Professional Documents

Culture Documents

Pentair Gas Overview Trifold

Uploaded by

Dian Purwa Dewa (Babeh)0 ratings0% found this document useful (0 votes)

5 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesPentair Gas Overview Trifold

Uploaded by

Dian Purwa Dewa (Babeh)Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

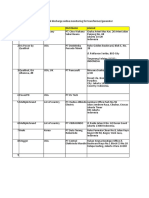

Vessel Rental Gas Application Areas

Performance Plus® Program

Process plants frequently encounter Processing

process upsets and other events Inlet Gas Separation

that affect throughput and increase

Amine Systems

POROUS MEDIA®

operating costs, thereby adversely

affecting profitability. In many cases, Glycol Dehydration

these events are related to solid or

liquid contaminants entering the unit

Lube Oil Systems

Designing and manufacturing in the liquid or gas streams. Once the Fuel Gas

causes of these process upsets or

Molecular Sieve

advanced technologies for the constraints are identified to pertain

to the need for better separations, Propane Refrigeration

separation of liquids, solids there is an immediate need for the

and gases separations equipment.

Production

Pentair Porous Media’s Performance Plus Program is Produced Water

specifically designed to help end-users and process owners

obtain the performance affiliated with our separations Frac Fluid Clean Up

technology plus a preferred means of acquiring the Injection/Disposal Wells

equipment. In cases where the end-user is looking for an

immediate solution, the program offers the equipment as part

of a vessel lease program. This program is for the U.S. only. Pipeline Transportation

Vessels available include:

• PROCESSOR™ - Particle-Liquid Separations

NGL/Fractionation

• LIQUISEP™ - Liquid-Liquid Separations

• ULTISEP™ - Liquid-Aerosols from Gases Upgrades for Existing

• INTERSEP® - Particle Gas Separations

Separators

Range of configurations:

• High Pressure (> 600 psi)

• High Temperature (> 400ºF)

• High Flow (Large Nozzles)

• Materials:

• Carbon Steel Post Weld Heat Treated

• Stainless Steel

• Horizontal or Vertical

• Coreless Technology

• Ergonomic Designs

Plants have taken advantage of the technology for a number

of systems:

Custody Transfer Catalyst Bed Protection

Fuel De-hazing Amine Systems

CAPABILITIES PROFILE Low NOx Burners

Caustic Treating

Gas Turbine Protection

Glycol Systems

GAS PROCESSING, GAS PRODUCTION, Aromatics Extraction Alkylation

RO systems Quality Control

PIPELINE TRANSPORTATION,

NGL/FRACTIONATION AND UPGRADES

(936) 788-1000 • www.porous.com

Reliable. Proven. Performance.

Pentair Porous Media is a global provider of

filtration and separation solutions. We design

and manufacture advanced technologies for

the separation of liquids, solids and gases.

Our S.T.A.R. Labs (Scientific Testing, Analysis and Research

Laboratories) are staffed with Ph.D. scientists who develop

innovative filter media for advanced separation applications.

These technologies help solve our customers most critical

filtration, separation and fluid process management

challenges. Some of these challenges include operating

instability and downtime caused by corrosion, fouling, UltiSep® – Solid Particle and Liquid Polarex® – Extractive Separations

foaming, chemical and energy loss and catalyst consumption. Aerosol Separation Polarex® technology provides

chemical manufacturers, refiners and

Our customers turn to us to increase the reliability of UltiSep® technology was developed to address

gas processors dramatically improved

their emission control systems, assure finished product the inherent deficiencies of the conventional

gas-liquid separators, to effectively remove separation of entrained and dissolved

specifications and enable better process throughput, contaminants relative to that

solid and liquid aerosols from gas streams.

resulting in reduced operating cost and the minimization of achievable through implementation

UltiSep flows from inside-to-the-outside,

waste. reducing the gas velocity as the liquid droplets of conventional water wash or solvent

are being removed. The media technology is scrubbing towers at a fraction of the

cost and plot space.

Just as the needs of our customers and their challenges specifically designed to provide the desired level

change, so do the solutions. Pentair Porous Media takes of separation and has the capability of providing

effective separation down to the nano-level.

pride in listening to, analyzing and executing solutions that

best fit our customer’s needs.

HRT™ – Hydrocarbon Recovery Technology

HRT™ provides refiners and gas processors dramatically

InterSep™ – Gas Particle Separation improved amine/hydrocarbon separation relative to that

achievable through implementation of conventional flash tanks.

The InterSep™ element flows from the outside-to-the-inside. Flash tanks are ineffective at separating emulsified hydrocarbon

InterSep™ is designed to remove particulate contamination from from amine, allowing essentially all dispersed hydrocarbon to

a dry gas stream at exceptionally high efficiencies. Should the gas pass through to the amine regenerator. HRT was developed

stream contain liquid aerosols, our UltiSep® technology helps provide to augment the performance of existing flash tanks, allowing

a purified stream. essentially zero free hydrocarbon to pass through to the

regenerator section of the amine unit. The technology is also

applicable to glycol systems.

LiquiSep® – Liquid-Liquid Separations

LiquiSep® technology has been ProcessOR™ - Particle-Liquid

POROUS MEDIA®

implemented specifically to help separate

emulsions that are not separable by Separations

conventional coalescers and flash-drums. The ProcessOR™ high performance

Conventional coalescers are unable to separation system is designed

(936) 788-1000 provide the degree of brightness and to be used for the removal of

clarity associated with the LiquiSep® particulate contaminants from

Web: www.porous.com technology due to the inability to capture rich amine, glycol, and other liquid

and remove the most penetrating process streams. It also utilizes our

Email: energy.inquiry@pentair.com droplets that indicate carry-over. LiquiSep® can separate these Compax coreless elements, which

dispersed and emulsified droplets from the primary fluid to practically is an optimized design for high

4301 West Davis, Conroe, TX 77304 nondetectable levels. efficiency separation.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Pentair Vessel and Skid RentalsDocument2 pagesPentair Vessel and Skid RentalsDian Purwa Dewa (Babeh)No ratings yet

- Datasheet Aqualine ALN05-60BDocument2 pagesDatasheet Aqualine ALN05-60BDian Purwa Dewa (Babeh)No ratings yet

- PURELAB Option-R Consumable Information SheetDocument1 pagePURELAB Option-R Consumable Information SheetDian Purwa Dewa (Babeh)No ratings yet

- PURELAB Option-R Consumable Information SheetDocument1 pagePURELAB Option-R Consumable Information SheetDian Purwa Dewa (Babeh)No ratings yet

- Filtration With Offline Oil Filters SDN Rev Feb 2013 01Document7 pagesFiltration With Offline Oil Filters SDN Rev Feb 2013 01Dian Purwa Dewa (Babeh)No ratings yet

- Datasheet Aqualine ALN05-60BDocument2 pagesDatasheet Aqualine ALN05-60BDian Purwa Dewa (Babeh)No ratings yet

- No Brand Asal Distributor AlamatDocument2 pagesNo Brand Asal Distributor AlamatDian Purwa Dewa (Babeh)No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Model 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityDocument2 pagesModel 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityGamal El Deen KamalNo ratings yet

- Data Sheet RFQ Air Cooler HEDocument1 pageData Sheet RFQ Air Cooler HEcharles bronsonNo ratings yet

- Condensate & CoolingDocument111 pagesCondensate & CoolingSantosh KumarNo ratings yet

- VIIRJ Journal For PublicationDocument9 pagesVIIRJ Journal For PublicationVellon 1No ratings yet

- Calculation ReportDocument1 pageCalculation ReportMohammedNo ratings yet

- Scientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterDocument5 pagesScientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterfaqdaniNo ratings yet

- PB 03 581 03Document4 pagesPB 03 581 03srinivasmanNo ratings yet

- 2 Multicomponent Flash Distillation 63Document32 pages2 Multicomponent Flash Distillation 63Tle Supawid50% (2)

- Dual+fuel+engines (GI and LGI) PDFDocument45 pagesDual+fuel+engines (GI and LGI) PDFRamprabu ChandrasekarNo ratings yet

- Environmental Planning & Practice: Unit 2: EcosphereDocument26 pagesEnvironmental Planning & Practice: Unit 2: Ecosphereadeel razi100% (1)

- DR Ambedkar Institute of Technology: Group Activity ON "Orifices and Mouthpieces"Document23 pagesDR Ambedkar Institute of Technology: Group Activity ON "Orifices and Mouthpieces"1TU20CV408- dinkyNo ratings yet

- C H O CO H 2O+ 3.76 N Look at Fuel Find Amount of C HDocument3 pagesC H O CO H 2O+ 3.76 N Look at Fuel Find Amount of C HybobbyxNo ratings yet

- Pipeline LosessDocument23 pagesPipeline Losessasl91No ratings yet

- Gas Holdup in A Gasliquid Up Flow Bubble Column in The Presence of Double Cone Promoter PDFDocument8 pagesGas Holdup in A Gasliquid Up Flow Bubble Column in The Presence of Double Cone Promoter PDFCastañeda ValeriaNo ratings yet

- Hitachi: Service Parts NewsDocument2 pagesHitachi: Service Parts Newsmarcyel Oliveira WoliveiraNo ratings yet

- Hydraulics' Quiz No. 2 - Module 4-5 - Google FormsDocument7 pagesHydraulics' Quiz No. 2 - Module 4-5 - Google FormsFrancis HernandezNo ratings yet

- Pressure Relief Device For Manifold 029730037: LegendDocument1 pagePressure Relief Device For Manifold 029730037: LegendMuhammad HassanNo ratings yet

- Valve Testing StandardsDocument6 pagesValve Testing Standardsjjirwin100% (2)

- 15 10BAC01CE051A MWHR Counter 16 10BAC01CE051B Mvarh CounterDocument14 pages15 10BAC01CE051A MWHR Counter 16 10BAC01CE051B Mvarh Counternectars59No ratings yet

- Ref System Components 2020 PDFDocument21 pagesRef System Components 2020 PDFJanine RenojoNo ratings yet

- Consistent Boundary Conditions For Integrated LES/RANS Simulations: LES Inflow ConditionsDocument12 pagesConsistent Boundary Conditions For Integrated LES/RANS Simulations: LES Inflow ConditionsB Bala Venkata GaneshNo ratings yet

- Elements of Aerospace EngineeringDocument12 pagesElements of Aerospace Engineeringrattan5No ratings yet

- Chapter 9: Convection Processes and Properties Basics of Heat and Mass Transfer by D. S. KumarDocument14 pagesChapter 9: Convection Processes and Properties Basics of Heat and Mass Transfer by D. S. KumarHajra AamirNo ratings yet

- Put RacDocument2 pagesPut RacVinod yadavNo ratings yet

- Gas and Gas LawsDocument30 pagesGas and Gas Lawslamberto revecheNo ratings yet

- Enhanced Coal Bed Methane Recovery and CO Sequestration in The Powder River BasinDocument35 pagesEnhanced Coal Bed Methane Recovery and CO Sequestration in The Powder River BasinArianne AntonucciNo ratings yet

- Fracture Propagation of Co2 PipelinesDocument10 pagesFracture Propagation of Co2 Pipelinesjemfus10100% (1)

- Unloading Arm DatasheetDocument2 pagesUnloading Arm DatasheetbecpavanNo ratings yet

- Seko Tekna Evo AklDocument4 pagesSeko Tekna Evo AklAndre ArmawanNo ratings yet

- ME 2204 Fluid Mechanics NotesDocument30 pagesME 2204 Fluid Mechanics NotesPraveen Raj100% (1)