mm in each layer after compaction.

n) Lying of fill and backfilling material shall be carried out mechanically using pay loaders and

bobcats, provided each layer filled material shall be levelled mechanically or manually with

respect to the proximity and accessibility of fill location.

o) Each layers of fill shall be compacted mechanically before filling each consecutive layers of

fill until the completion of fill to required grade of elevation.

7.3 Compaction & Testing:

A systematic and methodical compaction and testing shall be maintained during backfilling.

Following sequence of works shall be carried out under this section of earthwork.

a) Prior to compaction works the soil material to be compacted shall be tested for finding

out each optimum moisture content, relative density, CBR value etc. and sieve analysis

to qualify the soil as filling material and find us basic technical data or conducting the

compaction test of fills and backfill.

b) The backfill material shall be compacted to require density of 95% consolidation as per

project specification and tested through approved third party testing agency, witnessed

by the owner and certified by the third party inspection team.

c) Samples shall be taken from the site borrow pit, the sample shall be identified with

proper tagging before sending to approved laboratory for conducting required tests.

d) Fill materials shall be arranged as satisfactory material free of any contaminated

material or vegetation in order to comply with project specification of fill material.

Page 8 of 9

Sensitivity: LNT Construction Internal Use

LARSEN & TOUBRO SAUDI ARABIA LLC

SUDAIR 1.6GW PV SOLAR PROJECT

METHOD OF STATEMENT FOR SITE PREPARATION, EXCAVATION &

BACKFILL

e) All compaction tests related with backfill as its real turn and due courses during the

progress of works shall be properly planned in advance and programmed with third party

testing lab agency according to the requirements of the project.

f) Compaction of filling shall be done using Roller/ Plate/Jumping compactor.

g) All compaction tests carry out in the site shall be inspected, checks and certified by the

approve third party agency.

h) The compaction test records and certificates shall be properly documented and

preserved for project records.

7.4 Health, Safety and Risk Assessment:

To ensure security directives during the execution of earth works, all activities shall be

monitored in compliance with relevant standards, codes and procedures described in the

company manual and project specification as minimum as follows:

a) A safety officer shall be at site during the execution of works.

b) Daily tool box meetings shall be conducted as mandatory.

c) Following safety requirements shall be fulfilled.

d) Safety barricade shall be prepared wherever necessary.

e) Necessary safety sign boards shall be provided as required.

f) All workers shall be provided with job specific personal protective Equipment.

g) Safety flickering lights shall be provided for night-time indication.

h) All equipment shall be inspected by the approving authority prior to start of the work.

i) Working equipment shall be equipped with amber lights, homes, safety guards etc. as

required per safety provisions.

j) Any incident at site shall be immediately reported to company and recorded.

k) Weekly safety statistics reports and safety performance reports rtc. shall be prepared and

records.

Page 9 of 9

Sensitivity: LNT Construction Internal Use

You might also like

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Ms For MV Cable Pulling ProcedureDocument11 pagesMs For MV Cable Pulling ProcedureFaris Abandeh100% (1)

- UGFC-PQCP-49, Rev01 March 01Document7 pagesUGFC-PQCP-49, Rev01 March 01Mahaboob PashaNo ratings yet

- WM Statement For General Welding WorkDocument6 pagesWM Statement For General Welding Workahsan khaleeqNo ratings yet

- Site Administration and ControlDocument43 pagesSite Administration and Controlशर्मा अविनाशNo ratings yet

- 1.MS - FoundationDocument11 pages1.MS - FoundationMalik BilalNo ratings yet

- Work Methodology PCCDocument4 pagesWork Methodology PCClost love100% (1)

- NCRMP-TPQA Monthly Progress Report December 2013Document194 pagesNCRMP-TPQA Monthly Progress Report December 2013apncrmptpqaNo ratings yet

- List of Method Satement (MS)Document7 pagesList of Method Satement (MS)Imho Tep100% (1)

- Conbextra GP2 PDFDocument4 pagesConbextra GP2 PDFRaja SundaramNo ratings yet

- Ennangal by m s Udhayamurthi எண ணங களDocument42 pagesEnnangal by m s Udhayamurthi எண ணங களadmin4003No ratings yet

- MechanicalDocument57 pagesMechanicalSaid KarimNo ratings yet

- MS For Waterproofing of CulvertsDocument29 pagesMS For Waterproofing of CulvertsAdrian Frantescu100% (2)

- Method Statement For DS Installation Rev0Document15 pagesMethod Statement For DS Installation Rev0Mark DizonNo ratings yet

- CPC07E-ITP-STR-0010 Inspection and Test PlanDocument5 pagesCPC07E-ITP-STR-0010 Inspection and Test PlanMariam MousaNo ratings yet

- Method Statement-Condensate DrainDocument6 pagesMethod Statement-Condensate DrainFark Off100% (1)

- METHOD STATEMENT FOR Backfilling - Rev 0Document5 pagesMETHOD STATEMENT FOR Backfilling - Rev 0Osama MZNo ratings yet

- Method Statement Coal TipplerDocument10 pagesMethod Statement Coal TipplerSunil T V SuniNo ratings yet

- Diesel GenSet Specifications-1Document8 pagesDiesel GenSet Specifications-1Nahid KashmoulaNo ratings yet

- Astra Construction: INSTALLATION CHECK LIST For Irrigation Pipes, Valves, Controls, Sprinklers and DrippersDocument2 pagesAstra Construction: INSTALLATION CHECK LIST For Irrigation Pipes, Valves, Controls, Sprinklers and Drippersmd_rehan_2100% (2)

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- Water Proofing Toilets WorksDocument63 pagesWater Proofing Toilets WorksGhaffar Laghari100% (1)

- NCP 26 For PGPCM of NICMARDocument76 pagesNCP 26 For PGPCM of NICMARGunjan JaiswalNo ratings yet

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- MST For EARTHING SYSTEMDocument13 pagesMST For EARTHING SYSTEMمقاول تكييف كهرباء وصحيNo ratings yet

- 7.16: Electrical Safety OEMS Element: Safe Work PracticesDocument10 pages7.16: Electrical Safety OEMS Element: Safe Work Practicesum erNo ratings yet

- Method of Statement-13.8KVDocument57 pagesMethod of Statement-13.8KVzaheerNo ratings yet

- Construction of Acid Proof LiningDocument4 pagesConstruction of Acid Proof LiningHiren ThakkarNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- BRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTDocument66 pagesBRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTRizwanNo ratings yet

- Manpower DeploymentDocument18 pagesManpower DeploymentKrm ChariNo ratings yet

- Work Method Statement: ActivityDocument5 pagesWork Method Statement: ActivityamolNo ratings yet

- TECHNICAL Proposal: Solar Energy System For GSM Outdoor BTSDocument4 pagesTECHNICAL Proposal: Solar Energy System For GSM Outdoor BTSnn nnNo ratings yet

- Best Practices in Quality Assurance & Inspection IN NTPCDocument39 pagesBest Practices in Quality Assurance & Inspection IN NTPCPrincy SinghNo ratings yet

- L. Labour Charges For 11kV System 1Document17 pagesL. Labour Charges For 11kV System 1SagarNo ratings yet

- Masonry & PlasteringDocument18 pagesMasonry & PlasteringlavekushNo ratings yet

- Company Profile PDFDocument77 pagesCompany Profile PDFVishal PatelNo ratings yet

- Activity Schedule of ESSDocument17 pagesActivity Schedule of ESSkumar100% (1)

- Elec Foreman CVDocument4 pagesElec Foreman CVhitanshu0% (1)

- MS For Excavation at Choti ChauparDocument11 pagesMS For Excavation at Choti ChauparvikasNo ratings yet

- EHTESHAM KHAN - Electrical TechnicianDocument2 pagesEHTESHAM KHAN - Electrical TechniciancdeekyNo ratings yet

- MOS Cable LayingDocument17 pagesMOS Cable LayingadelenaNo ratings yet

- ITP-Line Hardware - Sample Test PDFDocument3 pagesITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- Method Statement Concrete PouringDocument4 pagesMethod Statement Concrete PouringSmart ShivaNo ratings yet

- Construction PackagesDocument9 pagesConstruction PackagesArun Chandra BabuNo ratings yet

- Is 15058 2002Document12 pagesIs 15058 2002Santosh KumarNo ratings yet

- Method Statement Megger TestingDocument11 pagesMethod Statement Megger TestingJemeraldNo ratings yet

- Concrete Batching and MixingDocument8 pagesConcrete Batching and MixingIm ChinithNo ratings yet

- 01 - PVC Conduits InstallationDocument11 pages01 - PVC Conduits InstallationRaju ManojNo ratings yet

- Method Statment For Bridge ConstructionDocument119 pagesMethod Statment For Bridge ConstructionSadek SinanNo ratings yet

- Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesMethod Statement For Domestic Water Piping Installation UG & AGBelal AlrwadiehNo ratings yet

- Method Statement For Asphalt Work-1Document7 pagesMethod Statement For Asphalt Work-1Jaafar LagayanNo ratings yet

- 4.WMS-04-reinforcement Steel Fixing WorkDocument11 pages4.WMS-04-reinforcement Steel Fixing WorkamolNo ratings yet

- Rental Quotation For ScaffoldingDocument1 pageRental Quotation For ScaffoldingDusty BunNo ratings yet

- Method Statement - Earth Grading and CompactingDocument7 pagesMethod Statement - Earth Grading and CompactingShielamae Gumaod SernaNo ratings yet

- Construction: Price List - Regional ManagersDocument23 pagesConstruction: Price List - Regional ManagersJoshua Hobson100% (1)

- ICTS Civil Tender Contract Conditions PDFDocument180 pagesICTS Civil Tender Contract Conditions PDFKusuma gowdaNo ratings yet

- Method Statement For PS Concrete WorksDocument12 pagesMethod Statement For PS Concrete WorksMuhammad Sami ParvezNo ratings yet

- Method Statement For Foundation WaterProofingDocument9 pagesMethod Statement For Foundation WaterProofingMuhammad Sami ParvezNo ratings yet

- Method StatementsDocument61 pagesMethod StatementssathishNo ratings yet

- Index From LinkDocument11 pagesIndex From LinkNaveen GladsonNo ratings yet

- Method Statement For Establishment of Site FacilitiesDocument9 pagesMethod Statement For Establishment of Site FacilitiesNaveen GladsonNo ratings yet

- Risk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- Inspection and Test Plan (ITP) - Civil WorksDocument1 pageInspection and Test Plan (ITP) - Civil WorksNaveen GladsonNo ratings yet

- Risk Assessment: Block Works Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Block Works Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- Risk Assessment And Analysis/رطاخﻤلا م يقﺗDocument3 pagesRisk Assessment And Analysis/رطاخﻤلا م يقﺗNaveen GladsonNo ratings yet

- sb485s rs232 A rs485Document24 pagessb485s rs232 A rs485KAYCONSYSTECSLA KAYLA CONTROL SYSTEMNo ratings yet

- Project On Brand Awareness of ICICI Prudential by SajadDocument99 pagesProject On Brand Awareness of ICICI Prudential by SajadSajadul Ashraf71% (7)

- Bảo MậtDocument2 pagesBảo MậtMinh Nghia PhamNo ratings yet

- Principles of Care-Nursing For Children: Principle DescriptionDocument3 pagesPrinciples of Care-Nursing For Children: Principle DescriptionSanthosh.S.UNo ratings yet

- Business and Finance TerminologyDocument15 pagesBusiness and Finance TerminologyKat KatNo ratings yet

- Analisis Pendapatan Dan Kesejahteraan Rumah Tangga Nelayan Cumi-Cumi Di Desa Sukajaya Lempasing Kecamatan Teluk Pandan Kabupaten PesawaranDocument12 pagesAnalisis Pendapatan Dan Kesejahteraan Rumah Tangga Nelayan Cumi-Cumi Di Desa Sukajaya Lempasing Kecamatan Teluk Pandan Kabupaten PesawaranAldy Suryo KuncoroNo ratings yet

- Soal Ujian SmaDocument26 pagesSoal Ujian SmaAyu RiskyNo ratings yet

- Namma Kalvi 12th Maths Chapter 4 Study Material em 213434Document17 pagesNamma Kalvi 12th Maths Chapter 4 Study Material em 213434TSG gaming 12No ratings yet

- Arti ResearchDocument10 pagesArti Researcharti nongbetNo ratings yet

- SRB 301 Ma Operating Instructions Safety-Monitoring ModulesDocument6 pagesSRB 301 Ma Operating Instructions Safety-Monitoring ModulesMustafa EranpurwalaNo ratings yet

- P102 Lesson 4Document24 pagesP102 Lesson 4Tracy Blair Napa-egNo ratings yet

- A Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional CoresDocument13 pagesA Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional Coresmsmsoft90No ratings yet

- Etpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsDocument3 pagesEtpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsLourdes LimaNo ratings yet

- Case Study 1Document2 pagesCase Study 1asad ee100% (1)

- BS en 12285-1-2003 (2006)Document162 pagesBS en 12285-1-2003 (2006)dahzahNo ratings yet

- 1GR FE LubricationDocument19 pages1GR FE LubricationJesus LayaNo ratings yet

- Incident Log - TemplateDocument10 pagesIncident Log - TemplateRajaNo ratings yet

- ALP Final Test KeyDocument3 pagesALP Final Test KeyPetro Nela50% (2)

- Green Tyre TechnologyDocument4 pagesGreen Tyre TechnologyAnuj SharmaNo ratings yet

- Suplayer Metal Working Sipil and Fabrication: Company ProfileDocument10 pagesSuplayer Metal Working Sipil and Fabrication: Company ProfileRuntian TeaNo ratings yet

- Conext Battery Monitor Quick Start Guide 975 0690-03-01 Rev B SPA1Document2 pagesConext Battery Monitor Quick Start Guide 975 0690-03-01 Rev B SPA1xray123zzzNo ratings yet

- RRB NTPC Previous Year Paper 20: WWW - Careerpower.inDocument16 pagesRRB NTPC Previous Year Paper 20: WWW - Careerpower.inSudarshan MaliNo ratings yet

- Epsilon Range Bomba HorizontalDocument8 pagesEpsilon Range Bomba HorizontalsalazarafaelNo ratings yet

- GROZ Tools & Equipment 2018Document3 pagesGROZ Tools & Equipment 2018ayush bansalNo ratings yet

- Tween 80 CoADocument1 pageTween 80 CoATấn Huy HồNo ratings yet

- Emailing Prime - Brochure - DigitalDocument32 pagesEmailing Prime - Brochure - DigitalCASA VALLINo ratings yet

- Section 8 33KVDocument13 pagesSection 8 33KVMuna HamidNo ratings yet

- Ashirvad SWR and SWR PLUS - Price List - 02nd April 2022Document14 pagesAshirvad SWR and SWR PLUS - Price List - 02nd April 2022Magnum ConstructionsNo ratings yet

- Tapspp0101 PDFDocument119 pagesTapspp0101 PDFAldriel GabayanNo ratings yet

- 3-DatAdvantage Advanced Installation For NAS and Linux Platforms 8.6Document47 pages3-DatAdvantage Advanced Installation For NAS and Linux Platforms 8.6yaritzaNo ratings yet