Professional Documents

Culture Documents

Project Report 2023

Uploaded by

Satyaranjan BeheraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Report 2023

Uploaded by

Satyaranjan BeheraCopyright:

Available Formats

www.ijcrt.

org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

DESIGN OF ECO-FRIENDLY ROAD AND

FLOOR CLEANER

Shingala Niraj R.1, Kondhiya Pankit B.2, Hardik A Khunt3, Dr. Arick M. Lakhani4,

Parth V. Delvadiya5

1,2,3,4,5 Assistance Professor, Mechanical Department, VVP Engineering College,Rajkot

Mechanical Dept, V.V.P Engineering Collage Rajkot.

Abstract - Cleaning has become a basic need for aimed to design, development and evaluation of a

all human beings and it is unavoidable daily manually operated road cleaning machine.

routine process. The conventional road cleaning AmaechiLawrenceetalevaluationhasshownhowthe

machine is most widely used in railway stations, use of multiple assessment techniques can providea

airports, hospitals, Bus stands, etc. also this comprehensiveappraisalofthedesign,usabilityand

machine needs electrical energy for its operation. musculoskeletal loading upon the operator. They

It is not user friendly as well as eco-friendly. In suggested that the trials with a larger number of

summertime there is power crisis and most of the subjects would certainly strengthen theconclusions.

roads cleaning machines are not used effectively AbhishekChakrabortyetal[6]reportedthatthemost

duetothisproblemparticularly.Inourprojectwe significant cause of road dust to the total suspended

are using easily available materials with low cost. particulate burden is vehicle traveling on paved and

It is the better alternative for conventional unpaved' surfaces. Consequently, data directly

machine. relatingdusttoroadaccidentsarerare,butinastudy if

dust is the cause of 10% of these accidents’

KeyWords:RoadCleaner,ManuallyOperated,Eco-

Friendly, Human Powered,Analysis. casualties,thenthecostcouldamounttoasmuchas

0.02%ofGDPinsomedevelopingcountriesandtotal

1. INTRODUCTION about$800millionannually.Thepresentstateofthe

Effectivecleaningandsanitizinghelpandprotectthe road cleaning process is described below. There are

health of the human beings directly and indirectly. two ways for road cleaning 1) Manual process 2)

Also, cleaning and sanitizing prevents the pest Machinated process. In manual process, the road

infestationsbyreducingresiduesthatcanattractand cleaning is done with the help of and shovel to clean

supportbees,pestsetc.Italsoimprovestheshelflife of off the debris, waste etc. hand to clean the road by

the floor, walls etc. due to regular cleaning and spreading the dust all over in the air. While in the

maintenance. In recent years, most of the people Machinated process, a vehicle containing broom at

prefertousetrainsorbusesforcommutingandhence bottomcontinuouslyrotating,cleantheroadaswellas

these places are littered with biscuits covers, cold sucksthedustspreadbyrotatingbroom.

drinkbottlesetc.Hence,itisnecessarytocleanthebus

standsandrailwaysstationsatregularinterval.There

isnoonesinglecleaningmethodthatissuitableforall Background Of Present Road Cleaning:

locations and occasions and effective cleaning The manual operated machines are time

depends upon type of cleaning device, cleaning consumingandlaborious,onothersideoftheflip,the

techniqueandtheequipmentshouldbeuserfriendly diesel operated machines are very costlier. These

problems instigate to think an alternative

Cleaning work can be physically demanding, and a arrangement which would nullify the limitations of

need has been identified to developed methods for former said processes. Further its initial cost is also

systematicergonomicevaluationofnewproducts.In less. The new evolved concept is a road cleaning

recent years, floor cleaning robots are getting more machineisoperatedbyhumanpower.Toaccomplish

popularforbusyandagingpopulationsduetolackof this new idea, the present work is well carried out

workers. However, in India, unemployment is more which is as under. 1. Firstly, the complete market

and hence there is a need to develop less labour

reviewandliteraturesurveybasedontheRoad

orientedcleaningmachine.Hence,thepresentworkis

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a886

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

Cleaningprocessesbeendone.2.Basedonthedemand Rollerbrush

power the machine component is designed. 3.Based Chain &sprocket

on obtained designed dimensions the fabrication Spurgear

work of the proposed manually operated road Cyclewheel

cleaningmachineiscarriedout.4.Atlast,thetesting Smallwheel

and trails have been taken to ascertain the load Scope of the project

capacity of themachine. Existing road clean methods are two typesi)

Electrically operated ii) manually operated.

1.1 Objective of Eco-Friendly Road and Floor Manualcleaningmaycauseshoulderproblemdue

Cleaner to continuous sweeping. Electrically operated

Toprovidethealternativemethodforroad road cleaner’s uses electrical energy to run the

cleaning motor. In our project manually operated road

To reduce humaneffort cleaning machine is alternative concept for

To save thetime avoiding such problems. It works veryefficiently

To reduce thecost withrespecttocoveringarea.Itisveryeconomical

To avoid noisepollution touse.

Methodology

1.2 Literaturesurvey

Mohsen Azadbakht et al 2014 [1] - “Design 1. Literaturesurvey

and fabrication of a tractor powered leaves 2. Identification of designparameters

collector machine equipped with suction-blower 3. Design

system”- The authors explained about the 4. Analysis

fabricationofleavescollectormachinebytractor 5. Fabrication

powered with suction blower system. He has 6. Testing

framed the machine by using chassis, pump, 7. Result &discussion

blower, gearbox, hydraulic jack. They concluded

total power consumption of that machine is Design calculation:

around 14634W. SprocketfreewheelRatio

M. Ranjith Kumar et al 2015 [2] - “Design 64 teeth ofsprocket

andAnalysisofManuallyOperatedFloorCleaning 16 teeth of free wheel

Machine”- The authors have been designed and 64/16 = 4

analysed manually operated floor cleaning Spur Gear Ratio

machine. From his research he concluded the 68 teeth of gear

stress level in the manually operated machine is 18teethofpinion

within the safelimit.

68/18 =3.77

Sandeep.J.Meshrametal2016[3]-“Design

BrushRevolution

and Development of Tricycle Operated Street

4*3.77=15

CleaningMachine”–Hehasdevelopedthestreet

1revolutionofcyclewheel=15revolutionofbrush

cleaning machine by tricycle operated. In this

research article he framed a model especially for Diameter of wheel=62cm

rural area. He concluded that the cleaning isless Radius=31cm

effective where the street seems to be veryrough Circumference=2πr

anddamaged. = 2π*31

=194.77cm

2. Components Used in RoadCleaner Assuming 50 revolutions of wheel in one

Pedestalbearing minute

Shaft =50*194.77

Frame =9738.5cm

=97m

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a887

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

(Revolutionofwheelinoneminute)*(Brush 3. ChainDrive:Achaindriveconsistsofonendless

revolutioninonerevolutionofwheel) chain running around two sprocket wheel the

= 50*15 chaindrivehasafeaturewhicharecommonto

= 750rpm both the gear drives and belt drives. Chain

drives are a means of transmitting power like

2. PARAMETERS CONSIDER DEVELOPING gears, shafts and belt drives. Chain drive is a

LOW COST MANUALLY OPERAED SWEEPING wayoftransmittingmechanicalpowerfromone

place to another. It is often used to convey

MACHINE

power to the wheels of a vehicle, particularly

1. Shaft(Axle):Axleisusedformountingsprocket

bicycleandmotorcycle.Itisalsousedinawide

andwheels.Weusethreeaxlefirstaxleisused

varietyofmachinesbesidesvehicles.Drivebelts

fortransmissionpower,secondaxleisusedfor

can slip unless they have teeth, which means

mountingsweeperbrush,andthirdaxleisused

thattheoutputsidemaynotrotateataprecise

for mounting supportingwheels.

speed,andsomeworkgetslosttothefrictionof

thebeltasitbendsaroundthepulleys.Wearon

Mildsteelmaterialisselectedforanaxledueto

rubber or plastic belts and their teeth is often

mild steel has a resistance to breakage. Mild

easier to observe, and chains wear out faster

steel, as opposed to higher carbon steels, is

thanbeltsifnotproperlylubricated.

quite malleable, even when cold this means it

has high tensile and impact strength higher

Table -2.1: components and material of eco-

carbon steels usually shatter or crack under

friendly road and floor cleaner

stress, while mild steel bends or deforms. In

some designs, this allows independent Components Material

suspension of the left and right wheels, and

therefore a smoother ride. Even when the Cycle wheel steel

suspension is not independent, split axles

Small wheel plastic

permittheuseofadifferential,allowingtheleft

andrightdrivewheelstobedrivenatdifferent

Roller brush plastic

speeds as the automobile turns, improving

traction and extending tirelife. Chain, sprocket Steel

2. ChainDrive:Achaindriveconsistsofonendless Brush ratio 1:15

chain running around two sprocket wheel the

chaindrivehasafeaturewhicharecommonto Gear ratio 1:3.77

both the gear drives and belt drives. Chain Sheet for bin GI sheet

drives are a means of transmitting power like

gears, shafts and belt drives. Chain drive is a Square pipe Mild steel

wayoftransmittingmechanicalpowerfromone Rod Mild steel

place to another. It is often used to convey

power to the wheels of a vehicle, particularly Pedestal bearing Cast iron

bicycleandmotorcycle.Itisalsousedinawide

Spur gear Steel

varietyofmachinesbesidesvehicles.Drivebelts

can slip unless they have teeth, which means

thattheoutputsidemaynotrotateataprecise

speed,andsomeworkgetslosttothefrictionof

thebeltasitbendsaroundthepulleys.Wearon

rubber or plastic belts and their teeth is often

easier to observe, and chains wear out faster

thanbeltsifnotproperlylubricated.

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a888

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

3. Design

Fig.3.1(a) cycle wheel

2. Supportingwheel

Fig.3.1Designofeco-friendlyroadandfloor

cleaner.

Eco friendly road cleaning machine is an

advanced type of machine used for theroads

or street. The machine is run by a human

effort or man power. The systen is fixedwith

pair of wheel which are connected with the

help of shaft. The shaft makes the wheel

connectedtooneother.Thewheelaremoved

for a desired position with a help of manual

forcewhichcanhandletomove.Achaindrive is

connected to the wheels and gear at one Fig.3.1(b) supporting wheel

side. The chain is moved according to the

Diameterofwheel60mm.Itisuseformovement

wheel and gear. The brush moving opposite

ofmachine

direction of the wheels move and the brush

brooms the waste present on the road also it 3. Sprocket

dumpsthewasteintothewastecollectingbox.

Thewastecollectingboxisremovedtodump

the waste into desiredplace.

In this work components used as given below

1. Cyclewheel:

A cycle wheel use for movement of our

machine. Use two wheels each wheel having

diameter of609.6mm.

Fig.3.1(c) sprocket

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a889

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

It is use for transmitting power from wheel to 6. Pedestalbearing

secondary sprocket to brush. It has outer

diameter is 150mm & 44 teeth.

4. Rollerbrush

Fig.3.1(f) pedestal bearing

Itisusedtosupportforarotatingshaftwith

the help of compatible bearing and various

accessories.Itsinnerdiameteris25mm.

Fig.3.1(d) Roller brush

7. CollectingBox

Rollerbrushhavingalengthoflengthof900mm

longandouterdiameterof250mm.

5. Spurgear

Fig.3.1(g) collecting box

Thefunctionofthecollectingboxistocollectthe

waste up to some quantity after that remove box

and dump thewaste.

Fig.3.1(e) spur gear

Usetwogeardriveranddriventhesmallgearhas a

diameter of 36mm and larger gear having a

diameter of 120mm and 64teeth.

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a890

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

8. Frame 4. WORKING PRINCIPLE OF ROAD CLEANING

MACHINE

Eco friendly road cleaning machine is an advanced

type of machine used for the roads or streets. The

detail working of the Eco-friendly Road cleaning

machineisexplainedbelowEcofriendlyroadcleaning

machine we are making without using any power

supply, fuels and engines. The machine is run by a

humaneffortoramanpower.Thesystemisfixedwith

pair of wheels which relate to the help of shaft. The

shaft makes the wheels connected to one and other.

The wheels are moved for a desired position with a

helpofmanualforcewhichcanhandleisprovidedto

move. The handle can be adjusted for a required

Fig.3.1(h) frame height and provided three adjusting holes for it. A

chaindriveisconnectedtothewheelsandgearatboth

Frame is the body part on which all the other

sides.Thechainismovedaccordingtothewheeland

components are assemble

gear. the brush moving opposite direction of the

Cyclewheel wheelsmoveandthebrushbroomsthewastepresent

Smallwheel on the road also it dumps the waste into the waste

Pedestalbearing collectingbox.Thewastecollectingboxisremovedto

Spurgear dump the waste into desiredplaces

Industrialbrush

Bin 5. ACKNOWLEDGEMENT

9. Chain We would like to express our deepest sense of

gratitude to our project Guide professor

pankitkondhiya Assistant professor Mechanical

Department

forhisconstantsupportandguidancethroughoutthe

projectwork.

6. CONCLUSION

The manually operated eco-friendly road and floor

cleaner is successfully designed. This project works

implementsthemanuallyoperatedeco-friendlyroad

cleaner for road cleaning that reducing the cost,

humaneffortsaswellastime.Itisthebestalternative for

automated road cleaning machine during power

Fig.3.1(I) chain

crisis. It is found that the existing road cleaning

Roller chain is most used to transmit the power. machinesworkswithahumansimpleeffort.Manual

cleaning may cause shoulder problem due to

continuous sweeping. The manually operated road

cleaning machine is alternative concept for avoiding

such problems. It works very efficiently with respect

to covering area. It is very economical to use. The

manuallyoperatedeco-friendlyroadandfloorcleaner

can work very efficiently with respect tocovering

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a891

www.ijcrt.org © 2022 IJCRT | Volume 10, Issue 4 April 2022 | ISSN: 2320-2882

area,timeandcostofroadcleaningprocesscompared

withtheexistingmachineries.Also,itiseconomical.It

wasseenwhiletestingofmachine,thatthecleaningis

less effective where the road seems to be very rough

and damaged. It can provide job to the uneducated

personwhoisinneedforsuchjobsashumanenergy is

needed to drive the machine. Maintenance of

machine is less, and it is easy to control and clean it

having health benefits and it mainly protects

environmentpollution.

7. REFERENCES

[1] MohsenAzadbakht,AliKiapey,AliJafari-“Design

andFabricationofatractorpoweredleavescollector

equipped with suction blower system” - September,

2014Agric Eng Int: CIGR Journal Open access at

http://www.cigrjournal.org Vol. 16,No.3.

[2] M.RanjithKumar,N.Kapilan-“DesignandAnalysis of

Manually Operated Floor Cleaning Machine” -

International Journal of Engineering Research

&Technology (IJERT) ISSN: 2278-0181 IJERT

IS040912[www.ijert.org]Vol.4Issue04,April-2015.

[3] Sandeep.J.Meshram,Dr.G.D.Mehta-“Designand

Development of Tricycle Operated Street Cleaning

Machine” - Journal of Information, Knowledge and

Research In Mechanical Engineering ISSN 0975 –

668X|Nov15ToOct16|Volume–04,Issue-01.

IJCRT2204106 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org a892

You might also like

- Road Side Dust Cleaner PDFDocument5 pagesRoad Side Dust Cleaner PDFSURAJ NAGNo ratings yet

- Road Cleaning and Scrap Collecting VehicleDocument4 pagesRoad Cleaning and Scrap Collecting VehicleKVSRIT Dept. of MENo ratings yet

- Document 2 EMQ7 09052017Document8 pagesDocument 2 EMQ7 09052017Mechanical ShieldtechnoNo ratings yet

- Design and Fabrication of Mini Industrial Vacuum Cleaner PDFDocument5 pagesDesign and Fabrication of Mini Industrial Vacuum Cleaner PDFPtomsa KemuelNo ratings yet

- Mech 101Document5 pagesMech 101Bowie PascualNo ratings yet

- Design and Development of Road Cleaner MachineDocument4 pagesDesign and Development of Road Cleaner MachineIJRASETPublicationsNo ratings yet

- New Microsoft Office Word DocumentDocument5 pagesNew Microsoft Office Word DocumentLikepageLikeitNo ratings yet

- 'Design and Fabrication of Manually Operated Floor Cleaning Machine''Document9 pages'Design and Fabrication of Manually Operated Floor Cleaning Machine''Manoj Karthik KingNo ratings yet

- D&DSCM (New 1)Document59 pagesD&DSCM (New 1)Shubham KalbhutNo ratings yet

- Eco Friendly Road Dust CleanerDocument5 pagesEco Friendly Road Dust CleanerrassNo ratings yet

- Design and Fabrication of Eco-Friendly Road Footpath Cleaning Machine For IndustriesDocument5 pagesDesign and Fabrication of Eco-Friendly Road Footpath Cleaning Machine For IndustriesIJRASETPublicationsNo ratings yet

- Research PaperDocument6 pagesResearch PaperAditya ChavanNo ratings yet

- (1 5) 2951 11443 1 - Edit FormatDocument5 pages(1 5) 2951 11443 1 - Edit FormatKVSRIT Dept. of MENo ratings yet

- Journalnx ReviewDocument4 pagesJournalnx ReviewJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Compressive Force Analysis On Piston of Automatic Screw Jack Compression DustbinDocument4 pagesCompressive Force Analysis On Piston of Automatic Screw Jack Compression DustbinPeter JammyNo ratings yet

- DESIGN AND FABRICATION OF MANUALLY OPERATED ECO - FRIENDLY CLEANING MACHINE - SynopsisDocument7 pagesDESIGN AND FABRICATION OF MANUALLY OPERATED ECO - FRIENDLY CLEANING MACHINE - SynopsisAkash KsNo ratings yet

- New Era University: College of Engineering and ArchitectureDocument10 pagesNew Era University: College of Engineering and ArchitectureDavid Soo YhomNo ratings yet

- JETIRGB06052Document5 pagesJETIRGB06052Aditya ChavanNo ratings yet

- An Innovative Solar Based Robotic Floor CleanerDocument6 pagesAn Innovative Solar Based Robotic Floor CleanerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Irjet V6i11340Document3 pagesIrjet V6i11340Rajat ShrirameNo ratings yet

- Smart Multifunction Floor Cleaning RobotDocument12 pagesSmart Multifunction Floor Cleaning RobotIJRASETPublicationsNo ratings yet

- Airframes and Engines OptionDocument14 pagesAirframes and Engines OptionBukein KennNo ratings yet

- Design and Fabrication of Electric Weeder1Document8 pagesDesign and Fabrication of Electric Weeder1muthyala ravitejaNo ratings yet

- Eco-Friendly Solar Powered Road Cleaning MachineDocument15 pagesEco-Friendly Solar Powered Road Cleaning Machineanurag trivediNo ratings yet

- Automatic Dish Washing MachineDocument4 pagesAutomatic Dish Washing MachineMohammed AwolNo ratings yet

- Automatic Drain CleanerDocument3 pagesAutomatic Drain CleanerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Fabrication of Floor Cleaning MachineDocument5 pagesDesign and Fabrication of Floor Cleaning MachineIJRASETPublicationsNo ratings yet

- Visvesvaraya Technology University, Belagavi - 590018: "Manual Operated Road Side Dust Cleaning Machine"Document17 pagesVisvesvaraya Technology University, Belagavi - 590018: "Manual Operated Road Side Dust Cleaning Machine"KALYAN KUMARNo ratings yet

- Project Synopsis: Department of Mechanical Engineering Submitted byDocument10 pagesProject Synopsis: Department of Mechanical Engineering Submitted byMintu VermaNo ratings yet

- 947npm_14.EPRA JOURNALS 13144Document3 pages947npm_14.EPRA JOURNALS 13144toto elopreNo ratings yet

- Design and Analysis of Manually Operated Floor Cleaning MachineDocument4 pagesDesign and Analysis of Manually Operated Floor Cleaning MachineAnonymous L9fB0XUNo ratings yet

- Automatic White Board Cleaner ARTICLE 1 DUERRDocument6 pagesAutomatic White Board Cleaner ARTICLE 1 DUERRborjajovenileNo ratings yet

- SSRN-id3372276Document7 pagesSSRN-id3372276toto elopreNo ratings yet

- Automatic Drain Cleaner Machine PaperDocument4 pagesAutomatic Drain Cleaner Machine PaperVikram PanchalNo ratings yet

- 36-39Document4 pages36-39Mechanical ShieldtechnoNo ratings yet

- MaheshDocument5 pagesMaheshKushal ManikantaNo ratings yet

- MD1Document6 pagesMD1Daniel YoworldNo ratings yet

- Design and fabrication of multi-purpose sieving machineDocument6 pagesDesign and fabrication of multi-purpose sieving machineMICHEL RAJ MechNo ratings yet

- Synopsis Drain CleanerDocument10 pagesSynopsis Drain CleanerRaja ManeNo ratings yet

- Guided By: Projectees: Prof. Sunil TelangDocument13 pagesGuided By: Projectees: Prof. Sunil TelangJaid KhanNo ratings yet

- HHHHBBDocument4 pagesHHHHBBThinesh Rau KrishnamurtyNo ratings yet

- Mahesh Doc 2Document5 pagesMahesh Doc 2Kushal ManikantaNo ratings yet

- Design and Analysis of An Hydraulic Trash Compactor: Test Engineering and Management February 2020Document13 pagesDesign and Analysis of An Hydraulic Trash Compactor: Test Engineering and Management February 2020Sanket ThoratNo ratings yet

- Fabrication of Switch Operated Sweeping and Floor Cleaning MachineDocument10 pagesFabrication of Switch Operated Sweeping and Floor Cleaning MachineEditor IJTSRDNo ratings yet

- Design and Fabrication of Multipurpose Eco-Friendly Cleaning MachineDocument6 pagesDesign and Fabrication of Multipurpose Eco-Friendly Cleaning MachinePrudhvi kurnoothalaNo ratings yet

- Paper2911 PDFDocument7 pagesPaper2911 PDFJustin RoxasNo ratings yet

- Sewage Cleaning System.Document6 pagesSewage Cleaning System.Mohd AsifNo ratings yet

- 5g Railway PDFDocument11 pages5g Railway PDFSk RainaNo ratings yet

- Project Report Final Edit 2Document33 pagesProject Report Final Edit 2446shahil28No ratings yet

- Semi Automated Wireless Beach Cleaning RobotDocument3 pagesSemi Automated Wireless Beach Cleaning RobotSanchit KapoorNo ratings yet

- Floor Cleaning Machine ReportDocument26 pagesFloor Cleaning Machine ReportMayur Madhukar MankarNo ratings yet

- 2STM - JoMA E DUSTBINDocument8 pages2STM - JoMA E DUSTBINBhairavi MoreNo ratings yet

- Design beach cleaning machineDocument6 pagesDesign beach cleaning machineruben dollarzNo ratings yet

- Automatic Garbage Collector Machine Cleans Drainage SystemsDocument3 pagesAutomatic Garbage Collector Machine Cleans Drainage Systemspramo_dassNo ratings yet

- Robotics FullDocument8 pagesRobotics FullDineshNo ratings yet

- Design and Fabrication of Compost MachineDocument8 pagesDesign and Fabrication of Compost MachineIJRASETPublicationsNo ratings yet

- Final Year Project Diploma SuryaDocument13 pagesFinal Year Project Diploma Suryasomnathsabne903No ratings yet

- Multipurpose Sieving MachineDocument9 pagesMultipurpose Sieving MachineIJRASETPublicationsNo ratings yet

- Design and Manufacturing of ECO Friendly Road Sweeper Machine Ijariie14789Document5 pagesDesign and Manufacturing of ECO Friendly Road Sweeper Machine Ijariie14789SANDIP PANDYANo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Cub Cadet Parts Manual For Model Rzt22Document4 pagesCub Cadet Parts Manual For Model Rzt22leon100% (27)

- Scania TerexDocument126 pagesScania TerexzoeNo ratings yet

- RISC vs CISC CharacteristicsDocument24 pagesRISC vs CISC CharacteristicsSunil MudhirajNo ratings yet

- Shibaura Diesel Engine S773L - Tier4 XXDocument28 pagesShibaura Diesel Engine S773L - Tier4 XXMihai PopaNo ratings yet

- PROJECT NI myRIO - ISLEM1Document33 pagesPROJECT NI myRIO - ISLEM1Eslem DriraNo ratings yet

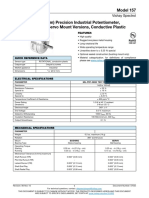

- Model 157: Vishay SpectrolDocument4 pagesModel 157: Vishay SpectrolJulio Vazquez MorenoNo ratings yet

- MultiFry: User Manual for De'Longhi Appliances Model FH1163 FH1363Document11 pagesMultiFry: User Manual for De'Longhi Appliances Model FH1163 FH1363Mihaela SamsonescuNo ratings yet

- Breaker TRV StudiesDocument28 pagesBreaker TRV StudiesCesar Agusto RamirezNo ratings yet

- Brochure of Huawei Site Power Solutions 04 - (20121205) Low Definition 1MDocument20 pagesBrochure of Huawei Site Power Solutions 04 - (20121205) Low Definition 1MDany Youssef MounsefNo ratings yet

- API 6A Gate ValveDocument26 pagesAPI 6A Gate ValveindraNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Document23 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Solofoniaina Ginô ChristianNo ratings yet

- Fusing Equipment: ELSP Current-Limiting Backup FuseDocument12 pagesFusing Equipment: ELSP Current-Limiting Backup FuseDiegoMirandaNo ratings yet

- Expt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectiveDocument6 pagesExpt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectivePriya DarshuNo ratings yet

- RAC CycleDocument10 pagesRAC CyclekavooriNo ratings yet

- Q470EA IM A DatasheetDocument4 pagesQ470EA IM A Datasheetsgx.premiumNo ratings yet

- Special Application Manual Stations Ms-700U Series: FeaturesDocument2 pagesSpecial Application Manual Stations Ms-700U Series: FeaturesJMAC SupplyNo ratings yet

- Alesis - Quadraverb - CopieDocument46 pagesAlesis - Quadraverb - CopieGeronimo BassmanNo ratings yet

- Simple, Sturdy Workbench: in Partnership WithDocument5 pagesSimple, Sturdy Workbench: in Partnership WithMarcelo SantosNo ratings yet

- Bally Pocket Guide GamemakerDocument48 pagesBally Pocket Guide GamemakersolensiNo ratings yet

- Philips LCD Monitor 220VW8FB Service ManualDocument71 pagesPhilips LCD Monitor 220VW8FB Service Manualpagy snv67% (3)

- Nomenclature - SRDocument4 pagesNomenclature - SRsayedNo ratings yet

- Using Fingerprints for ATM AuthenticationDocument25 pagesUsing Fingerprints for ATM AuthenticationsaRAth asgaRdianNo ratings yet

- Single Phase Two Wire, Split STS Prepaid/AMI Smart Meter: HighlightsDocument2 pagesSingle Phase Two Wire, Split STS Prepaid/AMI Smart Meter: HighlightsElisiö Dicälä Homem da LéiNo ratings yet

- MAGRAV Power Unit: Build and Grow: Lists of ItemsDocument11 pagesMAGRAV Power Unit: Build and Grow: Lists of ItemsDarzan Constantin100% (1)

- Abe33 22 2001 08 27Document12 pagesAbe33 22 2001 08 27haggNo ratings yet

- HHF-1600HL Drilling Pump Parts ListDocument27 pagesHHF-1600HL Drilling Pump Parts ListDaniel RinconNo ratings yet

- 3 4 W Control CablesDocument3 pages3 4 W Control CablesJaya SankaNo ratings yet

- An Analysis DC-Machine Commutation: JapanDocument9 pagesAn Analysis DC-Machine Commutation: JapanDanang AjiNo ratings yet

- 3406 D8R Water Pump PDFDocument4 pages3406 D8R Water Pump PDFmanu luvungaNo ratings yet

- EIM 9 Quarter Electrical ToolsDocument35 pagesEIM 9 Quarter Electrical ToolsJe Ann OlaytaNo ratings yet