Professional Documents

Culture Documents

Seeflex 040E: Product Spec Sheet

Uploaded by

DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seeflex 040E: Product Spec Sheet

Uploaded by

DanielCopyright:

Available Formats

| PRODUCT SPEC SHEET

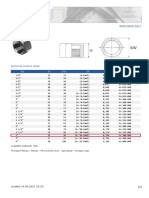

Seeflex 040E

• Used on all types of stationary, vibratory and PHYSICAL PROPERTIES:

gyratory sifters, screeners, feeders, bin discharges,

Surface Finish Gloss/Gloss

hoppers, conveyors, packing equipment or any

product handling equipment. Hardness (Shore A) 90

Wall Thickness (+/- 10%) 0.9 mm / 1/32 inch

• Seeflex 040E is a clear ether based thermoplastic

polyurethane alloy. Having no memory Seeflex Tensile Strength (MPa) 40

040E will not fracture as a result of constant -25 to 110˚C

Operating Temp Range

flexing. -13 to 230˚F

Max. Surge Temp 120˚C / 248˚F

• Superior chemical resistance for CIP and washing.

Low Temp Flexibility Good

• Excellent abrasion resistance.

Max. Operating Pressure

0.34 bar / 5.0 PSI

(for temp. to 90˚C / 195˚F)*

• Smooth welded seam.

Ultimate Elongation (%) 593

Tear Strength – Die C (N) 67

Surface Resistivity (0hms)

1010

(Tested to ASTM D-257)

100% Modulus (Mpa) 8.0

100%

300% Modulus (Mpa) 15.6

VIBRATION OSCILLATION COMPRESSION DUST TIGHT FOOD SAFETY ATEX Air Permeability 0

AVAILABLE SIZES: (In 50mm (2”) increments)

Diameter Ø100mm - 1,650mm

(also available in 125mm/5”) (Ø4” - 65“)

80mm, 100mm - 6,000mm

Length

(3”, 4” to 19ft 8”)

(Size range is in mm, so inch conversions are approximate only. Restrictions

apply for larger diameters, or when anti-collapse rings or TR versions used.

Refer to ‘Connector Sizes’ for more information.)

*We recommend using the shortest possible connector for

applications where increased pressure and/or high temperature

is expected. Please contact us for more information.

COMPLIANCE:

Atex Compliant: IBExU tested. Can be used in all

dust explosion hazardous areas (restrictions apply).

Complies with the following regulations:

FDA 21 CFR 177.1680 & 177.2600, USDA & 3A (20-),

(EC) 1935/2004, 2023–2006 & 10/2011

BFM® GLOBAL LTD. | EMAIL: sales@BFMfitting.com | WEB: BFMfitting.com PRODUCT SPEC SHEET- SEEFLEX 040E

V7 OCT 2021 PAGE 1 OF 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TB Unit3progresscheckfrq 5dc331c19f6919Document3 pagesTB Unit3progresscheckfrq 5dc331c19f6919api-486324042No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Zylinder en 20190424 142147 94 CompleteDocument5 pagesZylinder en 20190424 142147 94 CompleteDanielNo ratings yet

- Prompter - Visual NotebookDocument4 pagesPrompter - Visual NotebookDanielNo ratings yet

- Gasket (1: 2) : Flange Dimensions TableDocument1 pageGasket (1: 2) : Flange Dimensions TableDanielNo ratings yet

- Facts Type 455 - 456Document9 pagesFacts Type 455 - 456DanielNo ratings yet

- Spigot Product Spec Sheet 1635890080Document1 pageSpigot Product Spec Sheet 1635890080DanielNo ratings yet

- ZA6VSD RysDocument1 pageZA6VSD RysDanielNo ratings yet

- Fig. 97 Check Valve: FeaturesDocument2 pagesFig. 97 Check Valve: FeaturesDanielNo ratings yet

- Fig. 7444 PDFDocument2 pagesFig. 7444 PDFDanielNo ratings yet

- Heco Product Sheet 76 Stainless Steel Fittings PN 10 ECO Line Caps Plugs Hexagon CapsDocument2 pagesHeco Product Sheet 76 Stainless Steel Fittings PN 10 ECO Line Caps Plugs Hexagon CapsDanielNo ratings yet

- Rubber Buffers / Cellular Buffers Program 0170 / 0180Document32 pagesRubber Buffers / Cellular Buffers Program 0170 / 0180DanielNo ratings yet

- Fig. 3460 Ball Valve: ApplicationDocument2 pagesFig. 3460 Ball Valve: ApplicationDanielNo ratings yet

- Fig. 7289 ® Ball Valve: FeaturesDocument2 pagesFig. 7289 ® Ball Valve: FeaturesDanielNo ratings yet

- Fig. 3257 Check Valve: FeaturesDocument1 pageFig. 3257 Check Valve: FeaturesDanielNo ratings yet

- Facts 431, 433Document12 pagesFacts 431, 433DanielNo ratings yet

- Engineering: GREAT SolutionsDocument10 pagesEngineering: GREAT SolutionsDanielNo ratings yet

- Engineering: GREAT SolutionsDocument12 pagesEngineering: GREAT SolutionsDanielNo ratings yet

- Noris: StrainerDocument1 pageNoris: StrainerDanielNo ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service ApplicationsDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service ApplicationsDanielNo ratings yet

- BKH-F Flange Ball Valve Steel: Available Sizes ConnectionsDocument2 pagesBKH-F Flange Ball Valve Steel: Available Sizes ConnectionsDanielNo ratings yet

- BKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsDocument4 pagesBKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsDanielNo ratings yet

- Almatec E-Series 2016Document36 pagesAlmatec E-Series 2016DanielNo ratings yet

- Mankenberg dm618 enDocument3 pagesMankenberg dm618 enDanielNo ratings yet

- RK 86, 86A For Sandwiching Between Flanges PN 10/16/25/40, DN 15-200 ASME Class 125/150/300, NPS 1/2-8Document2 pagesRK 86, 86A For Sandwiching Between Flanges PN 10/16/25/40, DN 15-200 ASME Class 125/150/300, NPS 1/2-8DanielNo ratings yet

- Manual 10.3-1 PDFDocument138 pagesManual 10.3-1 PDFDanielNo ratings yet

- FLEXELEC English Complet PDFDocument99 pagesFLEXELEC English Complet PDFDaniel100% (1)

- Plastic Material Selection GuideDocument7 pagesPlastic Material Selection GuideThanachai TengjirathanapaNo ratings yet

- MOM Chapter 10 New-EditedDocument52 pagesMOM Chapter 10 New-EditedezoramajnunNo ratings yet

- Fundamentals of Energy Conversion P1 PDFDocument260 pagesFundamentals of Energy Conversion P1 PDFSienna SabadoNo ratings yet

- Lec 6 Technology of OperativeDocument8 pagesLec 6 Technology of OperativeHassan TantawyNo ratings yet

- 1411270731thermodynamics2014 PDFDocument29 pages1411270731thermodynamics2014 PDFPrinal KumatNo ratings yet

- Steam TableDocument10 pagesSteam TableLeo GMNo ratings yet

- GME Sample Questions - Fleet ManagementDocument4 pagesGME Sample Questions - Fleet ManagementRichardson Panavelil57% (7)

- Le Chatelier's PrincipleDocument15 pagesLe Chatelier's PrincipleAldrick VeranoNo ratings yet

- PHY3201Document3 pagesPHY3201Ting Woei LuenNo ratings yet

- SinteringDocument2 pagesSinteringEfvan Adhe Putra PradanaNo ratings yet

- Applied Physics Essays 22-23Document5 pagesApplied Physics Essays 22-23Aaron GurramNo ratings yet

- TUGAS LAPORAN KIMED 3 MARET 2020 AnfaqDocument8 pagesTUGAS LAPORAN KIMED 3 MARET 2020 AnfaqMelati Ihza Safara PermataNo ratings yet

- Orifice Plate CalculationDocument10 pagesOrifice Plate CalculationkswaghmareNo ratings yet

- 33KV Rigid Bus SupportDocument6 pages33KV Rigid Bus SupportNNANYELU CHINWUBANo ratings yet

- Residual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenDocument14 pagesResidual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Design and Analysis of Thick Walled Cylinders With HolesDocument47 pagesDesign and Analysis of Thick Walled Cylinders With HolesKeryn Pelled-FeldmanNo ratings yet

- Termokimia (Pertemuan 6)Document39 pagesTermokimia (Pertemuan 6)indah phebeNo ratings yet

- Ciclo BraytonDocument17 pagesCiclo BraytonNubia Bergamini100% (2)

- Ttgn5 4 Bostraben App4Document8 pagesTtgn5 4 Bostraben App4javierNo ratings yet

- Concentric Tube Heat ExchangerDocument10 pagesConcentric Tube Heat Exchangeramirhazwan93% (14)

- Broom WadeDocument20 pagesBroom WadeRamon SanhuezaNo ratings yet

- MT Steiner2010Document10 pagesMT Steiner2010Biraj SahooNo ratings yet

- Toolbox-Test 1 (Literacy, MeasureOptics) - 2019Document6 pagesToolbox-Test 1 (Literacy, MeasureOptics) - 2019mwelasethandolwethu53No ratings yet

- Example From Theory To Caesar IIDocument12 pagesExample From Theory To Caesar IITon Phichit100% (7)

- 04 - Sundaramoorthy - LAB - RLADocument56 pages04 - Sundaramoorthy - LAB - RLADSGNo ratings yet

- CE 370-Lecture-6 (Flexural Behavior of RC Beams - Cracked Stage) (Read-Only)Document13 pagesCE 370-Lecture-6 (Flexural Behavior of RC Beams - Cracked Stage) (Read-Only)Jamal RkhNo ratings yet

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Tabulated Values of Shockley-Queisser Limit For Single Junction Solar CellsDocument9 pagesTabulated Values of Shockley-Queisser Limit For Single Junction Solar CellsSachin DesaradaNo ratings yet