Professional Documents

Culture Documents

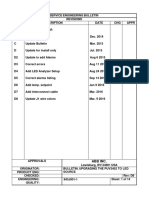

Installation: Edition: 33-2

Uploaded by

nguyen minhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation: Edition: 33-2

Uploaded by

nguyen minhCopyright:

Available Formats

Edition: 33-2

Chapter 7 Installation

7.1 Introduction .....................................................................................................................................1

7.2 Check before Installation ................................................................................................................1

7.2.1 Provided parts check list .........................................................................................................1

7.2.2 Instrument provided parts check list .......................................................................................1

7.3 Installation Space ...........................................................................................................................2

7.4 Remove Shipping Clamps ..............................................................................................................3

7.5 Remove Shipping Fixtures..............................................................................................................5

7.6 Attach Trap Chamber .....................................................................................................................6

7.7 Connect Rinse Bottle and Waste Bottle..........................................................................................7

7.8 Connect Power Cord and Connection Cord ...................................................................................8

7.9 Set Trash Box .................................................................................................................................9

7.10 Set Filters......................................................................................................................................9

7.11 Set Reagent Rack and Reaction Tube Rack ................................................................................9

7.12 Change language and insert program card ................................................................................10

7.13 ID Barcode Reader Installation...................................................................................................13

7.13.1 Application ..........................................................................................................................13

7.13.2 Preparation .........................................................................................................................13

7.13.2.1 Prepare KIT NO.190 (P/N: CS073970), additional item, and tool...............................13

7.13.2.2 Prepare the JIG for adjusting barcode position...........................................................14

7.13.3 Installation...........................................................................................................................14

7.13.4 Settings...............................................................................................................................17

7.13.5 ID barcode reader position adjustment ...............................................................................18

7.13.6 Checking .............................................................................................................................20

7.14 Hand-held Barcode Reader Installation......................................................................................22

7.14.1 Application ..........................................................................................................................22

7.14.2 Preparation .........................................................................................................................22

7.14.3 Installation...........................................................................................................................22

7.14.3.1 Installation procedure for the connecting cable(CBL-020-300-C00-SX1)...................22

7.14.3.2 Initialization of the Hand-held Barcode Reader ..........................................................23

7.14.3.3 Confirming if the Hand-held Barcode Reader is connected........................................24

CA-600 Series S/M Revised March 9, 2012

Chapter 7 Installation

7.1 Introduction

This product is a clinical test instrument. A representative is responsible for unpacking, installing, and

initial setup to ensure its proper and safe operation. This chapter will give some essential information for

installation of this instrument.

7.2 Check before Installation

Make sure that the instrument is free from external flaws and check the quantity of the provided parts.

7.2.1 Provided parts check list

Part No. Description Quantity

BD335959 Program Card 1

BK938255 Instruction For Use CA-600 Series 1

265-7151-8 Power Code (N.America) 1

073-2752-0 Sample Rack (White) 1

241-9223-6 Ferrite Core 1

AU071498 Instruction For Using Ferrite Core 1

BX177453 Label No.966 (Reagent Indication Mark) 1

7.2.2 Instrument provided parts check list

Quantity

Part No. Description

CA-620 CA-660

AS244534 Filter No.598 2 2

043-3581-4 Trap Chamber Complete 1 1

663-7175-7 Screw w/Knob TL-233-3 1 1

BP577416 Rinse Bottle Assy (5L) 1 1

AS977096 Waste Bottle Assy (5L) 1 1

AJ387179 Reagent Rack Assy 1 1

AJ046225 Reaction Tube Trash Box 1 1

668-6827-9 Reaction Tube Rack 2 4

363-2558-6 Holder No.89 (Sample Cup Adapter of Reagent Rack) 2 2

663-5117-3 Sample Tube Spacer 13 Phi 1 1

541-1352-1 Push Vial PV-10 2 2

013-1771-4 SLD Vial Assy (10/Pack) 1 1

424-1160-8 Sample Cup Conical (4mL) 1 1

541-0541-8 Reaction Tube 60 60

663-9184-8 Paper Thermal F1-2 2 2

BC963426 Fuse 250V 4.0A 2 2

CA-600 Series S/M 7-1 Revised March 9, 2012

7.3 Installation Space

To ensure optional instrument performance properly, install it at an appropriate location.

● Select a place where the power supply is located close.

● Be sure to use the supplied bottles to collect rinse solution and waste.

● Keep a space for maintenance and service. Giving consideration to heat radiation by the instrument,

provide at least 50 cm distance from the wall to sides, rear, and top panels.

The dimensions of the instrument are shown below. The power cord is 2.5 m long.

Width (mm) Depth (mm) Height (mm) Weight (kg)

Main unit 566 490 490 Approx. 42

Caution!

Be sure to place the rinse bottle and waste bottle on the base on which the instrument is

set. Do not place them on the instrument. They may cause the instrument to break down

or to fail to produce correct results.

CA-600 Series S/M 7-2 Revised March 9, 2012

7.4 Remove Shipping Clamps

Remove the shipping clamps used on movable components of the instrument.

(1) Open the front cover of the main unit.

(2) Remove the X-Y mechanism fixing metals.

Two fixing metals are retained with screws as shown. Loosen the screws and remove the metals.

NOTE:

Unless the fixing metals are removed, the instrument cannot operate.

(3) Move the sample probe unit by hand to a place where it is easy to operate.

Remove the sample probe retainer.

NOTE:

Unless the retainer is removed, the instrument cannot operate.

CA-600 Series S/M 7-3 Revised March 9, 2012

(4) Raise the sample probe by hand to a place where it is easy to operate.

Remove the catcher retainer.

NOTE:

Unless the retainer is removed, the instrument cannot operate.

CA-600 Series S/M 7-4 Revised March 9, 2012

7.5 Remove Shipping Fixtures

(1) Pull out the sampler until the screw becomes visible.

(2) Unscrew the fixing screws (two areas).

(3) Pull out the bottom of the side cover.

(4) Lift up and remove the side cover.

(5) Remove the tape fixing the cushioning material.

(6) Remove the cushioning material (two areas).

(7) Attach the side cover in the reverse order of removal.

CA-600 Series S/M 7-5 Revised March 9, 2012

7.6 Attach Trap Chamber

(1) Attach the supplied trap chamber to the rear panel.

Connect the trap chamber tube (green) to the waste vacuum nipple (green) on the rear panel.

Caution!

When draining the trap chamber, always wear latex or non latex examination gloves.

After completion of work, wash hands with disinfectant. Handle all instrument parts as

biologically hazardous. There is a risk of infection with pathogens etc.

CA-600 Series S/M 7-6 Revised March 9, 2012

7.7 Connect Rinse Bottle and Waste Bottle

Connect the rinse bottle and the waste bottle to the nipples on the instrument rear panel.

(1) Connect Rinse Bottle.

● Connect the rinse bottle to the pressure supply nipple (black), and rinse aspiration nipple (blue)

on the rear panel, at places where the color matches with the bottle.

● Connect the level-detecting float switch to the float switch connector on the rear panel.

(2) Connect Waste Bottle.

●Connect the waste bottle tube (red) to the waste drain nipple (red) on the rear panel. Connect the

waste bottle tube (yellow) to the trap chamber nipple (yellow).

● Connect the level-detecting float switch to the float switch connector on the rear panel.

NOTE:

● Even at a facility equipped with the waste channel (drain system), the waste bottle

should be connected. Also, put the rinse bottle and the waste bottle at the same level

as the instrument.

Be sure not to use any other tube than the supplied one; otherwise, the instrument's

hydraulic system may fail to operate properly.

● Remove the rubber tube that locks the float switch in the rinse bottle and waste bottle.

This rubber tube serve to prevent vibration in transit.

CA-600 Series S/M 7-7 Revised March 9, 2012

7.8 Connect Power Cord and Connection Cord

(1) Connect the supplied power cord.

● Make sure the power switch is OFF, at “O”.

Caution!

Confirm the power switch is OFF, at “O” before routing the power cord. Make sure to

ground the AC outlet; otherwise, there is a hazard of electrical shock.

(2) Connect the cable to link with the host computer.

● Make sure the power switch is OFF, at “O”.

● Connect the connection cord to Host Computer Serial Connector on the right side panel and

tighten the screw to fix it.

NOTE:

Confirm the power switch is OFF, at “O”, before routing the connection cord; otherwise,

there is a hazard of electrical shock.

CA-600 Series S/M 7-8 Revised March 9, 2012

7.9 Set Trash Box

Set the supplied trash box.

7.10 Set Filters

Insert the filters NO. 598 (two pieces) all the way in until they hit the back wall, with the arrow mark face up.

Make sure to insert the filters in line with the bottom plate guides of the instrument.

7.11 Set Reagent Rack and Reaction Tube Rack

Set the supplied reagent rack and reaction tube rack. Affix Indication Mark (Label No. 966) on the

reagent rack.

CA-600 Series S/M 7-9 Revised March 9, 2012

7.12 Change language and insert program card

A 201146

(1) Remove a memory card cover attached under serial port on right side of the instrument.

(2) Change the DIP switch of PC NO.60020 (main board) that suits to your language by referring to

the table below.

Language DSW-1 DSW-2 DSW-3

Japanese OFF OFF OFF

English 1 ON OFF OFF

(general)

Germany OFF ON OFF

French ON ON OFF

Italian OFF OFF ON

Spanish ON OFF ON

English 2 OFF ON ON

(Britain)

(3) Bring out program card from supply parts, and insert it to PC NO.60020 (main board).

(4) Attach the memory card cover.

(5) After turning on the main power, select [Global] as following screen appears. (The screen below

is an example of "English 1")

CA-600 Series S/M 7-10 Revised March 9, 2012

NOTE:

For Siemens market, following screen appears. Select [OUS Setting] (Out of US

Setting) or [US Setting].

(6) As following screen appears, select [Set].

CA-600 Series S/M 7-11 Revised March 9, 2012

CA-600 Series S/M 7-12 Revised March 9, 2012

7.13 ID Barcode Reader Installation

7.13.1 Application

This procedure applies to Automated Blood Coagulation Analyzer CA-620 ID Barcode Reader installation

(option).

7.13.2 Preparation

7.13.2.1 Prepare KIT NO.190 (P/N: CS073970), additional item, and tool

KIT NO.190 includes the following parts.

No. Part No. Description Quantity

HOLDER_ASSY NO.158

1 CB510884 1

COVER NO.2291

2 CY381573 1

LABEL NO.1066

3 CY034966 1

4 BF745766 PROCEDURE NO.35 1

Additional item (Not included in the kit)

No. Item Specification Quantity

OD : 15mm

1 Sample Tube 1

HT : 75 - 78mm

Tools

No. Item Specification Quantity

Phillips head

1 #2 1

Screwdriver

Caution!

Use the sample tube of OD:15mm for accurate detection in the range of scanning.

The sample tube of less than OD:15mm may not perform accurate adjustment

because the width of scanning will be narrower.

CA-600 Series S/M 7-13 Revised March 9, 2012

7.13.2.2 Prepare the JIG for adjusting barcode position

Put LABEL NO.1066 on the Sample Tube as shown below.

7.13.3 Installation

Caution!

●Risk of Infection●

When handling the Sampler, always wear latex or non latex examination gloves. After

completion of work, wash hands with disinfectant.

Handle all instrument parts as biologically hazardous.

There is a risk of infection with pathogens etc.

(1) Turn the power off, open the Light Shield Cover, and pull out the Sampler.

(2) Remove 3 screws on the Sampler and remove COVER NO.2063.

* Do not drop these screws inside the Sampler, as they will be used later in this procedure.

CA-600 Series S/M 7-14 Revised March 9, 2012

COVER NO.2063(This part may be discarded.)

(3) Move the ID barcode reader installation part to the left side.

(4) Install HOLDER_ASSY NO.158 using 2 screws.

* The installation part may be tilted when installing the holder.

(5) Connect the wiring cord of HOLDER_ASSY NO.158 with the base.

* Be sure to insert the cord securely, holding the connector housing.

CA-600 Series S/M 7-15 Revised March 9, 2012

(6) Install COVER NO.2291 using 3 screws.

* The ID barcode reader can be moved by hand if necessary.

(7) Remove the protective sheet on HOLDER_ASSY NO.158.

(8) Push the Sampler in.

CA-600 Series S/M 7-16 Revised March 9, 2012

7.13.4 Settings

(1) Turn the power on

Press 'Special Menu' -> Press 'Settings' -> Press 'I/O Settings' -> Press 'Barcode Scanner'

(2) Set as follows:

Sample BCR: 'Connected'

Kind: Select 'NW-7' on 1, 2, 3, or 4.

Check Digit: 'Mod.11'

(3) Press 'Return'

(4) Press 'Fix'

(5) Press 'Return' -> 'Return'

CA-600 Series S/M 7-17 Revised March 9, 2012

7.13.5 ID barcode reader position adjustment

(1) Enter Adjustment screen as follows:

Press 'ID No. Entry' -> Enter 'C9-0' -> Press 'Enter' -> Press 'Quit' -> Press 'Special Menu'

-> Press 'Special Operate' -> Press 'Service' -> Press 'Adjust' -> Press 'BCR Pos. Adjustment'

(2) Set the JIG in STAT Sample Rack.

* Check that the entire barcode is shown in the rack opening.

(3) Close the Light Shield Cover.

(4) Press 'STAT Adjust' to execute automatic position adjustment.

CA-600 Series S/M 7-18 Revised March 9, 2012

(5) Confirm that eight or more of 'o' are displayed in Reading status.

(6) Open the Light Shield Cover.

(7) Set the JIG in the position #5 of Sample Rack.

* Check that the entire barcode is shown in the rack opening.

(8) Close the Light Shield Cover.

(9) Press 'Pos. 5 Adjust' to execute automatic position adjustment.

A: 201203

NOTE:

For CA-620 with program Ver.00-02 and before (For Siemens, Ver.00-22 and

before), "CPU Failure (4)" could occur when selecting “Pos.5 Adjust” in position

adjustment for ID barcode reader during installation, and instrument could lock-

up.

In such case, restart the instrument, and check the instrument performance by

referring to Service Manual "7.13.6 Checking".

CA-600 Series S/M 7-19 Revised March 9, 2012

(10) Confirm that eight or more of 'o' are displayed in Reading status.

->Press 'Return'

(11) Press 'FIX'

(12) Press 'Return' -> 'Return' -> 'Main Menu'

7.13.6 Checking

CA-600 Series S/M 7-20 Revised March 9, 2012

Perform tests to check the following:

● No abnormal sound is heard when the ID barcode reader unit is operating.

● No error is detected when reading barcode.

CA-600 Series S/M 7-21 Revised March 9, 2012

7.14 Hand-held Barcode Reader Installation

7.14.1 Application

This procedure applies to Automated Blood Coagulation Analyzer CA-600 series Handheld Barcode

Reader.

7.14.2 Preparation

Prepare KIT NO.191 (P/N: BV088995). It includes the following parts.

No. Part No. Description Quantity

1 BF705470 CBL-020-300-C00-SX1 1

2 AQ610747 PROCEDURE NO.36 1

In addition to the kit, prepare the following product.

No. Part No. Description Quantity

1 CT904571 1900GSR-1 HANDHELD BARCODE READER 1

7.14.3 Installation

7.14.3.1 Installation procedure for the connecting cable(CBL-020-300-C00-SX1)

Caution!

Turn the power off before installing this kit.

(1) Remove the cap of Hand-held Barcode Reader Connector on the COVER NO.1966.

CA-600 Series S/M 7-22 Revised March 9, 2012

(2) Connect the connecting cable [CBL-020-300-C00-SX1(Included in the Kit)] to the Hand-held

Barcode Reader/1900GSR-1 and the Hand-held Barcode Reader connector of Main Unit.

7.14.3.2 Initialization of the Hand-held Barcode Reader

(1) Turn the power of the Main Unit on.

NOTE:

A 'beep' will sound indicating that the power is supplied to the barcode reader and the

barcode reader is ready to use.

(2) Press 'Special Menu' → 'Settings' → 'I/O Settings' → 'Barcode Scanner'.

(3) Hand-held BCR is set to 'Connected'.

(4) Press 'Return' → 'Fix'

(5) Scan the following barcode with the connected Hand-held Barcode Reader to initialize the set-

ting to use it in CA-600.

(6) Confirm that the barcode is scanned and a "Beep"sound is heard.

CA-600 Series S/M 7-23 Revised March 9, 2012

7.14.3.3 Confirming if the Hand-held Barcode Reader is connected

(1) Press 'Standard Curve' → 'Lot No. Entry' → 'Ref.'.

(2) Confirm the "HB" character and Hand-held Barcode Reader icon is displayed on the upper part

of the screen.

(3) Scan the following barcode with the connected Hand-held Barcode Reader to check the settings

have been done correctly.

(4) Confirm that the barcode is scanned and a "Beep"sound is heard.

(5) Confirm that the scanned information is the same as the information displayed on the following

screen.

(6) Press 'Cancel' → 'Quit' → 'Return' → 'Cancel' → 'Main Menu' to return to the stand-by menu.

CA-600 Series S/M 7-24 Revised March 9, 2012

You might also like

- Appendix: B Installation: To CoverDocument20 pagesAppendix: B Installation: To CoverNGUYEN MEDICALNo ratings yet

- 3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFDocument14 pages3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFAris Bodhi RNo ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- Stryker AHTO Irrigation Pump User ManualDocument290 pagesStryker AHTO Irrigation Pump User ManualThor Jeancarlo Whinie PhooNo ratings yet

- BS-200 Chemistry Analyzer Preventive Maintenance Manual: Global Technical Support Department For Bio-ChemistryDocument18 pagesBS-200 Chemistry Analyzer Preventive Maintenance Manual: Global Technical Support Department For Bio-ChemistryaaaaaaaNo ratings yet

- Shimadzu Autosampler Service ManualDocument32 pagesShimadzu Autosampler Service ManualKhalid ZghearNo ratings yet

- Pioneer Deh-2330r, 2300RB, 2300RDocument63 pagesPioneer Deh-2330r, 2300RB, 2300REdinilson BrazNo ratings yet

- TV Samsung LN32b530 Service ManualDocument20 pagesTV Samsung LN32b530 Service ManualEduardo Maia CardosoNo ratings yet

- LN37B530P7F Chassis-N64C-Service-Manual PDFDocument131 pagesLN37B530P7F Chassis-N64C-Service-Manual PDFlaratoralNo ratings yet

- Color Video Sounder FCV-667/668 Installation ManualDocument29 pagesColor Video Sounder FCV-667/668 Installation ManualOdair Fernandes de BritoNo ratings yet

- Bs-300 Preventive Maintenance Manual v1-1.0 enDocument19 pagesBs-300 Preventive Maintenance Manual v1-1.0 ennery castro100% (1)

- MANUAL016Document8 pagesMANUAL016kim johnNo ratings yet

- Sbs500 ManDocument21 pagesSbs500 ManEfrain Parra QuispeNo ratings yet

- Service Manual: DEH-3400RDocument73 pagesService Manual: DEH-3400RДианка РусалкаNo ratings yet

- Task 53-10-00-252 16. Fuselage To Wing Attach Fitting Lugs Special Detailed InspectionDocument4 pagesTask 53-10-00-252 16. Fuselage To Wing Attach Fitting Lugs Special Detailed Inspectionworm_stellNo ratings yet

- VSX-609 709 RRV2274Document64 pagesVSX-609 709 RRV2274sollersNo ratings yet

- New BS-380 Preventive Maintenance ManualDocument23 pagesNew BS-380 Preventive Maintenance ManualBikram Thapa100% (1)

- R-W660ERU9-2 Refrigerator Service Manual Parts CatalogDocument24 pagesR-W660ERU9-2 Refrigerator Service Manual Parts CatalogYacine GrarageNo ratings yet

- BWH型 (英文) 取扱説明書 2021.5Document16 pagesBWH型 (英文) 取扱説明書 2021.5Raul Costiniuc100% (1)

- VK1001 Standard Response Upright Sprinkler Technical Data SheetDocument16 pagesVK1001 Standard Response Upright Sprinkler Technical Data SheetPepeng GantengNo ratings yet

- Digital Home TheaterDocument90 pagesDigital Home TheaterBaciu NicolaeNo ratings yet

- New BS-400 - Preventive Maintenance Manual - V1.0 - EN - ZSH-12010-New BS-400Document28 pagesNew BS-400 - Preventive Maintenance Manual - V1.0 - EN - ZSH-12010-New BS-400kiarashkia64No ratings yet

- Boss DD-7 Service NotesDocument24 pagesBoss DD-7 Service NotesFernando GómezNo ratings yet

- Service Manual: Land Cruiser PradoDocument52 pagesService Manual: Land Cruiser Pradocarlos Gutierrez De La HozNo ratings yet

- Service ManualDocument38 pagesService ManualekgujjuNo ratings yet

- Transmissometer: C-StarDocument18 pagesTransmissometer: C-StarPrashant PrashantNo ratings yet

- Brookfield Manual PDFDocument36 pagesBrookfield Manual PDFAnonymous T32l1RNo ratings yet

- Trolley TR-20 User ManualDocument17 pagesTrolley TR-20 User ManualСергей МакановNo ratings yet

- Manual SA-AKX76LM-K - AudioDocument111 pagesManual SA-AKX76LM-K - AudioPedroNo ratings yet

- Fuji Switching Power Supply GuideDocument36 pagesFuji Switching Power Supply GuidePeter86 PersoNo ratings yet

- Pioneer Avh-X7800bt Avh-X7850bt Avh-X7850tv crt5826 PDFDocument124 pagesPioneer Avh-X7800bt Avh-X7850bt Avh-X7850tv crt5826 PDFGiovanniNo ratings yet

- BBK9903S Service ManualDocument94 pagesBBK9903S Service ManualRudiLMNo ratings yet

- 3PH Loader Manual LabotekDocument31 pages3PH Loader Manual LabotekMudassir HashmiNo ratings yet

- Harman Kardon HKTS-2 Service ManualDocument21 pagesHarman Kardon HKTS-2 Service ManualAlejandro AlcubierreNo ratings yet

- Samsung UE65HU7500L Chassis U8GADocument68 pagesSamsung UE65HU7500L Chassis U8GALuiz Roberto Honório Alves FilhoNo ratings yet

- Pioneer - FH m8527, FH m8627Document85 pagesPioneer - FH m8527, FH m8627Анатолій Романович ШаповаловNo ratings yet

- Service Manual: Bbk920SDocument64 pagesService Manual: Bbk920SMrbar BarstoynNo ratings yet

- Manual de Servicio Pioneer 2700Document152 pagesManual de Servicio Pioneer 2700Carlos Alonso Gonzalez VazquesNo ratings yet

- Sel027 PDFDocument9 pagesSel027 PDFSmart BiomedicalNo ratings yet

- IBM P72 Service ManualDocument38 pagesIBM P72 Service ManualMisko1978No ratings yet

- Pinger DatasheetDocument17 pagesPinger Datasheetjose razoNo ratings yet

- 09040913362876Document81 pages09040913362876John AngenentNo ratings yet

- Con - Evator ManualDocument30 pagesCon - Evator ManualsitirNo ratings yet

- Service Bulletin: Dowty Aerospace PropellersDocument6 pagesService Bulletin: Dowty Aerospace PropellersoscarNo ratings yet

- Audiolab 8000S Service Manual PDFDocument36 pagesAudiolab 8000S Service Manual PDFMarcelo IpolitoNo ratings yet

- Super Duplex Stainless Steel Vic-Ball ValveDocument4 pagesSuper Duplex Stainless Steel Vic-Ball Valvemayukhguha88No ratings yet

- Mindray BC-760 and BC-780 series hematology analyzer installation reportDocument9 pagesMindray BC-760 and BC-780 series hematology analyzer installation reportAndi UkengNo ratings yet

- HPL 72.5-300B1 Spare PartsDocument29 pagesHPL 72.5-300B1 Spare PartsDoan Anh TuanNo ratings yet

- B154ew08 V1Document36 pagesB154ew08 V1Alfa alfaNo ratings yet

- JVC TK-C720U Schematics Service ManualDocument52 pagesJVC TK-C720U Schematics Service ManualAntonio CarlosNo ratings yet

- AS860 English ManualDocument10 pagesAS860 English ManualPmohamedFazilNo ratings yet

- KTM Actuator CatalogueDocument12 pagesKTM Actuator CatalogueRahimNo ratings yet

- Manual AsepticoAEU 707AV2 Rev D 1Document12 pagesManual AsepticoAEU 707AV2 Rev D 1DavidNo ratings yet

- TV - Samsung Cl21z50mq-Chassis - KSBH-P-CB1J PDFDocument53 pagesTV - Samsung Cl21z50mq-Chassis - KSBH-P-CB1J PDFserrano.flia.coNo ratings yet

- Service Manual: Compact Component SystemDocument45 pagesService Manual: Compact Component SystemHarveysolar3916No ratings yet

- Viskometer BrookfieldDocument31 pagesViskometer Brookfieldechie2008No ratings yet

- SN 74 CBTLV 3257Document31 pagesSN 74 CBTLV 3257sas999333No ratings yet

- rf_service_man._232w__new_2016Document33 pagesrf_service_man._232w__new_2016gbotha671No ratings yet

- Chapter 5 Marketing ResearchDocument42 pagesChapter 5 Marketing ResearchPatrickz John NatividadNo ratings yet

- Business Analysis - Food WarehousingDocument27 pagesBusiness Analysis - Food WarehousingsathishKumarNo ratings yet

- Maintenance 8.6.0.0Document33 pagesMaintenance 8.6.0.0RulasVenegasNo ratings yet

- 2015 Catalog 4400 ParkerDocument448 pages2015 Catalog 4400 ParkerJustin Duffy100% (1)

- Walmart SC DriversDocument3 pagesWalmart SC DriversUsman AsifNo ratings yet

- Rfid Based Security System With Password & Door MechanismDocument77 pagesRfid Based Security System With Password & Door MechanismVipul GargNo ratings yet

- DESIGN OF AN INTELLIGENT SHOPPING BASKET USING IoTDocument7 pagesDESIGN OF AN INTELLIGENT SHOPPING BASKET USING IoTArthur AguilarNo ratings yet

- Resume of Joejoe9063Document2 pagesResume of Joejoe9063api-28161154No ratings yet

- Gas Cylinders Tracking2021Document37 pagesGas Cylinders Tracking2021Gourav PandeyNo ratings yet

- Roche Cobas Prime Pre Analytical System Specifications Sheet - ENDocument4 pagesRoche Cobas Prime Pre Analytical System Specifications Sheet - ENRubi VikernesNo ratings yet

- Arihant CCC Courses - RemovedDocument138 pagesArihant CCC Courses - RemovedSPEAK UP UniversalNo ratings yet

- Barcoding for MAPICS Accuracy and EfficiencyDocument45 pagesBarcoding for MAPICS Accuracy and EfficiencyRamzyNo ratings yet

- Presentation Track Trace Jan 2017Document24 pagesPresentation Track Trace Jan 2017OdunlamiNo ratings yet

- Bartender Robar Case Study Zimmer BiometDocument2 pagesBartender Robar Case Study Zimmer Biometdimiz77No ratings yet

- NV9 Range User Manual 1.6Document74 pagesNV9 Range User Manual 1.6Đạt NguyễnNo ratings yet

- Improved Productivity: High Contrast Text, Logos and Barcodes Right Code On The Right CaseDocument2 pagesImproved Productivity: High Contrast Text, Logos and Barcodes Right Code On The Right CasefabikduqueNo ratings yet

- Produk Untuk POS Toko Pungu JayaDocument2 pagesProduk Untuk POS Toko Pungu JayaachmadNo ratings yet

- Chapter12345softengwith Bib and DefDocument25 pagesChapter12345softengwith Bib and DefRoxanne MontealegreNo ratings yet

- Codigo Barra Manual XL 6800Document49 pagesCodigo Barra Manual XL 6800Lupi Lupi RodriguezNo ratings yet

- QR Code ThesisDocument24 pagesQR Code Thesismariel flores100% (1)

- Australia Post Parcel Post Barcode Guidelines v2Document11 pagesAustralia Post Parcel Post Barcode Guidelines v2Ryan HendoNo ratings yet

- Dolphin Power Tools ManualDocument114 pagesDolphin Power Tools Manualrao1307No ratings yet

- 14 Site Survey - InstallationDocument50 pages14 Site Survey - InstallationEsther Jaime - Ingeniera de Servicio TechnomedicalNo ratings yet

- Supermarket Billing System Using WebcamDocument5 pagesSupermarket Billing System Using WebcamIJRASETPublicationsNo ratings yet

- Retail TechDocument21 pagesRetail TechmadhavNo ratings yet

- EDI Label Tech - StandardsDocument26 pagesEDI Label Tech - StandardsBayu IrawanNo ratings yet

- De Thi Chon Hoc Sinh Gioi Mon Tieng Anh Lop 12 THPT Tinh Tay Ninh Nam 2014 2015Document18 pagesDe Thi Chon Hoc Sinh Gioi Mon Tieng Anh Lop 12 THPT Tinh Tay Ninh Nam 2014 2015Linh NguyenNo ratings yet

- Door Access Control Using RFID and Voice Recognition SystemDocument9 pagesDoor Access Control Using RFID and Voice Recognition SystemIJRASETPublicationsNo ratings yet

- Pharmaceutical SerializationDocument28 pagesPharmaceutical SerializationAjinkya MohiteNo ratings yet