Professional Documents

Culture Documents

(Class A Refer To CD # 5255600-2EN Direction # 5255600-8EN) (Class M Refer To CD # 5255608-2EN Direction # 5255608-8EN)

Uploaded by

40818248Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Class A Refer To CD # 5255600-2EN Direction # 5255600-8EN) (Class M Refer To CD # 5255608-2EN Direction # 5255608-8EN)

Uploaded by

40818248Copyright:

Available Formats

DEFINIUMTM 6000 PM Report

( Class A refer to CD # 5255600-2EN Direction # 5255600-8EN )

( Class M refer to CD # 5255608-2EN Direction # 5255608-8EN )

Site Name: System # do check

Installation Date:

F.E. Name: First PM Date: cancel check

Note : After filling, this PM report shall be inserted in the system Logbook on site, use a new PM paper report each year

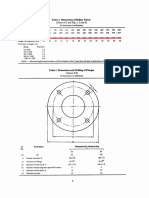

Time 1 2 3 4 5 6 7 8 9 10

Assembly Sub-assembly Frequency

(H ) Year Year Year Year Year Year Year Year Year Year

Replace counterpoise assembly (5140003)

To be replace 10 years 8

and main reel (5140035)

To be replace Replace main cable (5140082) 5 years 4

Replace Safety Reel (5139998) and Cable

To be replace 4 years 4

(5140052)

Check for wear of wall stand left and right

counterweight pulley belt (5149728,

To be replace 10 years 0.5

5159573) due to the weight of the

counterweight and carriage lay on the belt.

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

System General System Checks

mR/mAs 13 months 0.1

Beam Quality 13 months 0.1

Collimator Alignment 13 months 0.1

AEC Dose (procedure in DIRECTION

13 months 0.2

5135616-800 )

Evaluate Image Quality 13 months 0.3

Check Protective Circuits 13 months 0.1

Review Previous Performance 13 months 0.5

a) Check that the system can be manually

moved smoothly in all directions. Verify the

full range of motion. Pay close attention to 2 years 0.25

any high moving efforts, noises and

vibrations.

b) Check for any motions where interference

2 years 0.25

are now present (i.e., rubbing of cables...).

Logbook Rev1 Page 1 of 7

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

OTS Stationary Rails

13 months,

a) Check the rail mounting bolts and shims

then every 2

for tightness.

years

b) Check the longitudinal and lateral level of

2 years

the rails, level if necessary.

c) Verify that the wear strip is bonded to

stationary rail and is in center of rail groove. 2 years

Re-bond wear strip, if necessary.

d) Clean stationary rails and wear strips with

13 months,

general purpose cleaner and check for wear.

then every 2 1.5

Apply a light coating of SAE 30 lubricating oil

years

to wear strips.

e) Check condition of lock strips to be sure

they are straight and tight against stationary

rails. Clean the lock strips with general 13 months

purpose cleaner. Clean faces of locks but do

not use solvent.

OTS BRIDGE

a) Check tightness of end cap bolts. 2 years

b) Check fastening of lock strip to bridge. 2 years

c) Check bumpers for alignment condition. 2 years

d) Clean the bridge wheels and guide

bearings that ride on stationary rails. Do this

2 years

in conjunction Stationary Rails step 1d

above. 1

e) Clean the bridge dolly wheels and guide

13 months

bearings.

f) Clean the bridge rails and wear strips.

Apply a light coating of SAE 30 lubricating oil 13 months

to wear strips.

g) Clean lock strip with general purpose

cleaner. Clean faces of locks with general 13 months

purpose cleaner.

OTS CARRIAGE

a) Check tightness of 6 socket head bolts

2 years

fastening the carriage to axles.

b) Check tightness of telescoping column 1

2 years

mounting bolts.

c) Check tightness of 4 counterpoise

2 years

assembly mounting bolts.

OTS TELESCOPING COLUMN ASSEMBLY

a) Check that the vertical travel is smooth

and approximately 1500 mm +/- 10 mm 13 months

when the vertical lock is off.

b) Check for excessive lateral play with all

13 months 0.5

the locks on.

c) Check whether there's rust in the column,

especially the rail in the column. If have,

clean it up. 13 months

Note: Ensure that there's no rust on the rail

in the column

d) Check whether J Rod is broken. 2 years 1

e) Check whether the main cable needs

2 years

lubricated. If need, lubricate the main cable.

Logbook Rev1 Page 2 of 7

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

OTS COUNTERPOISE ASSEMBLY

a) Check for wear of the counterpoise cam Check it 13

due to cable pressure on the counterpoise months after

cam. Check the alignment of the installation,

REPLACE

counterpoise assembly to the main idler reel. and then 0.5

TO BE

With the tube at 1 m SID the cable should be every 2

(2)

directly in line between the cam and the idler years

reel. Adjust by loosening the four thereafter.

counterpoise frame bolts about 1 turn and (Replace

shifting the assembly so the cable lines up. every 10

Retighten the four bolts. years)

Check &

b) Move tube from full up to full down

REPLACE

REPLACE

clean every 0.5

position and check main cable wear using

TO BE

TO BE

year.

clean rag. If cable is kinked, worn, or has (2)

(Replace

broken strands, replace the cable. Clean the

cable every

cable with a clean rag.

5 years)

Check &

REPLACE

REPLACE

c) Check safety cable wear using clean rag. clean every 0.5

TO BE

TO BE

If cable is kinked, worn, or has broken year.

(2)

strands, replace the cable. Clean the cable (Replace

with a clean rag. cable every

4 years)

OTS Lateral, Longitudinal, Vertical, Rotational and Angular Drives

a) Check belt tension and alignment. 2 years

b) Remove bottom cover on tube support

and check 4 bolts inside tube support for 13 months 1

tightness. Replace cover.

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

WS General System Checks

a) Check that the system can be manually

moved smoothly in all directions. Verify the

full range of motion. Pay close attention to 2 years 0.25

any high moving efforts, noises and

vibrations.

b) Check for any motions where interference

2 years 0.25

are now present (i.e., rubbing of cables...).

WS Left/Right Counterweight Pulley Belt

Check it

REPLACE

Check for wear of wall stand left and right

every year

TO BE

counterweight pulley belt (5149728,

(replace 0.5

5159573) due to the weight of the

every 10

counterweight and carriage lay on the belt.

years)

Check whether wall stand floor anchors are

2 years 0.25

loose.

Check whether detector fan works 3 months 0.25

Logbook Rev1 Page 3 of 7

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

Table General System Checks

Visual inspection – Check for debris that

13 months 0.2

would indicate abnormal wear

Electrical cables – Check condition and

13 months 0.5

connections

Confirm that table power is removed when

the emergency button is pressed and power

13 months 0.1

is restored when the button is

twisted/released

Table Control pedals

Confirm that up/down pedals move freely

13 months

and cause proper movement of table.

Clean the dust around switch bar on down

pedals and confirm that the switch bar 13 months

0.3

causes proper protection for toe pinch.

Confirm that lock/unlock pedals allow table

top to move freely when depressed and lock 13 months

table top when released

Table Protective sensors:

Confirm that the 2 infrared sensor pairs

13 months

beneath table top are functioned properly.

Confirm that the 4 triggers inside table top

rails are functioned properly. Table top

13 months

moving will be stopped immediately when 0.2

the trigger is depressed.

Confirm that the 2 protective wings on TRAD

housing are functioned properly. Housing

13 months

moving will be stopped immediately when

the wing is touched

Table Inhibition buttons:

Confirm that all control pedals do not

function when the inhibit light is ON and do 13 months

function when the inhibit light is OFF.

Confirm that while keeping this button

depressed, toe pinch protection shall be 13 months

0.2

disabled until the button is released.

Confirm that while keeping this button

depressed, all finger pinch protections shall 13 months

be disabled until the button is released

Table Detector and Grid sensors

Confirm that the DETECTOR IN sensor is

ON when TRAD is inserted entirely, and is 13 months

OFF when TRAD is drawn out.

Confirm that both GRID PARTIAL IN and

GRID IN sensors are OFF when no grid 13 months

inserted,

0.2

Confirm that the GRID PARTIAL IN sensor is

13 months

ON when grid is inserted about half way.

Confirm that both GRID PARTIAL IN and

GRID IN sensor are ON when grid is 13 months

inserted to position.

Logbook Rev1 Page 4 of 7

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

Table Table Top Floating

Remove Table Top and clean oil and grease

from Lateral Table Top lock rod and locking 13 months 0.5

assembly

Check condition of longitudinal bearings and

13 months 0.2

lubricate with grease

Clean longitudinal bearing tracks and rails

13 months 0.2

and wipe with light machine oil.

Table Table Base

Remove table covers and inspect the ALB

and Inverter IF box for evidence of oil

contamination. Clean Scissors 13 months 0.5

assembly/rods as needed to remove excess

oil.

Inspect the 6 helping springs at the bottom

of scissors assembly. If anyone is broken, all

13 months 0.2

6 springs (part number 2259298-10) shall be

replaced

Check every 0.2

REPLACE

REPLACE

Inspect the 2 helping springs on the top of year.

TO BE

TO BE

scissors assembly. It is recommended to (Replace (1)

replace these 2 springs every 5 years every 5

years)

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

REPLACE

TO BE

TO BE

TO BE

TO BE

TO BE

TO BE

TO BE

TO BE

TO BE

TO BE

Replace

Replace the grease cups every 13 months. 1

every year

Table Table Height and Others:

Position the table top into its approximate

central position. Lower the table top until it

stops. The table top should measure

approximately 520+/-10 mm from the floor. 13 months 0.2

Raise the table top until it stops. The table

top should measure approximately 820+/-10

mm from the floor.

If a modification in the height limits (lower

and upper) is required, it is necessary to

recalibrate table height limit Encoder located

13 months 0.5

at the middle of scissors rods. See table

height limitation adjustment described in

Table Positioner Calibration.

Check condition of Rubber bumper end

stops (longitudinal & transversal) and 13 months 0.1

tightness of anchoring.

Verify that compression band and patient

hand grips are in good operating condition.

13 months 0.2

The clamp release button needs to be

tightened entirely if any loose observed,

Logbook Rev1 Page 5 of 7

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

ADS Computer

Maximize Computer Airflow 13 months

Clean workstation case 13 months

Configure Time Zone 6 months

Use% >=

Clean up disk space

60%

Clean Keyboard 13 months 1

Clean Monitor 13 months

Clean Mouse 13 months

Clean RCIM 13 months

Clean Hand Switch 13 months

Clean Barcode Reader 13 months

1 2 3 4 5 6 7 8 9 10

Maintenance Item Frequency Time

Year Year Year Year Year Year Year Year Year Year

Detector Detecor

Detector pigtail 13 months

Tether, detachable extension 13 months 0.5

TOOLS used during intervention

TOOLS Description Serial Number Calibration Date Comments

dates Comments

Logbook Rev1 Page 6 of 7

Intervention Date:…………………………………

Intervention Date:…………………………………

FE Sign Off:…………………………………

Logbook Rev1 Page 7 of 7

You might also like

- Carding University From Hell 666Document78 pagesCarding University From Hell 666Terry Barlow33% (3)

- Pass The PE - Practice ExamDocument62 pagesPass The PE - Practice Exameye4aneye1989100% (4)

- S33X USER MANUALrDocument112 pagesS33X USER MANUALrmarkpriceNo ratings yet

- BMW Wiring Symbols & ColorsDocument2 pagesBMW Wiring Symbols & ColorsProfCBSjr86% (7)

- IMS Replacements of Parts - ct02-025.841.04.09.02Document108 pagesIMS Replacements of Parts - ct02-025.841.04.09.0240818248No ratings yet

- Rock AnchorDocument49 pagesRock Anchorpandian100% (1)

- PHP NotesDocument149 pagesPHP NotesNavaneet Knights100% (1)

- فحص بلدية دبيDocument33 pagesفحص بلدية دبيFredj Kriaa67% (3)

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- Scope Proposal Ecommerce WebsiteDocument25 pagesScope Proposal Ecommerce WebsiteAle80% (10)

- NORMA API-936 - Testeo A MaterialesDocument2 pagesNORMA API-936 - Testeo A MaterialesSebastián Álcazar25% (4)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- ICT Action Plan 2019 2020Document4 pagesICT Action Plan 2019 2020Marjorie RaymundoNo ratings yet

- Digital Learning ObjectDocument60 pagesDigital Learning Objectust hafedz100% (3)

- Reformer Tubes Tim HillDocument20 pagesReformer Tubes Tim HillProkopNo ratings yet

- Non Return Valves PDFDocument2 pagesNon Return Valves PDFhpNo ratings yet

- Sno Equipment Activity Description Remark: Following Schedule Shall Be Followed For Preventive MaintenanceDocument2 pagesSno Equipment Activity Description Remark: Following Schedule Shall Be Followed For Preventive MaintenanceAjay VarmaNo ratings yet

- ZPMC Section 3 Maintenance InstructrueDocument39 pagesZPMC Section 3 Maintenance Instructrueitalo sanhuezaNo ratings yet

- ROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNDocument8 pagesROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNIzzi Al-AkbarNo ratings yet

- Engineering Academy: ESE Conventional Revision TEST - 4Document8 pagesEngineering Academy: ESE Conventional Revision TEST - 4vidya chakitwarNo ratings yet

- Experimental Study On Fiber Reinforced Self Compacting ConcreteDocument7 pagesExperimental Study On Fiber Reinforced Self Compacting ConcreteIJRASETPublicationsNo ratings yet

- Astm D5417-16Document3 pagesAstm D5417-16Sandra LopesNo ratings yet

- HPSM08030FU1Document9 pagesHPSM08030FU1Bhaumik DaveNo ratings yet

- Fitting & Acc.Document595 pagesFitting & Acc.jarekNo ratings yet

- Fitting & Acc PDFDocument663 pagesFitting & Acc PDFUncorrectableNameNo ratings yet

- Operation of The Vettermann Drum Tester: Standard Practice ForDocument3 pagesOperation of The Vettermann Drum Tester: Standard Practice ForJuanNo ratings yet

- Daily Exam 1 (Closed) : Professional Training and ConsultationDocument6 pagesDaily Exam 1 (Closed) : Professional Training and ConsultationAshish PatelNo ratings yet

- Regdoc 0 TRSCDocument193 pagesRegdoc 0 TRSCAnil MehtaNo ratings yet

- S BmittedDocument13 pagesS Bmittedhayel elnaggarNo ratings yet

- II B. Tech II Semester Regular Examinations, April - 2018 Kinematics of MachinaryDocument8 pagesII B. Tech II Semester Regular Examinations, April - 2018 Kinematics of MachinaryVenkatesh PaladuguNo ratings yet

- Lampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Document17 pagesLampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Cileungsi NarogongNo ratings yet

- Section 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication InspectionDocument25 pagesSection 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication Inspectionabdelhadi houssinNo ratings yet

- 1994-High Strength Concrete Columnes Confined by Rectrangular TiesDocument22 pages1994-High Strength Concrete Columnes Confined by Rectrangular Tiesnedim.halebic1No ratings yet

- Characteristics of Structural Breakdown in Plastic ConcreteDocument9 pagesCharacteristics of Structural Breakdown in Plastic Concretevelmurug_balaNo ratings yet

- TW PDFDocument3 pagesTW PDFahmedcoNo ratings yet

- Tensar BX1200Document1 pageTensar BX1200mohammazakNo ratings yet

- Resistência Ao Amarrotamento (Winkle Tester) - AATCC 128 - 2009Document2 pagesResistência Ao Amarrotamento (Winkle Tester) - AATCC 128 - 2009raissaNo ratings yet

- PermanchDocument5 pagesPermanchSharyn PolleyNo ratings yet

- IRC 112-2020-PartDocument19 pagesIRC 112-2020-Part2BA19CV059 Rakshita SarangmathNo ratings yet

- Daily Exam 4B (Open) : API 570 PreparatoryDocument4 pagesDaily Exam 4B (Open) : API 570 PreparatoryAshish PatelNo ratings yet

- Previous mechanical engineering question papersDocument2 pagesPrevious mechanical engineering question papersPraveen KumarNo ratings yet

- Fracture in DesignDocument4 pagesFracture in DesignSivakumar MvnNo ratings yet

- Reinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3)Document6 pagesReinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3)Shahid BhatNo ratings yet

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysDocument12 pagesRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JNo ratings yet

- Overland conveyors designed for efficient cost & performanceDocument17 pagesOverland conveyors designed for efficient cost & performanceEngineerMecNo ratings yet

- Dr. Kyung-Tae Bae - A Case Study of Settlement Behavior of Dynamic Compacted High Rock Embankment With Construction Path-2-2 PDFDocument4 pagesDr. Kyung-Tae Bae - A Case Study of Settlement Behavior of Dynamic Compacted High Rock Embankment With Construction Path-2-2 PDFthanhtrung87No ratings yet

- F859e Civil Structural 72 8Document14 pagesF859e Civil Structural 72 8hpowerNo ratings yet

- Flexural Strength TestDocument23 pagesFlexural Strength TestJommel GonzalesNo ratings yet

- Highway Engineering Feb Mar 2022Document2 pagesHighway Engineering Feb Mar 2022Sobha Ranjith KumarNo ratings yet

- Final Project ReviewDocument13 pagesFinal Project ReviewSiva VarmaNo ratings yet

- Bentomat Installation GuidelinesDocument16 pagesBentomat Installation GuidelinesAlessandraDaRochaFonsecaNo ratings yet

- E 519 - 02 - Rtuxoq - PDFDocument5 pagesE 519 - 02 - Rtuxoq - PDFLipikaNo ratings yet

- What Is The Test Before and After Casting?: TH TH TH THDocument7 pagesWhat Is The Test Before and After Casting?: TH TH TH THMohammad UmmerNo ratings yet

- Performance of Flowable Concrete For Application in Underground Structures - NATM Tunnel and Station Box of Mumbai Metro ProjectDocument19 pagesPerformance of Flowable Concrete For Application in Underground Structures - NATM Tunnel and Station Box of Mumbai Metro ProjectIJRASETPublicationsNo ratings yet

- Pa&d JalanDocument9 pagesPa&d JalanIkram MuzhaffarNo ratings yet

- Ultrasonic Pulse Velocity Test of Reinforced Concrete With Induced CorrosionDocument9 pagesUltrasonic Pulse Velocity Test of Reinforced Concrete With Induced Corrosionenquiry infoNo ratings yet

- WCSR Section 5Document3 pagesWCSR Section 5Inaam Ullah MughalNo ratings yet

- MECN 409 - June 2005 Page 1 of 5Document5 pagesMECN 409 - June 2005 Page 1 of 5Tinashe ErwinNo ratings yet

- Dynamics of MachineryDocument2 pagesDynamics of MachineryGopi TNo ratings yet

- Unbound MaterialsDocument3 pagesUnbound Materialsmadhav choudharyNo ratings yet

- Elastomeric Bridge Bearing StandardsDocument9 pagesElastomeric Bridge Bearing StandardsSuresh YedureswaramNo ratings yet

- Elastomeric Bearing 1Document9 pagesElastomeric Bearing 1Anonymous jLLjBdrNo ratings yet

- Rotopin-E Couplings: Use and Maintenance ManualDocument8 pagesRotopin-E Couplings: Use and Maintenance ManualIzzi Al-AkbarNo ratings yet

- A-III C-2 Fastening SystemDocument4 pagesA-III C-2 Fastening SystemTirumala RaoNo ratings yet

- Design Long Hand Flanged Beam PDFDocument66 pagesDesign Long Hand Flanged Beam PDFMauricio Bustamante HuaquipaNo ratings yet

- Ten Sar BX Geo GridsDocument10 pagesTen Sar BX Geo GridskydnavNo ratings yet

- Journal Homepage: - : IntroductionDocument12 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Scon-8atkj3 R0 enDocument10 pagesScon-8atkj3 R0 en40818248No ratings yet

- FAN4822Document10 pagesFAN482240818248No ratings yet

- 180585REVB, BT1855 33pDocument33 pages180585REVB, BT1855 33p40818248No ratings yet

- Easily Adjust Your Operating TableDocument21 pagesEasily Adjust Your Operating TableTường Nguyễn BáNo ratings yet

- BQ20Z80DBTDocument73 pagesBQ20Z80DBT40818248No ratings yet

- 787801Document1 page78780140818248No ratings yet

- Technical Publication: Direction 5135612-100 Revision 3 GE Healthcare EMC Conformance Statement (Definium™ 6000)Document30 pagesTechnical Publication: Direction 5135612-100 Revision 3 GE Healthcare EMC Conformance Statement (Definium™ 6000)40818248No ratings yet

- 180585revb, BT1855Document49 pages180585revb, BT185540818248No ratings yet

- Manual de Mantenimiento S331DDocument32 pagesManual de Mantenimiento S331DescalimetroNo ratings yet

- Technical Publications: Product Name(s)Document6 pagesTechnical Publications: Product Name(s)40818248No ratings yet

- 787800Document1 page78780040818248No ratings yet

- MS2711 10580-00027Document15 pagesMS2711 10580-0002740818248No ratings yet

- MCCB T6Document110 pagesMCCB T6Jie RongNo ratings yet

- Anritsu Site Master S332C Antenna Cable and Spectrum Analyzer Users GuideDocument120 pagesAnritsu Site Master S332C Antenna Cable and Spectrum Analyzer Users GuideSukrit ChaudharyNo ratings yet

- Pca82c250 1127362 PDFDocument19 pagesPca82c250 1127362 PDFecsa tallerNo ratings yet

- MB15F02Document24 pagesMB15F0240818248No ratings yet

- Monolithic 6A DC/DC Step-Down Regulator Features: FN7102.7 Data Sheet May 8, 2006Document14 pagesMonolithic 6A DC/DC Step-Down Regulator Features: FN7102.7 Data Sheet May 8, 200640818248No ratings yet

- PLL Performance Simulation and Design Fourth EditionDocument0 pagesPLL Performance Simulation and Design Fourth EditionvotasugsNo ratings yet

- HHST MSTDocument28 pagesHHST MST40818248No ratings yet

- LMX 2336Document18 pagesLMX 233640818248No ratings yet

- Anritsu S332C Site Master Handheld Code LoaderDocument26 pagesAnritsu S332C Site Master Handheld Code LoaderAbdelNo ratings yet

- HMC434Document7 pagesHMC43440818248No ratings yet

- Lmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal CommunicationsDocument16 pagesLmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal Communications40818248No ratings yet

- LMX2377USLBXDocument44 pagesLMX2377USLBX40818248No ratings yet

- Lmx2487E 7.5 GHZ High Performance Delta-Sigma Low Power Dual Pllatinum Frequency Synthesizers With 3.0 GHZ Integer PLLDocument38 pagesLmx2487E 7.5 GHZ High Performance Delta-Sigma Low Power Dual Pllatinum Frequency Synthesizers With 3.0 GHZ Integer PLL40818248No ratings yet

- Lmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal CommunicationsDocument16 pagesLmx2370/Lmx2371/Lmx2372 Pllatinum Dual Frequency Synthesizer For RF Personal Communications40818248No ratings yet

- LMX2331 2330LDocument23 pagesLMX2331 2330L40818248No ratings yet

- Lmx2354 Pllatinum Fractional N RF/ Integer N If Dual Low Power Frequency Synthesizer Lmx2354 2.5 Ghz/550 MHZDocument23 pagesLmx2354 Pllatinum Fractional N RF/ Integer N If Dual Low Power Frequency Synthesizer Lmx2354 2.5 Ghz/550 MHZ40818248No ratings yet

- Network Devices Configuration Lab ManualDocument17 pagesNetwork Devices Configuration Lab ManualmedrekNo ratings yet

- EOLP BasicDocument23 pagesEOLP BasicHEMIL ROBERTO RODRIGUEZ HERRERANo ratings yet

- Target For ArcgisDocument148 pagesTarget For Arcgisrenzoquim100% (2)

- Dokumen - Tips - Powerpoint Sage x3Document11 pagesDokumen - Tips - Powerpoint Sage x3harrar brahimNo ratings yet

- Abhinandan ResumeDocument2 pagesAbhinandan ResumeSHARAN SHETTYNo ratings yet

- Advance Word Processing Skill Learning ObjectivesDocument10 pagesAdvance Word Processing Skill Learning ObjectivesAlexis V. LarosaNo ratings yet

- Fundamentals of Data Science Lab RecordDocument59 pagesFundamentals of Data Science Lab RecordtbhumuytjNo ratings yet

- Maths Micro Project Semester 2Document15 pagesMaths Micro Project Semester 2AryanNo ratings yet

- Data Processor Cover LetterDocument5 pagesData Processor Cover Letterzys0vemap0m3100% (2)

- Learn Kivy MDDocument406 pagesLearn Kivy MDSaumya BondreNo ratings yet

- 7 Things You Should Know About Augmented Reality PDFDocument2 pages7 Things You Should Know About Augmented Reality PDFKartika LesmanaNo ratings yet

- B.N.M. Institute of Technology Microcontroller CourseDocument19 pagesB.N.M. Institute of Technology Microcontroller Coursekirthi bharadwajNo ratings yet

- PLC - Modicon M221 - TM221CE24RDocument17 pagesPLC - Modicon M221 - TM221CE24RAlfi Dzulfahmi KaduaNo ratings yet

- YCDC Register ManualDocument8 pagesYCDC Register ManualnyeinayeeeNo ratings yet

- RCS Interworking Guidelines 17 October 2019: This Is A Non-Binding Permanent Reference Document of The GSMADocument27 pagesRCS Interworking Guidelines 17 October 2019: This Is A Non-Binding Permanent Reference Document of The GSMAMohsin KhanNo ratings yet

- WinCC V70 Compatibility List eDocument2 pagesWinCC V70 Compatibility List eMarcelo Vicentini MartinsNo ratings yet

- 3.7 AI - DS Assignment2-1Document4 pages3.7 AI - DS Assignment2-1Anurag SinghNo ratings yet

- Time To Move On From MTBFDocument5 pagesTime To Move On From MTBFElvis DiazNo ratings yet

- DRF Questions AnswersDocument20 pagesDRF Questions AnswersShaid Hasan ShawonNo ratings yet

- Cosmetics ShopDocument7 pagesCosmetics ShopSanjay RajputNo ratings yet

- Online Food Ordering System ReportDocument7 pagesOnline Food Ordering System ReportS VarshithaNo ratings yet

- NGO Darpan How To Signup EnglishDocument10 pagesNGO Darpan How To Signup EnglishSkyhigh GoneNo ratings yet

- Đề khảo sát 12Document5 pagesĐề khảo sát 12Nguyen Thi Thu HienNo ratings yet

- ck7w User and Installation GuideDocument112 pagesck7w User and Installation GuideAleksandar KondićNo ratings yet