Professional Documents

Culture Documents

Bentonite Grade Details..

Uploaded by

moto rolaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bentonite Grade Details..

Uploaded by

moto rolaCopyright:

Available Formats

BENTONITE GRADE DETAILS

BALAJI CORPORATE Is Leading Manufacturer Of Various Bentonite Grades For Oil Drilling, Iron

Ore Pelletizing, Foundry, Fertilizer, Pilling Work, Bleaching Earth, Animal Feed, Construction

and Civil Engineering, Water Proofing, Pesticides, Cat Litter, Paper, Cosmetics, Paints And

Attapulgite clay.

1. OIL DRILLING GRADES:

The most common use of bentonite is in drilling fluids. The bentonite in the flush fluid

lubricates and cools the cutting tools whilst protecting against corrosion. As the drilling

fluid generates hydrostatic pressure in the borehole, it hinders fluid and gas penetration. As a

flushing fluid, bentonite seals the drilled shaft from water ingress downwards and at the

sides of the shaft. The mineral forms a firm sludge cake on the bore wall, which provides the

borehole with additional stability. The fine bentonite particles enter into the bore wall where they

swell and harden.

A. API-13 A SEC-9:

NO. PARAMETERS SPECIFICATION

1 Moisture % 12%

2 Suspension Properties Viscometer dial reading @ 600 rpm 30 MIN.

3 Yield point/plastic viscosity ratio 3MAX.

4 Filtrate volume 15 ML MAX.

5 Residue of diameter greater than 75 micron 4% MAX.

B. API-13 A SEC-10:

NO. PARAMETERS SPECIFICATION

1 Yield point/plastic viscosity ratio 3MAX.

2 DISPERSED PLASTIC VISCOSITY, 10 MIN.

3 Filtrate volume 12.5 ML MAX.

C. API-13A SEC-11:

NO. PARAMETERS SPECIFICATION

1 Moisture % 12%

2 Suspension Properties Viscometer dial reading @ 600 rpm 30 MIN.

3 Yield point/plastic viscosity ratio 6MAX.

4 Filtrate volume 16 ML MAX.

5 Residue of diameter greater than 75 micron 2.50% MAX.

D. API HIGH GEL:

NO. PARAMETERS SPECIFICATION

1 Viscometer dial reading at 600 RPM 50MIN.

2 Yield point/plastic viscosity ratio 6MAX.

3 Filtrate volume 18 cm3

4 Residue of diameter greater than 75 4% MAX.

5 Moisture 12% MAX.

6 MARSCONE VISCOSITY 6% 50 Sec. MIN.

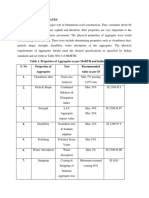

2. IOP (IRON ORE PELLETIZING) GRADES:

Bentonite is the most widely used binder in iron ore pelletizing. The use of bentonite is

favorable in terms of physical, mechanical and metallurgical pellet qualities, however, because

of its acid constituents (SiO2 and Al2O3) it is considered as a chemical impurity especially for

concentrate with high SiO2 content. Adding bentonite improves the strength of the green

pellet. The falling strength and compression strength of green pellet increase as bentonite

content increases. For homogeneous bentonites, the strength of the green pellet increases as

bentonite content increases.

A. IOP BALBOND (LUMPS/POWDER):

NO. PARAMETERS SPECIFICATION

CHEMICAL COMPOSITION

1 SiO2 % 52max.

2 Fe2O3 % 12min.

3 AL2O3 % 16max.

4 CaO% 0.5-1

5 Na2O% 2.0-2.5

6 MgO% 3.0max.

PHYSICAL COMPOSITION

1 Moisture % ( ARB) 14.00max.

2 PH 8.5 -10

3 Free Swelling Velum 28-30

4 Methylene Blue Absorption (MBA) mg/g. 400MIN.

5 Plate Water Absorption (PWA) % 600min.

3. FOUNDRY GRADES:

Green sand molds in foundry use bentonite as a binder. During the casting process, the

heat transferred to the surrounding sand in the mold leads to the degradation of bentonite

structure, thereby forming new types of deposits on the surface of sand grain.

A. 20-25 FSV GRADE:

NO PARAMETERS UNITS SPECIFICATION

1 pH 8.5 MIN

2 MOISTURE % WT 12-14

3 GELLING TIME SECOND INSTANT

4 GEL INDEX CC 65 MIN

5 FREE SWELLING VALUE CC 20-25

6 MBA VALUE MG/GM OF CLAY 390 MIN

7 FINESS (PASSING THROUGH 200 BSS) % WT 85 MIN

8 GREEN COMPRESSION STRENGTH PSI 8 MIN

B. 25-28 FSV GRADE:

NO PARAMETERS UNITS SPECIFICATION

1 pH 9-12

2 MOISTURE % WT 12-14

3 GELLING TIME SECOND Instant

4 GEL INDEX CC 85 MIN

5 FREE SWELLING VALUE CC 25-28

6 MBA VALUE MG/GM OF CLAY 400 MIN

7 FINESS (PASSING THROUGH 200 BSS) % WT 85 MIN

8 GREEN COMPRESSION STRENGTH 10MIN.

C. 28-30 FSV GRADE:

NO PARAMETERS UNITS SPECIFICATION

1 pH 8.5 MIN

2 MOISTURE % WT 12-14

3 GELLING TIME SECOND 40 MAX

4 GEL INDEX CC 65 MIN

5 FREE SWELLING VALUE CC 28-30

6 MBA VALUE MG/GM OF CLAY 400 MIN

7 FINESS (PASSING THROUGH 200 BSS) % WT 85 MIN

8 GREEN COMPRESSION STRENGTH PSI 12 MIN

4. FERTILIZER GRADE:

Sulphur Bentonite is a combination of pure sulphur and Bentonite clay. It is used as a

secondary nutrient and also to correct alkaline soil problems. Sulphur is one of the 17 essential

plant nutrients and it helps in the formation of essential enzymes and plant proteins. This makes

Bentonite Sulphur more effective in terms of supplying Sulphur to Crops.

A. SPECIAL GRADE:

NO. PARAMETERS UNIT SPECIFICATION

1 Free Swelling Value cc 22 - 30

2 Methylene Blue Absorption Mg/gm 375 - 400

3 Moisture Content % 10 – 12%

4 PH 8.50 - 10

5 FINEES 200MESH PASSING % 85 Min.

6 SiO2 % 45-55

7 AL2O3 % 13-18

8 MgO % 1-2.5

5. PILLING GRADES:

Bentonite support fluids are also widely used in the construction of large diameter bored

piles. This application is similar to that for diaphragm wall construction except for the shape of

the excavation. Our Piling Grade Bentonite Powder is used widely in many industries as a

support, lubricant agent in walls and foundations, tunneling and horizontal drilling. Our Piling

Grade Bentonite Powder covers large surface area, has good plasticity and lubricity, low filter

loss, excellent gel strength, good impermeability and low compressibility.

A. PILGEL:

NO PARAMETERS UNITS SPECIFICATION

1 Free Swelling Volume 2 gm/100 ml ML 25 to 30

2 Methylene Blue Absorption Value Mg/gm of Clay 300 to 500

3 Gel Time 2.5 gm/20 ml Seconds Instant

4 Moisture Content % by Weight % 10.00 - 12.00

5 PH Value 2 % Slurry pH 8.5 to 11.5

6 Dry Mesh % Passing 200 B.S.S % 85 Minimum

7 VISCOSITY Unit 30 Min

8 Filterate VOLUME ML 20 Max

9 Marsh Funnel Viscosity Sec 30 to 45

6. BLEACHING EARTH GRADES:

Bleaching Earth of highest bleachability and filterability for difficult-to-bleach oil fats and oils

such as Castor, Palm, Linseed, Rapeseed, Fish, Soyabean, Cottonseed, Rice Bran and Olive.

It exhibits high performance in both Chemical and Physical refining of edible oil.

A. BAL-BLEACHING EARTH GRADE:

NO. PARAMETERS SPECIFICATION

1 Bulk density 0.6 gm/ml (± 0.1)

2 Moisture @ 110'c 15 max

3 pH ( 5 % suspension) 2.8 - 4.5

4 Residual Acidity (mgKOH/g) 2.5 (± 1)

5 Acidity (%H2SO4) 0.4 % max

Granulometry

7 Average Particle Size 20 - 30

8 Less than 5 microns 10.5 % to 20.5% max

9 Less than 90 microns 90 % min

10 BET Surface Area 250 to 350 m2/gm

7. ATTAPULGITE CLAY:

Attapulgite is a kind of crystalloid hydrous magnesium-aluminum silicate mineral, having a

special laminated chain structure in which there is a crystalline lattice displacement existed.

Attapulgite has very good colloidal properties such as: specific features in dispersion, high

temperature endurance, salt and alkali resistance, and also high adsorbing and de-coloring

capabilities. Furthermore, Attapulgite has certain plastic and adhesive characters. It’s ideal

molecular formula is: Mg5Si8O20(HO)2(OH2)4•4H2O.

BALAJI CORPORATE offering various grades of Attapulgite for Drilling, Bleaching earth,

Petroleum oil Purification, Foundry Chemicals, Bio-Fertilizer, Paints, Adhesive, Cat Litter,

Adsorbent, Cosmetics and Pharmaceuticals.

A. API 13 A Sec.12:

NO TESTING PARAMETER UNIT SPECIFICATION RESULTS

1 Suspension Properties (Salt Viscosity) Viscometer CPS Min. 30 34

Dial Reading At 600 RPM

2 Form Powder Powder

3 Colour Off White off White

4 Moisture % Max. 16 8

5 Grit (Wet) Residue of diameter greater than % Max. 8 3.5

75μm/200 Mesh.

GARNET ABRASIVE SAND

Garnet abrasive is most commonly used as a high-performance blast media, for the cleaning of

aluminium and fibreglass structures. Because it is an inert, non-toxic, naturally-occurring mineral,

garnet abrasive is also used on sites where water contamination is a concern, such as dry docks,

bridges and harbours.

Available Grade Size (In Mesh): 12-24, 20-40, 20-60, 30-60, 80, 120

CHEMICAL PROPERTIES

NO. CHEMICAL COMPOSITION PERCENTAGE

1 SiO2 36-37%

2 Fe2O3 25-30%

3 Al2O3 20-24%

4 TiO2 0-2 %

5 CaO 1-3 %

6 MgO 5-9 %

7 OTHER 1-3%

MINERAL COMPOSITION

MINERALS PERCENTAGE

Garnet sand ( Almandine ) 97-99 %

Ilmenite 0-2 %

Others 0-1 %

PHYSICAL PROPERTIES

PARAMETER SPECIFICATION

Specific Gravity 4.1

conductivity 7-12 mS/m

hardness 7.6 in Moh’s scale

Bulk density 2.5 g/cm3

moisture 0.16%

Chloride 15-20 ppm

Acid solubility <1.0 %

Thanking You…

You might also like

- Harmony of The GospelsDocument11 pagesHarmony of The GospelsJesus LivesNo ratings yet

- Drilling Grade Bentonite PowderDocument4 pagesDrilling Grade Bentonite Powderjangri1098No ratings yet

- The Empire in FlamesDocument73 pagesThe Empire in FlamesSergio Esperalta Gata100% (2)

- CementDocument28 pagesCementhboespn100% (1)

- Oil Well Cement: Submitted By-Kajal Gangil BARN1AR130026Document12 pagesOil Well Cement: Submitted By-Kajal Gangil BARN1AR130026Ar Kajal GangilNo ratings yet

- WST Cement CalculationsDocument4 pagesWST Cement CalculationsSonia Mabel ChoqueNo ratings yet

- Mud Engineers HandbookDocument29 pagesMud Engineers HandbookWasif KarimNo ratings yet

- Chapter 14 - Drilling Fluids For ERD, Horizontal WellsDocument14 pagesChapter 14 - Drilling Fluids For ERD, Horizontal WellsAbbas AlkhudafiNo ratings yet

- Ultra LiteCRETE Technology - Case Studies (EEG Client)Document20 pagesUltra LiteCRETE Technology - Case Studies (EEG Client)Priyaranjan Maral0% (1)

- Cement CT BPDocument66 pagesCement CT BPJose Leonardo Materano PerozoNo ratings yet

- 01 Cement Operation - TawfikDocument56 pages01 Cement Operation - TawfikAhmed ManieaNo ratings yet

- Bentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaDocument5 pagesBentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaminingnovaNo ratings yet

- Micro Matrix CementDocument2 pagesMicro Matrix CementAminollah PayvandNo ratings yet

- Gypsum DewateringDocument9 pagesGypsum DewateringthayaNo ratings yet

- Test Certificate: SR No. Parameters Specifications ResultsDocument1 pageTest Certificate: SR No. Parameters Specifications ResultsKaustubh PalNo ratings yet

- WWCI Tech Data BookDocument56 pagesWWCI Tech Data BookazubuikNo ratings yet

- Cement Additives BookletDocument11 pagesCement Additives BookletWise SoNo ratings yet

- Well Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Document8 pagesWell Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Nitin GandhareNo ratings yet

- 13 38 in TP-194 (HAS-2) Cement Program V1Document21 pages13 38 in TP-194 (HAS-2) Cement Program V1hakoubNo ratings yet

- Classification of Lost Circulation MaterialsDocument4 pagesClassification of Lost Circulation MaterialspididiwNo ratings yet

- Ashapura Bentonite: Touching Lives Every Day Every MomentDocument11 pagesAshapura Bentonite: Touching Lives Every Day Every MomentKaustubh PalNo ratings yet

- Polymer Support FluidDocument2 pagesPolymer Support FluidhamsarajshettyNo ratings yet

- Borehole DataDocument5 pagesBorehole DataAnonymous f6uvF90zsNo ratings yet

- The Use and Misuse of Centrifuges PDFDocument4 pagesThe Use and Misuse of Centrifuges PDFChandrasekar Srinivas MohanNo ratings yet

- Cementing OverviewDocument23 pagesCementing OverviewAhmed Ali Alsubaih100% (1)

- Bentonite SpecificationDocument2 pagesBentonite SpecificationPritha Das100% (1)

- Bentonite Grade Details PDFDocument7 pagesBentonite Grade Details PDFZEC LIMITED100% (1)

- Bentonite Grade Details..Document6 pagesBentonite Grade Details..moto rola100% (1)

- B-64603en-1 - 01 (v3) - Vol2 - 0if Connection Manual (Function)Document900 pagesB-64603en-1 - 01 (v3) - Vol2 - 0if Connection Manual (Function)SergioNo ratings yet

- Presentation RAB Jalan Dan Jembatan PT. GUNUNG TANGINDocument9 pagesPresentation RAB Jalan Dan Jembatan PT. GUNUNG TANGINMuhammad Rabbil AlbadriNo ratings yet

- Fracseal (Fine)Document1 pageFracseal (Fine)Jaka TingkirNo ratings yet

- Cementing Job PlanDocument13 pagesCementing Job PlanBrihaspati VermaNo ratings yet

- Normet Microfine Cement Brochure Eng 0Document8 pagesNormet Microfine Cement Brochure Eng 0Sridhara GowdaNo ratings yet

- PNG 451 Lab Manual 2012Document96 pagesPNG 451 Lab Manual 2012Alex RobertNo ratings yet

- Ruspetro PI 413 P41 05 EOWDocument15 pagesRuspetro PI 413 P41 05 EOWOleg MalkovNo ratings yet

- Intro To Cement Laboratory TestDocument49 pagesIntro To Cement Laboratory TestAnonymous 6meMTlNo ratings yet

- HPHT - Cementing (Hart 2006)Document3 pagesHPHT - Cementing (Hart 2006)Sean CurnowNo ratings yet

- Sulfonated Asphalt CCCDocument7 pagesSulfonated Asphalt CCCwynneralphNo ratings yet

- 07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PDocument65 pages07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PjedossousNo ratings yet

- 2001: A Space Odyssey - Film AnalysisDocument4 pages2001: A Space Odyssey - Film AnalysisSummerNo ratings yet

- Tafsir Pimpinan Ar Rahman PDFDocument3 pagesTafsir Pimpinan Ar Rahman PDFUmar Mohd Jafar50% (12)

- Start Up Slug Catcher and Train 1Document43 pagesStart Up Slug Catcher and Train 1Larbi HammounNo ratings yet

- BENTONITE Grade (Balaji Corporate)Document7 pagesBENTONITE Grade (Balaji Corporate)BALAJI CORPORATENo ratings yet

- Ocma Bentonite PDSDocument1 pageOcma Bentonite PDSMannar1No ratings yet

- Cidco 2015 16Document344 pagesCidco 2015 16gdbhoir505No ratings yet

- Guide To Mixing Drilling Fluid Additives: Sandy GroundDocument15 pagesGuide To Mixing Drilling Fluid Additives: Sandy GroundRambabu Ch100% (1)

- Drilling Fluids EngineerDocument2 pagesDrilling Fluids EngineerLenin FontanaNo ratings yet

- TDS - Pulmix 4033Document1 pageTDS - Pulmix 4033dipen royNo ratings yet

- Evaluation CementDocument50 pagesEvaluation CementHamza HamzaNo ratings yet

- Acid Base CementsDocument420 pagesAcid Base Cementskka2000100% (1)

- Activated Fullers EarthDocument1 pageActivated Fullers EarthmayankNo ratings yet

- CPT Glycol in DrillingDocument3 pagesCPT Glycol in DrillingJulie SpencerNo ratings yet

- BaraBlend 665BaraLock 666russiaDocument2 pagesBaraBlend 665BaraLock 666russiaArun Raj LatchumananNo ratings yet

- Geovista Data LoggerDocument1 pageGeovista Data LoggerShahzad KhanNo ratings yet

- Rheological Properties of Drilling Fluids Containing Special Additives For Geothermal Drilling ApplicationsDocument10 pagesRheological Properties of Drilling Fluids Containing Special Additives For Geothermal Drilling Applicationsحسيننننن حسيننننن100% (1)

- Barablend - 665 LCM Standard Field Application Procedure: BaroidDocument16 pagesBarablend - 665 LCM Standard Field Application Procedure: Baroidrushikesh pandyaNo ratings yet

- Conversion Factors & Pressure Test & Casing and DPDocument4 pagesConversion Factors & Pressure Test & Casing and DPhaoues23No ratings yet

- API Casing Float Collar and ShoeDocument2 pagesAPI Casing Float Collar and Shoeisrar haiderNo ratings yet

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiNo ratings yet

- Futur TBT 4380966 01Document76 pagesFutur TBT 4380966 01Carlos David Obando0% (1)

- Glossary: API Specification 10A and API Recommended Practice 10BDocument7 pagesGlossary: API Specification 10A and API Recommended Practice 10BNaimat Ullah0% (1)

- Bha Sheet: Operator Field Rig / Hoist Well # Date Bha # Bha Type SupervisorDocument1 pageBha Sheet: Operator Field Rig / Hoist Well # Date Bha # Bha Type Supervisorhaoues23No ratings yet

- NT Build 492Document3 pagesNT Build 492pavan6595No ratings yet

- From Mud To Cement PDFDocument15 pagesFrom Mud To Cement PDFFabian MontoyaNo ratings yet

- Super Safety ValveDocument1 pageSuper Safety ValvePaul Ticona SNo ratings yet

- MCS Spacer Product BulletinDocument5 pagesMCS Spacer Product BulletinAquiles CarreraNo ratings yet

- Calcium BentoniteDocument5 pagesCalcium BentonitesunitaNo ratings yet

- 3.3 Tests On AggregatesDocument3 pages3.3 Tests On AggregatesG Shankar PandeyNo ratings yet

- Drilling Mud ChemicalsDocument15 pagesDrilling Mud ChemicalsSantosh JayasavalNo ratings yet

- Bleaching Earth-Carbon..Document2 pagesBleaching Earth-Carbon..moto rolaNo ratings yet

- Bleaching Earth-Carbon..Document2 pagesBleaching Earth-Carbon..moto rolaNo ratings yet

- Contact Us: Mining & MineralsDocument2 pagesContact Us: Mining & Mineralsmoto rolaNo ratings yet

- Clippers and ClampersDocument8 pagesClippers and Clamperspuneeth kumarNo ratings yet

- Advantages of Solid-State Relays Over Electro-Mechanical RelaysDocument11 pagesAdvantages of Solid-State Relays Over Electro-Mechanical RelaysKen Dela CernaNo ratings yet

- Model SS ChecklistDocument30 pagesModel SS ChecklistAnonymous PeuxGWWy8tNo ratings yet

- 0610 s14 QP 13Document16 pages0610 s14 QP 13hosni_syr50% (2)

- Mahamaya Technical University,: NoidaDocument49 pagesMahamaya Technical University,: NoidaAlam Mohammad Parvez SaifiNo ratings yet

- PDFDocument110 pagesPDFBikash NayakNo ratings yet

- Let's Study This TextDocument9 pagesLet's Study This TextAnara BhismaNo ratings yet

- Aqa CHM4 W QP Jun09Document20 pagesAqa CHM4 W QP Jun09dharmik47No ratings yet

- Gerus Air Driven Hydraulic PumpDocument7 pagesGerus Air Driven Hydraulic Pumpmahmoudayoub173No ratings yet

- Infertility NotesDocument41 pagesInfertility NotesPrasadNo ratings yet

- Operator PanelDocument11 pagesOperator PanelMostafa AlakhliNo ratings yet

- Examination, June/July: ExplainDocument6 pagesExamination, June/July: ExplainSandesh KulalNo ratings yet

- Fusibles NHDocument4 pagesFusibles NHPaul SchaefferNo ratings yet

- Ahmedabad BRTSDocument3 pagesAhmedabad BRTSVishal JainNo ratings yet

- Detection of Food AdulterationDocument10 pagesDetection of Food AdulterationDavara Paresh R.No ratings yet

- Commercial Galvanic Cells: BatteriesDocument9 pagesCommercial Galvanic Cells: BatteriesKamalpreet SinghNo ratings yet

- LogDocument8 pagesLogMaria SuyantiNo ratings yet

- Engineering Economy 15th Edition Sullivan Test BankDocument25 pagesEngineering Economy 15th Edition Sullivan Test BankDannyStaffordctbi100% (53)

- Hydraulic and Irrigation EnggDocument9 pagesHydraulic and Irrigation EnggUmar Farooq 175-17 CNo ratings yet

- Roco Fittings Contemporary Handles PDFDocument32 pagesRoco Fittings Contemporary Handles PDFIbrahim SaxoNo ratings yet

- Каталог Remeza - 2015 Ганновер 2015 PDFDocument32 pagesКаталог Remeza - 2015 Ганновер 2015 PDFbinhleduc36No ratings yet

- Design and Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument12 pagesDesign and Assembly Analysis of Piston, Connecting Rod & CrankshaftD MasthanNo ratings yet