Professional Documents

Culture Documents

RCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked Example

Uploaded by

Al Jameel0 ratings0% found this document useful (0 votes)

35 views13 pagesRCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked Example

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked Example

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views13 pagesRCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked Example

Uploaded by

Al JameelRCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked Example

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

Lectures on Reinforced Concrete Design

Solid Slabs

(Part 3)

(One-Way Solid Slabs)

Continuous Slab Example

Example 2: Continuous One-Way Slabs

The four-span slab shown supports a live load of 3 kN/m2, plus floor finishes and

ceiling load of 1 kN/m2, The characteristic material strengths are f,,=30 N/mm? and

£,=460 N/mm’, Assume 1hr fire resistance and mild exposure. All beams are 250mm

wide. —oe — ™

4@4,5=18m

20 -fU U UU

INITIAL PROPORTIONING

Long/Short = 10/4.5=2.22 >2 Onewayslab. Span =4.5m

Table 3.9 Span/d =26

Assume modification factor m= 1.3

Therefore, the effective depth d= 4500/(1.3x26) =133 mm

Durability

Table 3.3 Cover for mild durability = 25

Table 3.4 Cover for fire resistance = 20

Therefore Cover = 25

Assume bar size = 10 mm, Area of bar = 79 mm?

Totaldepth h = 133+25+10/2 =163 Say h=175mm

Therefore:

Effective depth d = 175-25-10/2 =145mm

k

3.4.6.3 Span/effective depth ratio for a

rectangular or flanged beam

‘The basic spaneffective depth ratios for beams are

given in table 39. These are based on limiting the total

deflection to sparv250 and this should normally ensure

that the part of the deflection occurring after

construction of finishes and partitions will be limited

to sparv500 or 20 mum, whichever is the lesser, for

spans up to 10m. For values of by/b greater than 0.3,

linear interpolation between the values given in

table 39 for rectangular sections and for flanged beams

with by/b of 0.3 may be used.

‘Table 3.9 Basic span/effective depth ratio for

rectangular or flanged beams

‘Support conditions | Rectangular [Flanged beams

seccions | with

esas

Cantilever 7 56

Simply supported 20 160

Contingpus 6 208

FINAL PROPORTIONING

Loading:

self weight = h*24 =4.2 kN/m2

Finishes =1 kN/m?

services =0 kN/m2

Partitions =0__kN/m?

Total Dead Load g, =5.2 kN/m?

Imposed q, =3 kN/m2

Total design ultimate load =1.4x5.2 + 1.6x3 = 12.08 kN/m?

Bending Moments:

Lx= 4.5, Ly=10, Area of bay= 45 m2

Since q, < 1.259, and the spans are equal, we can use Table 3.12

Table 3.12: F = 12.08 x 4.5 = 54.36 KN, /= 4.5m

Outer support " 0.0

First span 0.086x54.36x4.5= 21.0 kNm/m

First interior support 0.086x54.36x4.5= 21.0 kNm/m

Interior spans 0.063x54.36x4.5= 15.4 kNm/m

interior supports 0.063x54.36x4.5= 15.4 kNm/m

‘Table 3.12 Ultimate bending moment and shear forces in one-way spanning slabs

Se Saar aaa oe

= cae [ae |e,

= Sonia ox [ies [Ee

Tomer | Nearanias faves Ne ae

kee ESE [Gt Saas

Moment 0 0.086FT 0.0471 0.075FI —0.086FU 0.063FL —0.063F1

‘Shear 04F a O46F _— 0.6F —_ O.5F

See ee

ene

7 k

Fy = WyL, (KN) FL (KN)

W2 (kN/m)

wd 0

:;

7X

ZS L, a Lo

M(kN.m/m) 0. +0.086F,L, -0.086(F,L,+FL,) +0.063F,

2

Shear (kN/m) +0.4F, -0.6F, +0.5F, -0.5F,

Reinforcement:

(a) Main Steel:

K=M/bd?f.,,

3.4.4.4 Zid= 0.5+sqrt(0.25-K/0.9) Asmin= 189 (T8@250)

Table 3.12: M K Zid ASreq Spry

Outer support 0.0 0.0 0.95 189 201 T8@250

First span 21.0 0.0334 0.95 349 403 T8@125

First interior support 21.0 0.0334 0.95 349 403 T8@125

Interior spans 15.4 0.0244 0.95 256 288 T8@175

Interior supports 15.4 0.0244 0.95 256 288 T8@175

(b) Distribution Steel:

Table 3.25: As,,;,, =0.0013bh = 0.0013x1000xh= 188.5 T8@250

k

Check Deflection:

Mwax (+) = 21.0 kN.m/m

Table 3.9: Basic Span/d = 26

Mibd? = 10

A

Table 3.10: Steel stress f,=2 f, Av, 1

3°" A, roe Bs

fs=2/3x(349/403)x460 = 265.5 Nimm?

modification factor = m=055+—A7 So = 1.48

129

Allowable Span/d = 26x1.48 =38.4

Actual Span/d = 31.0< 38.4 Deflection OK

Vmax = 0.6x54.36 = 32.6 KN/m

v =Vmax/(bd) = 0.225 N/mm?

v,= Lesser of (0.8Vfcu,5) = 4.38 N/mm2

Since v189 Steel area OK

‘Table 3.8 Values of v. design concrete shear stress

is Bective depeh

ls a i oi Ya

Wem? Nini? (men | Niman? | Nam? ‘| Nin? (Ni? Na?

= 015 045) 043 oat 0.40 039) 038 036 034

025 058. O51 049) 047 0.46 04s 043 040

(050 067 064 062 0.60 058 056 Ont 050

075 O77 073 at 068 0.66 065 0.62 057

1.00 084 081 078 075 073 oni 0.68 06s

150 097 092 089 086 083 O81 078 072,

2.00 1.06 102, 098 095 092: 089 086 080

23.00 [122 16 12) 108) 1.05 102) 098 091

‘NOTE 1. Allowance has been made in dwse figures for a Ym, of 125,

'NOTE2 The values in the table are derived from the expression”

a7oftoader eg) (40015

where

100g

TEP sone be ten as rete than

© coat ot be akon a es than 1

For characteristic concrete strengths greater than 25 Nine, the values in this table may be multiplied by (f/25)*. The value off.

should not be taken as greater than 40

5076 of mid.span ste!

Detailing:

Figure 3.25: {9.14}

50%Top Steel extends =0.3x4.5 = 1.35m from face of support

50% Top Steel curtailed @ 0.15x4.5 0.675m from face of support

60% Bottom Steel Extends to =0.2x4.5 =0.9m from C.L. of support

Top Steel at end support: cl. 3.12.10.3.2:

50% of bottom=403/2= 201 mm2/m < AS pin

So use As,,;,, i.e. T8@250 cle (Length=0.15x4.5=0.675m in the span)

Anchorage at end support: cl. 3.12.9.3.c:

Since v<0.5vc, Bars can be extended max(250/3, 30)= ail (Straight bars)

ql

To ib To 18-260

a 2 4

4 e 4

ic [| re- 125 -Bot

a |

78-250 198-125 Z18-115 18-125 19-250

Uo Nre-125Tre-2s01T“te-175 Yre-2501J \te-s75 "18-250L] | \ 9-125 l

Reinforcement details in the continuous one-way slab example

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

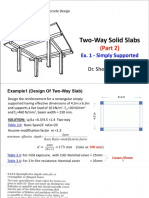

- RCD - Two-Way Solid Slabs (Part 2) - Simply Supported - Worked ExampleDocument14 pagesRCD - Two-Way Solid Slabs (Part 2) - Simply Supported - Worked ExampleAl JameelNo ratings yet

- RCD - Solid Slabs (Part 1) - One Way Solid SlabDocument24 pagesRCD - Solid Slabs (Part 1) - One Way Solid SlabAl JameelNo ratings yet

- Lateral Torsional Buckling: Icon LegendDocument3 pagesLateral Torsional Buckling: Icon LegendAl JameelNo ratings yet

- RCD - Two-Way Solid Slabs (Part 1)Document22 pagesRCD - Two-Way Solid Slabs (Part 1)Al JameelNo ratings yet

- RCD - Solid Slabs (Part 2) - Simply Supported One-Way Slab - Worked ExampleDocument13 pagesRCD - Solid Slabs (Part 2) - Simply Supported One-Way Slab - Worked ExampleAl JameelNo ratings yet

- RCD - Beams (Part 3) - Continuous BeamsDocument21 pagesRCD - Beams (Part 3) - Continuous BeamsAl JameelNo ratings yet

- RCD - Beams (Part 2) - Design ExampleDocument17 pagesRCD - Beams (Part 2) - Design ExampleAl JameelNo ratings yet

- A Car Free TownDocument55 pagesA Car Free TownAl JameelNo ratings yet

- DP Column-Beam-SlabDocument1 pageDP Column-Beam-SlabAl JameelNo ratings yet

- Design Criteria for FootbridgesDocument32 pagesDesign Criteria for FootbridgessuprayitnoNo ratings yet

- First floor beam layoutDocument1 pageFirst floor beam layoutAl JameelNo ratings yet

- Samaila Consultant Limited design calculations for single box culvertDocument8 pagesSamaila Consultant Limited design calculations for single box culvertebed_meleck100% (2)

- Column Design As Per BS 8110-1:1997Document16 pagesColumn Design As Per BS 8110-1:1997Al JameelNo ratings yet

- Watershed Analysis: Autocad Civil 3D 2010 Education Curriculum Unit 4: Environmental DesignDocument7 pagesWatershed Analysis: Autocad Civil 3D 2010 Education Curriculum Unit 4: Environmental DesignAl JameelNo ratings yet

- Nieuwen Huijsen and Khreis 2016 Car-Free CitiesDocument13 pagesNieuwen Huijsen and Khreis 2016 Car-Free CitiesAl JameelNo ratings yet

- Engineering Report Details Infrastructure Works for 31-Lot Residential DevelopmentDocument25 pagesEngineering Report Details Infrastructure Works for 31-Lot Residential DevelopmentAl Jameel100% (1)

- Strategies For A Car-Free Oslo - Action Plan For Increased City LifeDocument5 pagesStrategies For A Car-Free Oslo - Action Plan For Increased City LifeAl JameelNo ratings yet

- The Car Free City Model UT11013FU1Document12 pagesThe Car Free City Model UT11013FU1Al JameelNo ratings yet

- Project SampleDocument1 pageProject SampleAl JameelNo ratings yet

- Citizens Guide LEED-NDDocument44 pagesCitizens Guide LEED-NDDavid Moya ArancibiaNo ratings yet

- Dua CoronavirusDocument11 pagesDua CoronavirusOmer MubbasherNo ratings yet

- BS 08515-2009: Rainwater Harvesting Systems - Code of PracticeDocument52 pagesBS 08515-2009: Rainwater Harvesting Systems - Code of PracticeAl JameelNo ratings yet

- Alpha FCDocument10 pagesAlpha FCAl JameelNo ratings yet

- FC 400Document1 pageFC 400Al JameelNo ratings yet

- Romac Flanged Couplings for Water and Sewer PipesDocument3 pagesRomac Flanged Couplings for Water and Sewer PipesAl JameelNo ratings yet

- Style Cl2: Wider Range .80" W/ Removable LugsDocument1 pageStyle Cl2: Wider Range .80" W/ Removable LugsAl JameelNo ratings yet

- BS648-1964 Weights of Building Materials PDFDocument50 pagesBS648-1964 Weights of Building Materials PDFJeff Anderson Collins71% (7)

- Repair clamps for water and sewer pipes under 40 charactersDocument1 pageRepair clamps for water and sewer pipes under 40 charactersAl JameelNo ratings yet

- Style Cl1: Normal Range .40" W/ Removable LugsDocument1 pageStyle Cl1: Normal Range .40" W/ Removable LugsAl JameelNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)