Professional Documents

Culture Documents

TC10 Temperature Controller - Engineering-Manual

Uploaded by

coronaqcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TC10 Temperature Controller - Engineering-Manual

Uploaded by

coronaqcCopyright:

Available Formats

1.

3 MOUNTING REQUIREMENTS

TC10 This instrument is intended for permanent installation, for

indoor use only, in an electrical panel which encloses the

rear housing, exposed terminals and wiring on the back.

Select a mounting location having the following characteristics:

1. It should be easily accessible;

TEMPERATURE 2. There is minimum vibrations and no impact;

CONTROLLER 3. There are no corrosive gases;

4. There are no water or other fluids (i.e. condensation);

5. The ambient temperature is in accordance with the

operative temperature (0 to 50°C);

6. The relative humidity is in accordance with the instrument

specifications (20 to 90%);

The instrument can be mounted on panel with a maximum

thickness of 8 mm.

When the maximum front protection (IP65) is desired, the

optional gasket must be mounted.

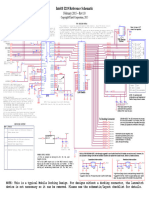

Engineering Manual 2. CONNECTION DIAGRAM

Code: IM 05C01E81-02EN

8

NO + + 16 DI1

Third edition: Feb. 2018

Out1

C

Yokogawa Electric Corporation DI2 7 - - 15

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750 Japan + NO

www.yokogawa.com/ns 6 D-

- 14 Out2

RS485

5 D+ C 13

+

1. OUTLINE DIMENSIONS (mm) 12 VDC/20 mA max. Out4 +- NO

+ 4 12 Out3

1.1 INSTRUMENT DIMENSIONS 3 C

11

-

48 11 48 14

2 10 Power

supply

+ + + 1 9

0/12 to 60 mV, 0/1 to 5V, 0/2 to 10V

Passive TX, 2 wires, 4 to 20 mA

4 to 20 mA (active)

Pt1000

Pt100

TC

PV

48

AT

Relay Out 1: 4 (4) A/250 VAC

Relay Out 2, 3: 2 (1) A/250 VAC

SSR Out 1, 2 , 3: 10 VDC/15 mA

Optional SSR Out4: 12 VDC/20 mA

8 mm max. Current Out1: 0/4 to 20 mA, 0/2 to 10V

gasket

1.2 PANEL CUT-OUT

65 mm min.

2.56 in min. 2.1 GENERAL NOTES ABOUT WIRING

1. Do not run input wires together with power cables.

2. External components (like zener barriers, etc.) connected

between sensor and input terminals may cause errors in

measurement due to excessive and/or not balanced line

resistance or possible leakage currents.

2.56 in min.

3. When a shielded cable is used, it should be connected at

65 mm min.

one point only.

4. Pay attention to the line resistance; a high line resistance

1.78+0.023 in

may cause measurement errors.

45+0.6 mm

45+0.6 mm

1.78+0.023 in

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 1

2.2 INPUTS 2.2.5 mA Input

2.2.1 Termocouple Input 0/4 to 20 mA input wiring for passive transmitter

using the auxiliary pws

2 _

+ 4

1 + 4 to 20 mA

Passive

transmitter

External resistance: 100Ω max., maximum error 25 mV. _ 1

Cold junction: automatic compensation between 0 to 50°C.

Cold junction accuracy: 0.05°C/°C after a warm-up of Input impedance: < 53Ω.

20 minutes. Internal auxiliary PWS: 12 VDC (±10%), 20 mA max..

Input impedance: > 1 MΩ.

0/4 to 20 mA input wiring for passive transmitter

Calibration: According to EN 60584-1. using an external pws

Note: For TC wiring use proper compensating cable

+ External

preferable shielded. 0/4 to 20 mA + PWS

_ 2 _

Passive

2.2.2 RTD Pt 100 Input transmitter _ 1 +

3

RTD 0/4 to 20 mA input wiring for active transmitter

2

0/4 to 20 mA _ 2 _

1 Active

transmitter + 1 +

Input circuit: Current injection (150 µA).

Line resistance: Automatic compensation up to 20Ω/wire 2.2.6 Logic Inputs

with maximum error ±0.1% of the input span.

Calibration: According to EN 60751/A2. Safety notes:

Note: The resistance of the 3 wires must be the same. ––Do not run logic input wiring together with power cables;

––The instrument needs 150 ms to recognize a contact

2.2.3 RTD Pt 1000 Input status variation;

––Logic inputs are NOT isolated by the measuring input.

3 A double or reinforced isolation between logic inputs and

Pt1000 power line must be assured by the external elements.

2

Logic input driven by dry contact

Line resistance: Not compensated.

Pt 1000 input circuit: Current injection (15 µA). 16

Pt 1000 calibration: According to EN 60751/A2.

15 Digital

2.2.4 V and mV Input Digital 4 Input 1

Input 2

mV

_ 2 _ Maximum contact resistance: 100Ω.

V + Contact rating: DI1 = 10 V, 6 mA;

1 + DI2 = 12 V, 30 mA.

Input impedance: > 1 MΩ for mV Input Logic inputs driven by 24 VDC

500 kΩ for Volt Input.

- 16 -

Digital

+ 15 + Input 1

Digital 4

Input 2

Logic status 1: 6 to 24 VDC;

Logic status 0: 0 to 3 VDC.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 2

2.3 OUTPUTS SSR Output

Safety notes: +

SSR 14

––To avoid electrical shocks, connect power line at last.

––For supply connections use No. 16 AWG or larger wires 13

rated for at last 75°C. -

––Use copper conductors only. Logic level 0: Vout < 0.5 VDC;

––SSR outputs are not isolated. A reinforced isolation must Logic level 1: 12 V ±20%, 15 mA max..

be assured by the external solid state relays.

––For SSR, mA and V outputs if the line length is longer than 2.3.3 Output 3 (OP3)

30 m use a shielded wire. Relay Output

––Do not short-circuit the terminals of the SSR output.

NO

WARNING! Before connecting the output actuators, 12

we recommend to configure the parameters to C

suit your application (e.g.: input type, Control 11

strategy, alarms, etc.).

Contact rating: • 2 A /250 V cosj = 1;

2.3.1 Output 1 (OP1) • 1 A /250 V cosj = 0.4.

Relay Output Operation: 1 x 105.

NO SSR Output

8

+

C SSR 12

7

- 11

Contact rating: • 4 A /250 V cosj =1;

• 2 A /250 V cosj =0.4.

Logic level 0: Vout < 0.5 VDC;

Operation: 1 x 105.

Logic level 1: 12 V ±20%, 15 mA max..

SSR Output

2.3.4 Output 4 (OP4)

+

8 SSR SSR Output

7 16

- -

Logic level 0: Vout < 0.5 VDC; + SSR

Logic level 1: 12 V ±20%, 15 mA max.. Out4 4

Current Analog Output

Logic level 0: Vout < 0.5 VDC;

+

8 mA Logic level 1: 12 V ±20%, 20 mA max..

Note: Overload protected.

7

-

mA output: 0/4... 20 mA, galvanically isolated, RL max. 600Ω.

Voltage Analog Output

+

8 V

7

-

V output: 0/2... 10 V, galvanically isolated, RL min.: 500Ω.

2.3.2 Output 2 (OP2)

Relay Output

NO

14

C 13

Contact rating: • 2 A /250 V cosj = 1;

• 1 A /250 V cosj = 0.4.

Operation: 1 x 105.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 3

2.4 SERIAL INTERFACE 3. TECHNICAL CHARACTERISTICS

RS-485 D - 3.1 TECHNICAL SPECIFICATION

D- 6 Case: Plastic, self-extinguishing degree: V-0 according to UL 94;

5 Front protection: IP 65 (when the optional panel gasket is

D+ mounted) for indoor locations according to EN 60070-1;

D+

Terminals protection: IP 20 according to EN 60070-1;

D-

Installation: Panel mounting;

D+ Terminal block: 16 screw terminals for cables of

0.25 to 2.5 mm2 (AWG22 to AWG14) with connection diagram,

tightening torque 0.5 Nm;

D- Dimensions: 48 x 48, depth 73 mm, (1.89 x 1.89 x 2.87 in.)

Panel cutout: 45[-0, +0.6] x 45[-0, +0.6] mm

D+ (1.78[- 0.000, +0.023] x 1.78[- 0.000, +0.023] in.)

Weight: 180 g max..

Interface type: Isolated (50 V) RS-485;

Voltage levels: According to EIA standard; Power supply: • 24 VAC/DC (±10% of the nominal value);

Protocol type: Modbus RTU; • 100 to 240 VAC (-15 to +10% of the

Byte format: 8 bit with no parity; nominal value);

Stop bit: 1 (one); Power consumption: 4.5 VA max. (24 VAC/DC)

Baud rate: Programmable between 1200 to 38400 baud; 6.0 VA max. (100 to 240 VAC);

Address: Programmable between 1 to 254. Insulation voltage: 2300 V rms according to EN 61010-1;

Notes: 1. RS-485 interface allows to connect up to 30 Display updating time: 500 ms;

devices with one remote master unit. Sampling time: 130 ms;

2. The cable length must not exceed 1.5 km at Resolution: 30000 counts;

9600 baud.

Total Accuracy: ±0.5% F.S.V. ±1 digit @ 25°C of room

2.5 POWER SUPPLY temperature;

Electromagnetic compatibility and safety requirements

10 Line Compliance: directive EMC 2004/108/CE (EN 61326-1),

Power Supply directive LV 2006/95/CE (EN 61010-1),

9 Neutral UL 61010-1 CSA 61010-1;

Note: During the test, the instrument continues to operate at

the measurement accuracy within specification.

Supply Voltage: • 24 VAC/DC (±10%);

• 100 to 240 VAC (-15 to +10%). Installation category: II;

Notes: 1. Before connecting the instrument to the power Pollution category: 2;

line, make sure that line voltage is equal to the Temperature drift: It is part of the global accuracy;

voltage shown on the identification label; Operating temperature: 0 to 50°C (32 to 122°F);

2. The polarity of the power supply has no importance; Storage temperature: -30 to +70°C (-22 to +158°F);

3. The power supply input is NOT fuse protected. Humidity: 20 to 90% RH, not condensing.

Please, provide a T type 1A, 250 V fuse externally.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 4

4. MODEL AND SUFFIX CODES

Model Code Suffix codes Description

TC10 -N o C o o o D o F Temperature Controller

Fixed code -N Always "-N"

L 24 VAC/DC (Custom order)

Power supply

H 100 to 240 VAC

Fixed code C Always "C"

R N N Relay output for on/off control

Relay output with 2 alarm relays,

R R R for ON/OFF or Heat/Cool control

with 1 alarm

V N N DC Output for SSR

DC Output for SSR with 2 alarm

OUT1 - 3 relays or DCV and relay output

V R R

for Heat/Cool control with 1

alarm

2 DCV outputs for SSR with 1

V V R

relay (Custom order)

Analog output with 2 alarm relays,

A R R or analog output and relay output

for Heat/Cool control with 1 alarm

Always "D" - Selectable I/O (logic

IN/OUT4 (Fixed code) D input/12 V SSR drive output/12VDC

20 mA transmitter power supply

S RS485 Modbus

Serial communication

N None

Fixed code F Always “F”

Option Code /GK Panel gasket for IP65

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 5

5. CONFIGURATION PROCEDURE 5.3 HOW TO ENTER THE

“CONFIGURATION MODES”

5.1 INTRODUCTION

Note: The TC10 is equipped with two different “configuration”

When the instrument is powered, it starts immediately to work methods:

according to the parameters values loaded in its memory. A) The “code” configuration method;

The instrument behaviour and its performance are governed B) The “complete” configuration method.

by the value of the stored parameters. The “code” configuration method is really fast but modifies

At the first start up the instrument will use a “default” only the most common configuration parameters.

parameter set (factory parameter set); this set is a generic The “complete” configuration method allows to take

one (e.g. a TC J input is programmed). advantage of all instrument features, giving more capabilities

WARNING! Before connecting the output actuators, it requires more actions and time.

we recommend to configure the parameters to Note that you can take advantage by both methods because if

suit your application (e.g.: input type, Control

you use the code configuration and then you enter in the

strategy, alarms, etc.).

complete configuration, all selections made by code are still valid.

To change these parameters you need to enter the

In both cases the instrument have one complete parameter set.

“Configuration mode”.

We call this set “configuration parameter set” (or

5.2 INSTRUMENT BEHAVIOUR AT “configuration parameters”).

POWER ON When code configuration method is used all the parameters

not modified by the code will maintain their default values.

At power ON the instrument can start in one of the following

mode depending on its configuration: In both cases the access to the configuration parameters is

protected by a password (a specific password for each method).

Auto mode

Note: The instrument will show only the parameters consis-

––The upper display shows the measured value; tent with the specific hardware and in accordance with

––The lower display shows the Set point value; the value assigned to the previous parameters

––The decimal figure of the less significant digit of the lower (e.g.: if you set an output as “not used” the instrument

display is OFF; will mask all other parameters related to this output).

–– The instrument is performing the standard closed loop control. 5.3.1 “Code” configuration procedure

Manual mode (OPLO) The controller configuration (Input type, Control mode, etc.)

––The upper display shows the measured value; can be made entering two 4-digit codes.

Before to enter into code configuration we suggest you to

––The lower display shows the power output [preceded by H

prepare the two codes according to the tables that follow.

(for heating) or C (for cooling)]. The MAN LED is lit;

Notes: 1. During the Code configuration procedure there is

––The instrument does not perform Automatic control;

no timeout.

––The control output is equal to 0% and can be manually

2. To leave, at any time, the Configuration session

modified by and buttons.

without saving the settings made, press the

Stand by mode (St.bY) button.

––The upper display shows the measured value; To enter into code configuration proceed as follows:

––The lower display shows alternately the set point value and 1. Push the button for more than 3 seconds.

the message St.bY or od; The upper display will show PASS (flashing) while the

––The instrument performs no control (the control outputs lower display will show 0;

are OFF); 2. Using and buttons set the password programmed

––The instrument is working as an indicator. in parameter [120] PAS4. The factory default password

We define all the above described conditions as for Code configuration is 300;

“Standard Display”. 3. Push the button;

If the password is correct the instrument will show one of

the following conditions:

• If no code is present, the display shows codE on the

upper display and oFF on the lower display.

Push the button to continue.

The upper display will flash cod1 while the lower display

shows 0000.

• If a previous code was stored, the upper display will

flash cod1 while the lower display shows the value of

cod1 stored in memory.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 6

4. Using and buttons set the code 1 value 5. Push the button.

according to the following tables. The upper display shows cod2 flashing while the lower

L M N O display shows 0000 or the cod2 value stored in memory.

Prepare your code 1 6. Using and buttons set the code 2 value

Input Type and Range L M according to the following tables.

TC J -50 to +1000°C 0 0 P Q R S

TC K -50 to +1370°C 0 1 Prepare your code 2

TC S -50 to 1760°C 0 2

Alarm 3 R

TC R -50 to +1760°C 0 3

Alarm 2 Q

TC T -70 to +400°C 0 4

Alarm 1 P

PT 100 -200 to +850°C 0 7

Not used 0 0 0

PT 1000 -200 to +850°C 0 8

Sensor break 1 1 1

Linear 0 to 60 mV 0 9

High 2 2 2

Linear 12 to 60 mV 1 0 Absolute

Low 3 3 3

Linear 0 to 20 mA (this selection forces Out 4 = TX) 1 1

External High/Low 4 4 4

Linear 4 to 20 mA (this selection forces Out 4 = TX) 1 2 Absolute High/Low

Internal High/Low 5 5 5

Linear 0 to 5 V 1 3

Deviation high 6 6 6

Linear 1 to 5 V 1 4 Deviation

Deviation low 7 7 7

Linear 0 to 10 V 1 5

External band 8 8 8

Linear 2 to 10 V 1 6 Band

Internal band 9 9 9

TC J -58 to +1832°F 1 7

TC K -58 to +2498°F 1 8

TC S -58 to 3200°F 1 9 c%d2: P Q R S

TC R -58 to +3200°F 2 0

TC T -94 to +752°F 2 1 Auxiliary functions activation S

PT 100 -328 to +1562°F 2 4 None 0

PT 1000 -328 to +1562°F 2 5 Wattmeter (instantaneous power expressed in W) 1

Wattmeter (energy expressed in Wh) 2

c%d1: L MN O Absolute worked time (expressed in days) 3

Absolute worked time (expressed in hours) 4

Control mode OP1 OP2 OP3 OP4 N O

H AL1 AL2 AL3 0 0 7. Push the button.

ON/OFF heating = H If the just entered codes are accepted, the upper display

NU AL1 AL2 H 0 1

C AL1 AL2 AL3 0 2 shows code while the lower display shows good.

ON/OFF cooling = C

NU AL1 AL2 C 0 3 8. Push the button to save the configuration code and

H C AL2 AL3 0 4 exit the Code configuration procedure.

H AL1 AL2 C 0 5

C H AL2 AL3 0 6

Note: After using the “Code configuration” method, it will

ON/OFF with neutral

zone (H/C) NU H AL2 C 0 7 always be possible to modify the parameters using the

C AL1 AL2 H 0 8 “Complete configuration” method. If the value of a

NU C AL2 H 0 9 parameter among those included in the configuration

H AL1 AL2 AL3 1 0 codes (cod1 - cod2) gets modified, the instrument

PID heating = H will acquire the change while maintaining all the other

NU AL1 AL2 H 1 1

C AL1 AL2 AL3 1 2 parameters.

PID cooling = C

NU AL1 AL2 C 1 3 WARNING! After a parameter change made as described

H C AL2 AL3 1 4 in the previous “Note”, when retrieving the

H AL1 AL2 C 1 5 configuration codes (cod1 - cod2), the lower

C H AL2 AL3 1 6

PID double action (H/C) display will show “oFF” to alert the operator that

NU H AL2 C 1 7

one of the parameters has been changed.

C AL1 AL2 H 1 8

NU C AL2 H 1 9

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 7

5.3.2 Complete configuration procedure 5.6 FACTORY RESET - DEFAULT

The configuration parameters are collected in various PARAMETERS LOADING PROCEDURE

groups. Every group defines all parameters related with a Sometime, e.g. when you re-configure an instrument

specific function (e.g.: control, alarms, output functions). previously used for other works or from other people or when

1. Push the button for more than 3 seconds. The upper you have made too many errors during configuration and

display will show PASS while the lower display will show 0. you decided to re-configure the instrument, it is possible to

2. Using and buttons set the programmed password. restore the factory configuration.

Notes: 1. The factory default password for configuration This action allows to put the instrument in a defined

parameters is equal to 30. condition (the same it was at the first power ON).

2. During parameter modification the instrument The default data are those typical values loaded in the

continue to perform the control. instrument prior to ship it from factory.

In certain conditions, when a configuration chan- To load the factory default parameter set, proceed as follows:

ge can produce a heavy bump to the process, it is 1. Press the button for more than 5 seconds. The upper

advisable to temporarily stop the controller from display will show PASS while the lower display shows 0;

controlling during the programming procedure

(control output will be OFF). 2. Using and buttons set the value -481;

A password equal to 2000 + the programmed 3. Push button;

value (e.g. 2000 + 30 = 2030). 4. The instrument will turn OFF all LEDs for a few seconds,

The control will restart automatically when the then the upper display will show dFLt (default) and then

configuration procedure will be manually closed. all LEDs are turned ON for 2 seconds. At this point the

Push the button instrument restarts as for a new power ON.

If the password is correct the display will show the acronym The procedure is complete.

].

of the first parameter group preceded by the symbol: Note: The complete list of the default parameters is available

In other words the upper display will show: ]inp

in Appendix A.

(group of the Input parameters). 5.7 CONFIGURING ALL THE PARAMETERS

The instrument is in configuration mode. In the following pages we will describe all the parameters of

the instrument. However, the instrument will only show the

5.4 HOW TO EXIT THE “CONFIGURATION parameters applicable to its hardware options in accordance

MODE” with the specific instrument configuration (i.e. setting AL1t

Push button for more than 3 seconds, the instrument will [Alarm 1 type] to nonE [not used], all parameters related to

come back to the “standard display”. alarm 1 will be skipped).

5.5 KEYBOARD FUNCTIONS DURING ]inP Group - Main and auxiliary input configuration

PARAMETER CHANGING [1] SEnS - Input type

A short press allows to exit from the current parameter Available: Always

group and select a new parameter group. Range: J = TC J

A long press allows you to close the configuration crAL = TC K

parameter procedure (the instrument will come back S = TC S

to the “standard display”). r = TC R

When the upper display is showing a group and the t = TC T

lower display is blank, this key allows to enter in the Pt1 = RTD Pt 100

selected group. Pt10 = RTD Pt 1000

When the upper display is showing a parameter and 0.60 = 0 to 60 mV linear

the lower display is showing its value, this key allows 12.60 = 12 to 60 mV linear

to store the selected value for the current parameter 0.20 = 0 to 20 mA linear

and access the next parameter within the same group. 4.20 = 4 to 20 mA linear

Allows to increase the value of the selected parameter. 0.5 = 0 to 5 V linear

Allows to decrease the value of the selected parameter. 1.5 = 1 to 5 V linear

+ These two keys allow to return to the previous 0.10 = 0 to 10 V linear

group. Proceed as follows: 2.10 = 2 to 10 V linear

Push the button and maintaining the pressure, Notes: 1. When a TC input is selected and a decimal figure

is programmed (see the next parameter) the max.

then push the button; release both the buttons.

displayed value becomes 999.9°C or 999.9°F.

Note: The group selection is cyclic as well as the selection

2. Every change of the SEnS parameter setting

of the parameters in a group.

will force the [2] dP = 0 and it will change all

parameters related with dP (e.g. set points,

proportional band, etc.).

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 8

[2] dP - Decimal point position [8] oPE - Safety output value

Available: Always. Available: Always.

Range: 0 to 3 when [1] SenS = Linear input; Range: -100 to 100 % (of the output).

0 or 1 when [1] SenS different from linear input. Notes: 1. When the instrument is programmed with one

Note: Every change of the dP parameter setting will produce control action only (heat or cool), setting a value

a change of the parameters related with it (e.g.: set outside of the available output range, the instrument

points, proportional band, etc.). will use Zero.

E.g.: When heat action only has been programmed,

[3] SSc - Initial scale read-out for linear inputs

and oPE is equal to -50% (cooling) the instrument

Available: When a linear input is selected by [1] SenS. will use Zero.

Range: -1999 to 9999.

2. When ON/OFF control is programmed and an out

Notes: 1. SSc allows the scaling of the analog input to set

of range is detected, the instrument will perform

the minimum displayed/measured value.

the safety output value using a fixed cycle time

The instrument will show a measured value up to

equal to 20 seconds.

5% less then SSc value and than it will show an

underrange error. [9] io4.F - I/O4 function selection

2. It is possible to set a initial scale read-out higher Available: Always.

then the full scale read-out in order to obtain a Range: on = Out4 will be ever ON (used as a transmitter

reverse read-out scaling. power supply);

E.g.: out4 = Used as digital output 4;

0 mA = 0 mBar and 20 mA = -1000 mBar (vacuum). dG2.c = Digital input 2 for contact closure;

dG2.U = Digital input 2 driven by 12 to 24 VDC.

[4] FSc - Full scale read-out for linear input

Notes: 1. Setting [9] io4.F = dG2.C or dG2U, the [25] O4F

Available: When a linear input is selected by [1] SenS. parameter becomes not visible while [11] diF2

Range: -1999 to 9999. parameter will become visible.

Notes: 1. Fsc allows the scaling of the analog input to set

2. Setting [9] io4F = on the [25] O4F parameter and

the maximum displayed/measured value.

the [11]diF2 parameter will NOT be visible.

The instrument will show a measured value up to

5% higher than [4] FSc value and then it will show 3. Setting [9] io4F different from dG2.c or dG2.U,

an overrange error. the instrument will force [13] diF2 parameter

equal to nonE. If [11] diF1 was equal to (SP4 or

2. It is possible to set a full scale read-out lower

UPDN) it will be forced to nonE.

than the initial scale read-out in order to obtain a

reverse read-out scaling. 4. The transfer from [9] io4F = ON to [9] io4F = Out4

E.g.: will make the [25] O4F parameter visible equal to

0 mA = 0 mBar and 20 mA = -1000 mBar (vacuum). nonE.

[5] unit - Engineering unit [10] diF1 - Digital input 1 function

Available: When a temperature sensor is selected by [1] Available: Always.

SenS parameter. Range: oFF = No function;

Range: °C = Celsius; 1 Alarm Reset [status];

°F = Fahrenheit. 2 Alarm acknowledge (ACK) [status];

3 Hold of the measured value [status]

[6] FiL - Digital filter on the measured value When the contact is closed the instrument ope-

Available: Always. rates in hold of the measured value;

Range: oFF (No filter); 4 Stand by mode of the instrument [status]

0.1 to 20.0 s. When the contact is closed the instrument oper-

Note: This is a first order digital filter applied on the ates in stand by mode;

measured value. For this reason it will affect the 5 Manual mode

measured value but also the control action and the When the contact is closed the instrument ope-

alarms behaviour. rates in manual mode;

6 HEAt with SP1 and CooL with “SP2” [status]

[7] inE - Selection of the Sensor Out of Range type

(see “Note about digital inputs”);

that will enable the safety output value 7 to 17 Reserved;

Available: Always. 18 Sequential set point selection [transition]

Range: our = When an overrange or an underrange is (see “Note about digital inputs”);

detected, the power output will be forced to 19 SP1/SP2 selection [status];

the value of [8] oPE parameter; 20 Binary selection of the set point made by digital

or = When an overrange is detected, the power input 1 (less significant bit) and digital input 2

output will be forced to the value of [8] oPE (most significant bit) [status];

parameter; 21 Digital input 1 will work in parallel with but-

ur = When an underrange is detected, the po- ton while digital input 2 will work in parallel with

wer output will be forced to the value of the button.

[8] oPE parameter. Note: When [11] diF2 is not available, items 20 and 21 are

not visible.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 9

[11] diF2 - Digital input 2 function 2 = DI1 Direct action,

Available: When [9] Io4.F = diG2. DI2 (if configured) Reverse action;

Range: oFF = No function; 3 = DI1 Reverse action,

1 Alarm Reset [status]; DI2 (if configured) Reverse action.

2 Alarm acknowledge (ACK) [status];

3 Hold of the measured value [status] ]out Group - Output parameters

When the contact is closed the instrument ope- 13] o1.t - Out 1 type

rates in hold of the measured value; Available: When the out 1 is a linear output.

4 Stand by mode of the instrument [status] Range: 0-20 0 to 20 mA;

When the contact is closed the instrument ope- 4-20 4 to 20 mA;

rates in stand by mode; 0-10 0 to 10 V;

5 Manual mode 2-10 2 to 10 V.

When the contact is closed the instrument ope-

[14] o1.F - Out 1 function

rates in manual mode;

Available: Always.

6 HEAt with SP1 and CooL with “SP2” [status]

Range: • When the out 1 is a linear output:

(see “Note about digital inputs”);

nonE = Output not used. With this setting the status

7 Timer Run/Hold/Reset [transition]

of this output can be driven directly from

Short closure allows to start timer execution

serial link;

and to suspend it while a long closure (longer

H.rEG = Heating output;

than 10 seconds) allows to reset the timer;

c.rEG = Cooling output;

7 to 17 Reserved;

r.inP = Measured value Analog retransmission.

18 Sequential set point selection [transition]

r.Err = Analog retransmission of the measured

(see “Note about digital inputs”);

error (PV-SP);

19 SP1/SP2 selection [status];

r.SP = Analog retransmission of the operative set

20 Binary selection of the set point made by digital

point;

input 1 (less significant bit) and digital input 2

r.SEr = Analog retransmission of a value coming

(most significant bit) [status];

from serial link;

21 Digital input 1 will work in parallel with the

• When the out 1 is a digital output (relay or SSR):

button while digital input 2 will work in parallel

nonE = Output not used. With this setting the status

with the button.

of this output can be driven directly from

Notes: 1. When [10] diF1 or [11] diF2 (e.g. diF1) are equal serial link;

to 6 the instrument operates as follows: H.rEG = Heating output;

• When the contact is open, the control action is an c.rEG = Cooling output;

heating action and the active set point is SP. AL = Alarm output;

• When the contact is closed, the control action is t.out = Reserved;

a cooling action and the active set point is SP2. t.HoF = Reserved;

2. When [10] diF1 = 20, [11] diF2 setting is forced to P.End = Reserved;

20 and diF2 cannot perform another function. P.HLd = Reserved;

3. When [10] diF1 = 20 and [11] diF2 = 20, the set P. uit = Reserved;

point selection will be in accordance with the P.run = Reserved;

following table: P.Et1 = Reserved;

Dig In1 Dig. In2 Operative set point P.Et2 = Reserved;

or.bo = Out-of-range or burn out indicator;

Off Off Set point 1

P.FAL = Power failure indicator;

On Off Set point 2 bo.PF = Out-of-range, Burnout and Power failure

Off On Set point 3 indicator;

On On Set point 4 St.By = Stand By status indicator;

diF1 = Repeats the digital input 1 status;

4. When [10] diF1 is equal to 21, [11] diF2 setting diF2 = Repeats the digital input 2 status;

is forced to up.du (21 value) and cannot perform on = Out1 always ON;

another function. riSP = Inspection request.

5. When a “Sequential set point selection” is used Notes: 1. When two or more outputs are programmed in the

(diF1 or diF2 = 18), every closure of of the logic same way, these outputs will be driven in parallel.

input increase the value of SPAT (active set point) 2. The power failure indicator will be reset when the

of one step. The selection is cyclic: instrument detect an alarm reset command by

SP -> SP2 -> SP3 -> SP4. key, digital input or serial link.

3. When no control output is programmed, all the

[12] di.A - Digital Inputs Action relative alarm (when present) will be forced to

Available: Always. nonE (not used).

Range: 0 = DI1 Direct action,

DI2 (if configured) Direct action;

1 = DI1 Reverse action,

DI2 (if configured) Direct action;

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 10

[15] A.o1L - Initial scale value of the analog bo.PF = Out-of-range, Burnout and Power failure

retransmission indicator;

Available: When Out 1 is a linear output and [14] O1F is St.By = Stand By status indicator;

equal to r.inp, r.Err, r.SP or r.SEr diF1 = Out2 repeates the digital input 1 status;

Range: -1999 to [16] Ao1H. diF2 = Out2 repeates the digital input 2 status;

on = Out 2 always ON;

[16] A.o1H - Full scale value of the analog riSP = Inspection request.For other details see

retransmission [14] O1F parameter.

Available: When Out 1 is a linear output and [14] O1F is [20] o2.AL - Alarms linked up with Out 2

equal to r.inp, r.Err, r.SP or r.SEr.

Available: When [18] o2F = AL.

Range: [15] Ao1L to 9999.

Range: 0 to 63 with the following rule:

[17] o1.AL - Alarms linked up with the out 1 +1 = Alarm 1;

Available: When [14] o1F = AL. +2 = Alarm 2;

Range: 0 to 63 with the following rules: +4 = Alarm 3;

+1 = Alarm 1; +8 = Loop break alarm;

+2 = Alarm 2; +16 = Sensor break (burn out);

+4 = Alarm 3; +32 = Overload on Out 4 (short circuit on OP4).

+8 = Loop break alarm; For more details see [17] o1.AL parameter.

+16 = Sensor break (burn out);

+32 = Overload on Out4 (short circuit on the Out4). [21] o2Ac - Out 2 action

Example 1: Setting 3 (2+1) the output will be driven by the Available: When [19] o2F is different from “nonE”.

alarm 1 and 2 (OR condition). Range: dir = Direct action;

rEU = Reverse action;

Example 2: Setting 13 (8+4+1) the output will be driven by

dir.r = Direct action with revers LED indication;

alarm 1 + alarm 3 + loop break alarm.

rEU.r = Reverse action with reverse LED indication.

[18] o1.Ac - Out 1 action For more details see [18] o1.Ac parameter.

Available: When [14] o1F is different from “nonE”. [22] o3F - Out 3 function

Range: dir = Direct action;

Available: When the instrument has out 3 option.

rEU = Reverse action;

Range: nonE = Output not used. With this setting the status

dir.r = Direct action with revers LED indication;

of the this output can be driven directly from

rEU.r = Reverse action with reverse LED indication.

serial link;

Notes: 1. Direct action: the output repeats the status of the

H.rEG = Heating output;

driven element.

c.rEG = Cooling output;

E.g.: The output is an alarm output with direct

AL = Alarm output;

action. When the alarm is ON, the relay will be

t.out = Reserved;

energized (logic output 1).

t.HoF = Reserved;

2. Reverse action: the output status is the opposite P.End = Reserved;

of the status of the driven element. P.HLd = Reserved;

E.g.: The output is an alarm output with reverse P. uit = Reserved;

action. When the alarm is OFF, the relay will be P.run = Reserved;

energized (logic output 1). This setting is usually P.Et1 = Reserved;

named “fail-safe” and it is generally used in P.Et2 = Reserved;

dangerous process in order to generate an alarm or.bo = Out-of-range or burn out indicator;

when the instrument power supply goes OFF or P.FAL = Power failure indicator;

the internal watchdog starts. bo.PF = Out-of-range, burn out and Power failure

[19] o2F - Out 2 function indicator;

Available: When the instrument has out 2 option. St.By = Stand By status indicator

Range: nonE = Output not used. With this setting the sta- diF1 = The output repeats the digital input 1 status;

tus of the this output can be driven directly diF2 = The output repeats the digital input 2 status;

from serial link; on = Out 3 always ON;

H.rEG = Heating output (see warning); riSP = Inspection request.

c.rEG = Cooling output; For other details see [14] O1F parameter.

AL = Alarm output; [23] o3.AL - Alarms linked up with Out 3

t.out = Reserved;

Available: When [21] o3F = AL.

t.HoF = Reserved;

Range: 0 to 63 with the following rule:

P.End = Reserved;

+1 = Alarm 1;

P.HLd = Reserved;

+2 = Alarm 2;

P. uit = Reserved;

+4 = Alarm 3;

P.run = Reserved;

+8 = Loop break alarm;

P.Et1 = Reserved;

+16 = Sensor break (burn out);

P.Et2 = Reserved;

+32 = Overload on Out 4 (short circuit on OP 4).

or.bo = Out-of-range or burn out indicator;

For more details see [17] o1.AL parameter.

P.FAL = Power failure indicator;

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 11

[24] o3Ac - Out 3 action LodE = Deviation low alarm (relative);

Available: when [21] o3F is different from “nonE”. HidE = Deviation high alarm (relative);

Range: dir = Direct action; LHdo = Relative band alarm with alarm indication

rEU = Reverse action; out of the band;

dir.r = Direct action with revers LED indication; LHdi = Relative band alarm with alarm indication

rEU.r = Reverse action with reverse LED indication. inside the band.

For more details see [18] o1.Ac parameter. • When no output is programmed as control output:

nonE = Alarm not used;

[25] o4F - Out 4 function LoAb = Absolute low alarm;

Available: When the [9] io4.F = Out4. HiAb = Absolute high alarm;

Range: nonE = Output not used. With this setting the status LHAo = Absolute band alarm with alarm indication

of the this output can be driven directly out of the band;

from serial link. LHAi = Absolute band alarm with alarm indication

H.rEG = Heating output; inside the band;

c.rEG = Cooling output; SE.br = Sensor break.

AL = Alarm output; Notes: 1. The relative and deviation alarms are “relative” to

t.out = Reserved; the operative set point value.

t.HoF = Reserved; PV PV

P.End = Reserved; AL1

HAL1

P.HLd = Reserved; HAL1

P. uit = Reserved; AL1

P.run = Reserved; OUT time OUT time

off ON off ON off off ON off ON off

P.Et1 = Reserved; AL1 AL1

P.Et2 = Reserved; LoAb HiAb

or.bo = Out-of-range or burn out indicator; PV PV

P.FAL = Power failure indicator; AL1H HAL1 AL1H HAL1

bo.PF = Out-of-range, burn out and Power failure SP

indicator; AL1L HAL1 -AL1L HAL1

St.By = Stand By status indicator.

OUT time time

For other details see [14] O1F parameter. AL1 off ON off ON off OUT off ON off ON off

AL1

[26] o4.AL - Alarms linked up with Out 4 LHAo LHdo

Available: When [25] o4F = AL. 2. The (SE.br) sensor break alarm will be ON when

Range: 0 to 63 with the following rule. the display shows ---- indication.

+1 = Alarm 1; [29] Ab1 - Alarm 1 function

+2 = Alarm 2;

Available: When [28] AL1t is different from “nonE”.

+4 = Alarm 3;

Range: 0 to 15 with the following rule:

+8 = loop break alarm;

+1 = Not active at power up;

+16 = Sensor break (burn out);

+2 = Latched alarm (manual reset);

+32 = overload on Out 4 (short circuit on OP4).

+4 = Acknowledgeable alarm;

For more details see [17] o1.AL parameter.

+8 = Relative alarm not active at set point change.

[27] o4Ac - Out 4 action Example: Setting Ab1 equal to 5 (1+4) the alarm 1 will be

Available: When [25] o4F is different from “nonE”. “not active at power up” and “Acknowledgeable”.

Range: dir = Direct action; Notes: 1. The “not active at power up” selection allows to

rEU = Reverse action; inhibit the alarm function at instrument power up

dir.r = Direct action with revers LED indication; or when the instrument detects a transfer from:

rEU.r = Reverse action with reverse LED indication. • Manual mode (oplo) to auto mode;

For more details see [18] o1.Ac parameter. • Stand-by mode to auto mode.

The alarm will be automatically enabled when

]AL1 Group - Alarm 1 parameters the measured value reaches, for the first time,

[28] AL1t - Alarm 1 type the alarm threshold ±hysteresis (in other words,

when the initial alarm condition disappears).

Available: Always.

Range: • When one or more outputs are programmed as PV

AL1

control output:

nonE = Alarm not used; time

LoAb = Absolute low alarm; Ab1 = +0 ON off ON off

HiAb = Absolute high alarm;

Ab1 = +1 off ON off

LHAo = Absolute band alarm with alarm indication

out of the band; PWR ON

LHAi = Absolute band alarm with alarm indication 2. A “Latched alarm” (manual reset) is an alarm

inside the band; that will remain active even if the conditions that

SE.br = Sensor break; generated the alarm no longer persist. Alarm

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 12

reset can be done only by an external command the Alarm threshold value and the point the Alarm

( button, digital inputs or serial link). automatically resets.

PV 2. When the alarm threshold plus or minus the

AL1

hysteresis is out of input range, the instrument

will not be able to reset the alarm.

time

Ab1 = +0 off ON off Example: Input range 0 to 1000 (mBar).

off ON off

––Set point equal to 900 (mBar);

Ab1 = +2

Alarm reset Alarm reset ––Deviation low alarm equal to 50 (mBar);

––Hysteresis equal to 160 (mBar) the theoretical reset point is

3. An “Acknowledgeable” alarm is an alarm that can

900 - 50 + 160 = 1010 (mBar) but this value is out of range.

be reset even if the conditions that generated the

The reset can be made only by turning the instrument

alarm are still present. Alarm acknowledge can

OFF, removing the condition that generate the alarm and

be done only by an external command ( button,

then turn the instrument ON again;

digital inputs or serial link).

––All band alarms use the same hysteresis value for both

PV

AL1

thresholds;

––When the hysteresis of a band alarm is bigger than the

time programmed band, the instrument will not be able to reset

Ab1 = +0 off ON off the alarm.

Ab1 = +4 off ON off ON off Example: Input range 0 to 500 (°C).

Alarm ACK Alarm ACK ––Set point equal to 250 (°C);

A “relative alarm not active at set point change” ––Relative band alarm;

is an alarm that masks the alarm condition after ––Low threshold equal to 10 (°C);

a set point change until process variable reaches ––High threshold equal to 10 (°C);

the alarm threshold ±hysteresis.

––Hysteresis equal to 25 (°C).

Sp2 PV

AL1 [34] AL1d - Alarm 1 delay

Sp1 Available: When [28] AL1t is different from “nonE”.

AL1

Range: From oFF (0) to 9999 seconds.

time

Ab1 = +0 ON off ON off ON off Note: The alarm goes ON only when the alarm condition

ON off ON off

persists for a time longer than [34] AL1d time but the

Ab1 = +8

reset is immediate.

4. The instrument does not store in EEPROM the [35] AL1o - Alarm 1 enabling during Stand-by mode

alarm status. For this reason, the alarm status and out of range indications

will be lost if a power down occurs.

Available: When [28] AL1t is different from “nonE”.

[30] AL1L - For High and low alarms it is the low Range: 0 = Never;

limit of the AL1 threshold 1 = During stand by;

- For band alarm it is low alarm threshold 2 = During overrange and underrange;

Available: When [28] AL1t is different from “nonE” or [28] 3 = During overrange, underrange and stand-by;

AL1t is different from “SE.br”.

Range: From -1999 to [31] AL1H engineering units. ]AL2 Group - Alarm 2 parameters

[31] AL1H - For High and low alarms, it is the high [36] AL2t - Alarm 2 type

limit of the AL1 threshold Available: Aways.

- For band alarm, it is the high alarm Range: • When one or more outputs are programmed as

threshold control output:

Available: When [28] AL1t is different from “nonE” or [28] nonE = Alarm not used;

AL1t is different from “SE.br”. LoAb = Absolute low alarm;

Range: From [30] AL1L to 9999 engineering units. HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication

[32] AL1- Alarm 1 threshold

out of the band;

Available: When: LHAi = Absolute band alarm with alarm indication

[28] AL1t = LoAb - Absolute low alarm; inside the band;

[28] AL1t = HiAb - Absolute high alarm; SE.br = Sensor break;

[28] AL1t = LodE - Deviation low alarm (relative); LodE = Deviation low alarm (relative);

[28] AL1t = LidE - Deviation high alarm (relative). HidE = Deviation high alarm (relative);

Range: From [30] AL1L to [31] AL1H engineering units. LHdo = Relative band alarm with alarm indication

[33] HAL1 - Alarm 1 hysteresis out of the band;

Available: When [28] AL1t is different from “nonE” or LHdi = Relative band alarm with alarm indication

[28] AL1t is different from “SE.br”. inside the band;

Range: 1 to 9999 engineering units. • When no output is programmed as control output:

Notes: 1. The hysteresis value is the difference between nonE = Alarm not used;

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 13

LoAb = Absolute low alarm; ]AL3 Group - Alarm 3 parameters

HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication

[44] AL3t - Alarm 3 type

out of the band; Available: Always.

LHAi = Absolute band alarm with alarm indication Range: • When one or more outputs are programmed as

inside the band; control output:

SE.br = Sensor break. nonE = Alarm not used;

Note: The relative alarm are “relative” to the current set point LoAb = Absolute low alarm;

(this may be different from the Target setpoint if you HiAb = Absolute high alarm;

are using the ramp to set point function). LHAo = Absolute band alarm with alarm indication

out of the band;

[37] Ab2 - Alarm 2 function LHAi = Absolute band alarm with alarm indication

Available: When [36] AL2t is different from “nonE”. inside the band;

Range: 0 to 15 with the following rule: SE.br = Sensor break;

+1 = Not active at power up; LodE = Deviation low alarm (relative);

+2 = Latched alarm (manual reset); HidE = Deviation high alarm (relative);

+4 = Acknowledgeable alarm; LHdo = Relative band alarm with alarm indication

+8 = Relative alarm not active at set point change. out of the band;

Example: Setting Ad2 equal to 5 (1+4) the alarm 2 will be LHdi = Relative band alarm with alarm indication

“not active at power up” and “Acknowledgeable”. inside the band.

Note: For other details see [28] Ab1 parameter. • When no output is programmed as control output:

nonE = Alarm not used;

[38] AL2L - For High and low alarms it is the low LoAb = Absolute low alarm;

limit of the AL2 threshold HiAb = Absolute high alarm;

- For band alarm it is low alarm threshold LHAo = Absolute band alarm with alarm indication

Available: When [36] AL2t is different from “nonE” or [36] out of the band;

AL2t is different from “SE.br”. LHAi = Absolute band alarm with alarm indication

Range: -1999 to [39] AL2H engineering units. inside the band;

[39] AL2H - For High and low alarms it is the high SE.br = Sensor break.

limit of the AL2 threshold Note: The relative alarm are “relative” to the current set point

(this may be different to the Target set point if you are

- For band alarm it is high alarm threshold

using the ramp to set point function).

Available: When [36] AL2t is different from “nonE” or

[36] AL2t is different from “SE.br”. [45] Ab3 - Alarm 3 function

Range: From [38] AL2L to 9999 engineering units. Available: When [43] AL3t is different from “nonE”.

[40] AL2 - Alarm 2 threshold Range: 0 to 15 with the following rule:

Available: When: +1 = Not active at power up;

[36] AL2t = LoAb Absolute low alarm; +2 = Latched alarm (manual reset);

[36] AL2t = HiAb Absolute high alarm; +4 = Acknowledgeable alarm;

[36] AL2t = LodE Deviation low alarm (relative); +8 = Relative alarm not active at set point change.

[36] AL2t = LidE Deviation high alarm (relative). Example: Setting Ad3 equal to 5 (1+4) the alarm 3 will be

Range: From [38] AL2L to [39] AL2H engineering units. “not active at power up” and “Acknowledgeable”.

[41] HAL2 - Alarm 2 hysteresis Note: For other details see [29] Ab1 parameter.

Available: When [36] AL2t is different to “nonE” or [36] AL2t [46] AL3L - For High and low alarms it is the low

is different from “SE.br”. limit of the AL3 threshold

Range: 1 to 9999 engineering units. - For band alarm, it is low alarm threshold

Note: For other details see [33] HAL1 parameter. Available: When [44] AL3t is different from “nonE” or [44]

[42] AL2d - Alarm 2 delay AL3t is different from “SE.br”.

Available: When [36] AL2t different form “nonE”. Range: -1999 to [47] AL3H engineering units.

Range: From oFF (0) to 9999 seconds. [47] AL3H - For High and low alarms it is the high

Note: The alarm goes ON only when the alarm condition limit of the AL3 threshold

persist for a time longer than [42] AL2d time but the - For band alarm it is high alarm threshold

reset is immediate. Available: When [44] AL3t is different from “nonE” or [44]

[43] AL2o - Alarm 2 enabling during Stand-by mode AL3t is different from “SE.br”.

Range: From [46] AL3L to 9999 engineering units.

and out of range indications

Available: When [36] AL2t different from “nonE”. [48] AL3 - Alarm 3 threshold

Range: 0 = Never; Available: When:

1 = During stand by; • [44] AL3t = LoAb Absolute low alarm;

2 = During overrange and underrange; • [44] AL3t = HiAb Absolute high alarm;

3 = During overrange, underrange and stand-by. • [44] AL3t = LodE Deviation low alarm (relative);

• [44] AL3t = LidE Deviation high alarm (relative).

Range: From [46] AL3L to [47] AL3H engineering units.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 14

[49] HAL3 - Alarm 3 hysteresis [55] LbcA - Condition for LBA enabling

Available: When [44] AL3t is different to “nonE” or [44] AL3t Available: when [52] LbAt is different from oFF.

is different from “SE.br”. Range: uP = Enabled when the PID requires the maxi-

Range: 1 to 9999 engineering units. mum power only;

Note: For other details see [33] HAL1 parameter. dn = Enabled when the PID requires the mini-

mum power only;

[50] AL3d - Alarm 3 delay both = Enabled in both condition (when the PID re-

Available: When [44] AL3t different form “nonE”. quires the maximum or the minimum power).

Range: From oFF (0) to 9999 seconds. LBA application example:

Note: The alarm goes ON only when the alarm condition LbAt (LBA time) = 120 seconds (2 minutes);

persist for a time longer than [50] AL3d time but the LbAS (delta LBA) = 5°C.

reset is immediate.

The machine has been designed in order to reach 200°C in

[51] AL3o - Alarm 3 enabling during Stand-by mode 20 minutes (20°C/min);

and out of range indications When the PID demands 100% power, the instrument starts

Available: When [44] AL3t is different from “nonE” or the time count.

[44] AL3t is different from “SE.br”. During time count if the measured value increases more

Range: 0 = Never; than 5°C, the instrument restarts the time count. Otherwise

1 = During stand by; if the measured value does not reach the programmed delta

2 = During overrange and underrange; (5°C in 2 minutes) the instrument will generate the alarm.

3 = During overrange, underrange and stand-by.

]rEG group - Control parameters

] LbA group - Loop break alarm

The rEG group will be available only when at least one

General note about LBA alarm output is programmed as control output (H.rEG or C.rEG).

The LBA operate as follows: applying the 100% of the power

[56] cont - Control type:

output to a process, the process variable, after a time due to the

process inertia, begins to change in a known direction (increases Available: When at least one output is programmed as con-

for an heating action or decreases for a cooling action). trol output (H.rEG or C.rEG).

Range: • When two control action (heat & cool) are pro-

Example: If I apply 100% of the power output to a furnace, grammed:

the temperature must go up unless one of the component in Pid = PID (heat and cool);

the loop is faulty (heater, sensor, power supply, fuse, etc.) nr = Heat/Cool ON/OFF control with neutral zone.

The same philosophy can be applied to the minimum power.

PV

In our example, when I turn OFF the power to a furnace, the HSEt

SP

temperature must go down, if not the SSR is in short circuit, HSEt

the valve is jammed, etc..

LBA function is automatically enabled when the PID requires OUTH.rEG time

the maximum or the minimum power. (heating) ON off ON

OUTc.rEG

When the process response is slower than the programmed (cooling)

off ON off

limit the instrument generates an alarm.

• When one control action (heat or cool) is programmed:

Notes: 1. When the instrument is in manual mode, the LBA Pid = PID (heat or cool);

function is disabled. On.FA = ON/OFF asymmetric hysteresis;

2. When LBA alarm is ON the instrument continues On.FS = ON/OFF symmetric hysteresis;

to perform the standard control. If the process

PV PV

response comes back into the programmed limit, SP

the instrument automatically resets the LBA alarm. HSEt

SP

HSEt

3. This function is available only when the programmed time time

control algorithm is equal to PID (Cont = PID). OUT OUT

ON off ON off ON ON off ON off ON

H.rEG C.rEG

[52] LbAt - LBA time HEAt - On.FA C oo L - O n .FA

Available: When [56] Cont = PID.

Range: oFF = LBA not used; PV

HSEt PV

SP

1 to 9999 seconds. HSEt SP HSEt

HSEt

[53] LbSt - Delta measure used by LBA during time time

Soft start OUT

off

OUT

ON ON off ON ON off ON off ON

Available: When [52] LbAt is different from oFF. H.rEG H.rEG

HEAt - On.FS C oo L - O n .FS

Range: oFF = loop break alarm is inhibit during soft start;

1 to 9999 engineering units. Notes: 1. ON/OFF control with asymmetric hysteresis:

• OFF when PV > SP;

[54] LbAS - Delta measure used by loop break • ON when PV < (SP - hysteresis).

alarm (loop break alarm step)

2. ON/OFF control with symmetric hysteresis:

Available: When [52] LbAt is different from oFF. • OFF when PV > (SP + hysteresis);

Range: 1 to 9999 engineering units. • ON when PV < (SP - hysteresis).

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 15

[57] Auto - Auto tune selection [60] HSEt - Hysteresis of the ON/OFF control

There are three auto-tune algorithms: Available: When [56] cont is different from PID.

• Oscillating auto-tune; Range: 0 to 9999 engineering units.

• Fast auto-tune; [61] cPdt - Time for compressor protection

• EvoTune. Available: When [56] cont = nr.

Range: OFF = Protection disabled

1. The oscillating auto-tune is the usual auto-tune and:

1 to 9999 seconds.

• It is more accurate;

• Can start even if PV is close to the set point; [62] Pb - Proportional band

• Can be used even if the set point is close to the Available: When [56] cont = PID and [59] SELF = no.

ambient temperature. Range: 1 to 9999 engineering units.

2. The fast type is suitable when: Note: Auto-tune functions calculate this value.

• The process is very slow and you want to be opera- [63] ti - Integral time

tive in a short time; Available: When [56] cont = PID and [59] SELF = no.

• When an overshoot is not acceptable; Range: • OFF = Integral action excluded;

• In multi loop machinery where the fast method reduces • 1 to 9999 seconds;

the calculation error due to the effect of the other loops. • inF= Integral action excluded.

3. The EvoTune type is suitable when: Note: Auto-tune functions calculate this value.

• You have no information about your process;

• You can not be sure about the end user skills; [64] td - Derivative time

• You desire an auto tune calculation independently Available: When [56] cont = PID and [59] SELF = no.

from the starting conditions (e.g. set point change Range: • oFF - derivative action excluded;

during tune execution, etc). • 1 to 9999 seconds.

Note: Fast auto-tune can start only when the measured Note: Auto-tune functions calculate this value.

value (PV) is lower than (SP + 1/2 SP). [65] Fuoc - Fuzzy overshoot control

Available: When [56] cont = PID

This parameter reduces the overshoot usually present at

Range: -4 to 8 where:

instrument start up or after a set point change and it will be

-4 = Oscillating auto-tune with automatic restart

active only in this two cases.

at all set point change;

-3 = Oscillating auto-tune with manual start; Setting a value between 0.00 and 1.00 it is possible to slow

-2 = Oscillating auto-tune with automatic start at down the instrument action during set point approach.

the first power up only; Setting Fuoc = 1 this function is disabled.

-1 = Oscillating auto-tune with automatic restart PV 2

at every power up; SP

1

0 = Not used;

1 = Fast auto tuning with automatic restart at 3

every power up;

2 = Fast auto-tune with automatic start at the time

first power up only;

3 = FAST auto-tune with manual start; Available: When [56] cont = PID and [59] SELF = no.

4 = FAST auto-tune with automatic restart at all Range: 0 to 2.00.

set point change. Note: Fast auto-tune calculates the Fuoc parameter while

5 = EvoTune with automatic restart at every the oscillating one sets it equal to 0.5.

power up; [66] tcH - Cycle time of the heating output

6 = EvoTune with automatic start at the first

Available: When at least one output is programmed in order

power up only;

to be the heating output (H.rEG),

7 = EvoTune with manual start;

[56] cont = PID and [59] SELF = no.

8 = EvoTune with automatic restart at all set

Range: 1.0 to 130.0 seconds.

point change.

[58] Aut.r - Manual start of the auto-tune [67] rcG - Power ratio between heating and

cooling action (relative cooling gain)

Available: When [56] cont = PID.

Range: oFF = The instrument is not performing the auto-tune; The instrument uses the same PID parameter set for heat

on = The instrument is performing the auto-tune. and for cool action but the efficiency of the two actions are

usually different.

[59] SELF - Self-tune enable

This parameter allows to define the ratio between the efficiency

The self-tuning is an adaptive algorithm able to optimize of the heating system and the efficiency of the cooling one.

continuously the PID parameter value.

An example will help us to explain you the philosophy.

This algorithm is specifically designed for all process subjected to

big load variation able to change heavily the process response. Consider one loop of a plastic extruder. The working

temperature is equal to 250°C.

Available: When [56] cont = PID .

Range: YES = self-tune active; When you want to increase the temperature from 250 to 270°C

no = self-tune not active. (DT = 20°C) using 100% of the heating power (resistor), you

will need 60 seconds.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 16

On the contrary, when you want to decrease the temperature [74] SSt - Soft start time

from 250 to 230°C (DT = 20°C) using 100% of the cooling Available: When at least one output is programmed as

power (fan), you will need 20 seconds only. control output.

In our example the ratio is equal to 60/20 = 3 ([67] rcG = 3) Range: oFF = Function not used;

and it say that the efficiency of the cooling system is 3 time 0.01 to 7.59 hh.mm;

more efficient of the heating one. inF = Soft start always active.

Available: When two control action are programmed

[75] SS.tH - Threshold for soft start disabling

(H.rEG and c.rEG) and [56] cont = PID and

[59] SELF = no. Available: When at least one output is programmed as

Range: 0.01 to 99.99. control output.

Range: -1999 to 9999 engineering units.

Note: auto-tune functions calculate this value.

Notes: 1. When the power limiter have a positive value (the

[68] tcc - Cycle time of the cooling output limit is applied to the heating action) the soft start

Available: When at least one output is programmed in order function will be aborted when the measured value

to be the cooling output (c.rEG), [56] cont = PID is greater or equal to SS.tH parameter.

and [59] SELF = no. 2. When the power limiter have a negative value

Range: 1.0 to 130.0 seconds. (the limit is applied to the cooling action) the soft

[69] rS - Manual reset (integral pre-load) start function will be aborted when the measured

It allows to drastically reduce the undershoot due to a value is lower or equal to SS.tH parameter.

hot restart. When your process is steady, the instrument

operates with a steady power output (e.g.: 30%).

]SP Group - Set point parameters

If a short power down occurs, the process restarts with a The SP group will be available only when at least one output

process variable close to the set point while the instrument is programmed as control output (H.rEG or C.rEG).

starts with an integral action equal to zero. [76] nSP - Number of used set points

Setting a manual reset equal to the average power output (in our Available: When at least one output is programmed as

example 30%) the instrument will start with a power output equal control output.

to the value it will use at steady state (instead of zero) and the Range: 1 to 4.

undershoot will become very little (in theory equal to zero).

Note: When you change the value of this parameter, the

Available: When [56] cont = PID.

instrument operates as follows:

Range: -100.0 to +100.0%.

• [83] A.SP parameter will be forced to SP.

[72] od - Delay at power up • The instrument verifies that all used set point are

Available: When at least one output is programmed as within the limits programmed by [77] SPLL and [78]

control output. SPHL. If an SP is out of this range, the instrument

Range: oFF: Function not used; forces it to the maximum acceptable value

0.01 to 99.59 hh.mm.

[77] SPLL - Minimum set point value

Notes: 1. This parameter defines the time during which

(after a power up) the instrument remains in stand Available: When at least one output is programmed as

by mode before to start all other function (control, control output.

alarms, program, etc.). Range: From -1999 to [78] SPHL engineering units.

2. When a program with automatic start at power up Notes: 1. When you change the [77] SPLL value, the

and od function are programmed, the instrument instrument checks all local set points (SP, SP2,

performs od function before to start the program. SP3 and SP4 parameters) and all set points of the

program ([97] Pr.S1, [102] Pr.S2, [107] Pr.S3, [112]

3. When an auto-tune with automatic start at power

Pr.S4 parameters). If an SP is out of this range, the

up and od function are programmed, the autotune

instrument forces it to the maximum acceptable value

will start at the end of od delay.

2. A [77] SPLL change produces the following actions:

[73] St.P - Maximum power output used during • When [84] SP.rt = SP the remote set point will

soft start be forced to be equal to the active set point

Available: When at least one output is programmed as • When [84] SP.rt = trim the remote set point will

control output. be forced to zero

Range: -100 to +100%. • When [84] SP.rt = PErc the remote set point

Notes: 1. When St.P parameter have a positive value, the will be forced to zero

limit will be applied to the heating output(s) only.

[78] SPHL - Maximum set point value

2. When St.P parameter have a negative value, the

Available: When at least one output is programmed as

limit will be applied to the cooling output(s) only.

control output.

3. When a program with automatic start at power

Range: From [78] SPLL to 9999 engineering units.

up and soft start function are programmed, the

instrument performs the soft start and than the Note: For other details see [78] SPLL parameter.

program function. [79] SP - Set Point 1

4. The auto-tune function will be performed after Available: When at least one output is programmed as

soft start function. control output.

5. The Soft start function is available also when ON/ Range: From [77] SPLL to [78] SPHL engineering units.

OFF contro l is used.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 17

[80] SP 2 - Set Point 2 The first zone is the master zone and it uses a set point

Available: When at least one output is programmed as con- equal to 210°C.

trol output and [76] nSP > 2. The second zone has a local set point equal to -45°C.

Range: From [77] SPLL to [78] SPHL engineering units. The third zone has a local set point equal to -45 (°C).

[81] SP 3 - Set Point 3 The fourth zone has a local set point equal to -30.

Available: When at least one output is programmed as con- The fifth zone has a local set point equal to +40.

trol output and [76] nSP > 3.

The sixth zone has a local set point equal to +50.

Range: From [77] SPLL to [78] SPHL engineering units.

In this way, the thermal profile will be the following:

[82] SP 4 - Set Point 4

––Master SP = 210°C;

Available: When at least one output is programmed as con-

trol output and [76] nSP =4. ––Second zone SP = 210 -45 = 165°C;

Range: From [77] SPLL to [78] SPHL engineering units. ––Third zone SP = 210 -45 = 165°C;

[83] A.SP - Selection of the active Set point ––Fourth zone SP = 210 - 30 = 180°C;

Available: When at least one output is programmed as ––Fifth zone SP = 210 + 40 = 250°C;

control output. ––Sixth zone SP = 210 + 50 = 260°C.

Range: From “SP” to [76] nSP. Changing the SP of the master unit, all the other slave units

Notes: 1. A [83] A.SP change produces the following actions: will immediately change their operative set point.

• When [84] SP.rt = SP - the remote set point will

be forced to be equal to the active set point;

[85] SPLr - Local/remote set point selection

• When [84] SP.rt = trin - the remote set point will Available: When at least one output is programmed as

be forced to zero; control output.

• When [84] SP.rt = PErc - the remote set point Range: Loc = Local set point selected by [83] A.SP;

will be forced to zero. rEn = Remote set point (coming from serial link).

2. SP2, SP3 and SP4 selection will be shown [86] SP.u - Rate of rise for positive set point

only when the relative set point is enabled (see change (ramp up)

[76] nSP parameter). Available: When at least one output is e programmed as

[84] SP.rt - Remote set point type control output.

These instruments will communicate with each other, using Range: • 0.01 to 99.99 units per minute;

RS 485 serial interface without a PC. An instrument can be • inF = ramp disabled (step transfer).

set as a Master while the other are (as usual) Slave units. The [87] SP.d - Rate of rise for negative set point

Master unit can send his operative set point to the slave units. change (ramp down)

In this way, for example, is possible to change simultaneously Available: When at least one output is e programmed as

the set point of 20 instruments by changing the set point of the control output.

master unit (e.g. hot runner application). Range: 0.01 to 99.99 units per minute;

SP.rt parameter defines how the slaves units will use the value inF = ramp disabled (step transfer).

coming from serial link. General note about remote set point: when the remote set

[133] tr.SP parameter [selection of the value to be retransmitted point (RSP) with trim action is programmed, the local set

(Master)] allows to define the value sent by master unit. point range becomes the following:

Available: When at least one output is e programmed as from [77] SPLL+ RSP to [78] SPHL - RSP

control output and the serial interface is present.

Range: rSP = The value coming from serial link is used ]PAn group - Operator HMI

as remote set point (RSP); [118] PAS2 - Level 2 password: Limited access level

trin = The value coming from serial link will be

Available: Always.

algebraically added to the local set point

Range: oFF = Level 2 not protected by password

selected by A.SP and the sum becomes

(as level 1 = Operator level);

the operative set point;

1 to 200.

PErc = The value coming from serial will be scaled

on the input range and this value will be [119] PAS3 - Level 3 password:

used as remote set point. Complete configuration level

Note: A [84] SPrt change produces the following actions: Available: Always.

• When [84] SP.rt = rSP - the remote set point will be Range: 3 to 200.

forced to be equal to the active set point; Note: Setting [118] PAS2 equal to [119] PAS3, the level 2

• When [84] SP.rt = trin - the remote set point will will be masked.

be forced to zero;

[120] PAS4 - Level 4 password:

• When [84] SP.rt = PErc - the remote set point will

be forced to zero.

CODE configuration level

Example: A 6 zone reflow-oven for PCB. Available: Always.

The master unit sends its set point value to 5 other zones Range: 201 to 400.

(slave controllers).

The Slave zones use it as a set point trim.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 18

[121] uSrb - button function during RUN TIME [125] diS.t - Display time out

Available: Always. Available: Always.

Range: nonE = No function; Range: oFF = The display is ever ON;

tunE = Auto-tune/self-tune enabling. A single 0.1 to 99.59 minutes and seconds.

press (longer than 1) starts the auto-tune; Note: This function allows to turn OFF the display when no

oPLo = Manual mode. The first pressure puts the alarm is present and no action is made on the instrument.

instrument in manual mode (OPLO) while a When diS.t is different from OFF and no button is

second one puts the instrument in Auto mode; pressed for more than the programmed time out, the

AAc = Alarm reset; display goes OFF and only 4 segments of the less

ASi = Alarm acknowledge; significant digit are turned ON in sequence in order to

chSP = Sequential set point selection (note); show that the instrument is working correctly.

St.by = Stand by mode. The first press puts the in- If an alarm occures or a buton is pressed, the display

strument in stand by mode while a second will come back to the normal operation.

one puts the instrument in Auto mode;

[126] FiLd - Filter on the displayed value

Str.t = Reserved;

P.run = Reserved; Available: Always.

P.rES = Reserved; Range: oFF = Filter disabled;

P.r.H.r = Reserved. From 0.0 (oFF) to 20.0 engineering units.

Notes: 1. When “Sequential set point selection” is used, Note: This is a “window filter” related to the set point; it is

every press of the button (longer than 1 applied to the displayed value only and it have no

second) increase the value of A.SP (active set effect on the other functions of the instrument (control,

point) of one step. alarms, etc.).

The selection is cyclic: SP -> SP2 -> SP3 -> SP4 [128] dSPu - Status of the instrument at power up

When a new set point is selected using the Available: Always.

key, the display will show for 2 seconds the Range: AS.Pr = Starts in the same way it was prior to the

acronym of the new set point (e.g. SP2). power down;

2. When “Sequential set point selection” is used, the Auto = Starts in Auto mode;

number of set points selectable is limited by [74] nSP. oP.0 = Starts in manual mode with a power output

equal to zero.

[122] diSP - Display management St.bY = Starts in stand-by mode

Available: Always. Notes: 1. When you change the value of [129] oPr.E, the

Range: nonE = Standard display; instrument forces [130] oPEr parameter to Auto.

Pou = Power output;

2. If the “[128] dSPu” parameter is different from

SPF = Final set point;

“AS.Pr” the memorization function is inhibited.

SPo = Operative set point;

AL1 = Alarm 1 threshold; [129] oPr.E - Operative modes enabling

AL2 = Alarm 2 threshold; Available: Always.

AL3 = Alarm 3 threshold;; Range: ALL = All modes will be selectable by the next

Pr.tu = Reserved; parameter;

Pr.td = Reserved; Au.oP = Auto and manual (OPLO) mode only will be

P.t.tu = Reserved; selectable by the next parameter;

P.t.td = Reserved; Au.Sb = Auto and Stand-by modes only will be se-

ti.uP = Reserved; lectable by the next parameter.

ti.du = Reserved; Note: When you change the value of [129] oPr.E, the

PErc = Percent of the power output used during soft instrument forces [130] oPEr parameter equal to Auto.

start (when the soft start time is equal to

infinite, the limit is ever active and it can be [130] oPEr - Operative mode selection

used also when ON/OFF control is selected); Available: Always.

PoS = Reserved. Range: • When [129] oPr.E = ALL:

[123] di.CL - Display colour Auto = Auto mode;

oPLo = Manual mode;

Available: Always.

St.bY = Stand by mod.e

Range: 0 = The display colour is used to show the

• When [129] oPr.E = Au.oP:

actual deviation (PV - SP);

Auto = Auto mode;

1 = Display red (fix);

oPLo = Manual mode.

2 = Display green (fix);

• When [129] oPr.E = Au.Sb:

3 = Display orange (fix).

Auto = Auto mode;

[124] AdE - Deviation for display colour management St.bY = Stand by mode.

Available: When [123] di.CL = 0. ]Ser group - Serial link parameter

Range: 1 to 9999 engineering units.

[131] Add - Instrument address

Available: Always.

Range: oFF = Serial interface not used;

1 to 254.

Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 19

[132] bAud - Baud rate reset causes the controller to exit the stand-by

Available: When [131] Add different from oFF. status returning to the control status.

Range: 1200 = 1200 baud; [135] UoLt - Nominal Voltage of the load

2400 = 2400 baud; Available: When [134] Co.tY = ist or

9600 = 9600 baud; [134] Co.tY = h or

19.2 = 19200 baud; [134] Co.tY = S.S.

38.4 = 38400 baud. Range: 1 to 9999 (V).

[133] trSP - Selection of the value to be [136] cur - Nominal current of the load

retransmitted (Master) Available: When [134] Co.tY = ist or

Available: When [131] Add different from oFF. [134] Co.tY = h or

Range: nonE = Retransmission not used (the instrument is [134] Co.tY = S.S.

a slave); Range: 1 to 999 (A).

rSP = The instrument become a Master and it

[137] h.Job - Threshold of the working period

retransmits the operative set point;

PErc = The instrument become a Master and it Available: When [134] Co.tY = tot.d or

retransmits the power output. [134] Co.tY = tot.H.

Range: oFF = Threshold not used

Note: For more details see [84] SP.rt (Remote set point type)

1 to 9999 days when [134] Co.tY = 4;

parameter.

1 to 9999 hours when [134] Co.tY = 5.

]COn Group - Consumption parameters [138] t.Job - Worked time (not resettable)

[134] Co.tY - Count type Available: Always.

Available: Always. Range: 1 to 9999 days.

Range: oFF Not used;

1 Instantaneous power (kW);

]CAL group - User calibration group

2 Consumed energy (kWh); This function allows to calibrate the complete measuring

3 Reserved; chain and to compensate the errors due to:

4 Total worked days: number of hours the instru- ––Sensor location;

ment is turned ON divided by 24; ––Sensor class (sensor errors);

5 Total worked hours: number of hours that the ––Instrument accuracy.

instrument is turned ON; [139] A.L.P - Adjust Low Point

6 Total worked days with threshold: number of Available: Always.

hours the instrument is turned ON divided by 24, Range: -1999 to (AH.P - 10) engineering units.

the controller is forced in stand-by when Co.ty