Professional Documents

Culture Documents

12 Remote Control: !!!WARNING!!!

Uploaded by

Lucía jandigOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Remote Control: !!!WARNING!!!

Uploaded by

Lucía jandigCopyright:

Available Formats

Software Documentation Page 12-1

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

12 Remote Control

12.1 Service of Remote Control

Remote control - in conjunction with measuring functions - is designed for operation on engine test stands to

simulate engine and vehicle by replacement values, which are transmitted from tester to ECU. Remote

control enables to override sensor inputs, actuator outputs and internal software values. As long as these

external values are active, e.g. missing sensors or even unusual conditions of operation, like defect

sensors, cable disconnection, short circuit a.s.o. can be simulated. Note that it is the testers responsibility

not to cause any dangerous working conditions or damages.

!!!WARNING!!!

If you activate remote control, there is danger for the engine, vehicle and human life, if you do not respect

the limits of the system. With some labels you can overwrite the timing, quantity and fuel pressure without

limiting by software or hardware.

Remote Control is a feature to overwrite EDC-internal values with external tools (ETK, ISO-Line, CAN).

Here some examples for Remote Control:

• Direct control of fuel quantity and timing without application and limits

• Replacement of missing sensors with plausible values

• Evaluation of strategies for controllers with external tools (ASCET)

• Override of setpoints for application purpose

• Test of outputs and actuators (diagnostic tests)

• Switch between different algorithms in application phases

• Force of unusual operation conditions (switch off a cylinder, etc.) to test the system

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

Software Documentation Page 12-2

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

12.2 Remote Control via KWP2000

It is possible to switch the EDC-internal calculated input/output values and to replace it with own values via

INCA or KWP2000 external tools. INCA has the highest remote control priority and switch off all other

Remote Control interfaces.

To start Remote Control via KWP2000 you need a communication Tool, DIAS for example.

To create a communication between ECU and Tester, you have to keep some conditions. One of the

conditions is the protocol witch have to transmit from tester in a timespace of 10ms - 200ms.

An other condition is the length of the protocol. The remote control software calculate the length of the

protocol with the maskinformation.

The order of the Mask have to be fixed. The following values have the same order like the activated

maskbits.

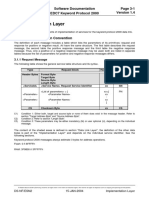

12.2.1 KWP2000 Remote Control Protocol:

The protocol mainly consist in two parts, the information witch covert the activated replacement values it

call mask and the information witch covert the accompanying value.

If you activate an mask bit, you have to sent the accompanying value in the same order like the activated

mask bits. The following protocol describe the order of the masks, details about the following value you see

in the tables.

For more information please see KWP2000 documentation:

12.2.2 EscapeCode - MaintainRemoteControl

Via keyword protocol 2000, remote control is started by sending an escapeCode - maintainRemoteControl

request message to the ECU. This message contains several bit coded masks that indicate which of the

signals shall be overridden. The respecting replacement values, intended to override the selected signals,

are included at the end of this message. The composition of remote control relevant signals and the

definition of masks are system specific and shall therefore be done in agreement of the vehicle

manufacturer and the system supplier. Refer to section "Remote Control" in the main software

documentation.

The parameter refreshTimeOut in the request message specifies the duration of how long the replacement

values shall be active from the time of request on. If the tester does not send another escapeCode -

maintainRemoteControl request message within the time refreshTimeOut, the ECU detects remote control

time-out, aborts the remote control mode and continues operation with the normal values respectively e. g.

the real sensor signals. The resolution of this parameter is: last significant bit = 4ms.

The following parameters in the request message are bit coded and specify the remote control masks:

• sensorInputs representing analog sensor signals (e. g. coolant temperature, boost pressure)

• switchInputs representing digital inputs (e. g. torque limit, engine brake)

• digitalOutputs representing digital outputs (e. g. diagnostic lamp)

• pwmOutputs representing pulse width modulated outputs (e. g. boost pressure actuator)

• forceAlgorithm representing specific EDC functions to be switched off (e. g. switch off cylinder 3, switch

off CAN, switch off multiplex output)

• switchAlgorithm representing a set of masks (there are 8 sets of masks defineable)

• setPoints representing internal software values that contain target setpoints (setpoints are normally

results of calculations or maps, e. g. begin of main injection, fuel pressure setpoint, low idle setpoint)

The parameters replacementValue#x are used by the escapeCode - maintainRemoteControl positive

response message to provide the replacement values as specified in the masks. The request message

contains only those replacement values, which are selected by the respective bits set to '1' within the masks.

The order of transmitted replacement values corresponds to the order of mask bits. The following table

specifies sizes of masks and replacement values:

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

Software Documentation Page 12-3

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

Remote control mask overview

Mask Size of mask = Size of Data length

number of replacementValues (number of replacementValues

replacementValues size of replacementValue)

sensorInputs 32 bit 2 bytes 64 bytes (32 ∑2 byte)

switchInputs 32 bit 1 bit 4 bytes (32 ∑1 bit)

digitalOutputs 32 bit 1 bit 4 bytes (32 ∑1 bit)

pwmOutputs 8 bit 2 bytes 16 bytes (8 ∑2 byte)

forceAlgorithm 16 bit - -

switchAlgorithm 8 bit 1 bit 1 byte (8 ∑1 bit)

setPoints 32 bit 2 bytes 64 bytes (32 ∑2 byte)

151 bytes maximum

Request

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 escapeCode Request Service Id M 80 EC

#2 manufacturerSpecificServiceId = [maintainRemoteControl] M 28 MSSID

#3 refreshTimeOut M xx RV_...

#4 sensorInputs (Highest Byte) M xx RV_...

#5 sensorInputs (Byte 2) M xx RV_...

#6 sensorInputs (Byte 3) M xx RV_...

#7 sensorInputs (Lowest Byte) M xx RV_...

#8 switchInputs (Highest Byte) M xx RV_...

#9 switchInputs (Byte 2) M xx RV_...

#10 switchInputs (Byte 3) M xx RV_...

#11 switchInputs (Lowest Byte) M xx RV_...

#12 digitalOutputs (Highest Byte) M xx RV_...

#13 digitalOutputs (Byte 2) M xx RV_...

#14 digitalOutputs (Byte 3) M xx RV_...

#15 digitalOutputs (Lowest Byte) M xx RV_...

#16 pwmOutputs M xx RV_...

#17 forceAlgorithm (High Byte) M xx RV_...

#18 forceAlgorithm (Low Byte) M xx RV_...

#19 switchAlgorithm M xx RV_...

#20 setPoints#1 (Highest Byte) M Xx RV_...

#21 setPoints#2 (Byte 2) M xx RV_...

#22 setPoints#3 (Byte 3) M xx RV_...

#23 setPoints#4 (Lowest Byte) M xx RV_...

#24 replacementValue#1 C xx RV_...

: : : : :

#n replacementValue#m (m ≤ 117) C xx RV_...

C: Included, if any mask bit set.

Positive Response

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 escapeCode Positive Response Service Id S C0 ECPR

#2 manufacturerSpecificServiceId = [maintainRemoteControl] M 28 MSSID

Negative Response

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 negativeResponse Service Id S 7F NR

#2 escapeCode Request Service Id M 80 EC

#3 manufacturerSpecificServiceId = [maintainRemoteControl] M 28 MSSID

#4 responseCode = [ M xx=[ RC_...

subFunctionNotSupported-invalidFormat 12,

(number of replacement values do not correspond to mask bits

set to '1'),

conditionsNotCorrectOrRequestSequenceError 22,

(remote control must not be started due to failure conditions)

requestOutOfRange (refreshTimeOut = 0) ] 31]

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

Software Documentation Page 12-4

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

12.2.3 EscapeCode - StopRemoteControl

To stop remote control before the refresh time is expired, the tester may send an escapeCode -

stopRemoteControl request message to the ECU.

Request

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 escapeCode Request Service Id M 80 EC

#2 manufacturerSpecificServiceId = [stopRemoteControl] M 29 MSSID

Positive Response

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 escapeCode Positive Response Service Id S C0 ECPR

#2 manufacturerSpecificServiceId = [stopRemoteControl] M 29 MSSID

Negative Response

Data Byte Parameter Name Cvt Hex Value Mnemonic

#1 negativeResponse Service Id S 7F NR

#2 escapeCode Request Service Id M 80 EC

#3 manufacturerSpecificServiceId = [stopRemoteControl] M 29 MSSID

#4 responseCode = [ M xx=[ RC_...

conditionsNotCorrectOrRequestSequenceError 22

(remote control is currently not active) ] ]

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

Software Documentation Page 12-5

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

INPUT VARIABLES:

rmtc_s_appl_on_b Remote control via INCA active flag

byps_s_act_b Status for bypass (0=inactive, 1=active)

INTERNAL VARIABLES:

k2rc_s_activ_b Remote Control on/off switch

DATA:

K2RC_DT_DEF_MAX_CUW KWP200 Remote Control upper timeout thresholt

K2RC_DT_DEF_MIN_CUW KWP200 Remote Control lower timeout thresholt

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

Software Documentation Page 12-6

Y281 S365_KWP_V14 EDC7 Keyword Protocol 2000 Version 1.4

This page intentionally left blank

© Robert Bosch GmbH (Germany) reserves all rights even in the event of industrial rights. We reserve all rights of disposal such as copying and passing to third parties.

DS-NF/ESN2 15-JAN-2004 Remote Control

You might also like

- ScanCONTROL 2900 Interface SpecificationDocument19 pagesScanCONTROL 2900 Interface SpecificationRadoje RadojicicNo ratings yet

- HGM400 MODBUS Protocol V1.0 enDocument14 pagesHGM400 MODBUS Protocol V1.0 enEmanuel ArguiñarenaNo ratings yet

- Communication System Simulation IEEE 802.11a 式 告Document11 pagesCommunication System Simulation IEEE 802.11a 式 告王韋棋No ratings yet

- Umg 20 CMDocument24 pagesUmg 20 CMxuyen tranNo ratings yet

- Technical Manual Modbus (Recloser-Map-S) Etr300-R & Evrc2a-Nt Ver1.01 201807Document28 pagesTechnical Manual Modbus (Recloser-Map-S) Etr300-R & Evrc2a-Nt Ver1.01 201807danh voNo ratings yet

- Low Power & Area Efficient Layout Analysis of Cmos EncoderDocument5 pagesLow Power & Area Efficient Layout Analysis of Cmos EncoderSamiksha GautamNo ratings yet

- Supraja DocumentDocument73 pagesSupraja DocumentAnonymous gWVMMa588pNo ratings yet

- Code Hopping Decoder Using A PIC16C56: Key FeaturesDocument14 pagesCode Hopping Decoder Using A PIC16C56: Key FeaturesrenampNo ratings yet

- Real-Time Data Exchange (RTDE) GuideDocument16 pagesReal-Time Data Exchange (RTDE) Guide徐海东No ratings yet

- ME440 Handheld Power Analyzer Modbus Tcp/Ip Communication ProtocolDocument21 pagesME440 Handheld Power Analyzer Modbus Tcp/Ip Communication ProtocolLuis GonzalezNo ratings yet

- RDP Se - P1N85898Document4 pagesRDP Se - P1N85898Danilo SilvaNo ratings yet

- Real Time Data Exchange (RTDE)Document18 pagesReal Time Data Exchange (RTDE)cosmin1975No ratings yet

- Mainstream ETCO2 Module CM2200 Technical SpecificationDocument13 pagesMainstream ETCO2 Module CM2200 Technical SpecificationEmilio CánepaNo ratings yet

- TCC8200 v0.2 20060425Document505 pagesTCC8200 v0.2 20060425Joe LuiNo ratings yet

- User's Guide: TMS320C2000 Motor Control PrimerDocument32 pagesUser's Guide: TMS320C2000 Motor Control PrimerlaloNo ratings yet

- MM Lab ManualDocument53 pagesMM Lab ManualDev SejvaniNo ratings yet

- Low Cost Thermocol Cutter: Tejal Jagdale, Monika Kirodiwal, Fatema Shaikh, Pranami SharmaDocument4 pagesLow Cost Thermocol Cutter: Tejal Jagdale, Monika Kirodiwal, Fatema Shaikh, Pranami SharmaerpublicationNo ratings yet

- Decoder Hoping CodeDocument18 pagesDecoder Hoping CodeEletrotec ErasmoNo ratings yet

- XC3-24R-E PLC Controller 14 Inputs 10 Relay OutputsDocument4 pagesXC3-24R-E PLC Controller 14 Inputs 10 Relay OutputsgarylikeuNo ratings yet

- Cellphone Operated Robotic ArmDocument55 pagesCellphone Operated Robotic ArmVinay ReddyNo ratings yet

- SPUD 604 ManualDocument37 pagesSPUD 604 ManualfbarrazaisaNo ratings yet

- Automatic fan speed control using microcontrollerDocument46 pagesAutomatic fan speed control using microcontrollerbhuvanaNo ratings yet

- Spma 057 DDocument10 pagesSpma 057 Dalaa salahNo ratings yet

- The Picmicro Mcu As An Ieee 1451.2 Compatible Smart Transducer Interface Module (Stim)Document63 pagesThe Picmicro Mcu As An Ieee 1451.2 Compatible Smart Transducer Interface Module (Stim)adilNo ratings yet

- Simulation and AnalysisDocument19 pagesSimulation and AnalysisARVINDNo ratings yet

- K L With Advanced Encryption Standard (AES) Receiver/DecoderDocument8 pagesK L With Advanced Encryption Standard (AES) Receiver/DecoderbilarodrigoNo ratings yet

- ATM Terminal Design Based On Figure Print Recognition DocuDocument115 pagesATM Terminal Design Based On Figure Print Recognition DocuPraveen NaiduNo ratings yet

- Training Report On 8051Document27 pagesTraining Report On 8051Sandeep SainiNo ratings yet

- Design of a High Speed Multi-Channel Data Acquisition SystemDocument16 pagesDesign of a High Speed Multi-Channel Data Acquisition SystemVinod HandiNo ratings yet

- Driver Aid Serial ProtocolDocument21 pagesDriver Aid Serial ProtocolBehnam GanjiNo ratings yet

- Smart Passive Sensort For Temperature Sensing Spsxt001Fom: DescriptionDocument8 pagesSmart Passive Sensort For Temperature Sensing Spsxt001Fom: DescriptionSero StivNo ratings yet

- Communication System Simulation IEEE 802.11a 程式報告Document20 pagesCommunication System Simulation IEEE 802.11a 程式報告王韋棋No ratings yet

- ECR MachineDocument37 pagesECR Machineapi-3721578100% (1)

- DC8xD MODBUS_Communication protocol_V1.0-20210710Document14 pagesDC8xD MODBUS_Communication protocol_V1.0-20210710iceman1983No ratings yet

- B.N.M. Institute of Technology Microcontroller CourseDocument19 pagesB.N.M. Institute of Technology Microcontroller Coursekirthi bharadwajNo ratings yet

- Remote Digital ClockDocument79 pagesRemote Digital ClockArdhika Dhennis Putra AnandaNo ratings yet

- Viterbi Decoder: IP CoresDocument6 pagesViterbi Decoder: IP Coresapi-19790923No ratings yet

- Design and Implementation of Digital Trigger Circuit For ConverterDocument6 pagesDesign and Implementation of Digital Trigger Circuit For ConverterBilal Ali AhmadNo ratings yet

- LPC81xM: 1. General DescriptionDocument77 pagesLPC81xM: 1. General DescriptionLê Hoàng DuyNo ratings yet

- EY-RC 500: Room Automation Station, Ecos500: FeaturesDocument14 pagesEY-RC 500: Room Automation Station, Ecos500: FeaturesRhizhailNo ratings yet

- Pstyro Arm214x UmDocument54 pagesPstyro Arm214x UmKavin SengodanNo ratings yet

- LCD SpecDocument21 pagesLCD SpecKC KiewNo ratings yet

- Hitachi L37v01e A U l37vr1 l37v01 l37vp01 l42vp01Document68 pagesHitachi L37v01e A U l37vr1 l37v01 l37vp01 l42vp01Kostas AthanasiadisNo ratings yet

- SI-MAG110 ModBus Ptotocol ManualDocument12 pagesSI-MAG110 ModBus Ptotocol ManualSatya BarikNo ratings yet

- Stone TFT LCD Stm32 Servo HeadDocument11 pagesStone TFT LCD Stm32 Servo HeadSami ÖzerNo ratings yet

- Design of Multifunction Vehicle Bus Controller: Abstract. The Train Communication Network (TCN) Is Widely Used in HighDocument7 pagesDesign of Multifunction Vehicle Bus Controller: Abstract. The Train Communication Network (TCN) Is Widely Used in Higherode els erodeNo ratings yet

- Remote Access Identification Device With Integrated 3D Wakeup Receiver and Immobilizer InterfaceDocument10 pagesRemote Access Identification Device With Integrated 3D Wakeup Receiver and Immobilizer InterfacecaptainNo ratings yet

- ConfiguracionDocument4 pagesConfiguracionPaul Richard Sanchez TapiaNo ratings yet

- SPEED CHECKER FOR HI-WAsYSDocument26 pagesSPEED CHECKER FOR HI-WAsYSAbhinav KumaarNo ratings yet

- Amm Cheet PrintDocument7 pagesAmm Cheet PrintjokerNo ratings yet

- Ifm 00057F 20210318 IODD11 enDocument34 pagesIfm 00057F 20210318 IODD11 enmulabunsNo ratings yet

- Sensorless Motor Control IC For Appliances: IRMCK343Document35 pagesSensorless Motor Control IC For Appliances: IRMCK343Gilvana Cristina FerreiraNo ratings yet

- IK 220 CardDocument4 pagesIK 220 CardArthur TalibulinNo ratings yet

- Presentation of Protection & Control IEDs - Selection GuideDocument12 pagesPresentation of Protection & Control IEDs - Selection GuidecostelchelariuNo ratings yet

- Report For Industrial Monitoring-1Document73 pagesReport For Industrial Monitoring-1Abin K MathewNo ratings yet

- Canbox: CAN BUS DecoderDocument12 pagesCanbox: CAN BUS Decoderanshad ejasNo ratings yet

- SEL-2240 Axion: Modular Real-Time Automation ControllerDocument16 pagesSEL-2240 Axion: Modular Real-Time Automation ControllerJulian Pineda100% (1)

- MATLAB BALL SEARCH ROBOTDocument24 pagesMATLAB BALL SEARCH ROBOTnikhil3298No ratings yet

- Experiment #6 Input / Output DesignDocument11 pagesExperiment #6 Input / Output DesignFelipe DiasNo ratings yet

- KT600 User Manual: Quick Start Guide to Kingtec Diagnostic SystemDocument50 pagesKT600 User Manual: Quick Start Guide to Kingtec Diagnostic SystemLucía jandigNo ratings yet

- N350 Electrical Diagram Final - EN JMCDocument124 pagesN350 Electrical Diagram Final - EN JMCLucía jandigNo ratings yet

- X60 Wiring Diagram MT AT LF-20130625 Lifan X60Document120 pagesX60 Wiring Diagram MT AT LF-20130625 Lifan X60Lucía jandigNo ratings yet

- ECM Diesel Engine ComponentsDocument45 pagesECM Diesel Engine ComponentsLucía jandigNo ratings yet

- n800-ELECTRICAL DIAGRAMDocument190 pagesn800-ELECTRICAL DIAGRAMLucía jandigNo ratings yet

- P020C Failure and Black Smoke Diagnosis of Yusheng Diesel EngineDocument12 pagesP020C Failure and Black Smoke Diagnosis of Yusheng Diesel EngineLucía jandigNo ratings yet

- 14 Data Link Layer: Software Documentation Page 14-1 EDC7 Keyword Protocol 2000Document14 pages14 Data Link Layer: Software Documentation Page 14-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 10 Fault Memory and Engine Diagnosis: Software Documentation Page 10-1 EDC7 Keyword Protocol 2000Document12 pages10 Fault Memory and Engine Diagnosis: Software Documentation Page 10-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 8 End of Line Programming: Software Documentation Page 8-1 EDC7 Keyword Protocol 2000Document14 pages8 End of Line Programming: Software Documentation Page 8-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 9 Serial Application: Software Documentation Page 9-1 EDC7 Keyword Protocol 2000Document10 pages9 Serial Application: Software Documentation Page 9-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 7 Flash Memory Programming: Software Documentation Page 7-1 EDC7 Keyword Protocol 2000Document10 pages7 Flash Memory Programming: Software Documentation Page 7-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 11 Measuring and Data Transmission: Software Documentation Page 11-1 EDC7 Keyword Protocol 2000Document20 pages11 Measuring and Data Transmission: Software Documentation Page 11-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 13 Physical Layer: Software Documentation Page 13-1 EDC7 Keyword Protocol 2000Document10 pages13 Physical Layer: Software Documentation Page 13-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 5 Diagnostic Management: Software Documentation Page 5-1 EDC7 Keyword Protocol 2000Document10 pages5 Diagnostic Management: Software Documentation Page 5-1 EDC7 Keyword Protocol 2000Lucía jandig100% (1)

- 2 Normative Reference: Software Documentation Page 2-1 EDC7 Keyword Protocol 2000Document2 pages2 Normative Reference: Software Documentation Page 2-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 4 Communication Services: Software Documentation Page 4-1 EDC7 Keyword Protocol 2000Document4 pages4 Communication Services: Software Documentation Page 4-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 6 1 Multi Level Security Access: Software Documentation Page 6-1 EDC7 Keyword Protocol 2000Document4 pages6 1 Multi Level Security Access: Software Documentation Page 6-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- 3 Implementation Layer: Software Documentation Page 3-1 EDC7 Keyword Protocol 2000Document8 pages3 Implementation Layer: Software Documentation Page 3-1 EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- Electronic Diesel Control: Softwaredocumentation EDC7 Keyword Protocol 2000Document8 pagesElectronic Diesel Control: Softwaredocumentation EDC7 Keyword Protocol 2000Lucía jandigNo ratings yet

- Software Documentation Page 1-1 EDC7 Keyword Protocol 2000: Y281 S365 - KWP - V14Document2 pagesSoftware Documentation Page 1-1 EDC7 Keyword Protocol 2000: Y281 S365 - KWP - V14Lucía jandigNo ratings yet

- How Vibration Dampers WorkDocument10 pagesHow Vibration Dampers WorkLucía jandigNo ratings yet

- Internship - Mobile Application DevelopmentDocument1 pageInternship - Mobile Application DevelopmentKomalNo ratings yet

- Smart BeltDocument9 pagesSmart BeltDavid SfkaNo ratings yet

- Edelson 2021Document27 pagesEdelson 2021juliopanzNo ratings yet

- Raspberry Pi Documentation - Remote AccessDocument51 pagesRaspberry Pi Documentation - Remote AccesshelioxNo ratings yet

- Assignment & LabDocument5 pagesAssignment & LabXyus PoudelNo ratings yet

- Business PlanDocument49 pagesBusiness Plandanie krisyaNo ratings yet

- Airbus Techdata AC A321 0322Document434 pagesAirbus Techdata AC A321 0322Mario AntonioNo ratings yet

- LAC 1 Session GuideDocument1 pageLAC 1 Session GuideCherry CarlosNo ratings yet

- Combined Assignment For Supply Chain Operations ManagementDocument22 pagesCombined Assignment For Supply Chain Operations ManagementAbood Thekrallah100% (2)

- 7 Figure Template BookDocument5 pages7 Figure Template Bookmattia89No ratings yet

- BDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSDocument1 pageBDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSMS.sumonNo ratings yet

- Zerust Flange Savers - WebDocument2 pagesZerust Flange Savers - WebFederico MoranNo ratings yet

- 188524-01, DW502 DW504 La - EngDocument9 pages188524-01, DW502 DW504 La - EngCilvio LewlawskyjNo ratings yet

- Azure InvoiceDocument2 pagesAzure InvoiceAnkit SambhareNo ratings yet

- RamchanderRaoKrishnamraj SAPABAP HyderabapDocument5 pagesRamchanderRaoKrishnamraj SAPABAP HyderabapAmit MahajanNo ratings yet

- Can't Stop RHCP Bass TabsDocument1 pageCan't Stop RHCP Bass TabsLengKeng Tan100% (1)

- Qualis VHDL-QuickReferenceCard V2.1 PDFDocument2 pagesQualis VHDL-QuickReferenceCard V2.1 PDFlakithaNo ratings yet

- Scientific Publishing in Biomedicine How To Choose A JournalDocument9 pagesScientific Publishing in Biomedicine How To Choose A JournalJuan Carlos Marcos EnriquezNo ratings yet

- Curses, Foiled Again, and AgainDocument68 pagesCurses, Foiled Again, and AgainPete TaltonNo ratings yet

- Relationship Between Sieve Mesh Size and Screen OpeningDocument3 pagesRelationship Between Sieve Mesh Size and Screen OpeningShubham RathoreNo ratings yet

- LAB EXERCISE - Module 1 - Welcome To TenableDocument2 pagesLAB EXERCISE - Module 1 - Welcome To Tenablenet flixNo ratings yet

- S Siva Kishore Project - BADocument5 pagesS Siva Kishore Project - BAosuri sudheer kumarNo ratings yet

- A General Contingency Theory of ManagementDocument16 pagesA General Contingency Theory of ManagementlucasNo ratings yet

- Universal Joint Alignment Proc 111606Document5 pagesUniversal Joint Alignment Proc 111606Slobodan GaricNo ratings yet

- Labview Thesis ProjectsDocument5 pagesLabview Thesis Projectsdwm7sa8p100% (2)

- Subscriber End Equipment: OP-XONT 71000Document3 pagesSubscriber End Equipment: OP-XONT 71000AnilNo ratings yet

- 2) N5, N6 and N7 (NPS2 - 300#) PDFDocument20 pages2) N5, N6 and N7 (NPS2 - 300#) PDFpraffulNo ratings yet

- Log Cat 1700663779292Document144 pagesLog Cat 1700663779292Enry GomezNo ratings yet

- Isogeometric Analysis For Modeling and Simulation of Building ProcessesDocument11 pagesIsogeometric Analysis For Modeling and Simulation of Building Processes董思辰No ratings yet

- D3E804F51B6-02T 5-Speed Manual GearboxDocument133 pagesD3E804F51B6-02T 5-Speed Manual GearboxjorgebautistagarciaNo ratings yet