Professional Documents

Culture Documents

4 Over All Internship Experiance

Uploaded by

girumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Over All Internship Experiance

Uploaded by

girumCopyright:

Available Formats

Final internship semester report 2011

Brief history of MH engineering plc

MH engineering is an Ethiopian engineering consultancy head quartered In Addis Ababa

established in 1997. It specializes in consultancy service for contract administration, building roads

and public works with 170 employees. It is one of the leading engineering firms in the country. And

its main objective is providing multi-disciplinary consulting service to the public as well as private

firms engaged in the development of the various types of economical and social infrastructures and

buildings. The firm has the capacity to undertake such tasks feasibility and engineering management

studies, engineering services including design, supervision and contract administration of buildings,

roads and other related works.

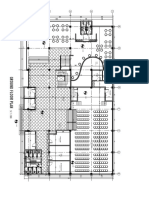

In the UCBP MH engineering coordinates and supervises architectural and engineering

consultants for each construction site. The company is also responsible for the design of four building

types in phase one. That means in UCBP MH engineering is responsible for the master plane,

building and infrastructure network design of the university campus.GIZ (the former GTZ)

international service coordinates every steps of this process from definition of the room programs

with regard to client demands to the final design for all trades.

University Capacity Building Program(UCBP)

The University Capacity Building Program (UCBP) is a large-scale capacity development and

construction project conceived, steered and fully funded by the Ethiopian Ministry of Education and

Ministry of Capacity Building

GIZ INTERNATIONAL SERVICE

GIZ international service is non-profit German development cooperation agency is contracted

by ministry of education to design plan and manage the execution of the project and coordinate and

supervise local contractor selected to construct to universities. In accordance with stipulation in

contract and collaboration with ministry of education and capacity building, GIZ will select local

contractor and commission the construction of the universities

One fundamental element of the planning process in the UCBP is to apply and improve the cost

efficient design (CED) methodology, developed and defined in the context of Ethio-German

cooperation. The methodology is established as standards in all UCBP universities buildings. The

CED

Saves money by reducing both construction time and material wastage

Allows a rapid construction without compromising quality

Streamlines established principles in construction efficiency

Here is a typical cost efficiently designed building in one of the 13 new university in UCBP

Jimma university, Jimma institute of technology-JIT Page 1

Final internship semester report 2011

MH engineering works with four consultants to carry out its responsibilities within UCBP these

partners are

- Fasil giorgis

- Gertta consultants

- Bet consultants

- Abba architects

In March 2008 MH engineering has received its iso 9001-2000 certificate. After 18 months of

hard work and as one of the first company in the Ethiopian construction sector. MH engineering has

been officially awarded for their success for the implementation of the quality management standard

Jimma university, Jimma institute of technology-JIT Page 2

Final internship semester report 2011

The main products or its service

Since the main work and service of our hosting company MH engineering plc is design and

supervision, it provides so many design and supervision works such as

Design and supervision of cost efficient house for house development agency

e.g. - condominium houses

Design and supervision of low cost building in UCBP

e.g. - in 13 new universities

Design and supervision of multi-purpose buildings

e.g. - multi-purpose building for athlete Seleshi Sihin and Derartu Tulu

Design and supervision of hotels and monuments

e.g. - 3 star hotel and shopping mall at Adama for Elemo Quiltu plc

-Oromo martyrs monument and related building at Adama

Design and supervision of offices and business complex buildings

e.g. - ministry of foreign affairs office building at A.A

-Biftu Adugna business complex at Adama

Design and supervision of hospitals

e.g. - Yetebon hospital at butajira for mercy project

Design and supervision of roads

e.g. – some road projects in A.A

- In u8niversities under UCBP

Design and supervision of stadiums

e.g.- Bahir dar stadium

-Awassa modern stadium

- Nekemt multi-purpose stadium

Design of real stats

e.g. - for sunshine real state at A.A

- For COD plc at legetafo

The main customers or end users of MH engineering plc

From the fact that MH engineering plc is a design and supervision office it gets in its hand in so many

sectors the clients widely varied from private investors to higher government offices, from single

business mans to huge contractors as well as nongovernmental organizations (NGO’S)

Jimma university, Jimma institute of technology-JIT Page 3

Final internship semester report 2011

Its over all organization and work flow

Resident engineer

These days the technology of construction industry has been improved very much.

Consequently modern design new construction techniques and material usage is in practice. This has

greatly required the improvement of the work methodology. As a result the supervision work shall

also be improved.It is clear that the supervisor has a big role to improve the time quality and cost

controlling in the construction industry. To implement these parameters (time, cost and quality) the

experience of the supervisor shall be carefully determined by the consultant depending on the size and

complexity of the project.

The main duty of the resident engineer is SUPERVISION AND CONTROL OF THE PROJEC

This includes:-

1. Quality control

2. Quantity and cost control

3. Program(time) control- (working schedule)

Quality control

Quality control is an essential need to ensure that the works are executed in

accordance to the specified standards

The contract document define the requirement for the quality if the material

Quality can be achieved through continuous inspection and checking of quality

material and workmanship. For every activity there is a check list for work permit

(inspection format). From sub structure excavation up to super structure finishing

work will be checked and inspection certificate will be issued to the contactor such

as:-

Earth work

Concrete work

Masonry work etc...

Types of quality control

a) Field test(e.g. Visual inspection)

b) Laboratory testing

1. Quantity (cost) control

One of the key elements to be controlled during supervision is to ensure that the project is

completed within the budget (original contract amount) this requires checking of the following

- Contract bill of quantities

- Drawings

If there are any changes further report the matter to the head office with possible

recommendation to keep the over all cost within the budget

Price escalation

Most of the time the bill of quantity is designed or prepared for ± six months from the day of signing

the agreement. now a days due to variation construction materials cost the contractor is forced to ask

price adjustment (better price than that specified on the contract document) the authorized body for

the price adjustment receive this request and by considering deferent condition which are necessary

and appropriate for the price adjustment (e.g. current price of construction materials, current price of

Jimma university, Jimma institute of technology-JIT Page 4

Final internship semester report 2011

transportation, etc..), he provide the new price which he assume it is enough for the current market.

This is what we call it price escalation

Here is the procedure, let say the contractor faced some variation (increase) in the costs of

construction materials then he apply his price adjustment request to the supervisor first at the site

level then if the supervisor believes that there is variation in the cost of construction materials by

checking it he transferred the request to the head office level and the price adjustment or price

escalation is done there at the head office level not at the site level.

2. Progress (time) control

The progress of the project has to be regularly controlled by comparing the actual progress against

the scheduled progress

If there are any delays analyse the cause and advise the contractor in writing to make remedial

measures where the delay is inevitable and not the fault of the contractor advise the client and head

office how to minimize the effect.

It has to be noted that recording the causes of delays is very important to settle claims amicably.

Delay from the promised schedule may be occurred due to the following reasons

Due to natural cases

There may be heavy rain or harsh environment like it may be too hot or too cold to

execute the work. At this time there may be delay

Due to client case

There may be problem in funding money for the executed items of work at this case

there may be delay

Due to contractor case

There may be miss management in the contractor office and works are not executed

in time so there may be problem in delivering the project in time

Due to shortage of construction materials in the market

This is the major case now a day in the most construction sites. That is due to

shortage of materials in the market the contractor is forced to stop the work

as u know the delay is occurred due to the above mentioned cases but time claim is not allowed for

the delay caused on the contractor side. But for the other cases the contracture has the right to ask

time claim for the delay he faced due to the cases other than his personal case.

Work pieces we have been executing

The works or the tasks that we are being executing during this four month internship program

are divided into two major parts

1 office work

2 and site work or site supervision buildings

3 site supervision of construction materials

1 office work

Jimma university, Jimma institute of technology-JIT Page 5

Final internship semester report 2011

the office works we are being executing were new for us because we didn’t take any theoretical

courses of such things. But it is not difficult for us when we were practicing, since it is not that much

effort needing.

The things that we were executing in the office are

- general office management

- preparing take off

- a little bit quantity surveying unit price analysis

- preparing payment

- a little bit official lettering

2 site work or site supervision buildings

as we previously tried to mention that the work of the hosting company is design, consulting and

supervision and we are only participate on the supervision because most of the design aspects of the

work are decided and finished at the head office level and the only thing that is left is whether the

work is executed correctly or not or in short supervision. Even though that is the case, but we tried to

ask all the supervisors near us that means we also aware of some design aspect of a building which we

don’t know before. One thing we want to notify is that we are not lucky to see the substructure that

means all the building in the site we assigned are in the superstructure stage. From the fact that there

are five contracting companies there in our site that means Dilla UCBP site so we had also the

opportunity to work with the contractor that means by being on their side. And some of the tasks we

were being executing are:-

Supervision:- we did some supervision of different items of superstructure works.

Those are:-

supervision of elevation column

supervision of intermediate and top tie beam

supervision of suspended slab

elements of structure stair case

supervision of block works

finishing work

roofing work

3 site supervision and quality of construction materials

in this context construction materials are the constituent of every building item of work such as slabs,

beams, roofs, etc.... for the good quality of such item of work, the constituent material that means the

construction materials should be inspected and supervised for quality.

We also dome project on the production of HCB, pre-cast, louver, man hall, etc...

How we get in to the company

First of all we would like to thank our industrial linkage office for helping us get the company

easily without any bureaucracy by directly contacting to our hosting company that means MH

Jimma university, Jimma institute of technology-JIT Page 6

Final internship semester report 2011

engineering plc by themselves. We are pretty lucky that our hosting company is located in our locality

and it helps us to save money and resources since we were living with our parents.

We did not want to west any time after we reach here in Dilla so we immediately apply to the

hosting company that means MH engineering plc Dilla UCBP site office. first they were not kind

since they did not receive any confirmation letter or oral order from the head office so the resident

engineer reject our application and advised as to inform our supervisor to do as he said. We call our

supervisor and told him as the resident engineer told us. then our supervisor inform us that he did us

we told him. When we went on the next day, the resident engineer proof that he had just received the

fax from the head office. After that moment we start the our work even though the first days are

simply a period of introduction with the stuffs it was not that much difficult for us since we know

most of them before.

Here in Dilla UCBP site there are five actively participating contracting companies such as

Teodrose Abera G.C

Kassu

Faver

Medrok foundation

Genale

So we get the chance to work with all the above companies since all the work they were being

executing were under the consultancy and supervision of MH engineering plc.

And one thing that i want to mention is that there are more than 20 buildings under progress here in

our site with different stage of progress which helps us to see most of the items of work in a given

building work except the substructure element.

Jimma university, Jimma institute of technology-JIT Page 7

Final internship semester report 2011

Procedures while performing our tasks

As we tried to mention previously the tasks we are being executing are being grouped in to

two major groups

1. Office work

2. Site work or site supervision

1 office work

From the fact that we didn’t take any theoretical lessons about the office works it is new for

us. But this didn’t stops us from working it we tried by our self. We got it not that much difficult.

Since it is not that much effort taking and not hard to understand.

The procedure we used while we have been executing the office work are not difficult and

sophisticated. Here in our site we were familiar with the stuffs so that we didn’t west any time to

communicate wit them. When we begin the office work they give us orientation about the work. Since

orientation is very important for every work because it create awareness about the work to the person

who oriented to execute the work. The orientation includes

I. General guidelines of office work

- Office discipline

- Office management

- Official lettering

II. Civil engineering office works

- Preparation of take off sheet

- Preparation of payment certificate

- Preparation of Quantity surveying

- Preparation of site diary and related letters

And then they told us how to execute what they oriented us before.

I. General guidelines of office work

Office discipline:- punctuality, responsibility, ethics ...

Office management:- about arrangement of your stuffs and related thing in order to make

your working environment good for work

Official lettering:- how to write official letters between different offices

II Civil engineering office works

Jimma university, Jimma institute of technology-JIT Page 8

Final internship semester report 2011

Since we got some information at the orientation we weren’t new for the thing. They first let

us to observe the executed work and then they tell us how to execute it. After that they gave us works

to exercise it. Then finally they give us some big assignment as a project and they prove how much

we are good. One thing that we want mention here is that they let us to do what they supposed to do to

build our confidence and now by this chance we would like mansion how mach than full we are. By

this procedure we execute most of the civil engineering office work such as

Take off sheet:-it is a chart used to determine the quantity of the particular item executed. It

Needs a personal skill of describing the item of work for one, to understand easily.

The chart consists of four rows with timing, quantity, result and description

respectively.

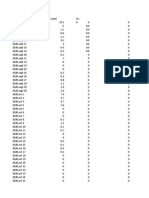

Below is a typical take off sheet

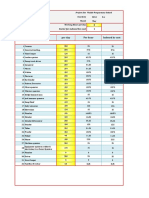

Payment certificate: - it is the certificate in which the body who executed the quantity of the

Work on the take off sheet gets paid. It includes all the taxes and related

things.

Jimma university, Jimma institute of technology-JIT Page 9

Final internship semester report 2011

Here is a typical certificate below

Quantity surveying:- this is the prediction of the materials required for a particular item of

Work

E.g. the quantities of the materials required for executing a single m 2 of slab

of known thickness are: -

x3 of sand

Y3 of aggregate

z3 (n bag) of cement)...etc

Site diary and related letters:-is a paper containing the daily life story of the site or the

project. It includes executed works, used materials, challenges etc...

2 Site work or supervision

Jimma university, Jimma institute of technology-JIT Page 10

Final internship semester report 2011

Since there are different contractors in the site, our hosting company assigned us at different

building with different contractors so we had the chance to supervise more than one building with

different stage of progress. So we can say that we were lucky. And We would like to describe the site

supervision work what we are being executing plus how to execute them by classifying them in

terms of the items of work executed such as:-

Methodology and supervision of elevation column

Methodology and supervision of intermediate and top tie beam

Methodology and supervision of suspended slab

Methodology and supervision of elements of structure stair

case

Methodology and supervision of block works

Methodology and supervision of finishing work

Methodology and supervision of roofing work

Elements of structure: elevation column

Since it is a concrete structural element the necessary inspection for quality of the concrete

and the way it is being executed.

Methodology

The reinforcement with the correct height, size and arrangement as per the design

are assembled.

Then the formwork fixed in position around the assembled column reinforcement

with specified clear cover as per the design

After that it will be filled with concrete ( in simple word it is casted)

Supervision

A. before casting

B. during casting

C. after casting

A. before casting

stirrup spacing should be cheeked it depends on the design (but in our case 5cm

from the floor and every 15cm up to the overlap end after that at every 20cm)

reinforcement diameter and overlap length(40 times diameter of the

reinforcement ) should be cheeked

the quality of formwork (cleanliness, smoothens and treatment with release agent

for the surface of formwork )

conformity of the formwork with the approved formwork design

Jimma university, Jimma institute of technology-JIT Page 11

Final internship semester report 2011

grout tightness and sufficiency of rigidity to prevent disturbance due to pressure

of concrete, effect of vibrator and other load

provision of spacer with the required dimension

provision of opening for maintaining pouring height of concrete without

segregation

the vertical and the horizontal alignment of the columns should be checked by

any method approved by the engineer (here in our case with ligna and tumbi )

column height should be checked

column spacing should be cheeked

stock balance should be checked (that means the quality and quantity of the

materials required to execute the required concrete volume )

Here I Would like to show you a typical elevation column before it is casted and

after the formwork is prepared

B. during casting

cheek the availability of enough man power and machineries

the appropriate use of vibrator

cheek the mix ratio(1:2:3) and the mix itself

Way of the execution of the work (way of mixing, way of placing, distance the

concrete travel from the mixing station to the casting station etc... )

C. after casting

cheek the time frame for the removal of formwork (16 hr)

proper curing (7days)

cheek if there is segregation

Element of structure: intermediate beam

Methodology

check the proceeding work acceptance

Then prepare the reinforcement as per the design (length, type, diameter, and cut,

bent...)

prepare the formwork and assemble them around the beam with the required clear

cover by providing spacer of the right thickness

place the prepared reinforcement on their position as per the design

Jimma university, Jimma institute of technology-JIT Page 12

Final internship semester report 2011

then it is ready to be casted after u check the alignment and it is ok

Supervision

- Before casting

- During casting

- After casting

Before casting

conformity of the formwork with approved formwork design

cleanliness, smoothness and treatment with release agent for the surface of formwork

conformity with the approved formwork design i.e. dimension, shape, strength,

method of fixing, rigidity, bracing detail and method of removing the formwork

reinforcement diameter, number and overlap length(40 times diameter of the

reinforcement) should be cheeked

position of overlap of reinforcement as per the design

stirrup spacing should be cheeked

check provision of spacer(type, shape, dimension, spacing and method of fixing it to

maintain the required concrete cover)

check stock balance(volume of the required material for the required concrete volume

)

man power

equipment

During casting

D. cheek the availability of enough man power and machineries

E. the appropriate use of vibrator

F. cheek the mix ratio(1:2:3) and the mix itself

G. Way of the execution of the work (way of mixing, way of placing, distance the concrete

travel...)

After casting

cheek the time frame for the removal of formwork(16 hr)

proper curing (7days)

cheek if there is segregation

check if there is bulging of the beam

maintenance and handling of executed works

For top tie beans it is the same to that of the above. But here I want to give attention for some the

inspection procedures such as

it should be level

it should be align and straight

provision of connection mechanism between the beam and the roof

truss (that means provision of plates and J dolts for steel truss and

provision of stirrups at every 1.2m or at every horizontal chord )

Jimma university, Jimma institute of technology-JIT Page 13

Final internship semester report 2011

Element of structure: suspended slab

here in our site there are two deferent types of slab: slid slab and ribbed slab( the

latest pre-cast technology). And we use solid slab only at the location where water tightness is

needed that means at bathes and toilets the rest of the building part is the new pre-cast

technology.

Methodology

the vertical wooden supports for the beam (the labour calls it cristi) and for pre-cast

(the labours call it modini) assembled in place with sufficient spacing (0.5-1m)

place the pre-cast in place with the spacing as per the design make sure that to

consider the cambering effect for the pre-cast slab that means 2cm up the central

support of the pre-cast (about the production of pre-cast beam see appendix 2)

Put the HCB between the pre-casts. Since the main purpose of ribbed slab is to

save economy by reducing the amount of concrete consumption. So the HCB at the

edges should be blinded to prevent the concrete from entering to the HCB halls

put the reinforcement (meshes and the main beam reinforcement as per the design)

Execute the necessary works such as sanitary, electric, etc... works

then we can cast the slab with thickness as per the design

Here is a typical ribbed slab with the latest precast technology

Supervision:

A. before casting

B. during casting

C. after casting

Before casting

submittal of form work design

conformity with approved formwork design i.e dimension, shape, strength, method

of fixing, rigidity, bracing detail, detail for false work, method of removing the form

of detail at joints (slab thickness waist)

Jimma university, Jimma institute of technology-JIT Page 14

Final internship semester report 2011

submittals of shop drawing showing diameter, spacing, number, lengths, method of

tying and bending dimension of main reinforcement bar in accordance with the

drawing

cleanliness of all reinforcement bars(free from dirt, paint, oil, rust and other foreign

substance)

reinforcement over lap location and length to be as shown in the drawing

attention for position of the reinforcement in cantilever section (presence of bar fixer

during placing of concrete for correction and positioning of reinforcement during

placing of concrete )

approval of toilet seat fixer so that the exact position for the outlet can be identified

provision of PVC pipes on the outlet position of the toilet seats to avoid further

chiselling

Proper provision and fixing of electrical conduits and sanitary pipes. approve the

work permit above before placing concrete

type of material to be used for form work

method used to treat the formwork to prevent adherence of concrete(coating with oil

or any other release agent)

cheek whether or not the effect of cambering is considered

Check the entire sanitary, electrical etc... works that are executed in that particular

slab

During casting

H. cheek the availability of enough man power and machineries

I. the appropriate use of vibrator

J. Cheek the mix ratio (1:2:3) and the mix itself (way of mixing, way of placing ....)

K. Way of the execution of the work (way of mixing, way of placing, distance the concrete

travel...)

After casting

-cheek the time frame for the removal of formwork (after 28 days for bottom supports

and after 16hr for side supports)

-proper curing (7days)

-cheek if there is segregation

Check the way of handling the executed works

Elements of structure: stair case

Here in this site (dial USBP), there are two types of stair cases

- Stair case from steel

- Stair case from RC

STAIR CASES FROM STEEL

Methodology

Jimma university, Jimma institute of technology-JIT Page 15

Final internship semester report 2011

The steels with full accessories of the stair cases are fixed or welded by the skilled

workman as per the drawing

Supervision

Qualification of the manufacturers/onsite production

Location of the items/actual position checking

Checking of the physical appearance with deliveries

Characteristics of material

Section of steel angle frame/ curbing

Type of weld thickness selected type of paint /appropriateness /antirust

Size of section

Projection over the level of the open mesh

Type of weld and connection details

Foundation of stand/ embedment depth footing

Vertical clearance between successive treads

STAIR CASE FROM RC

Methodology

The workman fix the riser and trade formwork as per the

design(drawing)that means the dimension of the trade and riser

Supervision

Since the RC stair case is one of the main structural element which need a great

follow up so we need to take care of its supervision and as before the supervision is divided

in to three as:-

- Supervision before the concrete is casted

- Supervision during concrete casting

- Supervision after concrete casting

Supervision before concrete casting

Pattern of contract trade /landing /riser including their dimension

The reinforcement(size, length, arrangement, length and position of

arrangement )

Provision of spacer

The stock balance(the quantity and quality of the materials required

to execute the required volume of concrete)

Supervision during casting

The same to other structural elements

The way they execute the work and closely follow up where they

have to stop the work if they needed to stop the work before

completing the work

Super vision after casting

The same to other concrete structural elements

Block work

Jimma university, Jimma institute of technology-JIT Page 16

Final internship semester report 2011

Methodology

Concrete blocks shall be obtained from an approved supplier or may be manufactured on site.

Samples and test results shall be submitted for approval by the engineer before any blocks are

delivered or used in the construction of the work

First of all the workman adjust the thickness of the mortar by relating the area to be covered

with the number of blocks it consume. This is to avoid the use half or broken HCB

Then by lying the block one over the other, we can execute any block works (external wall,

partition wall, elevated wall...)

A maximum of 5 course is allowed to execute once

Some important points

A. All block work shall be solidly bedded, jointed and pointed in mortar. Where wall faces will

be plastered or rendered or pointed , the joints shall be raked out to form a key. Blocks shall

be butt jointed and laid with nominal joint of 10mm in cement mortar

B. Concrete block walls shall be carried up in uniform manner with no adjoining portion raised

more than one meter above another, the open ends being racked up and not toothed, all

perrpends and quoins shall be strictly plumb square and in line.

C. During hot or dry weather and when absorption is excessive blocks shall be wetted with

clean water before laying

D. Newly and partial erected block walls shall be protected from drying out too rapidly by the

suns heat and they shall be kept well-watered for at least three days

E. Finished walling shall be protected from damage by subsequent operation ad where exposed

surface is specified in the drawing any mortar on the surface of wall shall be cleaned out

before setting of the mortar has occurred

F. All block work walls which are not rendered are to be fair faced. if required by the engineer, a

specimen panel of fair faced block work shall be erected for approval by the engineer

Supervision

Quality of the HCB block (about the production of HCB block see appendix-3 )

Maximum allowable height

Provision of stiffing column /beam

Bondage of masonry

Uniformity of colour, texture, size etc of the wall

Embedment of electrical and sanitary items

W/C ratio of mortar joint thickness

Jimma university, Jimma institute of technology-JIT Page 17

Final internship semester report 2011

Finishing work

Provided cement, lime, aggregate, labour equipment, and tools for plaster and pointing as

required for the satisfactory installation of the works

Pavers and plasterers shall be skilled workman who are thoroughly trained and

experienced in the necessary crafts.

Raw Materials(typically used in our site)

Aggregate:- The first step in making good mortar is obviously to see that the

aggregates are satisfactory. And so that it should be

Clean- Clay, mud or silt present in the aggregate will produce lower

strength mortar

Water content should be limited- The amount of water in the aggregate is

very important because it wiil affect the total amount of water in the mix

Storage- Aggregates need careful storing. It is no good making sure they

are clean when they arrive if you let them get dirty on the site.

Cement:- The type or types of cement to be used on the contract will normally

have been decided by the engineer or architect. It should be stored separately

from other items and protected from damp raised due to weather or ground

condition

Water:- All water used shall be cleaned, free from earthly vegetable or organic

Material and from acid and alkaline substance in suspension or solution or in

short it should be protected from contamination

Tiles:- it is most of the times from factories with approved quality

We would like to group the finishing work in to four groups( which are applied here in our site)

1. Plastering, pointing and screeding

Jimma university, Jimma institute of technology-JIT Page 18

Final internship semester report 2011

2. Tiling

3. Painting

Plastering

Plastering by definition is coating which may apply by thin successive layers on a

vertical supports of masonry or concrete with a decorative and/or protection aim or to

standardize a surface need to support another coating (paint for example). And plastering

worker is a worker who works the mortar covering on walls and usually builds work where

the cement or the lime is one of the main constituent

Plastering shall be applied after chases for service have been cut service

installed chesses made good

Surface to plastered shall be thoroughly washed with clean water before

plastering is commenced

Where joints exist between two surfaces of deferent material characteristics,

the engineer may direct the fitting wire mesh reinforcing the plastering or the

plaster shall be raked to a minimum of 10mm depth and the joins finished

and pointed cement mortar

Both external and internal plastering shall require the running of rules before

commencing the first coat and all plastering shall be plumped

Dumping out to make up uneven surface of walling shall be done before the

first coat of plaster is applied

Inspection

Qualification of the plasterer

Chiselling state of concrete surface

Quality of HCB, aggregate, water...

Levelling and plumping state of erected wall

Duration between first , second and third coat (minimum)

Mix proportion of plaster is uniform from start to end

Curing state of plastering

Linearity of plastered walls

Etc...

Pointing

Pointing is by definition to stuff mortar in to joints of a masonry using a pointer in or to bond

courses between them correctly

Joints of masonry surface to receive pointing shall be racked out to a

depth specified by the engineer and all mortar shall be removed

The joints shall be well wetted before the application of pointing

Any irregularities of joints shall be chased and made good

Jimma university, Jimma institute of technology-JIT Page 19

Final internship semester report 2011

Inspection

The quality of the workman

A pointed surface shall be well plane showing horizontal and vertical

pointing perfectly even and symmetrical

Cleanliness of the pointed wall surface

Proper curing

Screeding

Concrete floors to receive cement screed shall be cleaned thoroughly

with clean water

The surface of concrete shall be kept damp at least for 48 hours

The prepared surface shall be kept clean and free after application of the

final coat

Inspection

Qualification of the mason

Completion of preceding work(ceiling /plastering)

Checking of F.FL FROM nearby rooms (important)

Levelling state of floor to be screed

Adopting method of levelling source

Quality of fine aggregate, water etc...

Method of mixing of mortar

Nature of labour tools thickness of designed screed smooth nature of

finished surface

Curing of screed surface

Protection measure of finished surface From damage

Tiling

Provide cement, sand, aggregate, tiles, admixtures, and other finishing material labour and

tools for the satisfactory completion of the work and polishing at the end of the work. Pavers shall be

skilled workman who is thoroughly trained and skilled as well as experienced in the necessary craft.

The qualities of the constituent materials that means aggregate cement is as that of plastering

Inspection

Qualification of tiller/ methodology

Readiness of floor W.R.T other works / level

Level of floor(each room)

Material approval

Nature of adhesives (approved with new deliveries )

Duration from screed to tile placing

Presence of tile spacer

Method of stabilization tiled surfaces

Protection measure for unnecessary surface spread of adhesive cleaning area of finished

surfaces

Curing period

Jimma university, Jimma institute of technology-JIT Page 20

Final internship semester report 2011

Roofing work

General

For building with concrete roofing , the roof is designed with the required treatment.

Corrugated roof sheet or roof tiles may be used as alternatives if required by the engineer.

The work included is that provision of liquid members patching roof material, labour and tools and

perform waterproofing as shown on drawing as specified herein and as required for a complete and

satisfactory installation of the work.

In the qualification of the work, use adequate number of skilled workman who are thoroughly

trained and experienced on the necessary crafts and are thoroughly familiar with the specified

requirements and methods needed for the proper performance of the work in this section

Inspection

FOR ROOF COVERING

For roofing Qualification of workman

Type of roofing

Approval of roofing material

Protective cost to respective and purline members

Levelness of purlin

Length of each plain sheet accessories

Overlap length (side and end lap) of the roofing

Galvanization nature of the roofing

Fixing material quality weight per ml of EGA roof

Thickness of the roofing proposed access to roof precedence of fascia and

gutter fixing

For gutter work

Qualification of workman

Types of gutter

Material approval

Thickness, width, and length of the brackets

Nature of the material, (it’s galvanization and the like)

Type of lead material

Number of joints and type of connectors (for U PVC down pipes)

Sufficiency of overlap lengths

Presence of fascia board /final plastering

Slop of gutter

Spacing of straps

Means of fixing

For down pipes

Jimma university, Jimma institute of technology-JIT Page 21

Final internship semester report 2011

Qualification of workman

Type of down pipe material approval slip and samples

Thickness, width and length of the brackets

Nature of the material (its galvanization and the like)

Type of lead materials

Number of joints and types of connection (for U PVC down pipe)

Sufficiency of fascia board/ final plastering

Slope of straps

Means off fixing

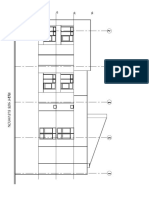

Here is a typical section of roof in our site

Supervision and inspection of construction materials

We got the chance to supervise the constituent materials of reinforced concrete. Most of the buildings

use reinforced concrete as the building material. It is the heart of every structure so it need to be

inspected and supervised for quality carefully more than any items of work.It is composed of both

concrete and reinforcement bars. And the concrete is composed of aggregate (fine and course

aggregate), cement, and water and some times admixtures . So the constituent material of the

reinforced concrete are :-

1. Aggregate(fine and course aggregate)

2. Cement

3. Water

4. admixtures(if any)

5. Reinforcement bares

Aggregate (both fine and course aggregate)

Jimma university, Jimma institute of technology-JIT Page 22

Final internship semester report 2011

The importance of using the right type and quality of aggregate, both fine and course, can’t be

overstressed since the stone and sand together make about three-quarter of the concrete. The first step

in making good concrete is obviously to see that the aggregates are satisfactory .Since such will affect

the concrete, it is your job to ensure that unsatisfactory aggregates are not tipped at the back of the

mixer or on to the stockpiles and used subsequently in concrete.

Cleanliness

Clay, mud or silt present in the aggregate will produce lower strength concrete. Equally

rubbished should not be allowed to contaminate stalk piles.One way of checking of such quality at the

site is by hand test. Rub some sand from the pile between the hands. If the sands leaves stain it may

be too dirty to use and must be given a further test. If the hands stay clean the sand is probably all

right. As you see in the figure below

Grading

The proportion or amounts of the varies sizes of particles making up the aggregate are found

by sieving and the result is known as the grading. if the amounts of the various sizes differ from batch

to batch of the concrete mix the workability of the concrete and its strength will also vary from batch

to batch

Water content

The amount of water in the aggregate is very important because it will affect the total amount

of water in the mix. A wet batch of aggregate will make the concrete mix wetter, too wet a mix makes

a weak concrete. The mixer driver can control the amount of water in the mix to some extent to allow

for over wet or over dry aggregate but this is easier said than done and it is much better if the mixer

driver does not have to make frequent changes in the amount of added water.Another point here is

that if the water in the mix is not kept constant the workability. As well as the strength will vary from

mix to mix

1.4 Storage

Aggregates need careful storing. It is no good making sure they are clean when they

arrive if you then let them get dirty on the site

1.5 Inspection

The type and quality of the aggregate to be used on the job will have been specified

by the engineer and before concreting begins a preliminary inspection of locally available

aggregate will normally have been made by the engineer and approval given to the user if

found satisfactory

coarse aggregate should be inspected for:

- Specific gravity(at the site by judging its weight

with our hands)

- Clay coating(visualy)

Jimma university, Jimma institute of technology-JIT Page 23

Final internship semester report 2011

- The grading(visually and sieve analysis if

necessary)

- Particle shape(visualy)

Fine aggregate should be inspected for:

- Gradation(visually and siev analysis if necessary)

- Organic impurity(visualy)

- Silt content(by taking jar test)

One thing we want to be noted here is that the inspection methodology we listed above are those

which we were using at the site

Cement

The type or types of cement to be used on the contract will normally have been decided by the

engineer or architect.

Cement storing

Everybody knows that cement must be kept dry, but it is not always realized that damp air do

as much harm as direct moisture. The length of time cement can be stored and then used satisfactorily

depends mainly on the storage container and climatic conditions. Cement delivered in bags should be

inspected as it is placed in the store.

2.2 Supervision

Fulfilment of quality test

Type of cement (ordinary Portland pozolana, sulphate resistance, etc...)

Stored separately from other items

Protected from damp raised due to weather or ground condition

Stored so that the cement will be used on the same order as it is delivered

Free from dampness and partial setting

Age of cement

3 Water

All water used shall be cleaned, free from earthly vegetable or organic material and from acid

and alkaline substance in suspension or solution. Water shall be stored and distributed about the site

in containers, vessels, and through pip work which shall not contaminate it.

3.1 Supervision

Protected from contamination

3. Admixtures

Admixtures are those things which are added to concrete mixes in order to improve the

quality of the concrete that means to improve there ability to withstand different environments.

Then the above four constituent materials are binded to form what we call it concrete. The good

quality of the constituent materials only cant ensure the good quality of the concrete work such as

Jimma university, Jimma institute of technology-JIT Page 24

Final internship semester report 2011

beam, slab and so on. The next question is how to mix them and how to place the concrete. If u need

unswer to this challenge u can see appendix 1 execution of concrete

Reinforcement

The success of a reinforced concrete job depends to a larger extent on the reinforcement being

correctly fixed in the concrete with the right cover. If it is not fixed properly, and moves during

concreting the member will not be as strong as it should be. Such weakening could lead to failer under

load in addition if the cover is not enough the reinforcement will rust, expand and eventually spall the

concrete which again will weaken the structure as well as spoil its appearance

Bar types and identification

There are two main grades of steel used for bar reinforcement, one is mild steel and the other

is high-yield steel (previously known as high-tensile steel).with material properties as shown on the

table below

Material Minimum Yield Point Ultimate Stress Minimum

Elongation

It

Unit 2 2 %

kg/cm kg/cm

Mild Steel 2400 3700 20

High yield Steel 4200 5000 18

is important to be aware of the different types of reinforcing steel, how to identify them and where to

use them.

. Storage of reinforcement

Bars for site cutting and bending if not already bundled and labelled, have to be stored into

sizes and lengths. Make arrangements for storing the bars until they are required by the bar

cutter/bender, So that they are conveniently handled. Stack the bars so that the different types, lengths

and sizes can be quickly and easily identified. One method is to make division by driving wooden

posts or large bars in to the ground so they stick out by about 0.5m to 1m and are about 0.5m to 1m

apart. Depending on the quantity to be stored, this method makes it easy to drop the bars in or to take

them out. If you have the ends of the bars butted against a timber stop at one end. You can easily

measure the length

The main points with storage are, first, to have the bars laid so that the correct size and length

are readily available without the need for any double handling. And second to ensure that they do not

become contaminated by such things as mud, oil and grease. U can see a good practice of handling

reinforcement bars at the site with that of bad handling below.

The reinforcement bars are inspected for:

- Ultimate tensile stress

- Yield point stress

- Elongation

Jimma university, Jimma institute of technology-JIT Page 25

Final internship semester report 2011

But most of the time this inspection is done at head office level because this testing machines are not

available at the site easily.

Our performance

as we told you before we were eager to know each and every thing and to be practically rich.

There were around 20 buildings under progress with deferent stages that’s why we get the chance to

see many things within this short time. In this case making us practically rich is not negotiable, so that

they evaluate us whenever they thick it is necessary. The evaluations are;-

- By preparing test sheets

- Giving projects

- Giving assignment

- Site oral examination

Test sheet: - after a month after we started the work they prepare them with test sheet of 12

test questions. Most of them are cases and which are practically being applied at the site now

a day’s including in our site. So we found it interesting. As I told you before in this section

we were eager to know everything so the test was not that much difficult for us and the

evaluation was pretty good

Project:-then next they give us a project on the production of construction materials which

have being execute in our site. Such us:-

- HCB

- Pre-cast beam

- Louver

- Man halls

This is important for one engineer to specifically inspect the quality of materials he is

going to use and we made it well from their raw materials to their inspection and how to

install them in one building. One thing here in our site is there is no efficiently working

printer machine. So most of the work we done are in soft copies in including this project

Assignment:- they also gave us assignment on office works that means preparing take of

sheet of a particular building located in the site named with central library

Site oral examination:- we also orally evaluated at the site with procedures and picking

default in the work with its possible recommendation

Challenges

When we work didn’t faced with that much challenges both inn quantities and their

difficulties that means they were not beyond our scope the challenges were:-

- Communication challenges

- Work challenges as:-

Jimma university, Jimma institute of technology-JIT Page 26

Final internship semester report 2011

o Typical words used at the site

o Segregation

o Cracking of finished wall surface fghfghgfjhj

Measures to overcame the challenges

Communication challenge

This challenge makes us not to have healthy communication with the site communities such

as; site engineer, ‘Forman’, ‘kabo’, daily labour etc.... from the fact that we come from the

supervision site that means we were in the consultant side and they were from the contractor side,

there is a trend that the two are looking each other as a cat and rat. So they consider us a watch dog

for our office so they don’t even talk with us. But through time we let them to know our work and

objective that we are here not as a snitch, rather to learn from them. And we told them that can’t let

happened without them. But one thing to be noted here is that when we see any default at any

building in our site we don’t pass without reminding them and thanks to them they respect every

suggestion we recommend to them. So we can say that we were lucky of having this types of

relationship

The other thing is that most of the workmen are afraid to tell us what we asked. Because they

think we know everything and now we are joking. In order to overcome this problem we ask

everything even we know. This is to build their confidence and to let them to know we know little and

they know better. At this time they are willing to talk.

Common words used at the site, this are the site words which we don’t know before when we

were at the school. such as:- table showing this words from kiwi this are also challenges because in

the early period of our internship we get difficulties of communicating with the labours. And the first

thing that we did before we go to the site is studying this words and familiar with them because we

need to know them to communicate with most of the site communities

Work challenges

This is challenges that we face when we are at our tasks and they need our suggestion and we did it.

And we would like to mention in the following section. These are:-

Segregation:- this is a phenomena when the reinforcement bars are exposed to the external

environment gets contact to air. This makes it to get rest corrode and this let it to reduce its strength

Segregation can be happened due to:-poor vibrator usage during casting

-placing concrete from height greater than 2.5m

-miss use of spacer

We didn’t let that happen by taking the above reasons but if it does the only thing that we can

do is covering the exposed reinforcement with mortar if it is not that much affect the design strength.

Cracking of finished wall surface:- this the phenomena when the wall gets cracked. This is

due to

Improper curing:-as we know the finished (plastered) wall surface should be kept wet for 7 days by

pouring water on it for at least 3 times a day. So in order to prevent this we recommend them to cure

it carefully

Jimma university, Jimma institute of technology-JIT Page 27

Final internship semester report 2011

Direct contact with the high sunshine;- this makes the wall to dry too rapidly even if we are curing

well. in most sites this may not happen because the sunshine is not that much significant. But here in

our site since the climate is to hot recommend them to make the wall under shad by any means they

can.

Over all benefits

Internship program is a method of letting the students to assume themselves as a potentially

responsible workman for a particular work by assigning them to actively participating construction as

well as consulting companies. And such trends helps us to have valuable work experience. Internship

programs are also potentially valuable to company. Unfortunately, some companies continue to

regard interns as little more than a free source of labour to catch up on filing and other tedious office

tasks. But many business owners and managers realize that internship programs can provide them

with an early opportunity to gauge the talents of a new generation of workers and, in many cases, sell

themselves as a quality place for students to begin their careers after they graduate.

In this internship that means within this four months we can observe what the outside

construction world looks like more than we know when we were at school. When we were at the

school we learned or take many theoretical lessons even difficult to understand theoretically. So in

this internship we get good opportunity to solve these difficulties. Because those things which were

theoretically difficult to understand, were not hard to understand when we learned practically.

The overall benefits of the intern ship are not limited to the practical skill only. We would like

to group the overall benefits in terms of different categories such as:-

In terms of improving our practical skill

In terms of upgrading our theoretical knowledge

In terms of improving our interpersonal communication skill

In terms of improving our team playing skill

In terms of improving our leadership skill

In terms of understanding about work ethics related issues

In terms of entrepreneurship skill

In terms improving our practical skill

In this context practical skill is that we gain by applying different type of construction

method, and we can improve our skill by relating the different construction methods with the

theoretical lessons that we learned at school. In this internship we have exposed our self to different

practical skill and ask to learn more. As we tried to mention above there are around five contracting

companies under the supervision of MH engineering plc here in our site so we gat the chance to work

with all of them that means we gat also the opportunity to work in the contractor side to.

Some of the practical skills that i gained or learned during the internship program are:-

General office works as:-

Preparation of take off sheet

Preparation of payment certificate

Quantity surveying

Supervision of different super structure items as:-

Jimma university, Jimma institute of technology-JIT Page 28

Final internship semester report 2011

Supervision of elevation column

Supervision of intermediate and top tie beams

Supervision of suspended slab

Supervision of HCB walls etc...

Production and supervision of different construction materials such as:-

HCB

Pre-cast beams

Louver

Man halls

Field test of concrete such as:-

Cube test- compressive strength test

Slump test- workability test

Creativity of construction methodology for executing deferent items of work

Creativity and expression of idea in solving problems

The ability to read complex blueprints and point out some design defects

Theoretical knowledge

Thanks to this program we got the chance to apply our theoretical knowledge in the real

construction world. And this builds our confidence in theoretical knowledge. In order to illustrate this

we would like to list some of them

In arrangement and curtailing of reinforcement bars

Moment zero condition (that means one third rule) etc...

As we know Almost all the courses we took were focused on theoretical part, thanks to this

internship program; we are now able to upgrade our theoretical knowledge by practice. So we can say

that our knowledge is upgraded by the practical things we have seen at the site.

Interpersonal communication skill

Interpersonal communication is usually defined by communication scholars in numerous

ways, usually describing participants who are dependent upon one another and have a shared history.

It can involve one on one conversations or individuals interacting with many people within a society.

It helps us understand how and why people behave and communicate in different ways to construct

and negotiate a social reality. While interpersonal communication can be defined as its own area of

study, it also occurs within other contexts like groups and organizations.

For any person communication is an important way of learning, which can be defined

formally as the act, process, or experience of gaining knowledge or skills. Cool communication is

important in the real constructions world and it can appear in different forms as speaking, writing, and

listening.

During our internship we have improved my communication skill by communicating starting

from daily labour to project manager learning different type of construction term

Construction is team work, team work is work performed by not only by one person rather

than cooperation with other. This success couldn’t be achieved without developing good

communication skill.

Jimma university, Jimma institute of technology-JIT Page 29

Final internship semester report 2011

Project that we have been involved has different people with various back ground came

together. They are vary in educational level, economic situations, cultural backgrounds and etc. Since

the aim of the project is to accomplish the work in good way, we need to have good communicative

skills .

During our internship I have improved my communication skill by communicating starting from daily

labour to project manager learning different type of construction term which are listed in the

following table

Site words Rough meaninng

solata slab

muzra spaceer

tumbi plumbo

fundo Soffit

musheleit Is a timber material used to join

two timbers

ponte T shape like scaffold for slab

Stanga to keep stand the

formworks

Kerebat Timber material used to keep the

column formwork fixed.

Squadrato keep some area rectangle or make

each angle 90

Fero reinforcement bar

Stafa stirrup

Team playing skills

At times, when different individuals come together to work for common goals of the company

for increasing productivity, The most important point is just reaching an agreement from different

points on the work to be done. There are some key point which describe what team playing skill ,

some of them are below relating to internship.

Demonstrates reliability

You can count on a reliable team member who gets work done and does his fair share to work

hard and meet commitments. He or she follows through on assignments. Consistency is key. You can

count on him or her to deliver good performance all the time, not just some of the time. We have been

reliable for the works that they gave during the internship program .that means since we are three we

onestly deliver our effert to the group work that is given. this encourage our involvement in team

playing skill .

Jimma university, Jimma institute of technology-JIT Page 30

Final internship semester report 2011

Shares openly and willingly

Good team players share. They're willing to share information, knowledge, and experience.

They take the initiative to keep other team members informed.

Much of the communication within teams takes place informally. Beyond discussion at

organized meetings, team members need to feel comfortable talking with one another and passing

along important news and information day-to-day. Good team players are active in this informal

sharing. They keep other team members in the loop with information and expertise that helps get the

job done and prevents surprises.

In our period of internship the company staff member share information and we also share

information or knowledge that we gain to one another since we are three and we were assigned in

three different groups of building. this helps us to know what activity was going on in all three

categories of buildings each day and improve our team playing skill

Works as a problem-solver

Teams, of course, deal with problems. Sometimes, it appears, that's the whole reason why a

team is created is to address problems. Good team players are willing to deal with all kinds of

problems in a solutions-oriented manner. They're problem-solvers, not problem-dwellers, problem-

blamers, or problem-avoiders. They don't simply rehash a problem the way problem-dwellers do.

They don't look for others to fault, as the blamers do. And they don't put off dealing with issues, the

way avoiders do.

In construction project problem often arise with different reason , we have seen some

technical problem encountered during executing a particular item of work and design defaults at this

time they let us involved in the problem solving procedure and we also put our effort proudly without

any fear. There also dispute arises between the contractor and consultant but they have solved

problem easily this helped me to improve my team player skill.

Leadership skill

A manager is the person in charge of commanding and running a business or a project.

Leadership deals with the interpersonal relations. Managing means planning, developing and

organizing. In the contemporary society leadership qualities along with managing abilities are a must.

In our internship we have done some tasks which were related more of with leadership and

management. we were responsible to control and supervise some activity. A leader is basic for the

whole project to be hindered well. Leadership stated from planning. This helps to know the progress

of the work to be done and the required goal to be achieved. After having a good plan by organizing

the team and creating best strategies we could achieve our goal. By doing so and getting more

leadership experiences from the site supervisor we could improved our leading ability.

Work ethics

Work ethics include not only how one feels about their job, career or vocation, but also how

one does his/her job or responsibilities. This involves attitude, behavior, respect, communication, and

interaction; how one gets along with others. Work ethics demonstrate many things about whom and

how a person is.

Jimma university, Jimma institute of technology-JIT Page 31

Final internship semester report 2011

Work ethics involve such characteristics as honesty and accountability. Essentially, work

ethics break down to what one does or would do in a particular situation. The begging question in a

situation involves what is right and acceptable, and above board, versus what is wrong, underhanded,

and under the table

In our period of internship we understand what work ethics, one of ethics is punctuality. To

be punctual is duties of every worker so that they could achieve there task with the time given and we

have been punctual .

Other work ethics is to be anti corruption which not taking thing that benefited us in illegal

way .other work ethics

Punctuality- means keeping the companies work beginning and ending time and to complete a

given task within the given period. That was challenging to become punctual for the 1 st days

of work. But gradually I began to start and end my tasks on time.

Office disciplines- in work place you don’t have to disturb the working atmosphere. For

example abstain from opening loud voice, loud music, songs and things which disturb other

workers’ working mood.

Reliability- The worker should be qualified for the part he is supposed to be

performing . He/she must have appropriate skill and knowledge for the task assigned .

Honesty- Regarding this value each worker regardless of its status should abstain from

bad behaviors such as cheating , bias , corruption etc..

Cooperation- Each worker should interact and cooperate with each other while working

. That is because it is through such system problems could be easily solved .

Avoiding potential or apparent conflict of interests

Entrepreneurship skill

Entrepreneurship is a key driver of economic growth and job creation. It provides many

people with career opportunities that better fit their preferences than waged employment.

After the completion of internship , we are more motivated to look forward in construction

business and to start taking sub contract with different technique.

Jimma university, Jimma institute of technology-JIT Page 32

Final internship semester report 2011

Appendixes

Appendix 1-Execution of concrete

Mix proportions.

The concrete mix shall be designed to have the minimum cement content and the grading

between the limits shown for course and fine aggregate shall be such as to produce a workable and

dense concrete with appropriate water-cement ratio

Mixing of concrete

The concrete shall be mixed in an efficient automatic mechanical mixer of an approved type

and of sufficient capacity. The speed of the drum is to be not more than twenty and not less than

fourteen revolution per minutes. Hand mixing will not be permitted.

The fine and coarse aggregate and the cement are to be placed in the drum and are to be mixed in a

dry state for at least ten turns of the drum.

The mixing operation shall continue until the cement is thoroughly distributed throughout the mass

and shall last at least 2 minutes or forty turns of the drum after the whole of the water has been added

Concrete as above shall not be modified by the addition of water or otherwise in order to facilitate

handling or for any other purpose.

No concrete mix shall be discharged from the machine unless it is properly mixed having uniform

colour and consistency

Additives to concrete

The agreed quantities of the additives must be strictly adhere to as specified by the engineer

and/or manufacturer of the additives

Transportation of concrete

Concrete is to be transferred from the place of mixing to the place of final deposit as rapidly

as possible to avoid re-handling and flowing and by methods whish will prevent segregation or lose of

ingredients. If there is long distance of traffic jam between the batching plant and the construction

site, special admixtures (retarders) should be used up on approval by the engineer

Placing of concrete

Concrete shall be placed before setting has commenced and in any case within 30 minutes

from the time that the water is added in the mixer

Concrete shall not be discharged during placing from a height in excess of 2.5m meter according to

EBCS. All methods of placing the concrete are to be such as not to cause any disturbance or

movement of the formwork or location of the reinforcement or embed fixtures

Compaction of concrete

All concrete shall be thoroughly compacted during the operation of placing so as to form a

dense homogenous mass properly worked around embedded fixtures, reinforcement and into the

corners of the formwork. Unless otherwise specified pr directed all concrete shall be compacted by

mechanical vibration as specified hereinafter.

Lean concrete.

Jimma university, Jimma institute of technology-JIT Page 33

Final internship semester report 2011

All ground to carry reinforced column bases and grounded beams shall be covered with a

minimum 50 mm blinding layer of grade 150kg concrete as previously specified

curing and protection of concrete

All concrete shall be properly cured and protected until it has set and hardened and acquired

the required strength.Care must be taken that no concrete is allowed to become prematurely dry and

the fresh concrete must be carefully protected from the rain , sun and wind for a period of at least

seven days by applying water on building paper, sacking, sand, sawdust, or other approved means

Concrete in foundation and other underground work shall be protected from admixtures with falling

earth or similar during and after placing

Inspection of concrete mix

Inspection of mix (in general the concrete prepared by taking good care of the above things should be

inspected for the following points)

size of gauging box for measuring aggregate

required duration to mix the cement and aggregate thoroughly/check manufacturers

instruction of the mixer

loading capacity of the mixer

cleanliness of the mixer

availability of aggregate , cement and equipment for production of the required

volume of concrete

aware of mix proportion

check maximum size of aggregate allowed in the mix

moisture content of aggregates

temperature of aggregate

check slump and water/cement ratio of freshly mixed concrete

workability of concrete for insuring proper placing and handling of concrete without

segregation /low, medium, high/

weather/care during heavy rain hot weather/

Testing of concrete

Most of the time the concrete spacemen from the site are tested for quality (workability,

compressive strength...). The specimens will be tested on site or if so directed by an independent

testing laboratory.

From the result of this test definite weight of each material for batching shall be ascertained

and agreed with the engineer

Work test specimens (WTS), cubs or cylinders, are to be made throughout the period of

contract from concrete drawn from newly laid concrete about to be placed in position. Such work test

specimens shall be made when directed by the engineer in his presence of the engineer, any of the

Jimma university, Jimma institute of technology-JIT Page 34

Final internship semester report 2011

results of the specified tests of concrete or materials be unsatisfactory, the engineer may order the

work to be stopped pending his further instruction

Purpose Maximum minimum

Rc foundation 7.5 3.0

Rc columns, beams and slabs 10.0 5.0

Executed works for which the test results are unsatisfactory shall be liable to rejection and if

so directed by the engineer, the work represented by the test shall be cut out and re-executed.

In the case of 7 days WTS proving unsatisfactory the work may be stopped, but shall not be

liable to rejection until the result of the 28 days test is known

In the event of the result of 28 days WTS proving unsatisfactory, the work represented shall

be immediately liable to rejection.

Jimma university, Jimma institute of technology-JIT Page 35

Final internship semester report 2011

Appendix 2-Production of pre- cast beams

A. Equipment required for the production of pre-cast beams :- these materials are vibrating table,

moulds, concrete mixer and reinforcement bending tables

B. Raw materials and mix ratio:- these are cement, aggregate of good quality(both fine and

course ), reinforcement

C. Procedure of production of pre-cast beams

First of all the production should be well prepared that means it should be both clean and wide

enough to produce the pre-cast beam without obstruction

It should be wide enough for the production (including reinforcement)

It should be wide enough for the storage of materials and

It should be wide enough for the storage of produced beams with the available

space of shade

Prepare all the equipments which are necessary for the production activity including adequate skilled

and unskilled man power should be prepared and should get ready

Prepare the moulds; the moulds should be good enough to execute the required quality of pre-cast

beams

The moulds should be straight

The moulds should be clean

They should be treated with release agent (painting or greasing)

Prepare the reinforcement: as we know the reinforcement are one of the main part of the concrete

structure (for PB too) so they should be prepared with great care i.e. all it’s dimensions, length,

arrangement and shapes, number of bars, etc..., Should be as per the design.

the plate form should be well prepared for easy and fast production

the stirrups need to be welded to the top of the main bare of the pre-cast

Bending of the reinforcement (both the stirrup and the main bars ) should be as

per the specification. i.e. bending diameter=4*bar diameter

Concrete casting: if all the above procedures are fulfilled and the reinforcements are placed in their

position inside the mould on the vibrator table the next step is concrete casting

covers should be kept properly in all position

fresh concrete with the slump of not less than 5cm can be used

to prevent honey combing and segregation the fresh concrete should be casted

in layers

Sand should be clean(it should not has more than 5% silt)

Concrete shall not be dry

It should be vibrated well (not much not less). Vibration of

concrete should be carried out for 10-20 seconds

depending on the capacity of the table vibrator

Mould dismantling and curing: after cleaning of the excess concrete and smoothening of the edge

while the concrete is fresh and transporting to the level surface the moulds should be dismantled and

cured properly

Jimma university, Jimma institute of technology-JIT Page 36

Final internship semester report 2011

Moulds can be dismantled after 24hr for PPC and after 12hr for OPC