Professional Documents

Culture Documents

CSS Data Sheet-500KVA

Uploaded by

Krish0 ratings0% found this document useful (0 votes)

32 views7 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views7 pagesCSS Data Sheet-500KVA

Uploaded by

KrishCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 7

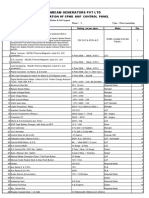

TECHNICAL DATA SHEET FOR COMPACT SUBSTATION (CSS)

A.) Technical Particulars for HV Vacuum Circuit‐Breaker

Sl. no Description Model / Type Make - Vendor to Remarks

confirm / Specify

1 Service Indoor

2 BUS BAR

a. Rating 12kV, TP Bus‐Bar

b. Phase 0

Suit to 630A Copper Flat with

c. Neutral

Colour coded PVC Insulation

d. Earth

3 VACUUM CIRCUIT BREAKER

a. Rated Voltage 11kV

b. Rated Current 630A

c Short Circuit Current 25kA / 3sec

d. No. of Pole Three Pole

e. Draw out type Horizontal

f. Spring Charging Electrical & Manual (by 230V

AC Motor)

g. Closing Operation Electrical & Manual (by110V DC

from Power Pack)

h. Trip Operation Electrical & Manual (by110V DC

from Power Pack) + Fuse

Trigger

i. Auxiliary Contact 8NO + 8NC along with all

indications and Push Buttons

4 CURRENT TRANSFORMER

a. Type ***

b. Rating ***

5 POTENTIAL TRANSFORMER

a. Type Cast Resin

b. Rating ***

c. Potential Transformer Fuse ***

6 PROTECTION RELAYS

a. Combined of 3 O/C + 1 E/F ***

Relay

b. Master Trip Relay ***

c. Anti‐Pumping Relay (2‐ 110V DC, 2NO + 2NC

Element)

7 METER

a. Multifunction Digital

b. Annunciator 8‐Window

c. Electronic Hooter 110V DC

8 INDICATION LAMP

a. ON / OFF 110V Red / Green

LED

b. Auto Trip 110V Amber LED

c. Spring Charging 110V Blue LED

d. Trip Circuit Healthy 110V White LED

e. R, Y & B Phase 110V Red / Yellow

9 PUSH BUTTONS

a. Trip Circuit Healthy

10 CONTROL

a. VCB TNC Switch 25A

b. Toggle Switch (Heater ON / OFF) 6A / 230V AC

c. Space Heater + Thermostat 230 VAC, 80W

d. Plug & Socket with Switch 240V AC, 16A

e. Cubicle Illumination + Holder 11W/230V AC

f. Door Limit Switch Yes

g. MCBs / Fuses for AC / DC Control Yes

h. Wiring 1.5 / 2.5

Sq.mm, Cu.

PVC Wire

i. Local / Remote Switch 16A

j. Disc‐Connecting Terminal Block Yes

k. Terminal Block Yes

11 POWER PACK

a. DC Power Source 230V AC to 110V DC

12 Support Insulator

a. Bus‐Bar Support Insulator Epoxy Resin Cast

13 Enclosure

a. Material CRCA Steel

b. Level of Ingress Protection IP 54

14 PAINT

a. Type & Shade Spray Siemens Grey,

RAL 7032

B.) Technical Particulars for Cast Resin Dry Type Transformer with Enclosure

1.0 General Specification

a. Rating (kVA) 500

b. Service Duty Continuous

c. Application Distribution Transformer

d. Type Cast Resin Dry

e. Type of Mounting Direct installation inside the

enclosures

f. Installation Outdoor

g. Altitude Above sea‐level but not

exceeding 1000m

h. Type of cooling AN

i. Reference standard IS / IEC

2.0 System Particulars

a. Nominal Voltage (kV) 11

b. Highest System Voltage (kV) 12

c. No. of Phases 3

d. Frequency (Hz) 50

e. Voltage Variation (%) ± 10

f. Frequency Variation (%) ±3

g. Combined Voltage and Frequency Variation (%) + 10

3.0 Terminal Arrangements:

a. HV For connecting cable

b. LV Through solid bus duct

4.0 Rating:

a. Rated HV Line Voltage (kV) / Line Current (A) ***

b. Rated LV Line Voltage (kV) / Line Current (A) ***

c. Ambient Temperature 50°C

d. Max. Temperature rise of winding by resistance method above 90°C

ambient

e. Insulation Class F

f. Over load Capacity As per IS : 6600

5.0 Winding Connection Details:

a. Connection

HV Winding Delta

LV Winding Star

Neutral brought out for earthing Solidly Earthed

b. Tapings

Tapping Range ***

Steps Range ***

No. of Steps & Position ***

Voltage of each step(V) ***

Tap Changer type Off‐Circuit Tap Links

Vector Group Dyn11

6.0 Losses & Others:

a. No Load Loss at rated frequency and voltage (kW) ***

b. Load Loss at rated current and rated frequency at principal tap (kW) ***

c. Total Load Loss at principal tap (kW) ***

d. Impedance at rated voltage @ 75°C and at principal tap(%) ***

e. Reactance at rated voltage @ 75°C and at principal tap(%) ***

f. No. load current at 90% of rated voltage and frequency(A) ***

g. No. load current at 100% of rated voltage and frequency(A) ***

h. No. load current at 100% of rated voltage and frequency(A) ***

i. Regulation at UPF / 0.8PF (%) ***

7.0 Efficiency:

a. Efficiency @ 75deg C UPF 0.9PF

b. a. 100% of full Load *** ***

c. b. 75% of full Load *** ***

d. c. 50% of full Load *** ***

e. d. 25% of full Load *** ***

f. Maximum Efficiency (%) ***

g. Load at which maximum efficiency occurs ***

8.0 Core Constructional Details & Material:

a. Core Lamination Material ***

b. Type of Construction ***

c. Insulation between laminations ***

d. Type of joint between core limp and yoke ***

9.0 Type of Winding & Material:

a. Material Electrolytic Copper

b. Winding Type Double Wound

c. Type of Winding

HV Winding Layer / Cross Over

LV Winding Helical / Spiral

10.0 Minimun Clearances:

a. HV Phase to Phase ***

b. LV Phase to Phase ***

c. HV Phase to Earth ***

d. LV Phase to Earth ***

11.0 Test Voltages:

a. Impulse (1.2/50 microsec wave) withstand voltage

HV Winding (kVpeak) ***

LV Winding (kVpeak) ***

b. One Minute Power Frequency withstand voltage

HV Winding (kVrms) ***

LV Winding (kVrms) ***

12.0 Fittings & Accessories:

a. Rating and terminal marking plate ***

b. Monogram plate ***

c. Earthing terminals ***

d. Lifting Lugs ***

e. Digital Winding temperature scanner with PT100 Sensor ***

f. Additional Neutral porcelain bushing as per IS 3347 ***

g. Bi‐Directional Rollers ***

h. Identification Labels Yes, Riveted type

13.0 Finish Paint Shade:

a. Epoxy Finish Paint Outside Siemens Grey [RAL 7032]

14.0 Weight & Dimensions:

a. Core and Winding (kg) ***

b. Enclosure (kg) [incl. fittings & accessories] ***

c. Total weight (kg) ***

d. Dimensions (Length x Width x Height)mm ***

15.0 Tests:

a. Routine test as per standard Yes

b. Type & special test if any as per standard Yes

C.) Technical Particulars for LV Air Circuit Breaker

1 Service Outdoor

2 BUS BAR

a. Rating 1kV, TPN Bus‐Bar

b. Phase ***

Suit to 630A ,Copper flat with

c. Neutral ***

color coded PVC insulation

d. Earth ***

3 AIR CIRCUIT BREAKER

a. Rated Voltage 1kV

b. Rated Current 800A

c Short Circuit Current 50kA / 1sec

d. No. of Pole Four Pole

e. Draw out type Horizontal

f. Spring Charging Electrical & Manual

g. Closing Operation Electrical & Manual

h. Trip Operation Electrical & Manual

4 CURRENT TRANSFORMER

a. Type ***

b. Rating ***

5 PROTECTION DEVICES

a. Over current + Earth fault Microprocessors with CT based

relay

6 METER

a. Multifunction Digital

7 INDICATION LAMP

a. ON / OFF 110V Red / Green

LED

b. Auto Trip 110V Amber LED

c. Spring Charging 110V Blue LED

d. R, Y & B Phase 110V Red / Yellow

9 PUSH BUTTONS

a. Trip Circuit Healthy

10 CONTROL

a. ACB TNC Switch 25A

b. Toggle Switch (Heater ON / OFF) 6A / 230V AC

c. Door limit switch 6A / 230V AC

d. MCB for AC supply 4P,6A

e. space heater + Thermostat 11W/230V AC

f. Plug & socket with switch 240C,16A

g. Cubicle illumination + Holder 11W/230V AC

h. Wiring 1.5 / 2.5

Sq.mm, Cu.

PVC Wire

i. Local / Remote Switch 16A

j. Dis‐Connecting Terminal Block Yes

k. Terminal Block Yes

11 Support Insulator

a. Bus‐Bar Support Insulator Epoxy Resin Cast

12 Enclosure

a. Material CRCA Steel

b. Level of Ingress Protection IP 54

13 PAINT

a. Type & Shade Spray Siemens Grey,

RAL 7032

D.) Technical Particulars for CSS Enclosures

1 CSS Enclosure

a. Service Outdoor

b. Ambient temperature 50 deg C.

c. Type of ventilation ***

a.) Normal condition

b.) Hot condition

d. Compartmentalized Yes

e. Degree of protection for IP 23 for transformer

external enclosure compartment & IP54 for HV &

LV compartment

f. Applicabe standard Yes

g. Dimension (LxDxH) in mm ***

h. Enclosure material CRCA steel sheet

i. Thickness of sheet 1.6mm for enclosures & 2mm

for CSS base

2 PAINT

a. Type & Shade Siemens grey ;Shade no –RAL

7032 powder coated

3 OTHER ACCESSORIES

a. space heater + Thermostat 11W/230V AC

b. Plug & socket with switch 240C,16A

c. Cubicle illumination + Holder 11W/230V AC

d. Wiring 1.5 / 2.5

Sq.mm, Cu.

PVC Wire

Note: *** Vendor has to address the details and for other particulars vendor has to confirm and if any deviation

is there vendor shall specify clearly.

You might also like

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignFrom EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo ratings yet

- Tunnel PLC System DrawingDocument6 pagesTunnel PLC System Drawingfadli.lpgNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- BSCPL 1600kVA-100kVA-PSS BOMDocument7 pagesBSCPL 1600kVA-100kVA-PSS BOMnewattelectricNo ratings yet

- Solar Plant Side HT Panel BOMDocument2 pagesSolar Plant Side HT Panel BOMRising Trans Infra SolutionsNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Operating & Maintenance Manual: 48V/100A Float Cum Boost ChargerDocument23 pagesOperating & Maintenance Manual: 48V/100A Float Cum Boost ChargerMushahary Anup100% (1)

- CSS 1250kva & 800kvaDocument4 pagesCSS 1250kva & 800kvaDarshit VyasNo ratings yet

- 11 KV HT VCBDocument8 pages11 KV HT VCBKEYSTONE INFRA PVT LTD0% (1)

- Technical DataDocument50 pagesTechnical DataYuzaly Salleh0% (2)

- Candolita - EE SPECPRO II EVALUATION EXAM II PDFDocument2 pagesCandolita - EE SPECPRO II EVALUATION EXAM II PDFCy CandolitsNo ratings yet

- Supply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDocument13 pagesSupply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDarwish MammiNo ratings yet

- Technical BOQ - 2787Document2 pagesTechnical BOQ - 2787siva nunnaNo ratings yet

- Aplab - DC PSDocument2 pagesAplab - DC PSsghoshNo ratings yet

- Relay Specs 201711289163724394-1272937Document6 pagesRelay Specs 201711289163724394-1272937jjjjjNo ratings yet

- 21 - ENG - 102715 Practical 03Document6 pages21 - ENG - 102715 Practical 03Waruna NirmanNo ratings yet

- String Inverter GTP CX SeriesDocument2 pagesString Inverter GTP CX SeriesBibhuti R DubeyNo ratings yet

- Spilsbury SBX 11A Service ManualDocument43 pagesSpilsbury SBX 11A Service ManualEudes ColmenaresNo ratings yet

- 450W - 900W Modular Power SupplyDocument5 pages450W - 900W Modular Power SupplyMiguel Andres VanegasNo ratings yet

- ABB 11kV BREAKER TECHNICAL SPECIFICATIONSDocument3 pagesABB 11kV BREAKER TECHNICAL SPECIFICATIONSHossam AlzubairyNo ratings yet

- Submission of Technical DocumentsDocument20 pagesSubmission of Technical DocumentsDarshit VyasNo ratings yet

- 9.cipet Boys Hoste-BoqDocument19 pages9.cipet Boys Hoste-Boqjaianit89No ratings yet

- Features: Song ChuanDocument6 pagesFeatures: Song ChuanCarlos Renato Zimermann FilettNo ratings yet

- Fresh Water Fire Pump - NP-FWF-MDB-0001Document15 pagesFresh Water Fire Pump - NP-FWF-MDB-0001SARAVANAN ANo ratings yet

- Iii. Factory Test For (25 MVA) Power TransformerDocument12 pagesIii. Factory Test For (25 MVA) Power TransformerleonadhoreNo ratings yet

- Tech Eq-50Document2 pagesTech Eq-50Mauricio Oropeza CabreraNo ratings yet

- Load Swlteh Gomblmatlon: Mileffum (Vecuurm (Pba)Document2 pagesLoad Swlteh Gomblmatlon: Mileffum (Vecuurm (Pba)alam132No ratings yet

- máy cắt sf6 abbDocument7 pagesmáy cắt sf6 abbQuảng Thành NamNo ratings yet

- Question Bank Series-1 For SSC & CESE Examination (P-101-180) - 2023Document80 pagesQuestion Bank Series-1 For SSC & CESE Examination (P-101-180) - 2023BikashGarnayakNo ratings yet

- Basic Mill Electrical CourseDocument116 pagesBasic Mill Electrical CourseUsop CRuzNo ratings yet

- 12 - BOM For MV Switchgear Pump Station 2nd LiftDocument2 pages12 - BOM For MV Switchgear Pump Station 2nd LiftHadad KarimiNo ratings yet

- MURB1020CT - MURB1060CT: PB FeaturesDocument4 pagesMURB1020CT - MURB1060CT: PB FeaturesJOHN BRICCO A. MATACSILNo ratings yet

- 6.manage Troubleshooting and Restoration of Electrical and Electronic ControlDocument15 pages6.manage Troubleshooting and Restoration of Electrical and Electronic ControlDaru ArusukeNo ratings yet

- Essential Electrician Exam QuestionsDocument4 pagesEssential Electrician Exam QuestionsRafael GianiniNo ratings yet

- S. No. Description Make Qty.: I 11 KV Panel ICOG TypeDocument2 pagesS. No. Description Make Qty.: I 11 KV Panel ICOG TypeaayushNo ratings yet

- Electrical DataDocument127 pagesElectrical DatabuntysuratNo ratings yet

- Degaussing Equipment of DWDocument18 pagesDegaussing Equipment of DWShoyeb AhmedNo ratings yet

- Gurranted Technical PartDocument9 pagesGurranted Technical PartTarun GodiyalNo ratings yet

- Oman Electricity Transmission Co Tender PDFDocument7 pagesOman Electricity Transmission Co Tender PDFHossam AlzubairyNo ratings yet

- FCS Capacitor SwitchDocument7 pagesFCS Capacitor SwitchJoe ChuengNo ratings yet

- 800w Rms Mosfet AmplifierDocument12 pages800w Rms Mosfet AmplifierpraveenNo ratings yet

- ME1Document5 pagesME1jj012586No ratings yet

- AfDB Electrical Works BoQDocument32 pagesAfDB Electrical Works BoQFelix IdeboghieNo ratings yet

- Maintenance and Repair ElectricalDocument43 pagesMaintenance and Repair ElectricalCisa Seaboy100% (1)

- PT and CVT maintenance and testingDocument25 pagesPT and CVT maintenance and testingAashwinAndeNo ratings yet

- 100 Kva125 Kva AMF Panel-Cpwd SpecDocument1 page100 Kva125 Kva AMF Panel-Cpwd Specbalu9999No ratings yet

- AV 800 amplifier power supply guideDocument12 pagesAV 800 amplifier power supply guideGerardo Contreras SaenzNo ratings yet

- Perawatan peralatan listrik dan elektronikDocument45 pagesPerawatan peralatan listrik dan elektronikRabbaniNo ratings yet

- Tubesamps@Dscc Dla MilDocument75 pagesTubesamps@Dscc Dla Mil3p1up1sjgfNo ratings yet

- 24kV Metal Enclosed Switchboard with Load Break Switch and Vacuum Circuit BreakerDocument3 pages24kV Metal Enclosed Switchboard with Load Break Switch and Vacuum Circuit Breakeralam132No ratings yet

- DTSU666-H and DTSU666-H 250 A (50 MA) Smart Power Sensor Quick GuideDocument11 pagesDTSU666-H and DTSU666-H 250 A (50 MA) Smart Power Sensor Quick GuideMzalendo Eustace OchiengNo ratings yet

- Qa0874 2023Document7 pagesQa0874 2023Jaks JaksNo ratings yet

- 6KV 18 PANEL BOARD SPECIFICATIONSDocument14 pages6KV 18 PANEL BOARD SPECIFICATIONSmathan_aeNo ratings yet

- PCB Relay G8P: Ordering InformationDocument5 pagesPCB Relay G8P: Ordering Informationjombo123No ratings yet

- PCP - 01 With DOL Cable SizingDocument1 pagePCP - 01 With DOL Cable SizingKrishNo ratings yet

- PCP - 01 With DOL Cable SizingDocument1 pagePCP - 01 With DOL Cable SizingKrishNo ratings yet

- CU-01 Cable SizingDocument1 pageCU-01 Cable SizingKrishNo ratings yet

- PCP - 01 With DOL Cable SizingDocument1 pagePCP - 01 With DOL Cable SizingKrishNo ratings yet

- CTP-02 Cable SizingDocument1 pageCTP-02 Cable SizingKrishNo ratings yet

- Sand and StoneDocument1 pageSand and StoneCloud AtlasNo ratings yet

- CWP-01 Cable SizingDocument1 pageCWP-01 Cable SizingKrishNo ratings yet

- CU-01 Cable SizingDocument1 pageCU-01 Cable SizingKrishNo ratings yet

- CTFM-01 Cable SizingDocument1 pageCTFM-01 Cable SizingKrishNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Heat Treatment For Heart AttackDocument1 pageHeat Treatment For Heart AttackKrishNo ratings yet

- Drugs and EffectsDocument2 pagesDrugs and EffectsKrishNo ratings yet

- Bus Stop Humor: Fat Lady & Watch vs Wife JokesDocument1 pageBus Stop Humor: Fat Lady & Watch vs Wife JokesKrishNo ratings yet

- Understanding the woman in your lifeDocument9 pagesUnderstanding the woman in your lifeKrishNo ratings yet

- She Makes Babies From Clay!: HI TO ALL...........................Document7 pagesShe Makes Babies From Clay!: HI TO ALL...........................KrishNo ratings yet

- Free tree planting experience with Trees For Free charityDocument1 pageFree tree planting experience with Trees For Free charityKrishNo ratings yet

- Call God for $1: American's funny experience with golden phones to heaven around the worldDocument3 pagesCall God for $1: American's funny experience with golden phones to heaven around the worldKrishNo ratings yet

- 10 KL LPG Underground Storage TankDocument2 pages10 KL LPG Underground Storage TankKrishNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Degasification CostingDocument1 pageDegasification CostingKrishNo ratings yet

- TLS-450+ UlDocument4 pagesTLS-450+ UlKrishNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- PNGRB Technical Standards 2018 Schedule 2Document34 pagesPNGRB Technical Standards 2018 Schedule 2KrishNo ratings yet

- Compare Different Fuels (19052016)Document2 pagesCompare Different Fuels (19052016)KrishNo ratings yet

- Draft Cover Letter For Renewal KolhapurDocument2 pagesDraft Cover Letter For Renewal KolhapurKrishNo ratings yet

- Proposed QAPDocument5 pagesProposed QAPKrishNo ratings yet

- Electrical Boq for Sulphuric Handling at EnclosureDocument2 pagesElectrical Boq for Sulphuric Handling at EnclosureKrishNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument10 pagesPipe Flow Friction Factor CalculationspanchitasiNo ratings yet

- SL - No. Fuel 1 High Speed Diesel Oil 2 Light Diesel Oil 3 Furnace Oil 4 LPGDocument2 pagesSL - No. Fuel 1 High Speed Diesel Oil 2 Light Diesel Oil 3 Furnace Oil 4 LPGKrishNo ratings yet

- HSC User Manual PDFDocument47 pagesHSC User Manual PDFMiguel Mauricio Delgadillo FernándezNo ratings yet

- EDS CourseDocument18 pagesEDS CourseSaikumarNo ratings yet

- Power System RestructuringDocument54 pagesPower System RestructuringsachinNo ratings yet

- Manual CFDocument90 pagesManual CFVascovici DanNo ratings yet

- Troubleshoot and maintain your MODEL TPSD battery chargerDocument18 pagesTroubleshoot and maintain your MODEL TPSD battery chargerpailis2002No ratings yet

- Hard FM - Job Plan - MaterialsDocument190 pagesHard FM - Job Plan - MaterialsBejoyAnandNo ratings yet

- ABB - Protectii Fotovoltaice, Protectii - FotovoltaiceDocument20 pagesABB - Protectii Fotovoltaice, Protectii - FotovoltaiceIeremeiov Vladimir100% (1)

- Generators and Standby Power Systems 2014NEC PDFDocument23 pagesGenerators and Standby Power Systems 2014NEC PDFmikeyNo ratings yet

- Immi1kservice A1Document513 pagesImmi1kservice A1pulrob100% (5)

- FLUSARC 36kV - 630A - 25ka Maintenance Manual PDFDocument18 pagesFLUSARC 36kV - 630A - 25ka Maintenance Manual PDFJoey Real CabalidaNo ratings yet

- I-Gard Consultant Specification GuideDocument16 pagesI-Gard Consultant Specification GuideMrNo ratings yet

- LV PanoramaDocument8 pagesLV PanoramaAhmadBintangNegoroNo ratings yet

- Installation and Operation Manual BR Series Module: WAAREE Energies LTDDocument11 pagesInstallation and Operation Manual BR Series Module: WAAREE Energies LTDfghNo ratings yet

- NetSure IPE Series - UpdateDocument16 pagesNetSure IPE Series - UpdateEdgepoint TowersNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Samsung CAC (Slim 1 Way Cassette) Service ManualDocument107 pagesSamsung CAC (Slim 1 Way Cassette) Service Manualsonic865967% (3)

- H-800 User ManualDocument98 pagesH-800 User ManualAlbeiro PiraquiveNo ratings yet

- 5100 ManualDocument33 pages5100 ManualamenstoNo ratings yet

- Mentor II: User GuideDocument48 pagesMentor II: User GuidejairoNo ratings yet

- Catalogo Perma-CoolDocument24 pagesCatalogo Perma-CoolrotnegerNo ratings yet

- Product Information: One-Channel Controller TOPAX LDocument4 pagesProduct Information: One-Channel Controller TOPAX LdanielitarichiNo ratings yet

- 3512 12in Manual103007Document28 pages3512 12in Manual103007Joe HartNo ratings yet

- Protection of Power System Using Relays and FusesDocument39 pagesProtection of Power System Using Relays and Fusesshakeel akram100% (7)

- LAB 12 To Investigate Double Bus-Bar Basic System: ObjectivesDocument5 pagesLAB 12 To Investigate Double Bus-Bar Basic System: ObjectivesFARYYAD RANANo ratings yet

- V-280 TK50561-1-MM Rev 9-99Document122 pagesV-280 TK50561-1-MM Rev 9-99vickersNo ratings yet

- Eee Viii Electrical Design Estimation and Costing 10ee81 Notes PDFDocument113 pagesEee Viii Electrical Design Estimation and Costing 10ee81 Notes PDFKaran Murthy33% (3)

- MD464 BrochureDocument5 pagesMD464 Brochurejopenaga9975No ratings yet

- Upstream Electro-Mechanical Relay Static Relay: Table 15-3-Minimum CtisDocument1 pageUpstream Electro-Mechanical Relay Static Relay: Table 15-3-Minimum Ctiskoteswara raoNo ratings yet

- FS9V4 Manual v1.02Document26 pagesFS9V4 Manual v1.02Gian BaktiNo ratings yet