Professional Documents

Culture Documents

Flyer CP sp11

Uploaded by

Bac NguyenOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSP SERIES

MODEL SP11

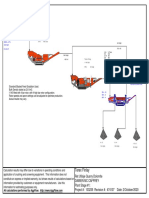

SP11 PERFORMANCE Flooded Suction 3450 RPM*

FLOW (m3/h) FEATURES &

70

0 5 10 15 20 25

21

CAPABILITIES

Cur ve Le gend

#1 # 1- 4.63" (118 mm) + Self-priming, magnetic drive

1.5 Hp

1.0 Hp 30% #2- 4.38" (111 mm)

60 35%

#3- 4.13" (105 mm) 18 + Five-year warranty

40%

HEAD (ft)

#2 #4- 3.88" (99 mm) + Provides up to 25 ft. (7.6 m) lift

HEAD (m)

#5- 3.63" (92 mm)

50

20% or equivalent

15

#3

45% 2.0 Hp + Primes 18 ft. (5.5 m) in 90 seconds

#4 with maximum diameter impeller

40 12

#5 + Retains fluid for re-priming when

shut off without a check valve

30 9

+ Extended run dry ability

Minimum Continuous Flow

(with carbon bushing)

20 6 + High operating efficiency

NPSHR (m)

NPSHR (ft)

+ Polypropylene or PVDF construction

10 3 + Powerful neodymium magnets

NPSHR + Close-coupled design

0 0 + Threaded (NPT or BSP), union or

0 20 40 60 80 100 120

flange connections

FLOW (USgpm)

+ Back pullout design

SP11 PERFORMANCE Flooded Suction 2900 RPM*

+ Mounts to NEMA and

(B5 & B14) IEC motor frames

25

Cur ve Le gend

+ Easy set measurement free drive

#6- 133 mm (5.25") + ISO 1940 G2.5 balancing

1.1 kW #7- 127 mm (5.00")

#6

#8- 121 mm (4.75") + CE certified

20 #9- 114 mm (4.50") + High working pressure up to

HEAD (m)

#7 #10- 108 mm (4.25")

90 psi (6.2 bar)

.75 kW

#8 20% 25%

+ Specific gravity over 1.8

35% 40% 45%

15 #9 + Polypropylene—180o F (82o C)

1.5 kW

+ PVDF—220o F (104o C)

#10

10

APPLICATIONS

+ Rail cars

NPSHR (m)

Minimum Continuous Flow

+ Tanker trucks

5 + Tanks with an opening on top

NPSHR + Bulk storage to day or process

tank transfer

0 + Sumps and reservoirs

0 5 10 15 20 25 + Below grade storage tanks

FLOW (m3/h)

+ Over-the-wall applications

Notes: Performance curves above are based on flooded suction. + When run-dry protection is needed

*Performance will vary with suction lift conditions. For performance at various suction lifts, see curve

book on FTI web site (www.finishthompson.com) or contact factory.

+ and many more!

Warning! SP Series not recommended for pumping flammables!

FINISH THOMPSON PUMPING SOLUTIONS AROUND THE WORLD finishthompson.com

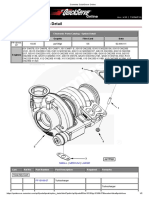

SP SERIES

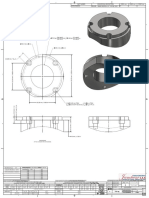

Specifications 7

4 6

Description Polypropylene PVDF 1

1 Housing Glass-fiber reinforced Carbon-fiber reinforced 8

4 Separator plate polypropylene (GF PP) PVDF (CF PVDF) 89 12

6 Inner volute

7 Impeller

3A, O-ring options FKM, EPDM

5, 10

3* Fill and drain plugs Polypropylene PVDF

6A Inner volute thrust High purity alumina ceramic, or silicon carbide (SiC)

ring 11

7A Impeller thrust ring GF molybdenum disulfide filled PTFE, or SiC

8 Inner drive Neodymium iron boron Neodymium iron boron 13

magnets encapsulated in magnets encapsulated in 3A

unfilled polypropylene unfilled PVDF

8A Bushing Carbon, PTFE, high purity alumina ceramic, or SiC 11A

9 Shaft High purity alumina ceramic, Hastelloy® C, or SiC

11 Barrier GF PP CF PVDF

11A Barrier thrust ring High purity alumina ceramic

12 Motor adapter Ductile iron 5 6A 7A

3

13 Outer drive magnets Nickel-plated neodymium iron boron magnets/steel 8A 10

14* Motor adapter Buna N

sealing kit (NEMA only) Hastelloy® C is a registered trademark of Haynes International, Inc.

*Not shown

Dimensions Also available 1-1/2” x 1-1/2” 150 lb.

ANSI/ISO PN20/PN40/JIS 10K or 'B' *

50mm x 50mm union connection. 'A'

6 1/8" 12 9/16"

Flanges are in compliance with bolting 1 1/2" FNPT 4 9/16" (319 mm)

(156 mm)

3 3/16"

dimensions only. OR FBSP (116 mm) 1 1/2" MNPT

(81 mm) OR MBSP

15 13/32"

(391 mm) 1 3/32"

9 13/32" (28 mm)

5" (239 mm)

(127 mm) 1/2" Ø 1/2"

Ø 3/8" (13 mm)

( Ø 9.5 mm) ( Ø13 mm)

'C'

4 11/32"

(110 mm) 'D'

8 21/32" 17 9/16"

(220 mm) (446 mm)

9 23/32"

(247 mm)

Motor Frame A B C† D† lbs. [kg] PP lbs. [kg] PVDF

NEMA 56C 12-9/16” [31.9 cm] 24-9/16” [62.4 cm] 3-3/4” [9.5 cm] 7-1/2” [19.1 cm] 25 [11.3] 30 [13.6]

NEMA 145TC 12-9/16” [31.9 cm] 23-5/16” [59.2 cm] 3-3/4” [9.5 cm] 7-1/2” [19.1 cm] 25 [11.3] 30 [13.6]

NEMA 184TC 13-7/16” [31.4 cm] 25-11/16” [66.6 cm] 3-3/4” [9.5 cm] 7-1/2” [ 19.1 cm] 26 [11.8] 31 [14.1]

IEC 80/90 w/B14 or B5 13-3/16” [33.5 cm] 23-7/8” [60.6 cm] 3-3/4” [9.5 cm] 7-1/2” [19.1 cm] 25.5 [11.6] 30.5 [13/8]

IEC 100 w/B14 13-1/4” [33.7 cm] 25-13/32” [64.5 cm] 3-5/32” [8.0 cm] 6-10/32” [16.0 cm] 25.5 [ 11.6] 30.5 [13.8]

IEC 112 w/B14 13-1/4” [33.7 cm] 25-29/32” [65.8 cm] 3-3/4” [9.5 cm] 7-1/2” [19.1 cm] 25.5 [11.6] 30.5 [13.8]

IEC 100 w/B5 13-1/4” [33.7 cm] 25-25/32” [65.5 cm] 3-5/32” [8.0 cm] 6-10/32” [16.0 cm] 31.5 [14.3] 36.5 [16.6]

IEC112 w/B5 13-1/4” [33.7 cm] 26-5/8” [67.6 cm] 3-3/4” [9.5 cm] 6-10/32” [16.0 cm] 31.5 [14.3] 36.5 [16.6]

Dimensions and weights are for reference only. Weights listed are for pump only; motor not included.

†Varies with motor manufacturer.

FINISH THOMPSON INC. - UNITED STATES FINISH THOMPSON INC. - GERMANY

921 Greengarden Road | Erie, PA 16501 Otto-Hahn-Strasse 16 | Maintal, D-63477 Germany

800.934.9384 | ph 814.455.4478 | fx 814.455.8518 49 (0)6181-90878-0 | fx 49 (0)6181-90878-18

finishthompson.com email fti@finishthompson.com email fti@finishthompson.com

You might also like

- SWOT Analysis Microtel by WyndhamDocument10 pagesSWOT Analysis Microtel by WyndhamAllyza Krizchelle Rosales BukidNo ratings yet

- Bơm hóa chấtDocument2 pagesBơm hóa chấtPhạm Hoang AnhNo ratings yet

- CatalogoDocument5 pagesCatalogoDiego Alonso Velez Villegas0% (1)

- J1480, I140, 984 Recirc Rev - 01Document3 pagesJ1480, I140, 984 Recirc Rev - 01Vlad BalanNo ratings yet

- FanucDocument2 pagesFanucAlmaz AbdyldaevNo ratings yet

- Cutout Templates For PV+ 7 Terminals (Standard Models) - 2711P-DS010B-EN-P - June 2014Document2 pagesCutout Templates For PV+ 7 Terminals (Standard Models) - 2711P-DS010B-EN-P - June 2014Nicolás A. SelvaggioNo ratings yet

- Fratello Pos MudançaDocument1 pageFratello Pos MudançaVagner NascimentoNo ratings yet

- Cross Reference Guide of Filter EfficienciesDocument1 pageCross Reference Guide of Filter EfficienciesJean Claude EidNo ratings yet

- SonarHub IG EN 988-10539-001 WDocument2 pagesSonarHub IG EN 988-10539-001 WDAFUNo ratings yet

- New Innovative: 91% More Dirt-Holding CapacityDocument2 pagesNew Innovative: 91% More Dirt-Holding CapacityrolexxNo ratings yet

- FTI Finish Thompson DB3 DB4 DB5 Centrifugal Pumps DatasheetDocument2 pagesFTI Finish Thompson DB3 DB4 DB5 Centrifugal Pumps DatasheetLê Hoàng GiangNo ratings yet

- ParlorDocument1 pageParlorDanieleNo ratings yet

- Jam003mqn400 409Document1 pageJam003mqn400 409Sebastian Davila hernandezNo ratings yet

- Jam003mqn400 410Document1 pageJam003mqn400 410Sebastian Davila hernandezNo ratings yet

- SRP (615 630) BTZ BG - 182 - EN - 2023V1.0 MinDocument2 pagesSRP (615 630) BTZ BG - 182 - EN - 2023V1.0 MinAssane FALLNo ratings yet

- UntitleddjeDocument1 pageUntitleddjevishwaNo ratings yet

- Tugas QFD - FRI-117Document12 pagesTugas QFD - FRI-117Tria AuliaNo ratings yet

- SOPRA XPS 40 - Technical Data SheetDocument2 pagesSOPRA XPS 40 - Technical Data SheetMark AdamsNo ratings yet

- For Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDocument4 pagesFor Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDNSXNo ratings yet

- 10-20 Belt Scale MT9101 8017.0113Document4 pages10-20 Belt Scale MT9101 8017.0113RickNo ratings yet

- Western Water Closet (American Standard) - 2Document1 pageWestern Water Closet (American Standard) - 2Vic BayotNo ratings yet

- Lube 118mm P174780Document2 pagesLube 118mm P174780Miguel Ángel MedinaNo ratings yet

- V300 PurgerDocument1 pageV300 PurgerGabriel Zumelzu AltamiranoNo ratings yet

- MicroPure HG Series Melt Blown FiltersDocument2 pagesMicroPure HG Series Melt Blown Filtersalberto99acevesNo ratings yet

- Flygt PumpDocument4 pagesFlygt PumpnawajhaNo ratings yet

- Jam003mqn400 406Document1 pageJam003mqn400 406Sebastian Davila hernandezNo ratings yet

- Cutout Templates For Panelview 5510 Terminals: 7-In. Touch Only 207 MM (8.15 In.) 6.5-In. Touch Only 184 MM (7.24 In.)Document2 pagesCutout Templates For Panelview 5510 Terminals: 7-In. Touch Only 207 MM (8.15 In.) 6.5-In. Touch Only 184 MM (7.24 In.)Melvis MellNo ratings yet

- D6P00301G0Document4 pagesD6P00301G0Hieu NguyenNo ratings yet

- Front Shovel enDocument15 pagesFront Shovel enAlejandro RodriguezNo ratings yet

- Curva 2x1.5Document1 pageCurva 2x1.5Vf MauroNo ratings yet

- ST-20Y Machine Views 2Document1 pageST-20Y Machine Views 2Abhishek VelagaNo ratings yet

- Quick Installation Guide: Ultimate VRV/VRF GatewayDocument2 pagesQuick Installation Guide: Ultimate VRV/VRF GatewayPunith RajNo ratings yet

- gn4000 PsDocument1 pagegn4000 Pszahramtk23No ratings yet

- Type tv2Document3 pagesType tv2Mamiherintsoa Issaia RanaivoarimananaNo ratings yet

- TTD 13Document1 pageTTD 13Hector RiveraNo ratings yet

- 900FH&1000FH Turbines 2Document12 pages900FH&1000FH Turbines 2RyanNo ratings yet

- tm-1 1p MLD 03 2022Document5 pagestm-1 1p MLD 03 20227xydmwqg5yNo ratings yet

- 4 - 3D Ah-5vcmDocument1 page4 - 3D Ah-5vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Pages From EXE-TAR-T-00105 Request For Approval of Asphalt Mix Design (Al Yamama Company) PDFDocument25 pagesPages From EXE-TAR-T-00105 Request For Approval of Asphalt Mix Design (Al Yamama Company) PDFSalahudin AbbasiNo ratings yet

- 6546310Document2 pages6546310Jendrek12No ratings yet

- Hydraulic Components Hansa TMP HT 01 A 317 0818 EDocument96 pagesHydraulic Components Hansa TMP HT 01 A 317 0818 ELuka BornaNo ratings yet

- (R1) Installation Topfix / Recessfix (R1) : ModelDocument2 pages(R1) Installation Topfix / Recessfix (R1) : ModelJakob Kinimond NielsenNo ratings yet

- Horyong Truck Mounted Concrete Pump - CompressedDocument28 pagesHoryong Truck Mounted Concrete Pump - CompressedSetavietnam Setavietnam0% (1)

- 4183SG 1diDocument2 pages4183SG 1diMeji irawanNo ratings yet

- ST-20 Machine ViewsDocument1 pageST-20 Machine ViewsAbhishek VelagaNo ratings yet

- Outline Drawing Liebert gxt5 5 6kva MV Racktower UpsDocument1 pageOutline Drawing Liebert gxt5 5 6kva MV Racktower UpsjuanNo ratings yet

- Amapro: Certificate of AnalysisDocument2 pagesAmapro: Certificate of Analysishafwen TranNo ratings yet

- 03 BMR-15Document4 pages03 BMR-15Anonymous q9c7KY1vNo ratings yet

- 900FH1000FH Turbines-ComprimidoDocument12 pages900FH1000FH Turbines-ComprimidolpiconNo ratings yet

- Hassasiyet HesabıDocument1 pageHassasiyet HesabıAhmet Akif KayaNo ratings yet

- Scanjet Datasheet Bio7SBDocument2 pagesScanjet Datasheet Bio7SBGabriel TravassosNo ratings yet

- Printing WPA108C11Document1 pagePrinting WPA108C11BM ThaísNo ratings yet

- Warnings and Cautions Views and Hydraulic Schematic: Hydraulic High Pressure Calibration Pump User's ManualDocument2 pagesWarnings and Cautions Views and Hydraulic Schematic: Hydraulic High Pressure Calibration Pump User's ManualLuis Marco Mora PobleteNo ratings yet

- Centrifugas 1 A 3 PDFDocument22 pagesCentrifugas 1 A 3 PDFAlejandro RosalesNo ratings yet

- d100 D100eco5 Small Air Pump Mar23Document2 pagesd100 D100eco5 Small Air Pump Mar23Anderson Leon SochaNo ratings yet

- Parameters: Typical One Way R.C. Slab DetailDocument1 pageParameters: Typical One Way R.C. Slab DetailJezreel FlotildeNo ratings yet

- Dyson LATABWash Dry WD06 Installation Guide ExDocument176 pagesDyson LATABWash Dry WD06 Installation Guide ExTathy DutraahNo ratings yet

- Turquia Argentina: Included Included Included Included Included IncludedDocument1 pageTurquia Argentina: Included Included Included Included Included Includeddaniel2rialNo ratings yet

- vf-3 Ss MLD 4 2022Document7 pagesvf-3 Ss MLD 4 2022kenNo ratings yet

- Catalogo Gates Acoples y Mangueras PDFDocument626 pagesCatalogo Gates Acoples y Mangueras PDFJose Antonio Gutierrez Lopez100% (1)

- 3RV20110CA15 Datasheet enDocument5 pages3RV20110CA15 Datasheet enBac NguyenNo ratings yet

- 3RW40372BB04 Datasheet enDocument4 pages3RW40372BB04 Datasheet enBac NguyenNo ratings yet

- STX+Engine부품 기본계약약관Document2 pagesSTX+Engine부품 기본계약약관Bac NguyenNo ratings yet

- Electronic Injector Catalog Jan 2022Document24 pagesElectronic Injector Catalog Jan 2022Bac NguyenNo ratings yet

- Salesman 05Document26 pagesSalesman 05Bac NguyenNo ratings yet

- Salesman 04Document26 pagesSalesman 04Bac NguyenNo ratings yet

- NS1-11HTA-M-KHI-3101 R1 Unit1 Flue Gas Duct General ArrangemDocument1 pageNS1-11HTA-M-KHI-3101 R1 Unit1 Flue Gas Duct General ArrangemBac NguyenNo ratings yet

- Salesman 03Document25 pagesSalesman 03Bac NguyenNo ratings yet

- Salesman 02Document27 pagesSalesman 02Bac NguyenNo ratings yet

- NS1-18HTA-M-KHI-1101 R2 General Assembly Drawing For ExpansiDocument10 pagesNS1-18HTA-M-KHI-1101 R2 General Assembly Drawing For ExpansiBac NguyenNo ratings yet

- NS1-11HTA-M-KHI-2012 R2 Unit1 Duct Arrangement Drawing (2 2)Document1 pageNS1-11HTA-M-KHI-2012 R2 Unit1 Duct Arrangement Drawing (2 2)Bac NguyenNo ratings yet

- Salesman 01Document27 pagesSalesman 01Bac NguyenNo ratings yet

- NS1-11HTA-M-KHI-2011 R2 Unit1 Duct Arrangement Drawing (1 2)Document1 pageNS1-11HTA-M-KHI-2011 R2 Unit1 Duct Arrangement Drawing (1 2)Bac NguyenNo ratings yet

- Base Fuel PumpDocument2 pagesBase Fuel PumpBac NguyenNo ratings yet

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- QSM11 Part PerformanceDocument8 pagesQSM11 Part PerformanceBac NguyenNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- High Pressure Compressor Unit Operating ManualDocument110 pagesHigh Pressure Compressor Unit Operating ManualBac Nguyen100% (2)

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- Diagram Detector 110KVADocument6 pagesDiagram Detector 110KVABac NguyenNo ratings yet

- Upper Engine Gasket Set 1Document2 pagesUpper Engine Gasket Set 1Bac NguyenNo ratings yet

- Overhead Set (OBC)Document21 pagesOverhead Set (OBC)Bac Nguyen100% (1)

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option DetailBac NguyenNo ratings yet

- Clean and Inspect For ReuseDocument8 pagesClean and Inspect For ReuseBac NguyenNo ratings yet

- InjectorDocument23 pagesInjectorBac Nguyen100% (1)

- Features Benefits Capabilities: AquaticDocument2 pagesFeatures Benefits Capabilities: AquaticBac NguyenNo ratings yet

- PT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaDocument16 pagesPT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaihsanlaidiNo ratings yet

- (Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFDocument317 pages(Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFSneha SinghNo ratings yet

- Legal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFDocument34 pagesLegal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFlongchadudz100% (12)

- Notes On Mass and Energy Balances For Membranes 2007 PDFDocument83 pagesNotes On Mass and Energy Balances For Membranes 2007 PDFM TNo ratings yet

- LG+32LX330C Ga LG5CBDocument55 pagesLG+32LX330C Ga LG5CBjampcarlosNo ratings yet

- PraxiarDocument8 pagesPraxiara_roy003No ratings yet

- Kilifi HRH Strategic Plan 2018-2021Document106 pagesKilifi HRH Strategic Plan 2018-2021Philip OlesitauNo ratings yet

- Sahara International Petrochemical Company (SIPCHEM)Document2 pagesSahara International Petrochemical Company (SIPCHEM)shahbaz1979No ratings yet

- Craske - Mastering Your Fears and FobiasDocument174 pagesCraske - Mastering Your Fears and Fobiasjuliana218No ratings yet

- 032017Document107 pages032017Aditya MakwanaNo ratings yet

- Kolodin Agreement For Discipline by ConsentDocument21 pagesKolodin Agreement For Discipline by ConsentJordan ConradsonNo ratings yet

- General Description Product Summery: Bvdss Rdson IDDocument4 pagesGeneral Description Product Summery: Bvdss Rdson IDJose Angel TorrealbaNo ratings yet

- Induction-Llgd 2022Document11 pagesInduction-Llgd 2022Phạm Trúc QuỳnhNo ratings yet

- NOS 65-200-90x60-30KWD PDFDocument2 pagesNOS 65-200-90x60-30KWD PDFDao The ThangNo ratings yet

- 14 DETEMINANTS & MATRICES PART 3 of 6 PDFDocument10 pages14 DETEMINANTS & MATRICES PART 3 of 6 PDFsabhari_ramNo ratings yet

- A-Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltDocument2 pagesA-Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltUzair AkbarNo ratings yet

- 2023 Reso-01Document3 pages2023 Reso-01John Mark Mercado JubelagNo ratings yet

- 25 - Marketing Channels - Value Networks.Document2 pages25 - Marketing Channels - Value Networks.zakavision100% (1)

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Document7 pagesHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- Danais 150 ActuadoresDocument28 pagesDanais 150 Actuadoresedark2009No ratings yet

- Br2e Int Readingfile10 PDFDocument2 pagesBr2e Int Readingfile10 PDFSanti RodriguezNo ratings yet

- Chapter 9 Audit SamplingDocument47 pagesChapter 9 Audit SamplingYenelyn Apistar CambarijanNo ratings yet

- IMS DB Interview Questions: Beginner LevelDocument19 pagesIMS DB Interview Questions: Beginner LevelsudhakarcheedaraNo ratings yet

- How To Make Affidavit at Pune Collector OfficeDocument1 pageHow To Make Affidavit at Pune Collector Officejayram1961No ratings yet

- Grade 5 Olympiad: Answer The QuestionsDocument14 pagesGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanNo ratings yet

- Case Chart Complete (Business Law)Document29 pagesCase Chart Complete (Business Law)LimShuLingNo ratings yet

- Payment Systems Worldwide: Appendix Country-by-Country AnswersDocument306 pagesPayment Systems Worldwide: Appendix Country-by-Country Answersravinewatia27No ratings yet

- WTO & MFA AnalysisDocument17 pagesWTO & MFA Analysisarun1974No ratings yet

- Management and Entrepreneurship Important QuestionsDocument1 pageManagement and Entrepreneurship Important QuestionslambazNo ratings yet