Professional Documents

Culture Documents

Design and Fabrication

Uploaded by

samadhan khaireOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication

Uploaded by

samadhan khaireCopyright:

Available Formats

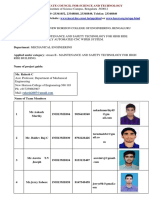

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

Design and Fabrication of Semi-Automatic Garbage Cleaner

Machine

Asst/Prof. A. Manivannan1,A.H. Mohamed Marwan2, R. Rabin3, N. Mohamed

Noorudeen4,

1

Assistant Professor,Department of mechanical engineering,Krishnasamy College of

Engineering and Technology, Cuddalore, Tamil Nadu, India

234

UG scholars, Department of mechanical engineering,Krishnasamy College of Engineering

and Technology, Cuddalore, Tamil Nadu, India

*Corresponding Author

E-Mail Id:

mohamedmarwan53@gmail.com,mohammednoorudeen0@gmail.com,rabinjos2000@gmail

.com,amanivannan57@gmail.com

ABSTRACT

To cleaning the beach properly, we are come up with new project, this project is not only

clean the garbage but also separate the garbage by density difference so it is easy to dispose

the waste in proper manner. Here the motor is plays a major role, In this motor, it consist

have high torque low power motor and conveyor belt with strainer is connect with its motor

chain This motor is responsible full driving mechanism, when the motor rotate it take the

wastage from the sand and it transferred to the storage bucket. Thus the waste from the

bucket is shifted to the recycling process hence pollution can be minimised and also beach

should cleaned.

Keyword: conveyor belt;strainer, recycle, chain

INTRODUCTION mechanism and conveyor with strainer is

In this era of world, beach is the best connect with motor chain so when motor

attractive tourism place so attract the rotate the conveyor is also rotate hence the

tourist, Beach cleaning is play a major role waste from the beach is taken away

for this purpose we should need some through strainer and it was transferred to

machine to clean the beach properly. On the wastage container. In our final year

this way, our project plays a vital role in project we are planned to implement the

cleaning process and very helpful to waste recycling machine so it may be

segregation of waste material. In this 21th useful to make such thing by recycled

century people were moving toward material, we are hopefully that our project

digitalization and automation so most of is should be eco friendly, Pollution free

the peoples were attracted through this and it might be very helpful for labour who

type of “smart work”. This machine are all involved in cleaning work.

consist of motor, It drives a whole

HBRP Publication Page 1-7 2020. All Rights Reserved Page 1

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

Fig. 1: Front View.

WORKING PRINCIPLE raking and shifting technology

This machine is placed in beach, So that

floating wastage on beach sand can be Ranking Method

taken through strainer and transferred to This machine is used in dry and wet sand,

storage container. When motor is started it it has “n” number of strainer on the

drive the shaft it connect through the belt conveyor, this method removes waste from

and then the sprocket in the shaft is also smaller size like pebbles, shards of glass,

rotate so that chain is moving around the and cigarette butts to larger debris, like

sprocket while moving it takes the dust seaweed and driftwood. It only remove the

from sand by strainer and it transfer to debris on the sand and it travel at high

storage tank. Finally wastages is speed

segregated by density difference, In future

the waste material is shifted to recycling Shifting Technology

machine for recycling process, it helps to This method is mostly used in dry sand

keep plastics out of the oceans and reduce and soft surface, it collect sand and waste

the amount of plastic in circulation. through the pick-up blade onto the

vibration screening belt of the vehicle,

sand is leaved at behind of the vehicle and

waste is gathered at collecting tray then it

shifted to the back side of the vehicle, size

of the waste is was predicted by the size of

hole in installed screen.

Combined Ranking and Shifting

Technology

Fig. 2: Pulley Belt Mechanism. It is the combination of both ranking and

shifting technology both are same as

TYPES OF BEACH CLEANING Normal method, It have has rotating tines

Manual method to carry sand and waste onto the screening

Automatic method belt, Instead of using pick up blade, By

Raking technology adjusting the position of tines to more

Shifting technology Combined effectively guide waste material

HBRP Publication Page 1-7 2020. All Rights Reserved Page 2

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

METHODOLOGY

DESIGN CALCULATION below formula,

Motor Specification α =360/z,

Voltage 230 V where, z=16 (no.of.teeth)

=360/16 α=22.5°

Rated speed 1440 rpm Dia of roller, dr=(5/8)*(p),(pitch=1.5cm)

Controlled speed 700 rpm =(5/8)*1.5

dr=0. 937 cm

Velocity of chain, v=Z*p*N/60

Current 2 Amp =(16*0.0156*700)/60

Phase 1 v= 2.9 m/s lp=2(a/p)+((z1+z2)/2)+((z2-

Frequency 50 Hz z1)/2π)2

Power 187 w =52

Length of chain,L= lp*p l p –No of link,

Torque of motor is calculated by using p-chain pitch

below formula, Length of chain = 52*3

P=2πNT/60 187=(2*π*700*T)/60 T=2.55 =156 cm

N-m, A =e+ 2-8M /4) *p

=(36+ (362))/4 *1.5

Chain Calculation =67.1 cm,

The below formula`s were referred from Belt Calculation

‘DTS’ book Nominal pitch length of the B

2

Pitch angle of chain is calculated by using elt,L={2C+(π/2)(D+d)+{((D-d) /4C)}}

HBRP Publication Page 1-7 2020. All Rights Reserved Page 3

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

=(2*42.5)+(π/2)((606-6)2/(4*42.5)) L=85 ACT

2

cm, =A+ -B)

By referring data book pg no:7.53

Ks=1(rolling mill) Calculation of total load on the driving

By referring data book pg:7.68 kα=180°- side of the chain(pt),

{(D-d)/C}*60 {total load on driving side}={tangential

=180-((6.6-6)/42.5)*60 B=0.045 cm CACT=32.59 cm2

=180-0.84 kα=179.16 Design power=(rated power*load

kd=0.7(it differ according to pulley dia) correction factor)/(arc of contact

Design power=(187*1)/(179.16*0.7) factor*small pulley factor)

=1.49W force due to power

transmission}+{centrifugal tension due to

Sprocket aped of the chain}+{tension due to chain

Pitch circle dia,D=P/(Sin(180/z) ) sagging}

D=1.5/(Sin(180/16)) PT= Pt +PC+PS

D=7.68 cm To find tangential force(Pt),

Roller seating Pt=1020N/v,

N=Transmitted power in KW=9.5kw

radius,ri(max)=0.505dr+0.0693 V=Velocity of chain in m/s,

Pt=1020*9.5/(2.8)

=(0.505*0.937)+(0.0693 =3460.71N

=0.54 cm 1) Centrifugal tension(Pc)=mv2.

Ri(min)=0.505dr M=mass of chain/metre=1.01 kgf

=0.473 Pc=(1.01)*(2.9)2

Outer dia,D0 =D+0.8dr =8.4941N

= 8.43 cm

Root dia,Df =D-2ri Tension due to sagging(ps),

=7.68-(2*0.54) Ps=k.w.a,

Root dia = 6.6cm K=2 (for more than 40°) (ref psg databook

Roller seating angle,αmax =[120°-90°/z] pg no:7.78)

=[120°-90°/16] W=m.g=1.01*9.81=9.9081N

= 114.37° a=0.671m Ps=2*9.9081*0.671 Ps=13.29N

α min=[140°-90°/z]

=[140°-90°/16] Total load(PT)=Pt+Pc+Ps

=134.4° PT=3460.71+8.4941+13.29

Tooth height above pitch polygon, h a =3482.49N

=0.625p-0.5dr+0.8p/z

=0.625*(1.5)-(0.5*0.937)+(0.8*1.5 /16) COMPONENTS

=0.544cm Sprocket and Chain

Tooth side relief,ba=0.15p Sprocket and chains are used to transfer

= 0.15*1.5 power from one end to other end, here we

=0.225cm have linked conveyor with chain so it carry

Actual centre distance,C A=L/4-π[(D+d)/8] waste from sand and shifted to the beside

A=16.3 cm2 of the vehicle (storage tank)

B=(D-d)2/8

HBRP Publication Page 1-7 2020. All Rights Reserved Page 4

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

Fig. 3: Sprocket and Chain.

Shaft attop of the frame and bottom, there are

Shaft is made up of mild steel and it is four type of shaft,1)Transmission Shaft,

solid circular rod here which is used to 2)Counter Shaft, 3)Line Shaft, 4)Over

transfer power from motor to chain and Head Shaft.

sprocket .There are two shaft are used

Fig. 4: Shaft.

Pulley Fig. 5: V-Pulley.

Pulley is used transmit power from motor

to the shaft by means of using pulley used plummer block as the support of the

through belt, here we preferred v-Belt Plummer block is used to support of the

pulley for the purpose of transfer high shaft and it provide smooth rotation of

power and minimize the loss occurs during shaft, this plummer block are made up cast

power transfer and also slippage can be iron and cast steels also available. Here we

reduced. shaft, there four plummer blocks are used.

Self-aligning ball bearing plummer block

Plummer Block is used for this machine.

HBRP Publication Page 1-7 2020. All Rights Reserved Page 5

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

Fig. 6: Plummer Block.

PHOTOGRAPHIC VIEW

CONCLUSION India. 1955, 519p.

This machine helps us to clean the beach 2. Hunt D. Farm Power and Machinery

and save the ocean lives from pollution, it Management. Laboratory Manual

does not need more number of labours. and Workbook, 7th Ed., Iowa State

There is no direct contact with wastage so University: AMES IOWA. 2002.

that It secured the human health from 3. Joseph C.K. Dibble sticks Donkeys

hazards things .This system helpful to and Diesels. International Rice

make green world with this kind of easy Research Institute, Philippines. 1990.

way, It is low in cost and production 4. Suravej K. RNAM Test Codes&

materials are available at local shops so Procedures for Farm Machinery.

fabrication process are very simplified, Technical Series No 12 Economic and

Working times is low when compared with Social Commission for Asia and the

conventional method. Pacific Regional Network for

Agriculture. 2005. Farm machinery

REFERENCE and crop production management. Co

1. Smith D., Pearson H. Farm machinery opthai printing, Bangkok.

and equipment. Tata McGraw-Hill, 5. Donald K. US Patent number

HBRP Publication Page 1-7 2020. All Rights Reserved Page 6

Advancement in Mechanical Engineering and Technology

Volume 3 Issue 1

4241792: Ground sweeper. 1979. 1976. Available Source:

Available Source: http://www.google.com/pat

6. http://www.google.com/patents/US ents/USPAT405 0518. December

4241792. December 2012. 2012\.

7. Prakobkarn K., Saitthiti B., 9. American Society of Agricultural

Intaravichai S. Design and Engineers, Standards. Agricultural

Construction of Beach Cleaning Machinery Management. 2000.

Trailer by Finite Element Method. Int 10. Daryl L.L. A first course in the Finite

Trans J Eng Manag Sci Tech. Element Method. Third Edition

2012.3(2). Available Source: Brooks/Cole, United States of

http://www.TuEngr.com/V03/111- America. 2002

123.pdf, February 2012.

8. Richard G. US Patent number

4050518: A beach cleaning apparatus.

HBRP Publication Page 1-7 2020. All Rights Reserved Page 7

You might also like

- Chapter 3-MethodologyDocument6 pagesChapter 3-MethodologyChristine SaliganNo ratings yet

- Project Report 2023Document7 pagesProject Report 2023Satyaranjan BeheraNo ratings yet

- Agricultural and Beach Cleaning RobotDocument20 pagesAgricultural and Beach Cleaning RobotChaitanya ShirodkarNo ratings yet

- Balasuthagar 2020 IOP Conf. Ser. Mater. Sci. Eng. 912 022048Document6 pagesBalasuthagar 2020 IOP Conf. Ser. Mater. Sci. Eng. 912 022048ruben dollarzNo ratings yet

- Report 125Document35 pagesReport 125DonNo ratings yet

- 2STM - JoMA E DUSTBINDocument8 pages2STM - JoMA E DUSTBINBhairavi MoreNo ratings yet

- Radio Controlled Beach Cleaning BotDocument6 pagesRadio Controlled Beach Cleaning Botvivin rajNo ratings yet

- (1 5) 2951 11443 1 - Edit FormatDocument5 pages(1 5) 2951 11443 1 - Edit FormatKVSRIT Dept. of MENo ratings yet

- Irjet V4i5711Document4 pagesIrjet V4i5711kumbirai john chiparaNo ratings yet

- Design and Analysis On Ajm NozzleDocument34 pagesDesign and Analysis On Ajm NozzleRahul KolukuluriNo ratings yet

- Sewage Waste Cum Blockage Cleaning Machine - A ReviewDocument6 pagesSewage Waste Cum Blockage Cleaning Machine - A ReviewIJRASETPublicationsNo ratings yet

- Compressive Force Analysis On Piston of Automatic Screw Jack Compression DustbinDocument4 pagesCompressive Force Analysis On Piston of Automatic Screw Jack Compression DustbinPeter JammyNo ratings yet

- Design & Fabrication of Groundnut Sheller MachineDocument5 pagesDesign & Fabrication of Groundnut Sheller MachineAnonymous kw8Yrp0R5rNo ratings yet

- Automatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. SakharkarDocument3 pagesAutomatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. Sakharkarpramo_dassNo ratings yet

- 1 Designing ReportDocument18 pages1 Designing ReportMohamed ArafathNo ratings yet

- Semi Automated Wireless Beach Cleaning RobotDocument3 pagesSemi Automated Wireless Beach Cleaning RobotSanchit KapoorNo ratings yet

- 234 DesignDocument6 pages234 DesignCardo dalisayNo ratings yet

- Design, Fabrication and Evaluation of Wheel Operated SprayerDocument11 pagesDesign, Fabrication and Evaluation of Wheel Operated SprayerSrikhar KondisettyNo ratings yet

- Multipurpose Cleaning RobotDocument5 pagesMultipurpose Cleaning RobotVISHAL ARAVINTH S S (RA2211047010024)No ratings yet

- Enhancement of Surface Integrity Using Spark Assisted Abrasive Flow Machining ProcessDocument8 pagesEnhancement of Surface Integrity Using Spark Assisted Abrasive Flow Machining ProcessTJPRC PublicationsNo ratings yet

- KOM OBT MID-2 Set-1Document7 pagesKOM OBT MID-2 Set-1Konduru Vinay Kumar ReddyNo ratings yet

- Swachh Yantramanav (A Multipurpose Cleaning Robot)Document5 pagesSwachh Yantramanav (A Multipurpose Cleaning Robot)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Build of Rate (Building Works)Document32 pagesBuild of Rate (Building Works)hanifanip14102001No ratings yet

- Dust Final Report NDocument25 pagesDust Final Report NPathan SahilNo ratings yet

- Layers of Flexible PavementDocument52 pagesLayers of Flexible Pavementsavan chavanNo ratings yet

- Fully Automated Grass CutterDocument48 pagesFully Automated Grass CutterV ArvindNo ratings yet

- Group 4Document64 pagesGroup 4Devendra Pratap SinghNo ratings yet

- Design and Construction of Dried Cassava Pellets Grinding MachineDocument11 pagesDesign and Construction of Dried Cassava Pellets Grinding MachineFemi TokunboNo ratings yet

- Irjet V7i4151Document3 pagesIrjet V7i4151Belha HentatiNo ratings yet

- CD Muthu LMMDocument47 pagesCD Muthu LMMDANIEL DASNo ratings yet

- Cement Process Engineering Vade-Mecum: 4. MillingDocument21 pagesCement Process Engineering Vade-Mecum: 4. Millinganwar saeedNo ratings yet

- Arduino Based Automated Braking Control System To Enhance Road SafetyDocument22 pagesArduino Based Automated Braking Control System To Enhance Road SafetyShreya ModiNo ratings yet

- Smart Beach Cleaner VehicleDocument6 pagesSmart Beach Cleaner VehicleVishwajitNo ratings yet

- Department of Mining Engineering: Indian Institute of Technology (Indian School of Mines) DhanbadDocument25 pagesDepartment of Mining Engineering: Indian Institute of Technology (Indian School of Mines) DhanbadAditya HimanshuNo ratings yet

- Automizing The Design of Francis Turbine Spiral CaseDocument10 pagesAutomizing The Design of Francis Turbine Spiral CaseGökhan ÇiçekNo ratings yet

- Review ...Document27 pagesReview ...251 Pradeep RNo ratings yet

- Irjet V5i1106 PDFDocument5 pagesIrjet V5i1106 PDFImran PashaNo ratings yet

- In Computer Science and Engineering Submitted byDocument27 pagesIn Computer Science and Engineering Submitted bybalaya babuNo ratings yet

- Project Presentationon AutomaticbrakingsystemDocument21 pagesProject Presentationon AutomaticbrakingsystemUtsav YadavNo ratings yet

- BEACH Cleaning RobotDocument7 pagesBEACH Cleaning RobotLeo BoyNo ratings yet

- Design and Fabrication of Automated Drain Cleaner IJERTCONV6IS04051 PDFDocument2 pagesDesign and Fabrication of Automated Drain Cleaner IJERTCONV6IS04051 PDFSathish.SNo ratings yet

- Autonomous Vaccum Cleaner ReportDocument10 pagesAutonomous Vaccum Cleaner ReportOmkar KarnikNo ratings yet

- Disposal of Solid Waste by Land FillingDocument19 pagesDisposal of Solid Waste by Land FillingAdithya ShripathiNo ratings yet

- Faculty of Civil and Environmental EngineeringDocument31 pagesFaculty of Civil and Environmental Engineeringalisa naziraNo ratings yet

- Design PDFDocument3 pagesDesign PDFKochuzNo ratings yet

- Telerobotics For Hang-Up Assessment and Removal - An Idea Whose Time Has ComeDocument12 pagesTelerobotics For Hang-Up Assessment and Removal - An Idea Whose Time Has ComeMatías Ignacio Loyola GaldamesNo ratings yet

- Design and Development of Plastic Recycle Machine Ijariie4084Document6 pagesDesign and Development of Plastic Recycle Machine Ijariie4084Mohamed MoradNo ratings yet

- Fabrication of Automatic Sewage Cleaning System by Using DC MoterDocument9 pagesFabrication of Automatic Sewage Cleaning System by Using DC MoterNaveen KumarNo ratings yet

- SPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyDocument12 pagesSPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyterminalcbrNo ratings yet

- Design and Fabrication of Paper Cutter 1Document29 pagesDesign and Fabrication of Paper Cutter 1Pát ŔiçkNo ratings yet

- Autonomous Trash Collecting RobotDocument4 pagesAutonomous Trash Collecting RobotakashlogicNo ratings yet

- Trashbot: A Beach Cleaning RobotDocument5 pagesTrashbot: A Beach Cleaning RobotVIVA-TECH IJRINo ratings yet

- Vibration Monitoring Crusher CoalDocument8 pagesVibration Monitoring Crusher CoalJay SantosNo ratings yet

- Automated Grass Cutter-1Document15 pagesAutomated Grass Cutter-1Mwiza LuhangaNo ratings yet

- Ralla AnanthapuramuDocument72 pagesRalla AnanthapuramuVannurSwamyNo ratings yet

- Automatic Floor Cleaning Robot: Mariappan. S Thanga Dhinesh S Esakki Durai M Bala Sathya VDocument20 pagesAutomatic Floor Cleaning Robot: Mariappan. S Thanga Dhinesh S Esakki Durai M Bala Sathya VSmolin ReniNo ratings yet

- Aqua Drone Ieee PaperDocument3 pagesAqua Drone Ieee PaperAkash ShahuNo ratings yet

- Paper 1 - Overview of Geometric Design of Roads 2013aDocument38 pagesPaper 1 - Overview of Geometric Design of Roads 2013aObinna ObiefuleNo ratings yet

- Energizing Green Cities in Southeast Asia: Applying Sustainable Urban Energy and Emissions PlanningFrom EverandEnergizing Green Cities in Southeast Asia: Applying Sustainable Urban Energy and Emissions PlanningNo ratings yet

- Wireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsFrom EverandWireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsRating: 5 out of 5 stars5/5 (1)

- FINALREPORT2Document90 pagesFINALREPORT2samadhan khaireNo ratings yet

- Automatic Tshirt Folding Machine Project ReportDocument65 pagesAutomatic Tshirt Folding Machine Project Reportsamadhan khaire100% (1)

- Bullet Shooting Robot CPPDocument15 pagesBullet Shooting Robot CPPsamadhan khaireNo ratings yet

- Automatoc Stamping MachineDocument5 pagesAutomatoc Stamping Machinesamadhan khaireNo ratings yet

- Kavayitri Bahinabai Chaudhari North Maharashtra University, Jalgaon Provisional List of Exempted Candidates From PET-2021Document10 pagesKavayitri Bahinabai Chaudhari North Maharashtra University, Jalgaon Provisional List of Exempted Candidates From PET-2021samadhan khaireNo ratings yet

- Development of Road Cleaning and Scrap Collecting Robotic VehicleDocument12 pagesDevelopment of Road Cleaning and Scrap Collecting Robotic Vehiclesamadhan khaireNo ratings yet

- Lathe Machine and It'S Mechanism 1.1. Introdunction: Mechanics and Mechanical Engineering June 2020Document13 pagesLathe Machine and It'S Mechanism 1.1. Introdunction: Mechanics and Mechanical Engineering June 2020hoan thanhNo ratings yet

- Automatic Hand Brake SysrtemDocument50 pagesAutomatic Hand Brake Sysrtemsamadhan khaireNo ratings yet

- Pneumatic Bench Vice Project-Report PDFDocument30 pagesPneumatic Bench Vice Project-Report PDFrahul bhatt100% (4)

- Internal Exam Grievance ReportDocument1 pageInternal Exam Grievance Reportsamadhan khaireNo ratings yet

- Mechanical Engineering: "Title of Project"Document3 pagesMechanical Engineering: "Title of Project"samadhan khaireNo ratings yet

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Major Project Report On War Field Spy RobotDocument52 pagesMajor Project Report On War Field Spy RobotBarun Dhiman75% (8)

- Three Axis Turning Truli Intractor PaperDocument6 pagesThree Axis Turning Truli Intractor Papersamadhan khaireNo ratings yet

- Pipe Inspection RobotsDocument49 pagesPipe Inspection Robotssamadhan khaireNo ratings yet

- Four Wheel Stering SystemDocument59 pagesFour Wheel Stering Systemsamadhan khaireNo ratings yet

- Soplar Sprinkel Robot PaperDocument6 pagesSoplar Sprinkel Robot Papersamadhan khaireNo ratings yet

- Three Axis Turning Truli Intractor PaperDocument6 pagesThree Axis Turning Truli Intractor Papersamadhan khaireNo ratings yet

- Automatic Lubricvation SystemDocument9 pagesAutomatic Lubricvation Systemsamadhan khaireNo ratings yet

- Moving Head LightDocument59 pagesMoving Head Lightsamadhan khaireNo ratings yet

- Ijser: Fabrication of Pneumatically Operated Paper Cup and Dish Making MachineDocument3 pagesIjser: Fabrication of Pneumatically Operated Paper Cup and Dish Making MachineManoj NagarajNo ratings yet

- Pneumatic Paper Cup Making Machine Final ReportDocument62 pagesPneumatic Paper Cup Making Machine Final Reportsamadhan khaireNo ratings yet

- Paper Moving Head LightDocument5 pagesPaper Moving Head Lightsamadhan khaireNo ratings yet

- Paper Moving Head LightDocument5 pagesPaper Moving Head Lightsamadhan khaireNo ratings yet

- Pneumatic Bench Vice ModelDocument30 pagesPneumatic Bench Vice Modelsamadhan khaireNo ratings yet

- Irjet V6i5228 PDFDocument6 pagesIrjet V6i5228 PDFmahesh kumbhareNo ratings yet

- Pneumatic Paper Cup Making Machine Final ReportDocument62 pagesPneumatic Paper Cup Making Machine Final Reportsamadhan khaireNo ratings yet

- Moving Head LightDocument59 pagesMoving Head Lightsamadhan khaireNo ratings yet

- Catalog en Eurocoustic 0Document132 pagesCatalog en Eurocoustic 0Vikash KumarNo ratings yet

- DICGC - For Depositors - A Guide To Deposit InsuranceDocument10 pagesDICGC - For Depositors - A Guide To Deposit InsuranceSachinNo ratings yet

- Pay Slip SampleDocument3 pagesPay Slip SampleJoseph ClaveriaNo ratings yet

- Quorum Sensing PDFDocument9 pagesQuorum Sensing PDFShareenMuneebNo ratings yet

- Vocabulary June v22Document2 pagesVocabulary June v22Wiston TonwisNo ratings yet

- CS1 Epoxy Curing AgentsDocument21 pagesCS1 Epoxy Curing AgentsAlptekin100% (1)

- Mechanism of Enzyme ActionDocument19 pagesMechanism of Enzyme ActionRubi AnnNo ratings yet

- Weaning Guidelines 2007Document4 pagesWeaning Guidelines 2007deliejoyceNo ratings yet

- L-2 Single and Composite Heat TransferDocument44 pagesL-2 Single and Composite Heat Transfer271758 ktr.chem.18No ratings yet

- LaserDocument12 pagesLasercabe79No ratings yet

- Different Types of FermentationDocument26 pagesDifferent Types of FermentationCats and DogNo ratings yet

- V. Aa. Gram A/S: DescriptionDocument2 pagesV. Aa. Gram A/S: Descriptioncontango O&GNo ratings yet

- Machine Design II: Prof. K.Gopinath & Prof. M.M.MayuramDocument4 pagesMachine Design II: Prof. K.Gopinath & Prof. M.M.Mayurampredrag10No ratings yet

- Scala: Service InstructionsDocument16 pagesScala: Service Instructionsmario_turbinadoNo ratings yet

- Lesson 3.3 Inside An AtomDocument42 pagesLesson 3.3 Inside An AtomReign CallosNo ratings yet

- Convecc Ao Forc Ada Externa: Vicente Luiz ScalonDocument18 pagesConvecc Ao Forc Ada Externa: Vicente Luiz ScalonMaria VitóriaNo ratings yet

- History of Crime and Criminal Justice in America EditedDocument7 pagesHistory of Crime and Criminal Justice in America EditedcarolineNo ratings yet

- Composition Solidus Temperature Liquidus Temperature: (WT% Si) (°C) (°C)Document7 pagesComposition Solidus Temperature Liquidus Temperature: (WT% Si) (°C) (°C)Muhammad Ibkar YusranNo ratings yet

- Manual Servicio Soxte 2050Document46 pagesManual Servicio Soxte 2050Quimica JordanlabNo ratings yet

- AT-502 - AT-504 - OM-0-Introduction-1 - 10-12-2019Document6 pagesAT-502 - AT-504 - OM-0-Introduction-1 - 10-12-2019Vinicius RodriguesNo ratings yet

- Chapter 4 - Medical Aspects of Food SafetyDocument17 pagesChapter 4 - Medical Aspects of Food SafetyasushkNo ratings yet

- Full Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFDocument41 pagesFull Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFmildred.walker324100% (15)

- Jurnal Kasus Etikolegal Dalam Praktik KebidananDocument13 pagesJurnal Kasus Etikolegal Dalam Praktik KebidananErni AnggieNo ratings yet

- ST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCDocument3 pagesST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCjodelle11No ratings yet

- Dan Zahavi Josef Parnas - Schizophrenic - Autism - Clinical - Phenomenology PDFDocument6 pagesDan Zahavi Josef Parnas - Schizophrenic - Autism - Clinical - Phenomenology PDFAdelar Conceição Dos SantosNo ratings yet

- Lesson 5: Prejudice and StereotypesDocument31 pagesLesson 5: Prejudice and StereotypesZeynep SulaimankulovaNo ratings yet

- Increase Credit Limit PDFDocument1 pageIncrease Credit Limit PDFemc2_mcvNo ratings yet

- Afcat Question Paper 01-2014 PDFDocument10 pagesAfcat Question Paper 01-2014 PDFTuhin AzadNo ratings yet

- Fulltext PDFDocument55 pagesFulltext PDFManikandan VpNo ratings yet

- Main Group Oganometallics: Shriver and Atkins, Chapter 15Document24 pagesMain Group Oganometallics: Shriver and Atkins, Chapter 15José Augusto VillarNo ratings yet