Professional Documents

Culture Documents

Gas Leak Detector 355764002-1

Uploaded by

Amic BanatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Leak Detector 355764002-1

Uploaded by

Amic BanatCopyright:

Available Formats

5764H002 Ed.

02 GB General warnings

-Using the unit without observing the manufacturer's instructions may alter the appliance's safety requirements.

- Detectors should be installed in a place protected from vibrations, water and corrosive gases, where the ambient

Instructions temperature does not exceed the value indicated in the technical data.

- Detectors supervise a point and not an area. If the gas leak does not reach the sensor, or the level of

concentration in that point does not reach the alarm values, no alarm will be activated. If perimeter

supervision is required, several sensors should be installed around that area.

Working conditions:

-Keep the detector work environment free of chemical agents (such as solvent, paints, alcohol, acetone, silicone, etc.), and

free of engine fumes or gases from fermentations (bread, pizza) or ripening (breathing) of fruits.

-The detector should generally be installed in an area of potential concentration/accumulation of gas, in low positions (due

to the greater relative density, in relation to air, of the gases subject to detection).

-The AKO-576410 / 576032 refrigerant gas detector may only be used in locations that have not been classified with risk

of explosion.

-Reference regulations: EN 378

AKO-576410 AKO-576032 -Applicable local regulations: Compliance must be ensured

Installation

Option A

3 Fixied by an

adhesive

2

4

3.3

3.2

3.1

Carefully perforate the rear entry so as not to damage

the electronic board.

This option involves changing from IP68 to IP40.

Opción B Connect following the

Fixed by screws x2 diagrams

36

mm

Ø 2,8 mm

70

mm

+ x2

3 Ø 5 mm

With cable entry using cable gland

website.

described in our Technical Sheets. Updated information is available on our

We reserve the right to supply materials that might vary slightly to those

2 www.ako.com

355764002 REV.01 2022

If the cable entry at the

1

Fax: +34 938 934 054

back has not been drilled, Tel.: +34 902 333 145

this option provides the

IP68 rating. Barcelona • Spain.

08812 • Sant Pere de Ribes.

Avda. Roquetes, 30-38

Technical specifications AKO ELECTROMECÁNICA , S.A.L.

Power supply ...............................................................................................................................................................12-30 Vdc

Consumption........................................................................................................................... Typical: 75 mA, Maximum:150 mA

Alarm relay .........................................................................................................................................SPDT 30 Vdc, 2A, cos j =1

Working ambient temperature....................................................................................................................................-25 to 50 ºC

Storage ambient temperature.....................................................................................................................................-25 to 60 ºC

Range of moisture permitted...................................................................................................0 - 95 % RH (Without condensation)

Protection degree With cable entry using cable gland .............................................................................................................IP68

With cable entry from the back ...................................................................................................................IP40

Dimensions ..........................................................................................................................107 mm (W) x 85 mm (H) x 39 mm (D)

Complies with the EN 14624 standard.

Description

Refrigerant gas detector, which can be used in independent operation or connected to alarm stations AKOCam, AKOAlarm and AKOGas.

Independent detector: The detector makes a certain warning sound in the event of an Alarm, Pre-Alarm or sensor error and the red indicator lights up (See operation section).

Detector connected to the alarm station: The detector notifies the station of its status (Alarm, Pre-Alarm or sensor error) and the station notifies the alarm through sound and indicators (for

further information consult the station's manual).

Configuration push-button Always disconnect the power supply to do the wiring.

The wiring between the detector/transmitter and the station should NEVER be installed in

Pre-alarm jumper a conduit together with power, control or supply cables.

Pre-alarm enabled Cables for wiring the relay contact should have an adequate section depending on the unit

to be connected.

Pre-alarm disabled

Certain international standards maintain that the power supply of the alarm should

originate from a different circuit to that used by the refrigeration and ventilation system.

Delay and alarm Please ensure that you comply with current local regulations.

levels configuration

Connection strip

GASES DETECTED

AKO-576410 R-410A

AKO-576032 R-32

A LEVELS B LEVELS *

PRE-ALARM ALARM PRE-ALARM ALARM

Alarm delay Alarm levels AKO-576410 500 ppm 1000 ppm 1500 ppm 3000 ppm

Without

ON ON

A

ON

B

ON AKO-576032 500 ppm 1000 ppm 1000 ppm 2000 ppm

delay 180 s levels levels

1 2 1 2 1 2 1 2 *Factory configuration

Wiring

Connection to alarm station Independent operation

Alarm Input x Alarm

RS485 RS485

Gnd

Gnd

Gnd

Gnd

Gnd

15V

15V

15V

Tr+

Tr+

Tr-

Tr-

In

S

NC C NO

S

GAS

NC C NO

Alarm station Gas

12 - 30 Vdc Alarm

Green:

Operation Red: Alarms Operation

Mute push-button Mute Blue: Operating

push-button mode

In the event of an Alarm or Pre-Alarm in process, any push-button press silences the Alarm/Pre-Alarm tone.

Any push-button press deletes saved alarms.

Medium press (between 3 and 9 sec.): It activates or deactivates the SET-HOLD mode. Should there be a sensor error, reset the detector.

Long press (> 9 sec.): It activates or deactivates the MAINTENANCE mode. Should there be a sensor error, reset the detector.

Indicators Audible alarm

Red Green Blue Pre-Alarm Alarm Sensor error

OFF No alarms Detector turned off A levels active Intermittent Bi-tonal 3 tones

ON Alarm / Pre-Alarm activated Standard operation B levels active sound sound every 2 minutes

Standard operation, acoustic MAINTENANCE mode Alarm relay

Flashing* Alarm / Pre-Alarm saved

alarm disabled activated Pre-Alarm Alarm Sensor error

Detector in initialisation

Flash* Detector error SET HOLD mode activated NC C NO NC C NO NC C NO

process

*Flashing: 0.5 s ON / 0.5 s ON / Flash: 0.1 s ON / 0.8 s OFF

Configuration

In this mode the acoustic alarm can be activated / deactivated or the detector can be returned to factory settings.

To activate it:

1.- Disconnect the power supply, reconnect it and press the “CONFIGURATION” push-button 5 times within 2 minutes; the detector will emit a confirmation beep and the blue indicator will show the

status of the acoustic alarm: ON: Acoustic alarm enabled / Flashing: Acoustic alarm disabled.

2.- Press the Mute push-button to enable / disable the acoustic alarm.

3.- Press the “CONFIGURATION” push-button for 5 seconds to save the changes and exit the configuration mode; the detector will make 5 short beeps.

Optionally, you can return the detector to its factory settings. To do so, press the “CONFIGURATION” push-button 5 times before step 3.

Pre-alarm jumper

Allows for Pre-alarm detection to be enabled / disabled. Before using this option, ensure that regulations allow for two alarm levels.

SET-HOLD mode

Prevents false alarms when charging or cleaning the chambers. While this mode is activated, pre-alarms will not signal and alarms will signal as pre-alarms when faced with all effects (sound, relay

activation and signalling). This mode will remain active for a maximum of 5 hours, then will deactivate automatically.

Maintenance mode

Disables gas pre-alarms and alarms for 1 hour for maintenance tasks. While this mode is activated, no gas pre-alarm or alarm will sound.

You might also like

- Gas Detector: Quick GuideDocument2 pagesGas Detector: Quick GuideAmic BanatNo ratings yet

- Assembly Instruction Radio Control Unit 161006Document16 pagesAssembly Instruction Radio Control Unit 161006Oguz KayhanNo ratings yet

- Sanyo DVD-650V-MTK Reproductor DVD Manual de Servicio DVD 8100Document23 pagesSanyo DVD-650V-MTK Reproductor DVD Manual de Servicio DVD 8100Luciano CamposNo ratings yet

- Reply To The Engineer Comments-25-3-23 PDFDocument2 pagesReply To The Engineer Comments-25-3-23 PDFMrDeathnetNo ratings yet

- Ghirri - Redutores - Classificação - Um-Vs-Rev.20.06.06-Eng3Document35 pagesGhirri - Redutores - Classificação - Um-Vs-Rev.20.06.06-Eng3Jeferson DantasNo ratings yet

- AKO 5981x 5982x InstructionsDocument2 pagesAKO 5981x 5982x InstructionsedwindossantosNo ratings yet

- Manual U ValveDocument16 pagesManual U ValveFrancisco PradoNo ratings yet

- Soplador Industrial Instrucción - ENDocument15 pagesSoplador Industrial Instrucción - ENPercy Garnique AngelesNo ratings yet

- TC10 Temperature Controller - Engineering-ManualDocument36 pagesTC10 Temperature Controller - Engineering-ManualcoronaqcNo ratings yet

- Im05c01e81 02enDocument36 pagesIm05c01e81 02enHardik LanghnojaNo ratings yet

- ConduitDocument2 pagesConduitRabah AmidiNo ratings yet

- Riken-Keiki Monitors-Hydrogen ManualDocument101 pagesRiken-Keiki Monitors-Hydrogen Manualebin vargheseNo ratings yet

- Ni CRIO-9063 DatasheetDocument17 pagesNi CRIO-9063 DatasheetAntonio HerreraNo ratings yet

- 8M0104800 Smart Tachometer Smart Speedometer InstallationDocument6 pages8M0104800 Smart Tachometer Smart Speedometer Installationabduallah muhammadNo ratings yet

- Gas Transmitter With Nbiot Communication: Without AlarmsDocument2 pagesGas Transmitter With Nbiot Communication: Without AlarmsAmic BanatNo ratings yet

- 1 Safety Instructions: Bluetooth Low Energy Radio TransmitterDocument4 pages1 Safety Instructions: Bluetooth Low Energy Radio TransmitterMohamed Tahar BoussahaNo ratings yet

- TELECOMMANDE FILAIRE IOM 042021 DX Control KJR-120X 14LDocument646 pagesTELECOMMANDE FILAIRE IOM 042021 DX Control KJR-120X 14LEL KEHELNo ratings yet

- ABB Ability™ Smart Sensor: Install Ation GuideDocument4 pagesABB Ability™ Smart Sensor: Install Ation GuideNisharani PatilNo ratings yet

- Meter T ENDocument40 pagesMeter T ENAbderrahim ErragragyNo ratings yet

- Instruction Manual: Rishabh Instruments Pvt. LTDDocument3 pagesInstruction Manual: Rishabh Instruments Pvt. LTDShiaTVfanNo ratings yet

- Smartcraft System Tachometer and Speedometer Installation: Thank YouDocument6 pagesSmartcraft System Tachometer and Speedometer Installation: Thank YouthesaneroneNo ratings yet

- New Methods of RepairingDocument4 pagesNew Methods of RepairingGeorge MogaNo ratings yet

- Mode Demploi 1416228 Indicateur de Niveau Electronique Avec Relais Secutech Smartbox 3 1 PcsDocument20 pagesMode Demploi 1416228 Indicateur de Niveau Electronique Avec Relais Secutech Smartbox 3 1 PcsBenjamin Bes SauvantNo ratings yet

- Meter Si18001a enDocument2 pagesMeter Si18001a enAbderrahim ErragragyNo ratings yet

- 2071 1062 Installation and Use of Gas Detection Equipment Rev5.9 PDFDocument30 pages2071 1062 Installation and Use of Gas Detection Equipment Rev5.9 PDFSurendar VeerarajNo ratings yet

- 5782DEC 1v0Document60 pages5782DEC 1v0dkchqmpNo ratings yet

- 52A InteriorDocument26 pages52A InteriorMichael YazonNo ratings yet

- GT26 Quick GuidDocument4 pagesGT26 Quick GuidHubert Chang EscalanteNo ratings yet

- Installation Guide AUA234C Issue 3 SLC 5 SLC 2000 Intelligent All Rate DS0 DataportDocument2 pagesInstallation Guide AUA234C Issue 3 SLC 5 SLC 2000 Intelligent All Rate DS0 DataportKendric ShahidNo ratings yet

- Safety Instructions VEGADIS DIS61.C - VEGADIS DIS 81.ACDocument8 pagesSafety Instructions VEGADIS DIS61.C - VEGADIS DIS 81.ACMihai RaduNo ratings yet

- 1 Safety Instructions: Friends of Hue Switch SetDocument4 pages1 Safety Instructions: Friends of Hue Switch SetMohamed Tahar BoussahaNo ratings yet

- Quick Installation Guide: ASW3000-S-G2/ASW3680-S-G2/ASW4000-S-G2 ASW5000-S-G2/ASW6000-S-G2Document13 pagesQuick Installation Guide: ASW3000-S-G2/ASW3680-S-G2/ASW4000-S-G2 ASW5000-S-G2/ASW6000-S-G2ClaudiNo ratings yet

- Manual KM5PDocument44 pagesManual KM5Pd3xterNo ratings yet

- Gas Detector: Quick GuideDocument2 pagesGas Detector: Quick GuideAmic BanatNo ratings yet

- Sanitary RTD Temperature Sensor TH17: Supplementary DocumentationDocument8 pagesSanitary RTD Temperature Sensor TH17: Supplementary DocumentationChristian CastilleroNo ratings yet

- Installation Instructions: (Catalog Number 1771-IL Series C)Document16 pagesInstallation Instructions: (Catalog Number 1771-IL Series C)Jan Richardo GultomNo ratings yet

- Gas Detector Series Installation ManualDocument12 pagesGas Detector Series Installation Manualhatem hbibiNo ratings yet

- Gas Transmitter: AKO-575xxxDocument2 pagesGas Transmitter: AKO-575xxxAmic BanatNo ratings yet

- XMT SI 485 and XMP SI RF ATG Probes Technical GuideDocument32 pagesXMT SI 485 and XMP SI RF ATG Probes Technical GuideAbraham Flores100% (2)

- Mg-Rem1: Magellan Remote Control With Backlight V3.0Document2 pagesMg-Rem1: Magellan Remote Control With Backlight V3.0Metalurgica VISILUNo ratings yet

- en EL 4 Conductive Multiple Rod ElectrodeDocument2 pagesen EL 4 Conductive Multiple Rod ElectrodeJavier CarrizoNo ratings yet

- User Manual-Version 1.0.0Document77 pagesUser Manual-Version 1.0.0Reza Rifqil AzizNo ratings yet

- Owner'S Manual: Manual Do UsuárioDocument20 pagesOwner'S Manual: Manual Do UsuáriofelipizilNo ratings yet

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemDocument9 pages1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Air Fuel Ratio GaugesDocument6 pagesAir Fuel Ratio GaugesadrianNo ratings yet

- 2a. 704020 SC3ML Installation and Operating Manual V3a Ben EN 0416 A4F (GBSCOM1200416)Document28 pages2a. 704020 SC3ML Installation and Operating Manual V3a Ben EN 0416 A4F (GBSCOM1200416)Mustapha BoulahiaNo ratings yet

- 10.13 .Installation Manual of HXE310CT CTPT Meter-V2Document18 pages10.13 .Installation Manual of HXE310CT CTPT Meter-V2Ashfaque AhmedNo ratings yet

- Heathkit ET 3400 Microprocessor TrainerDocument24 pagesHeathkit ET 3400 Microprocessor TrainerAlfredo Meurer JuniorNo ratings yet

- Low Voltage Alternators - 4 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternators - 4 Pole: Installation and MaintenanceJuan David Abadia LopezNo ratings yet

- ComfortZoneII - Installation Zonekit-14siDocument28 pagesComfortZoneII - Installation Zonekit-14siAaron HeadNo ratings yet

- Enforcer 32-WE APP V10-Installation Manual-1Document24 pagesEnforcer 32-WE APP V10-Installation Manual-1Pal IstvanNo ratings yet

- ABB - Smart Sensor Installation - 8.5x11 - 9.17 - LR PDFDocument4 pagesABB - Smart Sensor Installation - 8.5x11 - 9.17 - LR PDFFerozMujawarNo ratings yet

- Lx70 ManualDocument23 pagesLx70 Manualsrabani dashNo ratings yet

- 9AKK106930A9455 ABB Smart Sensor Motor Installation Guide Putty RevB en 012019Document4 pages9AKK106930A9455 ABB Smart Sensor Motor Installation Guide Putty RevB en 012019De RaNo ratings yet

- User Guide: IT6000-IOT Series HMIDocument2 pagesUser Guide: IT6000-IOT Series HMINgọc NhấtNo ratings yet

- WIKA GDM-RC-100 SF6 Gas Dandeity MonitorDocument88 pagesWIKA GDM-RC-100 SF6 Gas Dandeity MonitorDaniel StaigerNo ratings yet

- Operating Instructions Flow Monitors: SI6000 SI6100 SI6200Document17 pagesOperating Instructions Flow Monitors: SI6000 SI6100 SI6200harisNo ratings yet

- ATV320 IS Option Module Adapter NVE22661 02Document2 pagesATV320 IS Option Module Adapter NVE22661 02Jefferson PachecoNo ratings yet

- UserManualM18C 17Document92 pagesUserManualM18C 17Loai AhmedNo ratings yet

- Sound Parallel Calculation - EDocument1 pageSound Parallel Calculation - EAmic BanatNo ratings yet

- Sound Emission Calculation - EDocument15 pagesSound Emission Calculation - EAmic BanatNo ratings yet

- DS Secr03 en R2203Document6 pagesDS Secr03 en R2203Amic BanatNo ratings yet

- En Aspen Xtra BigFoot Catalogue 2 18Document118 pagesEn Aspen Xtra BigFoot Catalogue 2 18Amic BanatNo ratings yet

- Aspera 2pgDocument2 pagesAspera 2pgAmic BanatNo ratings yet

- Leaflet NEUDocument2 pagesLeaflet NEUAmic BanatNo ratings yet

- Leaflet Natural RefrigerantsDocument2 pagesLeaflet Natural RefrigerantsAmic BanatNo ratings yet

- Akocable enDocument16 pagesAkocable enAmic BanatNo ratings yet

- Catalog Agregate 2011 06001Document26 pagesCatalog Agregate 2011 06001Amic BanatNo ratings yet

- Mini Split Kit Fix-it-Foot-SpecDocument2 pagesMini Split Kit Fix-it-Foot-SpecAmic BanatNo ratings yet

- Formación AKOPRO CoolDocument12 pagesFormación AKOPRO CoolAmic BanatNo ratings yet

- Multi Frame Range Tech Sheet USDocument1 pageMulti Frame Range Tech Sheet USAmic BanatNo ratings yet

- Mini Split Stand-Range-SpecDocument2 pagesMini Split Stand-Range-SpecAmic BanatNo ratings yet

- List of Part Numbers and Details For Temperature Controlling ThermometersDocument2 pagesList of Part Numbers and Details For Temperature Controlling ThermometersAmic BanatNo ratings yet

- Gas Detector: Quick GuideDocument2 pagesGas Detector: Quick GuideAmic BanatNo ratings yet

- Gas Transmitter: AKO-575xxxDocument28 pagesGas Transmitter: AKO-575xxxAmic BanatNo ratings yet

- Procool Electronic Panel: Ako-17635-1 Ako-17635-2Document23 pagesProcool Electronic Panel: Ako-17635-1 Ako-17635-2Amic BanatNo ratings yet

- Gas Transmitter: AKO-575xxxDocument28 pagesGas Transmitter: AKO-575xxxAmic BanatNo ratings yet

- Procool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Document4 pagesProcool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Amic BanatNo ratings yet

- Gas Transmitter: AKO-575xxxDocument2 pagesGas Transmitter: AKO-575xxxAmic BanatNo ratings yet

- MOD BUS Map355762452Document4 pagesMOD BUS Map355762452Amic BanatNo ratings yet

- Akocore: La Máxima Eficiencia en Control de Cámaras FrigoríficasDocument4 pagesAkocore: La Máxima Eficiencia en Control de Cámaras FrigoríficasAmic BanatNo ratings yet

- Gas Transmitter With Nbiot Communication: Without AlarmsDocument2 pagesGas Transmitter With Nbiot Communication: Without AlarmsAmic BanatNo ratings yet

- Gas Leak Detection Alarm: AKO-55624 AKO-55724Document16 pagesGas Leak Detection Alarm: AKO-55624 AKO-55724Amic BanatNo ratings yet

- Ignition System VijayDocument19 pagesIgnition System VijayIshita SharmaNo ratings yet

- GB112 Manual UtilizareDocument8 pagesGB112 Manual UtilizarefaceosNo ratings yet

- Promag 10L1FDocument36 pagesPromag 10L1FCharles MartinNo ratings yet

- Challenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANEDocument73 pagesChallenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANETigist HaileNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

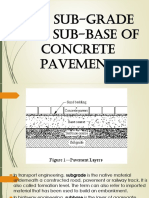

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 pagesThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorNo ratings yet

- TSI Runflat Systems: Fitting Instructions and User GuideDocument6 pagesTSI Runflat Systems: Fitting Instructions and User Guideabdelrhmangbr86No ratings yet

- Astm D7522M-21Document6 pagesAstm D7522M-21Edgar Joel Perez CarvajalNo ratings yet

- Aqualine SinglesoftenerDocument2 pagesAqualine Singlesoftenernermeen ahmedNo ratings yet

- FBE Installation Manual PDFDocument60 pagesFBE Installation Manual PDFMario R. KallabNo ratings yet

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- Polycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiDocument1 pagePolycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiAshwin SupeNo ratings yet

- LC3 For Cem Tech Oct 2020Document62 pagesLC3 For Cem Tech Oct 2020Subhan MuhammadNo ratings yet

- Strand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383Document1 pageStrand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383rocketvtNo ratings yet

- ROLLING MILL REPORT RevampDocument31 pagesROLLING MILL REPORT RevamprohitNo ratings yet

- ASV ST50 Service ManualDocument114 pagesASV ST50 Service ManualbrunosamaeianNo ratings yet

- CP Repair Tools and EquipmentDocument68 pagesCP Repair Tools and EquipmentJay R BallonNo ratings yet

- Manual Instrucciones TyphoonDocument46 pagesManual Instrucciones TyphoonGabriel TanaseNo ratings yet

- Pittcote 404 PDFDocument2 pagesPittcote 404 PDFJuan Manuel DiazNo ratings yet

- ASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Document3 pagesASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Paul CassellsNo ratings yet

- Multis Ep 2 TDS v171023Document1 pageMultis Ep 2 TDS v171023Stefan UngurNo ratings yet

- Pentadyne VSS BrochureDocument4 pagesPentadyne VSS BrochureWalid WahyudiNo ratings yet

- Civil Engineering: 1 Mortar, Masonry, Concrete and Steel ReinforcementDocument50 pagesCivil Engineering: 1 Mortar, Masonry, Concrete and Steel ReinforcementZuhal ZaeemNo ratings yet

- Cement PPT-BMC PDFDocument120 pagesCement PPT-BMC PDFAdhyyan JoshiNo ratings yet

- Project Report On GearsDocument40 pagesProject Report On Gearsjai70% (27)

- Rotary Pallet Rack CenterDocument1 pageRotary Pallet Rack CenterKittisak SungsanaNo ratings yet

- TF4L3 We 889ar PDFDocument229 pagesTF4L3 We 889ar PDFFelipe ChimborazoNo ratings yet

- Single Electron Transistor NanoDocument2 pagesSingle Electron Transistor NanoDerry PermanaNo ratings yet

- Airtronic D2-D4 Diagnostic Repair Manual 2013Document33 pagesAirtronic D2-D4 Diagnostic Repair Manual 2013sdfrNo ratings yet

- TDS Manganese Phosphating BCM MP-1501 PDFDocument3 pagesTDS Manganese Phosphating BCM MP-1501 PDFanon_666700113No ratings yet