Professional Documents

Culture Documents

Frru004 Dcm4 en

Uploaded by

Maurice Iam IlhamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frru004 Dcm4 en

Uploaded by

Maurice Iam IlhamCopyright:

Available Formats

Multicrest

TM

fire alarm system

FRRU004-DCM4

DUAL CONTACT MODULE

Features

• One simple LED for status indication

• NFPA Class A (Styles 6 & 7) and Class B (Style 4) for SLC

• NFPA Class A (Style D) and Class B (Style B) for IDC

• Electronic address setting

• Downsized unit

• Easy installation

Description

The Dual Contact Module (FRRU004-DCM4) is used to supervise multiple contact points with unique addresses from a single device. The

FRRU004-DCM4 may be configured to monitor a normally open or normally closed contact. In addition, the FRRU004-DCM4 may be configured

as a single contact utilizing Class A wiring methods. In case of one contact supervising, wiring shall comply with the Class A (Style D) wiring. In

case of two contacts supervising, wiring shall comply with the Class B (Style B) wiring.

The FRRU004-DCM4 is fully supervised if wired in accordance with the wiring diagrams on next page.

FRRU004-DCM4 employs one red LED to indicate the status. In normal condition, the LED flashes. When the contact is activated, the LED will

turn on constantly. In case of trouble, the LED will turn off. In case of two contacts supervising, if the conditions of two contacts are different each

other, the LED shall activate with higher priority condition. The highest priority of contact condition is activated condition of contact, the middle

priority is open circuit, and the lowest priority is normal condition.

Ordering Information

Model no. FRRU004-DCM4

Specifications

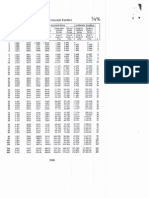

Specification

No. Item

In case of one contact supervising In case of two contacts supervising

1 Rated voltage range of SLC input power (S+,S-) 22.0 to 24.0V

2 Maximum SLC 24 VDC standby current (S+,S-) 250µA

3 Maximum SLC 24 VDC alarm current (S+,S-) 1mA

4 IDC input circuit wiring style NFPA Class A (Style D) NFPA Class B (Style B)

5 End-of-line resistor for IDC N/A 5.1kΩ, 1/2W

6 Maximum wiring resistance of IDC 100Ω

7 Maximum wiring capacitance of IDC 1µF

8 Operating temperature range 0°C to 49°C (32°F to 120°F)

9 Operating humidity range 0 to 93% (non-condensing)

10 Address per module 1 Address 2 Addresses

11 Dimensions 106mm (4.17 inches) (H) × 106mm (4.17 inches) (W) × 29mm (1.14 inch) (D)

North American 64mm (2-1/2 inches) deep 2-gang box

12 Applicable electrical box for installation

Standard 4 inches square box 38mm (1-1/2 inch) deep box

Setting the Address

Each addressable module, smoke detector, heat detector and combination detector must have the address set prior connecting the device to the

Signaling Line Circuit (SLC) loop. The address is set using the hand held device programmer.

A dedicated address number is configured per FRRU004-DCM4 module prior to connecting the module to SLC loop. When FRRU004-DCM4 is

used as two contacts supervising, two addresses are assigned. When the first address number is assigned by address setting unit, the second

address number shall be assigned automatically with adding one (1) to first address number. For example, if the first address number is assigned

as “n”, the second address number shall be assigned as “n+1” automatically.

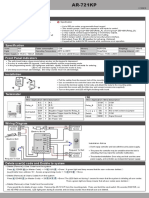

Installation

Figure 1: Installation into the compatible electrical box

Wiring Diagram

Figure 2: Wiring diagram in case of one contact supervising

From FACP or

previous module C1

SLC Loop NO1

To the next S+ Z1

module S- C2

JP1 NO2

LED Z2

Select Style D

Note: End-of-line resister is not required.

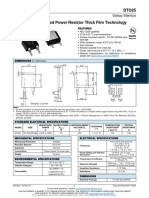

Figure 3: Wiring diagram in case of two contacts supervising (Normally-open contact)

From FACP or

previous module C1

SLC Loop NO1

End of line resistor

To the next S+ Z1

5.1k ohm 1/2W

module S- C2

JP1 NO2

LED Z2

Select Style B

End of line resistor

5.1k ohm 1/2W

Figure 4: Wiring diagram in case of two contacts supervising (Normally-closed contact) (Not recognized as NFPA Initiating Device Circuit)

Only one normally-closed contact

From FACP or

previous module C1 Note: End-of-line resister is not

SLC Loop NO1 required.

To the next S

Z1

module +

S- C2

NO2 Only one normally-closed contact

JP1

LED Z2

Note: End-of-line resister is not

Select Style B required.

NOTE

・The information contained herein does not purport to cover all the details or variations of the equipment described, nor to provide for every

possible contingency that may be met in connection with its installation, operation or maintenance.

・Specifications are subject to change without notice. Contact Nohmi before relying on the information.

・Actual performance is based on proper application of the product by a qualified professional.

・Should further information be required or should particular concerns arise that are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to Nohmi or your nearest distributor.

Contact

• Head Office: 4-7-3 Kudan-Minami, Chiyoda-ku, Tokyo

102-8277, Japan

• Phone: (81) 3 - 3265 - 0231

• F A X: (81) 3 - 3265 - 5348

URL http://www.nohmi.co.jp/english/

Catalog Number 131020Ⓓ-F-16001

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- 9 Electricity Test - CircuitsDocument5 pages9 Electricity Test - CircuitsRahmonGreenNo ratings yet

- HHO Pulse Charger 2.0 InfoDocument4 pagesHHO Pulse Charger 2.0 InfoAleksa Nataša Rančić100% (1)

- Night SwitchDocument2 pagesNight Switchrhie capitis100% (1)

- T3D Ac Servo Driver 200VDocument36 pagesT3D Ac Servo Driver 200Vantonio lopez50% (2)

- Reverse Engineering a Discrete Component Switch-Mode Power SupplyDocument6 pagesReverse Engineering a Discrete Component Switch-Mode Power Supplysafet100% (2)

- Busbar Protection TheoryDocument13 pagesBusbar Protection TheoryDEADMANNo ratings yet

- FRRU004-SCM4 Single Contact ModuleDocument2 pagesFRRU004-SCM4 Single Contact ModuleAnung HaryantoNo ratings yet

- FRRU004-SCM4 Single Contact ModuleDocument2 pagesFRRU004-SCM4 Single Contact ModuleRedigo Travel & UtilityNo ratings yet

- Frru004 Mom4Document2 pagesFrru004 Mom4virtechNo ratings yet

- FRRU004-MCM Miniature Contact ModuleDocument2 pagesFRRU004-MCM Miniature Contact ModuleAnung HaryantoNo ratings yet

- TB-D5016 YOK-001: Characteristics: Technical DataDocument16 pagesTB-D5016 YOK-001: Characteristics: Technical DataJava ScriptNo ratings yet

- FRRU004-CIZM4 Conventional Initiating Zone ModuleDocument2 pagesFRRU004-CIZM4 Conventional Initiating Zone ModuleAnung HaryantoNo ratings yet

- Sky13374-397Lf: 300 KHZ To 6.0 GHZ SPDT Switch: ApplicationsDocument9 pagesSky13374-397Lf: 300 KHZ To 6.0 GHZ SPDT Switch: Applicationsriyanto_fisika5535No ratings yet

- DiversitySwitch WLAN SKY13377 313LF 201558EDocument9 pagesDiversitySwitch WLAN SKY13377 313LF 201558ErfidguysNo ratings yet

- Instruction & Safety Manual: SIL 3 Relay Output Module DIN-Rail Models D1092S-069, D1092D-069Document8 pagesInstruction & Safety Manual: SIL 3 Relay Output Module DIN-Rail Models D1092S-069, D1092D-069Luis Alfredo Ramos FernandezNo ratings yet

- Rele Omron PDFDocument12 pagesRele Omron PDFjavier gutierrez pizaNo ratings yet

- Attch-1G Digital Output Module F3334-EDocument2 pagesAttch-1G Digital Output Module F3334-EchochoroyNo ratings yet

- 721kp enDocument2 pages721kp enCristian GonzalezNo ratings yet

- D5098 Ism0305 enDocument6 pagesD5098 Ism0305 enayubNo ratings yet

- D5098 DTS0675 enDocument2 pagesD5098 DTS0675 enmbidNo ratings yet

- 4-Channel Input Module Evaluates Safety SignalsDocument6 pages4-Channel Input Module Evaluates Safety SignalsAndy Kong KingNo ratings yet

- Omron P2RF 08 E DatasheetDocument11 pagesOmron P2RF 08 E DatasheetAgus Itonk SuwardonoNo ratings yet

- DatasheetDocument21 pagesDatasheetKunal SononeNo ratings yet

- TB-D5016 YOK-002: Characteristics: Technical DataDocument14 pagesTB-D5016 YOK-002: Characteristics: Technical DataJava ScriptNo ratings yet

- Interface Modules: Catalogue 1 3 - 1 4Document68 pagesInterface Modules: Catalogue 1 3 - 1 4Prabhavathi RamasamyNo ratings yet

- MCLN1 Series: Product DescriptionDocument2 pagesMCLN1 Series: Product DescriptionAndrés MayorgaNo ratings yet

- GTL2010 10-Bit Bidirectional Low-Voltage Translator: FeaturesDocument19 pagesGTL2010 10-Bit Bidirectional Low-Voltage Translator: FeaturesMigue SolinasNo ratings yet

- General Purpose Relay - G2RS: Slim and Space-Saving Power Plug-In RelayDocument10 pagesGeneral Purpose Relay - G2RS: Slim and Space-Saving Power Plug-In Relaydiarjohn9979No ratings yet

- Tmdoc0404 EngDocument3 pagesTmdoc0404 EngBananyNo ratings yet

- Isolating Switching AmplifierDocument3 pagesIsolating Switching Amplifierzeropoint_romeoNo ratings yet

- Fire Frcma AiDocument2 pagesFire Frcma AiDenis RGNo ratings yet

- Frcma - Ai - 03-2014Document2 pagesFrcma - Ai - 03-2014Denis RGNo ratings yet

- FCM/1 & FRM/1 Series: Control and Relay ModulesDocument2 pagesFCM/1 & FRM/1 Series: Control and Relay Modulesbagadi binathaNo ratings yet

- SIL 3 Relay Output Module DIN-Rail Models D1092S, D1092D: Characteristics: Technical DataDocument3 pagesSIL 3 Relay Output Module DIN-Rail Models D1092S, D1092D: Characteristics: Technical DataMarvvvNo ratings yet

- The New-generation General-purpose Relay G2RSDocument12 pagesThe New-generation General-purpose Relay G2RSJulius Aldana BeltranNo ratings yet

- OMRON MK3P Relay-1Document13 pagesOMRON MK3P Relay-1Antonio TancevNo ratings yet

- Switch Amplifier Technical SpecificationsDocument5 pagesSwitch Amplifier Technical Specificationsmuhammad mustajabNo ratings yet

- ADR823En112 PDFDocument7 pagesADR823En112 PDFJoseph BoshehNo ratings yet

- AL9910/ AL9910A/ AL9910-5/ AL9910A-5: Universal High Voltage High Brightness Led DriverDocument15 pagesAL9910/ AL9910A/ AL9910-5/ AL9910A-5: Universal High Voltage High Brightness Led DrivernareshNo ratings yet

- End Term Bridge Type Power Supply DesignDocument2 pagesEnd Term Bridge Type Power Supply DesigndolarmarizninaNo ratings yet

- SR33 ManualDocument4 pagesSR33 ManualВалентин МазаевNo ratings yet

- D5091S-103 SIL3 Relay ModuleDocument5 pagesD5091S-103 SIL3 Relay ModuledesmauroNo ratings yet

- 03 Dahari - RCD - VD March 2019Document22 pages03 Dahari - RCD - VD March 2019Rodney TanNo ratings yet

- Xw2rseriesxw2series G129-E1 2 3 Csm1058356Document21 pagesXw2rseriesxw2series G129-E1 2 3 Csm1058356Cabe IsaiasNo ratings yet

- DC Voltage Input Digital Panel Meter: 1 Before Using The Unit 3 Terminals and ConnectionsDocument10 pagesDC Voltage Input Digital Panel Meter: 1 Before Using The Unit 3 Terminals and ConnectionsAgustantoNo ratings yet

- ERM01Document3 pagesERM01api-3749499No ratings yet

- ULLD For Nohmi - Brand - (TN51483e - Rev.0)Document33 pagesULLD For Nohmi - Brand - (TN51483e - Rev.0)vu thien100% (1)

- Dcp-Frcme-M Module Giam Sat Ngo VaoDocument2 pagesDcp-Frcme-M Module Giam Sat Ngo VaoNguyễn Văn LongNo ratings yet

- Attch-1E Digital Input Module F3237-EDocument2 pagesAttch-1E Digital Input Module F3237-EchochoroyNo ratings yet

- TX-D Relays: FeaturesDocument7 pagesTX-D Relays: FeaturesVld ThreedeeNo ratings yet

- Features: Twin Relay ModuleDocument2 pagesFeatures: Twin Relay ModuleHaroldo RamosNo ratings yet

- TPS5125Document21 pagesTPS5125Shaun Dwyer Van HeerdenNo ratings yet

- Overview Data Sheets: F 3222: 8 Fold Input ModuleDocument2 pagesOverview Data Sheets: F 3222: 8 Fold Input ModulemohamadziNo ratings yet

- g2r1 PDFDocument21 pagesg2r1 PDFg1763970No ratings yet

- JVC LT-32DR9BJ LT-32DR9BU Chassis FT4 Televisor LCDDocument19 pagesJVC LT-32DR9BJ LT-32DR9BU Chassis FT4 Televisor LCDElectronica MeizaNo ratings yet

- Small Terminal Board User's GuideDocument12 pagesSmall Terminal Board User's GuideQwertyNo ratings yet

- Conveyor PeripheralDocument8 pagesConveyor PeripheralKandang DownloadNo ratings yet

- Module DI ModbusDocument8 pagesModule DI ModbusfakhriNo ratings yet

- Ficha Tecnica DCDU-12BDocument7 pagesFicha Tecnica DCDU-12BRicardo Bazan CNo ratings yet

- 16-Channel Analogue Input Termination Card: Triguard SC300E Tai16AirDocument11 pages16-Channel Analogue Input Termination Card: Triguard SC300E Tai16AirSanthosh Paul FernandesNo ratings yet

- Mil Ldcbs1x2 DsDocument5 pagesMil Ldcbs1x2 DsnliviusNo ratings yet

- NCP431A, SC431A, NCP431B, NCP432B Series Programmable Precision ReferencesDocument17 pagesNCP431A, SC431A, NCP431B, NCP432B Series Programmable Precision ReferencesPedro OrtegaNo ratings yet

- FS 8705 21 Integlex FACP1Document58 pagesFS 8705 21 Integlex FACP1Maurice Iam IlhamNo ratings yet

- Frru004 Dcm4 enDocument2 pagesFrru004 Dcm4 enMaurice Iam IlhamNo ratings yet

- Frru004 Trm4 enDocument2 pagesFrru004 Trm4 enMaurice Iam IlhamNo ratings yet

- Frru004 Cizm4 enDocument2 pagesFrru004 Cizm4 enMaurice Iam IlhamNo ratings yet

- 2006 Plumbing CodeDocument316 pages2006 Plumbing CodecromaazNo ratings yet

- Guidance for commissioning and maintaining new plumbing systemsDocument2 pagesGuidance for commissioning and maintaining new plumbing systemsdilimgeNo ratings yet

- Standard Plumbing Engineering DesignDocument214 pagesStandard Plumbing Engineering Designdimaomar67% (3)

- Nomer TelephoneDocument2 pagesNomer TelephoneMaurice Iam IlhamNo ratings yet

- Compound Interest Table (Odd Page) PDFDocument16 pagesCompound Interest Table (Odd Page) PDFMaurice Iam IlhamNo ratings yet

- Compound Interest Table (Even Page) PDFDocument16 pagesCompound Interest Table (Even Page) PDFMaurice Iam IlhamNo ratings yet

- Design Guide For The Control of ESD in The eSATA InterfaceDocument10 pagesDesign Guide For The Control of ESD in The eSATA InterfaceNilesh NarkhedeNo ratings yet

- Control Panel Active Faults MenuDocument2 pagesControl Panel Active Faults Menuxargle100% (2)

- Tips for Teachers: Circuit Construction KitDocument3 pagesTips for Teachers: Circuit Construction KitDannisa aaNo ratings yet

- Boozhound Laboratories JFETPhono PreampDocument3 pagesBoozhound Laboratories JFETPhono Preampvali29No ratings yet

- Vishay Sfernice: FeaturesDocument6 pagesVishay Sfernice: Featuresاياد النعيميNo ratings yet

- Iot For Engineers Ece3501 Digital Assignment-1: L.Anirudh 18bec0559Document28 pagesIot For Engineers Ece3501 Digital Assignment-1: L.Anirudh 18bec0559anirudh lakshminarasimhanNo ratings yet

- Unit2l1s PDFDocument20 pagesUnit2l1s PDFJack CardiagNo ratings yet

- s1000 Voltage RegulatorDocument36 pagess1000 Voltage RegulatorAnonymous 7PtTlrNo ratings yet

- Scan Sep 15, 2019 PDFDocument12 pagesScan Sep 15, 2019 PDFAshish SonkarNo ratings yet

- Electronics-Q2 M5Document27 pagesElectronics-Q2 M5Radleigh Vesarius RiegoNo ratings yet

- Pope 1984Document9 pagesPope 1984pedroNo ratings yet

- Unit 1 - Fire Engineering Science: IFE Level 4 Certificate in Fire Science and Fire SafetyDocument8 pagesUnit 1 - Fire Engineering Science: IFE Level 4 Certificate in Fire Science and Fire SafetyTom MoranNo ratings yet

- Cell Phone Battery Flashlight DIY: Build a Bright LED Light Using Old Phone BatteriesDocument6 pagesCell Phone Battery Flashlight DIY: Build a Bright LED Light Using Old Phone Batteriesnita_alecsandruNo ratings yet

- Cabin Fan Controller ManualDocument18 pagesCabin Fan Controller ManualJohn DosherNo ratings yet

- US5881 Datasheet MelexisDocument11 pagesUS5881 Datasheet MelexisKukinjosNo ratings yet

- LCD TV: Service ManualDocument41 pagesLCD TV: Service ManualbjesodragNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument8 pagesCambridge International Advanced Subsidiary and Advanced LevelHafsah JoomunNo ratings yet

- Pull Up ResistorsDocument12 pagesPull Up ResistorsMohammadMoizNo ratings yet

- Micro-Speed: Operation ManualDocument44 pagesMicro-Speed: Operation Manualelectricidad industrialNo ratings yet

- Mazda Protege 5 Control SystemDocument14 pagesMazda Protege 5 Control SystemJGAR2009No ratings yet

- HCS08 Peripheral Module Quick Reference: Users GuideDocument116 pagesHCS08 Peripheral Module Quick Reference: Users GuideDaniel KarasaniNo ratings yet

- Manual Sony - kdl-32bx320 - 321 - 420 - 421 - 40-46bx420 - 421 - Chassis - Az2-UkDocument35 pagesManual Sony - kdl-32bx320 - 321 - 420 - 421 - 40-46bx420 - 421 - Chassis - Az2-UkGerardo Espinosa EspinosaNo ratings yet

- Simple Circuit Resistance CalculationsDocument50 pagesSimple Circuit Resistance CalculationsSabrine SannakyNo ratings yet

- Electronics For ArtistsDocument35 pagesElectronics For Artistsdb5fx100% (1)

- XP95A - Mini Switch Monitor ModuleDocument2 pagesXP95A - Mini Switch Monitor ModuleguilhermegomNo ratings yet

- AURORA-J-IMAC User ManualDocument71 pagesAURORA-J-IMAC User ManualCodigo Arduino CaliNo ratings yet

- Install electronic instruments on Sonex aircraftDocument4 pagesInstall electronic instruments on Sonex aircraftviorelu99No ratings yet