Professional Documents

Culture Documents

Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, Hamburg

Uploaded by

Edwar ZulmiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, Hamburg

Uploaded by

Edwar ZulmiCopyright:

Available Formats

Airbus Material, Logistics and Suppliers, Hamburg

INTEGRATED PROVISIONING SERVICES

Part 3 – The Mathematical Model

INTEGRATED PROVISIONING SERVICES

Part 3 – The Mathematical Model

Integrated Provisioning Services The Mathematical Model

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................................................................................................................ 2

2. MATHEMATICAL PRINCIPLES .................................................................................................................................................................... 3

2.1. BASIC FORMULAS .............................................................................................................................................................................. 3

2.2. CUSTOMER PARAMETERS ................................................................................................................................................................ 3

2.3. PART and AIRCRAFT PARAMETERS ................................................................................................................................................. 3

2.4. FURTHER VARIABLES USED ............................................................................................................................................................. 4

2.5. POISSON DISTRIBUTION ................................................................................................................................................................... 4

3. APPLICATION OF THE POISSON DISTRIBUTION ..................................................................................................................................... 5

3.1. MANUAL DETERMINATION OF RECOMMENDED QUANTITY ......................................................................................................... 5

3.2. HOW TO USE THE POISSON DISTRIBUTION TABLE ...................................................................................................................... 6

3.3. POISSON TABLES ............................................................................................................................................................................... 7

Issue 16, September 2013 Page 1

Integrated Provisioning Services The Mathematical Model

1. INTRODUCTION

This brochure explains to you the process of the standard Mathematical Model that is used to determine recommended spare parts quantities.

Once you go through the examples provided hereafter, you will see that the model is just straightforward.

Since this model is nothing but basic, we have developed other methods of provisioning recommendations which go beyond the range of these

ground rules. However, understanding the groundwork helps in any case to identify the major cost driving factors of the initial spares investment

and the link of these factors to the operational profile of the airlines.

These basic understandings will also enable you to pose the correct questions leading to reduction of your initial provisioning investment.

Tamas Stefka

Director Integrated Provisioning Services

Issue 16, September 2013 Page 2

Integrated Provisioning Services The Mathematical Model

2. MATHEMATICAL PRINCIPLES 2.2. CUSTOMER PARAMETERS

2.1. BASIC FORMULAS AT Administration Time

Generically a part is analysed for its risk of failure within the first FC average Flight Cycle time

year of operation via testing the annual demand (Dann) versus the FH Flight Hours per aircraft per year

minimum annual demand (MAD). In case Dann ≥ MAD the first MAD Minimum Annual Demand

spare is allocated to the stock. Further risks out of re-supply chain FS Number of A/C in the IP period

delays are mitigated by adding further spares to obtain sufficient TT Transit Time

protection in line with the expected demand (Drst) during the re-

supply time.

2.3. PART and AIRCRAFT PARAMETERS

Annual Demand: QPA Quantity per aircraft

SCR Scrap Rate

LTM Lead Time

FH FS QPA

D ann MST Max/Mean shop processing time

MTBUR TAT Turn-Around-Time (= TT + MSPT)

MCBUR Mean Cycles Between Unscheduled Removals

MTBUR Mean Time Between Unscheduled Removals

Expected Demand during Re-Supply Time: For certain items the operation is measured in

cycles. In these cases the MTBUR is

calculated as follows: MTBUR = MCBUR x

FC.

SCR SCR

RST MST TT 1 LTM AT

In most cases, the IP MTBUR equals the guaranteed MTBUR

1000 1000

factored by 1.5. However, variations may apply to specific

suppliers, programmes or part numbers.

Issue 16, September 2013 Page 3

Integrated Provisioning Services The Mathematical Model

Formula

2.4. FURTHER VARIABLES USED

Dann Annual Demand

P R m e D rst

m

D rst m P = Probability

R = number of

Drst Expected Demand during Re-Supply Time removals

m Recommended Quantity 0 m!

PL Spares Protection Level The Dann versus MAD test is assumed to have the part qualified as

may vary from 80.0% to 98.0% and may be selected as spare. Then the formula describes the probability to have no more

function of equipment’s Essentiality Code (ESS) and removals than spares during the re-supply time

Spare Part Class (SPC) or as function of ESS and 3

different price ranges (Low, Medium, High) where range Whereas above may be done by programmable IT tools, the

limits are defined by the customer following page illustrates how m may be obtained manually from

PLT Tolerance used when testing PL obtained from m versus tables showing P against various m to a given Er.

PL requested by customer may vary from 0 to 10 percent

points

CRF Customised Redundancy Factor Remark:

may vary from 0.0 to 1.0 (0% to 100%) with Go If

equipment when n > 1. Captures the amount of system When the customer selects the Price Range option, parts

redundancy a customer intends to consider in spares lacking a price are considered to have a medium range price.

planning.

CRF = 0 for No Go and Go Equipment For Parts, where LT data is not available, LT defaults to preset

values depending on the type of material.

2.5. POISSON DISTRIBUTION

Type of material LT days

Recommended quantities (m) and Protection Levels (PL) are now

Airbus Proprietary Parts 10

assessed assuming a Poisson distribution of part failures across

time. In a Poisson process m cannot be calculated Supplier Equipment 60

straightforwardly. It requires an iterative process of assuming m, Supplier Equipment Breakdown Parts 60

testing it against the PL requirement and incrementing m to test it Standard Hardware 30

again, etc. Others 90

Issue 16, September 2013 Page 4

Integrated Provisioning Services The Mathematical Model

3. APPLICATION OF THE POISSON DISTRIBUTION Case C: as Case B above but PLT = 1%

3.1. MANUAL DETERMINATION OF RECOMMENDED PL (m=3) = 0.974 = 97,4% is above PL–PLT = 97% m=3

QUANTITY ! The tolerance reduces stocks by 1 spare

See as well the table(s) on next the page(s)

Case A: MAD = 1,0 Dann = 0,50 Case D: as Case B above but PLT = 1% and CRF = 100%

(Part is Go If and n=2)

Dann is less than MAD part does not qualify as spare m =0

1

! Probability of failure is considered too low The Drst calculation needs to consider the factor

1 CRF

D rst

New Drst is then 1 1 = 0,55 (see table on page 7)

Case B: MAD = 1,0 Dann = 2,0 PL = 98% Drst = 1,1

PL (m=1) = 0.894 = 89,4% is below PL-PLT increment by 1

Dann ≥ MAD part qualified as spare m = 1

PL (m=2) = 0.982 = 98,2% is above PL-PLT m=2

PL (m=1) = 0.699 = 69,9% is below PL increment by 1

PL (m=2) = 0.900 = 90,0% is below PL increment by 1

! The redundancy reduces stocks by 2 units

PL (m=3) = 0.974 = 97,4% is below PL increment by 1

PL (m=4) = 0.996 = 99,6% is above PL m=4

Issue 16, September 2013 Page 5

Integrated Provisioning Services The Mathematical Model

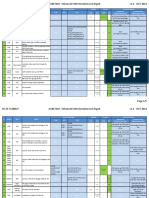

3.2. HOW TO USE THE POISSON DISTRIBUTION TABLE

Sample table for Drst = 1.0 to 2.0

ESTIMATED

DEMAND Drst

m 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

0 .368 .333 .301 .273 .247 .223 .202 .183 .165 .150 .135

1 .736 .699 .663 .627 .592 .558 .525 .493 .463 .434 .406

2 .920 .900 .879 .857 .833 .809 .783 .757 .731 .704 .677

3 .981 .974 .966 .957 .946 .934 .921 .907 .891 .875 .857

4 .996 .996 .992 .989 .986 .981 .976 .970 .964 .956 .947

5 .999 .999 .998 .998 .997 .996 .994 .992 .990 .987 .983

6 1.000 1.000 1.000 1.000 .999 .999 .999 .998 .997 .997 .995

7 1.000 1.000 1.000 1.000 .999 .999 .999

8 1.000 1.000 1.000

RECOMMENDED

PROTECTION

QUANTITY m

LEVEL PL

Issue 16, September 2013 Page 6

Integrated Provisioning Services The Mathematical Model

3.3. POISSON TABLES

Estimated Demand

m .02 .04 .06 .08 .10 .15 .20 .25 .30 .35 .40

0 .980 .961 .942 .923 .905 .861 .819 .779 .741 .705 .670

1 1.000 .999 .998 .997 .995 .990 .982 .974 .963 .951 .938

2 1.000 1.000 1.000 1.000 .999 .999 .998 .996 .994 .992

3 1.000 1.000 1.000 1.000 1.000 .999

4 1.000

Table 1

Estimated Demand

m .45 .50 .55 .60 .65 .70 .75 .80 .85 .90 .95

0 .638 .607 .577 .549 .522 .497 .472 .449 .427 .407 .387

1 .925 .910 .894 .878 .861 .844 .827 .809 .791 .772 .754

2 .989 .986 .982 .977 .972 .966 .959 .953 .945 .937 .929

3 .999 .998 .998 .997 .996 .994 .993 .991 .989 .987 .984

4 1.000 1.000 1.000 1.000 .999 .999 .999 .999 .998 .998 .997

5 1.000 1.000 1.000 1.000 1.000 1.000 1.000

Issue 16, September 2013 Page 7

Integrated Provisioning Services The Mathematical Model

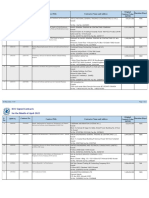

POISSON TABLES (continued)

Estimated Demand

m 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

0 .368 .333 .301 .273 .247 .223 .202 .183 .165 .150 .135

1 .736 .699 .663 .627 .592 .558 .525 .493 .463 .434 .406

2 .920 .900 .879 .857 .833 .809 .783 .757 .731 .704 .677

3 .981 .974 .966 .957 .946 .934 .921 .907 .891 .875 .857

4 .996 .996 .992 .989 .986 .981 .976 .970 .964 .956 .947

5 .999 .999 .998 .998 .997 .996 .994 .992 .990 .987 .983

6 1.000 1.000 1.000 1.000 .999 .999 .999 .998 .997 .997 .995

7 1.000 1.000 1.000 1.000 .999 .999 .999

8 1.000 1.000 1.000

Issue 16, September 2013 Page 8

Integrated Provisioning Services The Mathematical Model

POISSON TABLES (continued)

Estimated Demand

m 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2

0 .111 .091 .074 .061 .050 .041 .033 .027 .022 .018 .015

1 .355 .308 .267 .231 .199 .171 .147 .126 .107 .092 .078

2 .623 .570 .518 .469 .423 .380 .340 .303 .269 .238 .210

3 .819 .779 .736 .692 .647 .603 .558 .515 .473 .433 .395

4 .928 .904 .877 .848 .815 .781 .744 .706 .668 .629 .590

5 .975 .964 .951 .935 .916 .895 .871 .844 .816 .785 .753

6 .993 .988 .983 .976 .966 .955 .942 .927 .909 .889 .867

7 .998 .997 .995 .992 .988 .983 .977 .969 .960 .949 .936

8 1.000 .999 .999 .998 .996 .994 .992 .988 .984 .979 .972

9 1.000 1.000 .999 .999 .998 .997 .996 .994 .992 .989

10 1.000 1.000 1.000 .999 .999 .998 .997 .996

11 1.000 1.000 .999 .999 .999

12 1.000 1.000 1.000

Issue 16, September 2013 Page 9

Integrated Provisioning Services The Mathematical Model

POISSON TABLES (continued)

Estimated Demand

m 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8 6.0 6.2 6.4

0 .012 .010 .008 .007 .006 .005 .004 .003 .002 .002 .002

1 .066 .056 .047 .040 .034 .029 .024 .021 .017 .014 .012

2 .185 .163 .143 .125 .109 .095 .082 .072 .062 .054 .049

3 .359 .326 .294 .265 .238 .213 .191 .170 .151 .134 .119

4 .551 .513 .476 .440 .406 .373 .342 .313 .285 .259 .235

5 .720 .686 .651 .616 .581 .546 .512 .478 .446 .414 .384

6 .844 .818 .791 .762 .732 .702 .670 .638 .606 .574 .542

7 .921 .905 .887 .867 .845 .822 .797 .771 .744 .716 .687

8 .964 .955 .944 .932 .918 .903 .886 .867 .847 .826 .803

9 .985 .980 .975 .968 .960 .951 .941 .929 .916 .902 .886

10 .994 .992 .990 .986 .982 .977 .972 .965 .957 .949 .939

11 .998 .997 .996 .995 .993 .990 .988 .984 .980 .975 .969

12 .999 .999 .999 .998 .997 .996 .995 .993 .991 .989 .986

13 1.000 1.000 1.000 .999 .999 .999 .998 .997 .996 .995 .994

14 1.000 1.000 1.000 .999 .999 .999 .998 .997

15 1.000 1.000 .999 .999 .999

16 1.000 1.000 1.000

Issue 16, September 2013 Page 10

Integrated Provisioning Services The Mathematical Model

POISSON TABLES (continued)

Estimated Demand

m 6.6 6.8 7.0 7.2 7.4 7.6 7.8 8.0 8.5 9.0 9.5 10.0

1 .010 .009 .007 .006 .005 .004 .004 .003 .002 .001 .001 .000

2 .040 .034 .030 .025 .022 .019 .016 .014 .009 .006 .004 .003

3 .105 .093 .082 .072 .063 .055 .048 .042 .030 .021 .015 .010

4 .213 .192 .173 .156 .140 .125 .112 .100 .074 .055 .040 .029

5 .355 .327 .301 .276 .253 .231 .210 .191 .150 .116 .089 .067

6 .511 .480 .450 .420 .392 .365 .338 .313 .256 .207 .165 .130

7 .658 .628 .599 .569 .539 .510 .481 .453 .386 .324 .269 .220

8 .780 .755 .729 .703 .676 .648 .620 .593 .523 .456 .392 .333

9 .869 .850 .830 .810 .788 .765 .741 .717 .653 .587 .522 .458

10 .927 .915 .901 .887 .871 .854 .835 .816 .763 .706 .645 .583

11 .963 .955 .947 .937 .926 .915 .902 .888 .849 .803 .752 .697

12 .982 .978 .973 .967 .961 .954 .945 .936 .909 .876 .836 .792

13 .992 .990 .987 .984 .980 .976 .971 .966 .949 .926 .898 .864

14 .997 .996 .994 .993 .991 .989 .986 .983 .973 .959 .940 .917

15 .999 .998 .998 .997 .996 .995 .993 .992 .986 .978 .967 .951

16 .999 .999 .999 .999 .998 .998 .997 .996 .993 .989 .982 .973

17 1.000 1.000 1.000 .999 .999 .999 .999 .998 .997 .995 .991 .986

18 1.000 1.000 1.000 1.000 .999 .999 .998 .996 .993

19 1.000 .999 .999 .998 .997

20 1.000 1.000 .999 .998

21 1.000 .999

22 1.000

Issue 16, September 2013 Page 11

Integrated Provisioning Services The Mathematical Model

POISSON TABLES (continued)

Estimated Demand

m 11 12 13 14 15 16 17 18 19 20 21 22

11 .579 .462 .353 .260 .185 .127 .085 .055 .035 .021 .013 .008

12 .689 .576 .463 .358 .268 .193 .135 .092 .061 .039 .025 .015

13 .781 .682 .573 .464 .363 .275 .201 .143 .098 .066 .043 .028

14 .854 .772 .675 .570 .466 .368 .281 .208 .150 .105 .072 .048

15 .907 .844 .764 .669 .568 .467 .371 .287 .215 .157 .111 .077

16 .944 .899 .835 .756 .664 .566 .468 .375 .292 .221 .163 .117

17 .968 .937 .890 .827 .749 .659 .564 .469 .378 .297 .227 .169

18 .982 .963 .930 .883 .819 .742 .655 .562 .469 .381 .302 .232

19 .991 .979 .957 .923 .875 .812 .736 .651 .561 .470 .384 .306

20 .995 .988 .975 .952 .917 .868 .805 .731 .647 .559 .471 .387

21 .998 .994 .986 .971 .947 .911 .861 .799 .725 .644 .558 .472

22 .999 .997 .992 .983 .967 .942 .905 .855 .793 .721 .640 .556

23 1.000 .999 .996 .991 .981 .963 .937 .899 .849 .787 .716 .637

24 .999 .998 .995 .989 .978 .959 .932 .893 .843 .782 .712

25 1.000 .999 .997 .994 .987 .975 .955 .927 .888 .838 .777

26 1.000 .999 .997 .993 .985 .972 .951 .922 .883 .832

27 .999 .998 .996 .991 .983 .969 .948 .917 .877

28 1.000 .999 .998 .995 .990 .980 .966 .944 .913

29 1.000 .999 .997 .994 .988 .978 .963 .940

30 .999 .999 .997 .993 .987 .976 .959

31 1.000 .999 .998 .996 .992 .985 .973

32 1.000 .999 .998 .995 .991 .983

33 1.000 .999 .997 .994 .989

Issue 16, September 2013 Page 12

Integrated Provisioning Services The Mathematical Model

© AIRBUS S.A.S. All rights reserved. Confidential and

proprietary document.

This document and all information contained herein is the sole

property of AIRBUS S.A.S. No intellectual property rights are

granted by the delivery of this document or the disclosure of its

content. This document shall not be reproduced or disclosed to a

third party without the express written consent of AIRBUS S.A.S.

This document and its content shall not be used for any purpose

other than that for which it is supplied. The statements made herein

do not constitute an offer. They are based on the mentioned

assumptions and are expressed in good faith. Where the supporting

grounds for these statements are not shown, AIRBUS S.A.S. will be

pleased to explain the basis thereof.

AIRBUS, its logo, A300, A310, A318, A319, A320, A321, A330,

A340, A350, A380, A400M are registered trademarks

Airbus Material, Logistics and Suppliers

Integrated Provisioning Services

Weg beim Jäger 150

22335 Hamburg, Germany

email: material-readiness.provisioning@airbus.com

Phone: +49.40.50 76 0

Issue 16, September 2013 Page 13

You might also like

- Managing reverse logistics using system dynamics: A generic end-to-end approachFrom EverandManaging reverse logistics using system dynamics: A generic end-to-end approachNo ratings yet

- Maintenance Management Program: FOR Irrigation InfrastructureDocument49 pagesMaintenance Management Program: FOR Irrigation InfrastructureahmedNo ratings yet

- System Engineering Article 2Document3 pagesSystem Engineering Article 2AuslanderNo ratings yet

- MTTR MTBF Calculation PDFDocument5 pagesMTTR MTBF Calculation PDFpradeep singh100% (1)

- 9303 p4 Cons enDocument38 pages9303 p4 Cons enmheskolNo ratings yet

- Mumbai Metro Line 3Document34 pagesMumbai Metro Line 3sanjaig100% (1)

- PDF Article: MTBF Calculations in A NutshellDocument3 pagesPDF Article: MTBF Calculations in A NutshellGustavo AgudeloNo ratings yet

- 12254207Document74 pages12254207Erwin AriolaNo ratings yet

- PM5365Document244 pagesPM5365BaCresNo ratings yet

- Damas Upgrade - Market Participant User Guide For BRPs 0.01Document24 pagesDamas Upgrade - Market Participant User Guide For BRPs 0.01amitea.disv.2014No ratings yet

- Mil STD 1553c - DokumanDocument52 pagesMil STD 1553c - DokumanmücahitNo ratings yet

- 1 1 3 Talstra ADocument13 pages1 1 3 Talstra AAlex PothenNo ratings yet

- O&M Doc For Telecom SitesDocument13 pagesO&M Doc For Telecom SitesJose SegorbeNo ratings yet

- Optimization in Modern Power Systems DTU Course 31765: Lecture NotesDocument48 pagesOptimization in Modern Power Systems DTU Course 31765: Lecture NotesAwol AbduNo ratings yet

- Modelo Matematico ComprasDocument39 pagesModelo Matematico ComprasLenyn TorresNo ratings yet

- Saturn FinalReport v6.1Document74 pagesSaturn FinalReport v6.1Anonymous g8YR8b9No ratings yet

- 18 Scheduled MaintenanceDocument20 pages18 Scheduled MaintenanceUGINo ratings yet

- Getting To Grips With The Cost IndexDocument105 pagesGetting To Grips With The Cost Indexjhonnbra100% (1)

- Frankfurt Acdm 1Document42 pagesFrankfurt Acdm 1IgnacioNo ratings yet

- Machine Readable Travel Documents: Eighth Edition, 2021Document40 pagesMachine Readable Travel Documents: Eighth Edition, 2021Hao VanNo ratings yet

- WEG CFW300 Modbus Rtu User Manual 10003806158 enDocument27 pagesWEG CFW300 Modbus Rtu User Manual 10003806158 enandersonNo ratings yet

- Mining EarthmovingDocument17 pagesMining EarthmovingLatha100% (1)

- Operation Manual: TPS52-F31Document116 pagesOperation Manual: TPS52-F31chao wangNo ratings yet

- ITTC Guidelines CFDDocument19 pagesITTC Guidelines CFDFauzan MahadityaNo ratings yet

- Overcurrent Relay Coordination in A Grid-Connected Microgrid SystemDocument5 pagesOvercurrent Relay Coordination in A Grid-Connected Microgrid SystemWirangga Septiano PutraNo ratings yet

- Slva 432Document16 pagesSlva 432Nikos LambNo ratings yet

- Material PlanningDocument44 pagesMaterial PlanningSiti Rizka FauziyahNo ratings yet

- Guyana LTSA Indicative Price To EPC 8x SGT700 33 MWDocument23 pagesGuyana LTSA Indicative Price To EPC 8x SGT700 33 MWJose FavaNo ratings yet

- ZXUR 9000 UR13 UMTS Dimension PricipleDocument22 pagesZXUR 9000 UR13 UMTS Dimension PricipleMokbelNo ratings yet

- Toc 001Document1 pageToc 001technoramaNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship CFD Ap-PlicationsDocument20 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship CFD Ap-PlicationsK Divya Soujanya oe18m001No ratings yet

- Machine Rates For Selected Forest Harvesting MachinesDocument32 pagesMachine Rates For Selected Forest Harvesting MachinesRuben DarioNo ratings yet

- Intro To FDMDocument90 pagesIntro To FDMLisbella SebastianNo ratings yet

- Generic ATM Interface User Guide PDFDocument90 pagesGeneric ATM Interface User Guide PDFBIDC Email100% (1)

- Itb Part I - Instruction To BiddersDocument16 pagesItb Part I - Instruction To BiddersilsaNo ratings yet

- Protection SchemesDocument33 pagesProtection SchemesAdhyartha KerafNo ratings yet

- 2G Optimization Trial ReportDocument21 pages2G Optimization Trial Reportshirjeel1981100% (2)

- FMDS0517Document38 pagesFMDS0517Buelvas NicanorNo ratings yet

- Aim 2020-1 e RpaDocument30 pagesAim 2020-1 e RpaFarid Widodo SugiartoNo ratings yet

- Ers 5000 Techsim Man Diesel 32/40 Twin Medium Speed Engine + CPP - Ro-Pax FerryDocument217 pagesErs 5000 Techsim Man Diesel 32/40 Twin Medium Speed Engine + CPP - Ro-Pax FerryВалерий РыбалкаNo ratings yet

- MB-Part 3 - FSDocument70 pagesMB-Part 3 - FSrachel.amoilsNo ratings yet

- Tmuk GSM Umts Kpi v31Document31 pagesTmuk GSM Umts Kpi v31Florin IvanNo ratings yet

- 07 3BHS161559-612 MinLib Communication ObjectsDocument28 pages07 3BHS161559-612 MinLib Communication ObjectsManuel Alejandro Retamales GuzmánNo ratings yet

- Uganda REFIT Stakeholder ConsultationDocument37 pagesUganda REFIT Stakeholder ConsultationSubroto KarmokarNo ratings yet

- Car Rental and Leasing Standard - en ESGDocument11 pagesCar Rental and Leasing Standard - en ESGLuis SantosNo ratings yet

- International Telecommunication Union: RecommendationDocument42 pagesInternational Telecommunication Union: Recommendationkumarsaurabh3980No ratings yet

- Combustion Interna (2) KJKJKJKDocument9 pagesCombustion Interna (2) KJKJKJKMaria Jose SaenzNo ratings yet

- Operation & Maintenance Service Report Fourth Quarter 2020 (Q4 2020) Generacion Solar Spa 72.371 MWPDocument56 pagesOperation & Maintenance Service Report Fourth Quarter 2020 (Q4 2020) Generacion Solar Spa 72.371 MWPAlex LambertNo ratings yet

- Manual Multical403 ENGDocument135 pagesManual Multical403 ENGMastershot97WoTNo ratings yet

- BFM136 Modbus PDFDocument79 pagesBFM136 Modbus PDFJason MijNo ratings yet

- A Mixed Integer Programming Approach ForDocument15 pagesA Mixed Integer Programming Approach ForGilles DakouriNo ratings yet

- Tesis Felipe AstudilloDocument116 pagesTesis Felipe AstudilloMartin ArdilesNo ratings yet

- Extended Abstract - RAMS Analysis of Railway Track Infrastructure (Reliability, Availability, Maintainability and Safety)Document14 pagesExtended Abstract - RAMS Analysis of Railway Track Infrastructure (Reliability, Availability, Maintainability and Safety)RubenNo ratings yet

- 03 KPI DefinitionDocument39 pages03 KPI Definitiongh_jazaniNo ratings yet

- Modbus2300 PDFDocument494 pagesModbus2300 PDFmaurosergiorovettaNo ratings yet

- Attachment 0Document25 pagesAttachment 0amourqtriNo ratings yet

- Technical NotesDocument113 pagesTechnical NotesNovianto Arif SetiawanNo ratings yet

- Queuing Analysis: Lecture Notes in Transportation Systems EngineeringDocument13 pagesQueuing Analysis: Lecture Notes in Transportation Systems EngineeringGhulam Hazrat RezaiNo ratings yet

- Maintenance StrategiesDocument6 pagesMaintenance Strategiestapera_mangeziNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument27 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00 DefinitionsDocument33 pagesAircraft Weighing Report 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing ReportsDocument31 pagesAircraft Weighing ReportsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report Table of Content 2.00 DefinitionsDocument31 pagesAircraft Weighing Report Table of Content 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document27 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument27 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2.00: Weight CGDocument30 pagesAircraft Weighing Report 2.00: Weight CGEdwar ZulmiNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- PDF F WBM Xax Standard ST8 Eu 20170209 WBMDocument472 pagesPDF F WBM Xax Standard ST8 Eu 20170209 WBMEdwar ZulmiNo ratings yet

- Weight and Balance Manual: Reference: Xax A330-300 Fleet WBM Issue Date: 09 Feb 17Document6 pagesWeight and Balance Manual: Reference: Xax A330-300 Fleet WBM Issue Date: 09 Feb 17Edwar ZulmiNo ratings yet

- General Summary of Highlights: Weight and Balance ManualDocument10 pagesGeneral Summary of Highlights: Weight and Balance ManualEdwar ZulmiNo ratings yet

- Aircraft Weighing Report Table of Content 2.00 DefinitionsDocument32 pagesAircraft Weighing Report Table of Content 2.00 DefinitionsEdwar ZulmiNo ratings yet

- Reliability Programs: Civil Aviation Advisory Publication July 2001Document15 pagesReliability Programs: Civil Aviation Advisory Publication July 2001mclarenmercmanNo ratings yet

- Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgDocument12 pagesIntegrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgEdwar ZulmiNo ratings yet

- Integrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgDocument34 pagesIntegrated Provisioning Services: Airbus Material, Logistics and Suppliers, HamburgEdwar ZulmiNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument21 pagesAlert Operators Transmission - Aot: Customer Services DirectorateEdwar ZulmiNo ratings yet

- eCIDS Deviations List ISI 23.73.00027 - A320 FAMDocument5 pageseCIDS Deviations List ISI 23.73.00027 - A320 FAMEdwar ZulmiNo ratings yet

- Conventional Detector Bases: Ns6 and Ns4 Series BaseDocument2 pagesConventional Detector Bases: Ns6 and Ns4 Series Baseuygar öztürkNo ratings yet

- And Periwinkle Modern Nature Tree Planting PresentationDocument24 pagesAnd Periwinkle Modern Nature Tree Planting Presentationchrist fellowshipNo ratings yet

- Fact CSU501Document2 pagesFact CSU501ankurNo ratings yet

- Lab-2-Course Matlab Manual For LCSDocument12 pagesLab-2-Course Matlab Manual For LCSAshno KhanNo ratings yet

- Overload ManualDocument16 pagesOverload ManualUuganbayar TsevegsurenNo ratings yet

- Programming Microcontrollers Using Openocd On Raspberry PiDocument17 pagesProgramming Microcontrollers Using Openocd On Raspberry PiСветлозар АнгеловNo ratings yet

- Contract Title Contract No. Contractor Name and Address Original Contract Value (KWD) RFP No. Duration (Days) S. NoDocument2 pagesContract Title Contract No. Contractor Name and Address Original Contract Value (KWD) RFP No. Duration (Days) S. NoKoteswar MandavaNo ratings yet

- MBD Blockchain e Brochure 6 MonthsDocument22 pagesMBD Blockchain e Brochure 6 MonthsZrake 24No ratings yet

- ThorX6 USER MANUALDocument22 pagesThorX6 USER MANUALMustafa Sabry100% (1)

- Data Structure - Lesson 1Document4 pagesData Structure - Lesson 1Lady Marj RosarioNo ratings yet

- Dockerfile Reference Docker DocsDocument68 pagesDockerfile Reference Docker DocsRamaroson JosoaNo ratings yet

- View Full VersionDocument14 pagesView Full VersionHadi SusenoNo ratings yet

- Speeduino Manual-1Document16 pagesSpeeduino Manual-1Makson VieiraNo ratings yet

- 5 Instalasi Dan Konfigurasi VPN ServerDocument19 pages5 Instalasi Dan Konfigurasi VPN ServerRendra SaputraNo ratings yet

- Helvarnet CrestronDocument46 pagesHelvarnet Crestroncnrk777inNo ratings yet

- 350201F - O&m - I&mdocs 500-55 (-Ce)Document250 pages350201F - O&m - I&mdocs 500-55 (-Ce)Euler Mairena100% (1)

- Federated Learning ArticleDocument68 pagesFederated Learning Articlesunk86No ratings yet

- 00 IntroductionDocument17 pages00 IntroductionMonica AlaminoNo ratings yet

- Technical Notification: Using The Old TT-3026x Cable Together With The TT-3027x TransceiverDocument5 pagesTechnical Notification: Using The Old TT-3026x Cable Together With The TT-3027x TransceiverNishant PandyaNo ratings yet

- HANA ABAP MiniChecksDocument16 pagesHANA ABAP MiniCheckss4 hanaNo ratings yet

- Epson Command Code For ProgrammingDocument131 pagesEpson Command Code For ProgrammingSudarno SilabanNo ratings yet

- Transcript Russia CryptoDocument13 pagesTranscript Russia CryptoSean PowersNo ratings yet

- Literature Review Network SecurityDocument8 pagesLiterature Review Network Securityc5q8g5tz100% (1)

- tNavReleaseNotesEnglish PDFDocument220 pagestNavReleaseNotesEnglish PDFstbernardjNo ratings yet

- Desi QnA MentoringDocument9 pagesDesi QnA MentoringCharan KasanagottuNo ratings yet

- Automata Theory-NotesDocument92 pagesAutomata Theory-NotesMansi MalapNo ratings yet

- WLS Psu 12.2.1.3.0Document21 pagesWLS Psu 12.2.1.3.0Marco FigueroaNo ratings yet

- The Ultimate Guide To HL Global Politics PresentationsDocument17 pagesThe Ultimate Guide To HL Global Politics Presentationsayah sadiehNo ratings yet

- Gv8 Tutorial Manual-4Document60 pagesGv8 Tutorial Manual-4Pedro JaraNo ratings yet

- Fortisiem External Systems Configuration Guide PDFDocument622 pagesFortisiem External Systems Configuration Guide PDFaykargilNo ratings yet