Professional Documents

Culture Documents

Darmatt and Darmatt Jet Fire Passive Fire Protection

Uploaded by

Rozane Da Silva ChavesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Darmatt and Darmatt Jet Fire Passive Fire Protection

Uploaded by

Rozane Da Silva ChavesCopyright:

Available Formats

UNCONTROLLED WHEN PRINTED

Darchem Thermal Protection Systems

Darchem Engineering Limited

Stillington, Stockton on Tees

TS21 1LB, United Kingdom

Tel: +44 (0) 1740 630461

Fax: +44 (0) 1740 632912

Email: dtpssales@darchem.co.uk

URL: http://www.darchem.co.uk

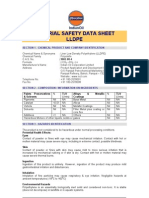

Material Safety Data Sheet

1 PRODUCT & COMPANY INFORMATION

2 HAZARD IDENTIFICATION

3 COMPOSITION/INFORMATION ON INGREDIENTS

4 FIRST AID MEASURES

5 FIRE FIGHTING MEASURES

6 ACCIDENTAL RELEASE MEASURES

7 HANDLING AND STORAGE

8 EXPOSURE CONTROL / PERSONAL PROTECTION

9 PHYSICAL AND CHEMICAL PROPERTIES

10 STABILITY & REACTIVITY

11 TOXICOLOGICAL INFORMAITON

12 ECOLOGICAL INFORMATION

13 DISPOSAL CONSIDERATIONS

14 TRANSPORT INFORMATION

15 REGULATORY INFORMATION

16 OTHER INFORMATION

1 PRODUCT & COMPANY INFORMATION

Description: Darmatt and Darmatt Jet Fire Passive Fire Protection

MSDS No: DTP073

Revision: 3

Prepared By: G Smailes

Date of Issue: November 2009

Manufacturer / Supplier Darchem Thermal Protection Systems

Darchem Engineering Limited

Stillington, Stockton on Tees

TS21 1LB, United Kingdom

Tel: +44 (0) 1740 632871

Fax: +44 (0) 1740 632912

The Darmatt Passive Fire Protection system widely used in the petrochemical and power generation markets

for the protection of electrical cables and related safety critical equipment such as E.S.D Valves, actuators,

vessels and pipe-work. The Darmatt System is a flexible composite mattress system constructed with both a

varying number of layers and density using flame and heat resistant insulation blanket. The specific

composite for each project is dependent upon the time/temperature requirement, site conditions such as

localised configurations, the thermal mass of the materials being protected, local fuel sources, airflow, and a

number of other variables.

Depending on the environmental and process conditions the sacrificial exterior layer is generally either a

vinyl coated polyester fabric or a coated high temperature fibreglass cloth. In the event of a fire this outer

cover burns off, the nylon pins melt, allowing the composite to expand, increasing the insulating effect of the

fibre.

The Darmatt ‘J120’ Jet Fire variant contains additional inner layers, which enables it to resist the severe

erosion of a Jet Fire scenario and drag forces associated with blast overpressure scenarios.

September 2009 DTP073 Issue 3 Page 1 of 6

UNCONTROLLED WHEN PRINTED

2 HAZARD IDENTIFICATION

Darmatt requires little to no maintenance once installed. However, when panel modifications are required

during installation dust may be created from the outer cloth and fibre. Some mechanical irritation to skin,

eyes and upper respiratory system may result due to exposure.

Pre-existing skin and respiratory conditions such as dermatitis and asthma may be affected by exposure.

These effects are usually temporary.

3 COMPOSITION/INFORMATION ON INGREDIENTS

The Darmatt and Darmatt J120 PFP Systems are manufactured using a number of raw materials. The

individual MSDS documents for these materials are available upon request.

Insulation Fibre

Component / Description Alkaline Earth Silicate Fibres (AES)

CAS No 436 083 99 7

Composition (SiO2) 60 – 70% and a (CaO + MgO) of 30 – 40%

Melting Point >1330oC

Standard Outer Cloth

Component / Description PVC Coated Nylon Fabric

Composition This product does not contain any ingredients that are deemed hazardous

Melting Point 150oC

High Temperature Outer Cloth

Component / Description TBA Silicone Polymer coated Fortaglas Glass Fabric Fabrics

CAS No 65997-17-3

Composition This product does not contain any ingredients that are deemed hazardous

Melting Point >700 oC

Nylon Mattress Pins

Component / Description Polyamide Resin

CAS No 32131-17-2

Composition Nylon 66

Melting Point 250 – 260 oC

Starlock Washers

Composition C: 069%, Si: 0.220, Mg: 0.74%, S: 0.002%, P: 0.011%, Cr, 0.25%, Al: 0.029%

Stainless Steel Wire Cloth (Jet Fire Only)

Composition Stainless Steel Grade 316

C: 0.07% Max, Mn: 1.0% Max, Si: 2.0% Max, P: 0.045% Max, S: 0.030% Max,

Cr: 16.5 – 18.5%, Ni: 10.5 – 13.5%, Mo: 2 – 3%

Melting Point 1370 – 1520 oC

Nylon Coated Stainless Steel Lacing Wire

Composition Stainless Steel Grade 316

C: 0.08% Max, Mn: 2%, Si: 0.75%, P: 0.045%, S: 0.030%,

Cr: 16 – 18%, Ni: 10 – 14%, Mo: 2 – 3%, N: 0.10%, Fe: Balance

Melting Point (Nylon) 215oC

Melting Point (St. Steel) 1390oC – 1440oC

September 2009 DTP073 Issue 3 Page 2 of 6

UNCONTROLLED WHEN PRINTED

4 FIRST AID MEASURES

Although unlikely, the following first aid measures should be considered.

Inhalation In case of respiratory problems move to a dust free area.

Skin Irritation In case of skin irritation rinse affected areas with cold water and wash gently.

Do not rub or scratch exposed skin.

Eye Irritation In case of contact with eyes resulting in irritation flush abundantly with water,

have eye bath if available. Do not rub eyes.

Nose & Throat Irritation If these become irritated move to a dust free area, drink water and blow nose.

Any adverse effects should be temporary, if symptoms persist seek medical advice.

5 FIRE FIGHTING MEASURES

Flammability This product is employed as passive fire protection and is non-combustible.

However, in the event of a fire the outer cloth, pins and washers will be

consumed, allowing the fibre to expand. This will result in the emission of

Carbon Monoxide, Hydrogen Chloride, Silicone Oxide and small amounts of

hydrogen cyanide, ammonia and aldehydes.

Special Fire fighting None, use procedures suitable for surrounding plant.

Procedures

Extinguishing Media Use extinguishing media suitable for surrounding plant.

(Only if trained to do so).

6 ACCIDENTAL RELEASE MEASURES

Pick up any large pieces, if available use a vacuum cleaner fitted with high efficiency filter (HEPA) when

release is in an enclosed environment.

If brushing is used, ensure the area is wetted first to prevent the spreading of dust.

Do not use compressed air for clean-up

Do not flush waste into drains and prevent from entering natural watercourses.

Other local regulations may apply.

7 HANDLING AND STORAGE

Handling

Darmatt panels can be heavy, considerations should be made with regard to manual handling when

installing or removing panels.

In the event of adverse weather conditions, panels may suffer water ingress. In the event of water ingress

the weight of a panel will increase.

Personal Protective Equipment should be used when installing or removing panels, see section 8 for more

information.

Storage

It is advisable to always attempt to store Darmatt in a dry area prior to installation to avoid water ingress.

September 2009 DTP073 Issue 3 Page 3 of 6

UNCONTROLLED WHEN PRINTED

8 EXPOSURE CONTROL / PERSONAL PROTECTION

To reduce the risk of skin irritation and personal injury, PPE such as safety glasses, gloves, coveralls and

safety shoes should be worn when handling this product. All PPE worn should be in line with the regulations

of each individual site on which it is to be installed.

If modifications are required to the Darmatt unit in an enclosed environment, it is recommended to wear a

dust mask and disposable paper overalls to reduce the risk of irritation to skin, nose and throat.

9 PHYSICAL AND CHEMICAL PROPERTIES

Material Physical Flammability Appearance Melting Point Exposure Odour

State Properties

Fibre Solid None White >1330oC None None

PVC Coated Outer Solid None Various1 150oC None None

Cloth

Silicone Coated Solid None Various1 700oC None None

Outer Cloth

St. Steel Mesh Solid None Metallic grey 1370oC – 1520oC None None

Nylon Coated Solid None Grey Nylon Coating: 215oC None None

Lacing Wire Wire: 1390oC – 1440oC

1

Colour generally Grey but may differ based on customer requirements

10 STABILITY & REACTIVITY

Conditions to Avoid: N/A Materials to Avoid N/A

11 TOXICOLOGICAL INFORMAITON

Irritant Properties

When tested using approved methods, fibres contained in this material give negative results. All man-made

mineral fibres, like some natural fibres, can produce a mild irritation resulting in itching or rarely, in some

sensitive individuals, in slight reddening. Unlike other irritant reactions this is not the result of allergy or

chemical skin damage but is caused by a temporary mechanical effect.

Other Animal Studies

These materials have been designed to allow rapid clearance from tissue. This low biopersistence has been

confirmed in many studies using EU protocol ECB/TM/27(rev 7) and the German method specified in TRGS

905 (1999). When inhaled, even at very high doses, they do not accumulate to any level capable of

producing a serious adverse biological effect. In lifetime chronic studies there was no exposure-related effect

more than would be seen with any “inert” dust. Sub-chronic studies at the highest doses achievable

produced, at worst, a transient mild inflammatory response. Fibres with the same ability to persist in tissue

do not produce tumours when injected into the peritoneal cavity of rats.

12 ECOLOGICAL INFORMATION

These products are inert materials, which remain stable overtime.

No adverse effects of this material on the environment are anticipated.

September 2009 DTP073 Issue 3 Page 4 of 6

UNCONTROLLED WHEN PRINTED

13 DISPOSAL CONSIDERATIONS

Waste from this product and it supporting raw materials are classed as non-hazardous and can generally

disposed of at landfill. Waste should be disposed of in a suitable container to prevent the release of dust

and in line with local disposal regulations.

14 TRANSPORT INFORMATION

None of the raw materials used in the manufacture of Darmatt are classed as Dangerous.

15 REGULATORY INFORMATION

The following statement relates to the Insulation fibre and is taken from the Unifrax MSDS Document no

200E.

Regulatory status in the EU, comes from European Directive 67/548/EEC, on the classification, labelling and

packaging of dangerous substances and preparations as modified by Directive 97/69/EEC and its

implementations by the Member States. According to Directive 67/548/EEC, the fibre contained in this

product is a mineral wool belonging to the group of “man made vitreous (silicate) fibres with random

orientation with alkaline oxide and alkali earth oxide (Na2O+K2O+CaO+MgO+BaO) content greater than

18% by weight”.

Under Directive 67/548/EEC all types of man made vitreous(silicate) fibres are classified as “irritant “ despite

the fact that testing by the appropriate EU method (B4 in annex 5 of Directive 67/548/EEC) is providing no

response and would not result in irritant classification. Under criteria listed in nota Q of Directive

67/548/EEC, AES wools are exonerated from carcinogen classification because of low pulmonary

biopersistence measured by the methods specified in European Union and German regulations ( EU

protocol ECB/TM/27(rev 7) and German method as specified in TRGS 905 (1999)).

16 OTHER INFORMATION

Useful references taken from the Unifrax MSDS Document no 200E, relating to the fibre used within

Darmatt products. (The directives which are cited must be considered in their amended versions).

Council Directive 89/391/EEC dated 12thJune 1989 “on the introduction of measures to encourage

improvements in the safety and health of workers at work” (OJEC L 183 of 29thJune 1989, p.1).

Council Directive 67/548/EEC on the “approximation of the laws, regulations and administrative provision

relating to the classification, packaging and labelling of dangerous substances as modified and adapted to

the technical progress” (OJEC L 196 of 16thAugust 1967, p.1 and its modifications and adaptations to

technical progress).

Commission Directive 97/69/EC of 5thDecember 1997 “adapting to technical progress for the 23rdtime”

Council Directive 67/548/EEC, (OJEC L 343 “Official Journal of the European Communities”, 13thDecember

1997, p.19)

Council Directive 98/24/EC of 7thApril 1998 “on the protection of the health and safety of workers from risks

related to chemical agents at work” (OJEC L 131 of 5thMay 1998, p.11)

TRGS 521 : Faserstaube 5/2000 – Germany

Definitions

ADR – Transport by road, Council Directive 94/55/EC

IMDG – Regulations relating to transport by sea.

RID – Transport by rail, Council Directive 96/49/EC

ICAO/IATA – Regulations relating to transport by air.

September 2009 DTP073 Issue 3 Page 5 of 6

UNCONTROLLED WHEN PRINTED

Precautionary measures to be taken after service and upon removal.

As produced, Insulfrax fibres are vitreous (glassy) materials which, upon continued exposure to elevated

temperatures (above 900 degrees C) might de-vitrify. The occurrence and extent of crystalline phase

formation is dependent on the duration and temperature of exposure, fibre chemistry and/or the presence of

fluxing agents. The presence of crystalline phases can be confirmed only through laboratory analysis of the

“hot-face” fibre.

Simulated after-use (up to 8 weeks at 1000 degrees C), Insulfrax fibres were not toxic to macrophage-like

cells.

High concentrations of fibres and other dusts may be generated when after-service products are

mechanically disturbed during operations such as wrecking. These dusts may contain crystalline silica, which

some authorities have classified as a carcinogen. Therefore ECFIA recommends:

Control measures are taken to reduce dust emissions.

All personnel directly involved wear an appropriate respirator to minimise exposure and comply with

local regulatory limits.

These procedures will ensure compliance with local regulatory standards for free crystalline silica. Because

de-vitrified fibres containing silica mixed with amorphous and other crystalline phases are far less biologically

active than free crystalline silica dusts, these measures will provide a high degree of protection.

Care Programme

The European Ceramic Fibres Industry Association (ECFIA) has undertaken an extensive industrial hygiene

programme for High Temperature Insulation Wool (HTIW).

The objectives are twofold:

To monitor workplace dust concentrations at both manufacturers’ and customers’ premises.

To document manufacturing and use of HTIW products from an industrial hygiene perspective in

order to establish appropriate recommendations to reduce exposures.

If you wish to participate in the CARE programme, contact ECFIA or your supplier.

NOTE:

The directives and subsequent regulations detailed in this ‘Material Safety Data Sheet’ are only applicable to

the European Union (EU) Countries and not to countries outside of the EU.

Websites

The European Ceramic Fibres Industry Association (ECFIA): 3 Rue du Colonel Moll, 75017 Paris.

Tel: +33(0)1 44 05 54 84 Fax: +33(0)1 44 05 54 94 Web-site: www.ecfia.org

Or to Deutsche Keramikfaser-Gesellschafte.V. Web-site: www.dkfg.de

NOTICE:

The information presented above is based on data considered to be accurate at the date of compilation of

this Material Safety Data Sheet. However, no warranty or representation, expressed or implied is made as to

the accuracy or completeness of the foregoing data and safety information. Neither is any authorisation

given or implied to practise any patented invention without a license. In addition, no responsibility can be

assumed by the vendor for any damage or injury resulting from abnormal use or from any failure to adhere to

recommended practices, or from any hazards inherent in the nature of the product.

The above information has been compiled using current Supplier2 Material Safety Data Sheets.

Individual materials used in the manufacture of all Darmatt products are available upon request.

September 2009 DTP073 Issue 3 Page 6 of 6

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Question and Answers For Introduction To TextilesDocument7 pagesQuestion and Answers For Introduction To TextilesProf Dr Md Saifur RahmanNo ratings yet

- CASDS01 General Purpose CementDocument6 pagesCASDS01 General Purpose CementMatt LNo ratings yet

- MSDSDocument6 pagesMSDSangelitzNo ratings yet

- Fly Ash: Safety Data SheetDocument5 pagesFly Ash: Safety Data SheetGaluh AlmasNo ratings yet

- SDS-Fly Ash (Cement Australia)Document5 pagesSDS-Fly Ash (Cement Australia)Nguyen Ngoc TuanNo ratings yet

- ECOTREAT 130 MSDS - Mould & Die ProtectorDocument4 pagesECOTREAT 130 MSDS - Mould & Die ProtectorVishnu NNo ratings yet

- Portland Cement: Material Safety Data Sheet (MSDS)Document6 pagesPortland Cement: Material Safety Data Sheet (MSDS)eslam sokaNo ratings yet

- Polypropylene (Homopolymer)Document4 pagesPolypropylene (Homopolymer)Fadilla Soraya IsfahaniNo ratings yet

- Material Safety Datasheet - MDF-MRDocument2 pagesMaterial Safety Datasheet - MDF-MRMay Ann DuronNo ratings yet

- Material Safety Data Sheet - LLDPE PDFDocument6 pagesMaterial Safety Data Sheet - LLDPE PDFJihād MukhlisNo ratings yet

- Rimula x30Document7 pagesRimula x30hastaNo ratings yet

- Sds Fiberglass CeilingsDocument10 pagesSds Fiberglass Ceilingsjus alfonsoNo ratings yet

- Material Safety Data Sheet: Portland and Blended CementDocument6 pagesMaterial Safety Data Sheet: Portland and Blended CementBoo Mark DusalNo ratings yet

- Msds Gma GarnetDocument4 pagesMsds Gma GarnetAbah AmaniNo ratings yet

- CSR - Base Coat and Adhesive - SDS - 20.11.2019Document7 pagesCSR - Base Coat and Adhesive - SDS - 20.11.2019jr-nts ntsNo ratings yet

- TM LF Yel Alk Mi - Aa Extrd - Us Ghs - EnglishDocument7 pagesTM LF Yel Alk Mi - Aa Extrd - Us Ghs - Englishallan258No ratings yet

- Hebel Autoclaved Aerated ConcreteDocument7 pagesHebel Autoclaved Aerated Concreteaditarian .pNo ratings yet

- 115-116 (Blue)Document5 pages115-116 (Blue)juyta0% (1)

- Product Safety Data Sheet PRODUCTS: L7A2/L6-Ex/L6A-Ex/L160/L170/M2/W2Document5 pagesProduct Safety Data Sheet PRODUCTS: L7A2/L6-Ex/L6A-Ex/L160/L170/M2/W2Ian DuncanNo ratings yet

- MSDS Abs Pipe PDFDocument4 pagesMSDS Abs Pipe PDFelsa 88No ratings yet

- Addocat® 10-9 (MSDS)Document5 pagesAddocat® 10-9 (MSDS)Mahmoud FlefilNo ratings yet

- Abrasive Description and MSDS - Garnet - AustralianDocument6 pagesAbrasive Description and MSDS - Garnet - AustralianVijay Allimuthu AvathipalayamNo ratings yet

- NAX Premila 2K Polyester Putty-MSDSDocument6 pagesNAX Premila 2K Polyester Putty-MSDSjanakaNo ratings yet

- Safety Data Sheet Linx Fast-Drying Solvent 1512Document5 pagesSafety Data Sheet Linx Fast-Drying Solvent 1512Anselmo SanchezNo ratings yet

- Sds Mineral FiberDocument10 pagesSds Mineral FiberAnonymous SKbL67p9No ratings yet

- 3011 Pittsburgh Pulverized Coal - 1213Document3 pages3011 Pittsburgh Pulverized Coal - 1213abdullah amanullah100% (1)

- Tds & Msds 100gsx and 100gsxxDocument8 pagesTds & Msds 100gsx and 100gsxxSajid UddinNo ratings yet

- Tuff Kote MSDS (A+B)Document10 pagesTuff Kote MSDS (A+B)Mounir BoutaghaneNo ratings yet

- BS 50Document7 pagesBS 50albaraha albarahaNo ratings yet

- Anti Carbonation PaintDocument4 pagesAnti Carbonation Paintptk94287No ratings yet

- Fly Ash - Bottom Ash: Safety Data SheetDocument5 pagesFly Ash - Bottom Ash: Safety Data SheetMatt LNo ratings yet

- Safety Data Sheet of Porland Cement HolcimDocument6 pagesSafety Data Sheet of Porland Cement HolcimRisma cahya putriNo ratings yet

- 02E Zinc WireDocument4 pages02E Zinc WireElias AlvesNo ratings yet

- Material Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationruksfarhanNo ratings yet

- TempDocument4 pagesTempvperhealthNo ratings yet

- 3 - 2 - 4 - Hdpe Blow 9 - B1258 Tasnee - MSDSDocument6 pages3 - 2 - 4 - Hdpe Blow 9 - B1258 Tasnee - MSDSSalman AhmedNo ratings yet

- Safety Data Sheet Omala F320Document7 pagesSafety Data Sheet Omala F320Isabela BoceanuNo ratings yet

- ROCKWOOL SDS Amd-11-Curr PDFDocument7 pagesROCKWOOL SDS Amd-11-Curr PDFr afriantoNo ratings yet

- Lagermeister XXL-SDSDocument6 pagesLagermeister XXL-SDSPratik MoreNo ratings yet

- Safety Data Sheet Colron Refined Danish Oil: 1 Identification of The Substance/Preparation and of The Company/UndertakingDocument5 pagesSafety Data Sheet Colron Refined Danish Oil: 1 Identification of The Substance/Preparation and of The Company/UndertakingteehoweNo ratings yet

- Sds Daiamid Ws Black (English) Ver.5Document3 pagesSds Daiamid Ws Black (English) Ver.5Jihād MukhlisNo ratings yet

- 19012.10 SDSR Stat X Class 1.4SDocument5 pages19012.10 SDSR Stat X Class 1.4SHảo Nguyễn ĐN HBNo ratings yet

- Safety Data Sheet: Ingredient Name Ec No Cas No % W/W Symbol R PhrasesDocument5 pagesSafety Data Sheet: Ingredient Name Ec No Cas No % W/W Symbol R PhrasesongtatianaNo ratings yet

- CSR Gyprock Plasterboard - Cornices - Ceiling Tiles SDS - 7.12.2020Document6 pagesCSR Gyprock Plasterboard - Cornices - Ceiling Tiles SDS - 7.12.2020jr-nts ntsNo ratings yet

- Material Safety Data Sheet: 1 - Identification of Product and Supplier Peppermint Essential OilDocument4 pagesMaterial Safety Data Sheet: 1 - Identification of Product and Supplier Peppermint Essential OilSamanthaNo ratings yet

- Maskote WB Zinc Stop-OffDocument7 pagesMaskote WB Zinc Stop-OffbondsivamaniNo ratings yet

- Asphalt PG 58-28: Material Safety Data SheetDocument3 pagesAsphalt PG 58-28: Material Safety Data SheetSen HuNo ratings yet

- MSDS Exceed3Document10 pagesMSDS Exceed3真幸运No ratings yet

- Material Safety Data Sheet: TankleenDocument6 pagesMaterial Safety Data Sheet: TankleenJezrell JaravataNo ratings yet

- Marlex® D139FK Polyethylene: Safety Data SheetDocument10 pagesMarlex® D139FK Polyethylene: Safety Data SheetManufaktur Sinar JoyoboyoNo ratings yet

- MSDS For CERAMIC MOULDDocument4 pagesMSDS For CERAMIC MOULDKukira KopiNo ratings yet

- As 010579709Document13 pagesAs 010579709jeanada phillipsNo ratings yet

- MSDS IMG GarnetDocument5 pagesMSDS IMG GarnetWirdaniati EmiliaNo ratings yet

- UHT PrimerDocument8 pagesUHT Primerfumakiller_23No ratings yet

- Themax N1 - TDS Issue A0Document5 pagesThemax N1 - TDS Issue A0Saif KhanNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingDocument5 pagesSafety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingclaudiomctNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetfaridkhanNo ratings yet

- VCPL SDS - Ee133Document7 pagesVCPL SDS - Ee133Dhia GhoniyyahNo ratings yet

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureDocument4 pagesTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanNo ratings yet

- System 3000 BrochureDocument3 pagesSystem 3000 BrochureEdwin HarrisNo ratings yet

- Hood Duct and Stack Design PDFDocument59 pagesHood Duct and Stack Design PDFSanth RaulNo ratings yet

- Space Out-V E Out-HDocument4 pagesSpace Out-V E Out-HhanamanNo ratings yet

- Manual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateDocument5 pagesManual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateMohamed IbrahimNo ratings yet

- Asme Section Viii Div-1,2,3Document73 pagesAsme Section Viii Div-1,2,3me2437090% (39)

- Wet Etching BasicsDocument48 pagesWet Etching BasicsWinston WinNo ratings yet

- Recent Progress On Long Service Life Design of Chinese Blast Furnace HearthDocument11 pagesRecent Progress On Long Service Life Design of Chinese Blast Furnace HearthSaumit PalNo ratings yet

- Reducerea FrecariiDocument82 pagesReducerea FrecariiDragomir IsabellaNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideMvomoNo ratings yet

- Medium Density Fiberboard (MDF)Document20 pagesMedium Density Fiberboard (MDF)anon_414184376No ratings yet

- Ipc-Tm-650 2.4.24.1Document2 pagesIpc-Tm-650 2.4.24.1RaduNo ratings yet

- TC-NVL - Infracem - Opc WK-19-2023-7DDocument1 pageTC-NVL - Infracem - Opc WK-19-2023-7DSirajul IslamNo ratings yet

- 120 GF1 RecessedDocument2 pages120 GF1 RecessedJohn FernandesNo ratings yet

- Peng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesDocument7 pagesPeng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesgeorgenzNo ratings yet

- AE 2304 Propulsion II 2 Marks PDFDocument13 pagesAE 2304 Propulsion II 2 Marks PDFvaskaneNo ratings yet

- 8-Hydraulic and Pnuematic Power SystemsDocument26 pages8-Hydraulic and Pnuematic Power SystemsjestyNo ratings yet

- Astm 638MDocument12 pagesAstm 638Mjose diazNo ratings yet

- Industrial Steam Turbines PDFDocument56 pagesIndustrial Steam Turbines PDFmember1000No ratings yet

- Vascomill MMS FA 2 EsiteDocument1 pageVascomill MMS FA 2 EsiteDaniel ReyesNo ratings yet

- PGM-PTM2 Material Data Safety SheetDocument1 pagePGM-PTM2 Material Data Safety SheetDamien OlverNo ratings yet

- Hydraulic System (B 60)Document21 pagesHydraulic System (B 60)Gaurav SinghNo ratings yet

- 14 WosDocument6 pages14 WosATUL KURZEKARNo ratings yet

- THASOS. Service ManualDocument14 pagesTHASOS. Service ManualCosmin MihoreanuNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- Piping 2Document7 pagesPiping 2Jeffrey SsalonNo ratings yet

- 6.hydraulic Machinery TurbinesDocument17 pages6.hydraulic Machinery TurbinesHitesh GahlawatNo ratings yet

- Lesson 5 Packed Tower ScrubbersDocument20 pagesLesson 5 Packed Tower ScrubbersinsomniaticstatNo ratings yet

- Determination of Boiling Point of Organic CompoundsDocument28 pagesDetermination of Boiling Point of Organic CompoundsDotsha Raheem83% (6)