Professional Documents

Culture Documents

ITB - Thang Long II (General Instruction)

Uploaded by

Hong Trung Duong0 ratings0% found this document useful (0 votes)

24 views15 pages1. ITB_Thang Long II (General Instruction)

Original Title

1. ITB_Thang Long II (General Instruction)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. ITB_Thang Long II (General Instruction)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views15 pagesITB - Thang Long II (General Instruction)

Uploaded by

Hong Trung Duong1. ITB_Thang Long II (General Instruction)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

Contractor Selection of The Expansion project of TLIPII's Wastewater

Treatment Plant (STP-3)

I. General Instruction

No. Item Description

1 | Project Name ‘The Expansion project of TLIPI's Wastewater Treatment Plant (STP-3) |

2 | Owner ‘Thang Long Industrial Park II Corporation (TLIPI)

3. | User of Project Office | TLIPIL

4. | Project location TLIPH Water Plan (WPP) area (refer to Drawing)

It is requested to propose to complete the construction at the end of

January 2019 for all wastewater treatment system after necessary

Completion of the official inspection

* | construction Commencement date ofthe construction shall be the beginning of April

2018 and after the issuance date of Letter of Intent by TLIPII addressed

to the Contractor.

6 | Language of Proposal _| In English

The Contractors who are invited by this Invitation for Proposal |

(hereinafter called a5 the Contractor) shall submit Proposal in one

original and two copies in sealed envelopes.

The alternative proposal can be acceptable

7 | Submission of Proposal | The complete set of the proposal documents shall be addressed and

delivered to:

‘Thang Long Industrial Park I Corporation

Address: Thang Long Industrial Park Il Yen My district, Hung yen

Province, Vietnam

[- The proposal should be directly delivered by hand to the above address

not later than:

8 | Closing date of Proposal | + 17:00 on 22™ March 2018 for Full proposal document,

Any proposal, which is not delivered by this time, will not be considered

and will be returned unopened.

All cost incurred directly or indirectly by for site vist and investigation,

including but not limited to, preparation and presentation of proposal and

9 | Expenses any other cost related thereto and application fee for authorities shall be

at the Contractor's expenses and no claim for any kind of reimbursement

shall be considered, |

Documents to be Each proposal shall be completed documents in one envelop:

10 | included in the Proposal | Contractor shall submit the documents that shown at

document 1, Necessary Documents on 1, Document to be prepare in I,

Technical Requirement. (hereunder).

And we will not limit to submit one proposal for this tender submission.

Contractor can submit more than one proposal.

u

Signing of the Proposal

‘An authorized representative shall sign the proposals in handwriting with |

the corporation’s seal affixed or stamped.

‘The Proposal shall be firm valid for acceptance or rejection for a period

12 | Validity of Proposal

of Ninety (90) calendar days from the closing date of submission.

1. Proposal should be on basis of Engineering, Procurement and

Construction (refer to 2. Technical Requirement) for the reference

Engineering, which Contractor may propose its own design proposal.

13 | Procurement and 2, Alll governmental authorities’ approval and permission related to the

Construction (EPC)

construction such as, but not limited to, design approval, environment

Protection, fire-fighting authority inspection and test charge should be

the scope of work of the Contractor

24 months after the completion of the construction (The date of hand

zee reese ett Perio certificate issued by TLIPID.

7 hy Vietnamese Dong (VND)

The Proposal should mention net price and VAT, BIT and import tax

separately.

. It should be clearly mentioned whether or not the VAT invoige can be

16 | VAT BITand import |

ieee The Contractor, who does not apply the Vietnamese accounting system,

shall submit to TLIPH copy of contract’ invoices and payment

documents with its major local Sub-contractors)

1. All payment shall be made by Vietnamese Dong (VND).

2. Payment to the Contractor shall be made by bank transfer as follows:

20% of the contract amount

within 2 weeks after signing date ofthe contraet.

25% of the contract amount

within 2 weeks after completion of conerete structure work.

17 | Payment Method

30% of the contract amount:

within 2 weeks after completion of the M&E work.

20% of the contract amount:

within 2 weeks after get final certificate of TLIPIL

05% of the contract amount:

within 2 weeks after completion of the defect liability period.

Security bond for advance payment shall be issued on the payment of the

Security bond for

Is ‘advance money (20%) by a bank acceptable to TLIPH The validity of

advance payment

the bond shall be until the estimated completion date.

AN

W237

Performance Bond

Performance Bond for an amount equal to 10% (ten percent) to be issued

by a bank acceptable to TLIPI shall be required. The validity of the bond

shall be until the estimated completion date

20

Evaluation of Proposal

The Proposal shall be evaluated by TLIPII solely and exclusively based

fon commercial and technical aspects; therefore, each Contractor's

proposal and the evaluation result shall not be announced officially.

TLIPIT shall inform and have negotiation with the Contractor

individually under the evaluation result.

21

Importation

In case contractor will import the material from foreign countries, the

contractor shall perform all the necessary works for importation.

And contractor shall provide the Import equipment list for to get the

import license from HYIZA in advance (If it is required),

2

Penalty

‘The designated delay penalty shall be born by the Contractor (0.1% (zero |

point one percent) of the Contract Price per day of delay to a maximum

of 10% (ten percent) of the Contract Price).

23

Applicable Law

Law of Socialist Republic of Vietnam (SRV).

24

Definition

STP-1: Existing Wastewater Treatment Plant (3,000m3/day)

STP-2: Existing Wastewater Treatment Plant (6,000m3/day)

SPT-3: The Expansion project of TLIPI's Wastewater Treatment Plant

(this Tender)

e@ Contractor Selection of The Expansion project of TLIPII's Wastewater

7 t ‘Treatment Plan (STP-3)

II. Requirements

No. Tem Description

This Expansion work is EPC (Engineering ~ Procurement ~ Construction)

1_| Documents to be prepared

(1) Employer's Requirement

(2) Drawings

1. | Documents prepared 1) Construction area Layout

by the Employer 2) Utility supply drawings

() Existing boring data

(4) Others

12 Priority of ‘The order of precedence shall be the order in which the Employer's

documents Requirement is listed in Item 1.1 above.

(1) Technical Specification

(2) Drawings

a. Flow sheet

b. General Layout

ce. Water Level Diagram

d. Equipment Layout and Section

(3) One (01) Quotation for both Cases hereunder & Specification of et

Quotation (c/w Bill of Quantity: Civil, Mechanical, Electric ete.) N

(4) Scope of works (Contractor shall clearly mention) q

(5) Operation Cost (for reference) a

1.3 | Documents prepared] a. Electricity cost (per m3 treated water) =

by the Applicant b. Chemical cost (per m3 treated water)

¢. Disposal cost of dehydrated cake (per m3 treated water)

d, Labor cost (per m3 treated water)

| (6) Maintenance cost

a. Maintenance cost (per year)

b. Replacement cost (for equipment) (per period/per year)

( Construction Schedule.

(8) Equipment list (It shall be clearly mentioned about brand, specification,

country of origin etc. And it shall be separated import equipment and

local procurement.)

(9) List of Sub contractors and their scope.

2__| General Information

2.1 | Project Name TLIP-3 Expansion STP project (STP-3)

“ae

2.2 | Employer ‘Thang Long Industrial Park I] Corporation

2.3 | Contract terms EPC basis

(1) Construction area : (2,072) m2 (34.74) m x (59.65) m

(2) Expansion STP area :(1,714) m2 (28.73) m x (59.65) m (will be fixed by

2.4 | Construction Area

Applicant)

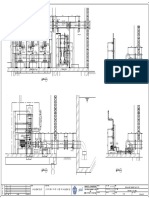

Refer to drawing : STP 010 & STP - 020

25 | Type of payment _| Following to Item 17 of General Instruction.

2.6 | Construction Period _ | (10) months after government approval

3_| DESIGN STANDARD

Plant can be operated at flow of 3,000 m3/d in case the inlet wastewater

3.1 | Demand quality as in Case -I at Table of Item 4 and at flow of 6,000 m3/d in case the

inlet wastewater quality as in Case—2 at Table of Item 4

3.2 | Piping Work Code & Standard of material: JIS, ISO, ANSI, BS, DIN, TISI, or equivalent.

3.3 | Wiring Work Standard of material: JEC, IEC, BS, DIN, TISI, or equivalent

44 | CWiland building | Standard of materia: IS, ISOMEC, TCVN/TCXDIother construction related

works Vietnam standards, oF equivalent.

5 | Foundation & To be designed by Contractor. The Contractor can refer the existing structure

| structure and related draving which is provided by TLIPIL

4. | Sewage Treatment Plant

Case 1 3,000 m3/d) Case 2 (6,000 m3/d)

BOD: 150 mg/l

cop: 180 in

COD 350 mg/L oe

SS :200 mg/L

SS: 200mgL

NH4EN 30 mg/L

NH4HN :60mg/L

TN :30mg/L

TN :60mgL

TP: 1SmylL

TP: 1S mg/L

Coliform: 3,000 MPN/100 mL

Coliform : 3,000,000 MPN/100 ml.

Color: 100 PuCo

Color: 100 PUCo

4.1 | Wastewater quality

* The Contractor is requested to consider '

: : In case of inlet parameter of

incase of concentration of BOD :

A ‘wastewater increase to be same as

parameter at inlet-point lower than 60

mg/L. The detail explanation for

adjustment and operation cost to

Case 1, the Plant can be improved

to treat wastewater without major

an changing of Civil structure.

compare with normal condition of Case 1

and Case 2 shall be described detail in

the Contractor proposal |

42

Treated water quality

BOD — :24.3mg/L.

COD — :60.75mgy/L.

ss 2 40.5mg/L_

NHN: 4.05mg/L

TN 16.2mg/L

TP :3.24mgiL.

Coliform: 3,000 MPN/100mL.

Color +50 PCo

43

Power

3 phase *380 V x 50 Hz x 4 Line x (300) KVA for equipment

3 phase * 380 V x 50 Hz x 4 Line x (5) KVA for building

«4

ines : 3 power / 1 Neutral)

44

45

Utility supply

Conditions for civil

and building

construction

Refer to drawing : STP - 010

(1) Raw water's intake point

(2) Treated water's discharge point

3) Electric power of low voltage

n : Refer to document (3) of 1.1

: (30) m (the Civil and Building work shall be change

Result of soil investiga

(2) Length of

any change occurs related to the boring condition change).

(3) Exterior: pavement, road lighting, landscaping...)

(4) Construction soil disposal: can be disposed by Owner’s instruction.

(5) Construction waste disposal : Applicant’s responsibility

(6) Charge of temporary water and electricity supply: shall be charged by

‘TLIPI’s tariff based on actual usage of the Contractor.

(7) Height of weight limitation of truck accessing : (20 ton weight, 20 m

length)

(8) Firefighting system’s specification : compliant with Vietnam Law on

Fire Prevention and Fire Fighting

46

Unit Price of

operation cost (for

reference)

(1) Electricity : (1,500) VNDKWh

(2) Chemical

a. NaCIO : (3,600) VNDIL.

b. NaOH : (5,500) VND/L

¢. PAC : (8,600) VND/Kg

4, Polymer : (90,000) VND/kg

(3) Disposal of dehydrated cake : (1,800,000)VND/m3

(4)_Labor : (250,000) VND/day/person

47

Specified requirement

for material and

equipment

By the Contractor according to demand of design life as hereunder:

(1) Sewage conveyance structures: 50 years (Sewer pipe lines and plant

piping)

(2) Other structures: 40 years (buildings, tanks, basins, pumping stations)

(3)_ Process Equipment: 15 years

Ge!

(4)_ Ancillary Equipment : 10 years

5_| SLUDGE PRESSING SYSTEM = a

No requirement.

5.1 | Demand Discharge sludge from STP-3 to connecting the existing Sludge pressing

system

5.2 | Location Refer to drawing : STP—010

6_ | CONNECTION TO EXISTING

‘New facilities must be merged to the existing system (STP with capacity of 6,000m3/day) and work as

an integrated part. The incoming wastewater as well as outgoing treated water has to consider the

capacity and connection point for future expansion plan.

Si ‘The Control system of STP-3 should be harmonized — synchronized with the existing system that

‘TLIPI’s engineer could manage ~ control — operate — maintain it from existing Administration

Buildings. So the additional electrical and control panels shall allocate inside those buildings.

7_| ELECTRICITY :

Electric power shall be tapped from existing Transformer house No.6 (see the

attached drawings No. STP-010).

7.1 | Power Sources

Power meter (Indirect type; 3 phases/3 price; class for P= 0.5; class for Q=1)

shall be installed by the contractor at Control panel of STP-3.

7.2 | Cable and protection _| Ls brand is required, design by contractor.

: Alll necessary electric materials and equipment shall be submitted by the

73 | Materials

Contractor subjected to the approval of TLIPIL

Standby generator with requirement as the following:

- Branch: KOHLER

- Model: 750REOZM

- Prime capacity: 750-760kVA

- Voltage: 230/400V

~ 3 phase 4 wire

= Protective function of generator: under/over voltage, under/over

speed, under/over pressure of lubricant, over temperature, low fuel

tank and other basie function

74 | Standby generator = Spare part: air filter, oil filter, lubricant filter

Other requirement:

= Connect generator to the existing MDB ensure it can run at manual

mode and auto mode well

= Connect fault signal of generator to monitoring panel at WPP (using

LS cable Cu/XLPE/PVC 4x3.5mm2)

~ Make fuel tank 2m3 with fuel level measuring ruler and connect

direct fuel tank to generator (not use tank of generator itself) with

supplying fuel pipe from fuel tank to generator and back fuel pipe

from generator to fuel tani

= Make industrial fan on wall to supply fresh air from outside to ]

generator room with control box have temperature sensor for |

‘generator room. (this control box have run manual and auto mode)

- Supply power for battery charger set from MDB panel

(Designed by contractor). oe

7.5 | Connection

Alll additional electrical and control panels shall be allocated inside existing

Administration Building

8 | FUTURE PLANT

8.1

‘Total capacity of all STP of TLIPIT in the future is ~ 25,000m3/day (full

operation). The Contractor is requested to make design of STP-3 this time

could meet with final demand.

9 | OTHERS

9.1 | Requirement

Al wastewater shall collect into pump-pit before transfer to Treatment

system, STP-1 & STP-2 & STP-3 should operate in mutual support condition

to meet highest effective with save the operation cost.

9.2 | Control system

= Chemical Storage (Around 35 m2

93 | Other - Internal Road by asphalt with 4m width between STP2 & STP3

= Install

of automatically adjusting pH system in equalization tank.

~ Separation for pipeline of sand pump in Grit chamber

| - Installation of control equipment for discharge sludge automatically

| - Installation of online monitoring system to control each processing of STP-3

(monitor DO, pH, MLSS...)

~ Installation of circulating pipeline to inlet pump pit in case of wastewater

has trouble.

- Installation Water meter at inlet, outlet & to control each processing of

‘STP-3. Flow meter (Aichi Tokei) is required, design by contractor.

~ Remove the existing Online monitoring system at outlet of STP-1 to new

position can monitoring outlet of STP-1, STP-2 & STP-3.

= Galvanization for handrail and stai

= Internal walkway is designed by the Contractor

~ Landscape work is included Contractor's seope

020 - dS

VSYNV NOILONYLSNOO Sd lS

QVOU WNYSLNI

ele

cu yb

&

z

0

°

NIGSLINOW

Zz

=

mM

A

za

>

ee

>

Wn

U

-

LP

fe

Ho

A

Co

>

O

BS

<=

00

rl fain

LNIOd J9YVHOSIG

STP - 010

| =

ele

Oo oo = |

oO a! a& Hl |

on (iN

“| | Ie a : |

a (Ht ¢ enon

o IE 2

a if cu

Ui 393.650

STP3 CONSTRUCTION AREA

YSLNI \ nN 5

-— | 5 ane

NPA ay =

ae | ME R 60

= CSS ng

| xt

(w)

Oe

2 z

ay a

S Wr GVO LIWVHdSY TWNYSLNI Hoy

INT

' oN |

STP - 020

BORING LOG yeaa

Fee Sa Tainen Par

Toe Tang ang nal an Uy Oa gan Pe

Bester 03

ce So cvs alpina canara Weare Ss S|

vagy: rg. Tavan

| ve

lee

a sor fst ramen serower

on] aes ig

4 ave round

7 st sony

tons

eunsares sane eect spe

Data soe SPT Std penctration est

BORING LOG

Gintiemear

a gyre

ee oom cuiimida malta oe

al elle te] ote cee foc

tani ay

arse

Veunsee simple eke

Dstted spe SPT. Sind pensation est

BORING LOG

Fae Song Tea Pare

Toeen Tangy naa Pa Yona Rg Venfooe | SGN OT

Besoin a ay

(ie ue Varig Gaguy we crac Ineo SER [Dae S26

is

iE ‘SPT CHART

iE re

“Tureen Fok sample

D:D ple ST Sumter pevcttion test

BORING LOG ee

aie Sap Teainow Mat

hea Thang ng aol Pat Yon Dai rg Vx Ps EOGTOE BT

enim 03 ae

Des rain

ig] sre

epeleel eit [RSME sa es ‘SPT. CHART

a a] | maemo | rani

im

tase round |

[sree aay | 2

stony

ra ey

Feniosot san

ay nso

trometry

Lunde sample Roc sample

Debates sampte SPP Shand entation xt

BORING LOG ees

Fas Sonag Team POT

Tesi Trg eg bal Pou Tony rg Venfrmes | Be RE

Her 3 peony 0

Dx Se eng Sogn Baron Ine SoC Dts

ing Eg a Van

Belbed ST fect ene serounr

3) SBE a] Pa [ame [tm on)

a

Fem sey

ownage

Ream

SPT: Sion pecraon ot

BORING LOG

aj Se Tene Fon?

hese gia Par any i tg Tonos | Sta eo

Bevan 0 oesnin 0

ee Scie gS a arin ene Seven RC | Dae 3H

ie |g] sve

E ct amt steers spr nant

be] | ee | re

SPT. Sind pencnion est

SWOGE TREATMENT FACIUTY FOR

<< WASTE WATER TREATMENT PLANT (STP)

[WASTE WATER TREATMENT PLANT (SIP-2)

MAT BANG V] TRi HO KHOAN (BO SUNG)

‘BORING HOLE POSITIONING PLAN(ADD)

GHLCHE: gu 4 eino moan

nore: OM

Appendix 2

Sheet 1

os

GEOTECHNICAL PROFILE No :

i fof cone YN

z{ TWH YE

| atu o6NG NoIEP

@ Layer 1 - Made ground: Fine sand

a3

Layer2: St sandy day, yellowish

@ ary brorish rey

“16 166 [153 16.0 [757 Layer: Frm o soft sandy clay wits

sand, brownish grey

-2y GD] taere vey sty. shown

21 21.0) |-20.7 20.8] [-20.5,

Layers Fi saa oy, bon

©} ow

Layer 6: Sif sandy cay with sand

pinks’ brown

Layer 7: Medium dense to dense

fine sand, bownish grey

== Undergound water level

“Note: Supose that the existing elvaton ofthe oad lot

‘onstruction area is 000m

__Soll layer boundary

A

Depth Elevation

Boring hole

45)

Boing Heo ut on

Elation (ry 193 103

Distance (=) z0

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AtheneqDocument3 pagesAtheneqHong Trung DuongNo ratings yet

- DT GKV 061Document1 pageDT GKV 061Hong Trung DuongNo ratings yet

- DT GKV 068Document1 pageDT GKV 068Hong Trung DuongNo ratings yet

- AsecoDocument1 pageAsecoHong Trung DuongNo ratings yet

- DT GKV 078Document1 pageDT GKV 078Hong Trung DuongNo ratings yet

- Instruction Manual: ADONY Series AHDocument47 pagesInstruction Manual: ADONY Series AHHong Trung DuongNo ratings yet

- C0M-38 Diaphragm PumpDocument1 pageC0M-38 Diaphragm PumpHong Trung DuongNo ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- C0M-11 Hydrostatic Pressure Test (Piping)Document3 pagesC0M-11 Hydrostatic Pressure Test (Piping)Hong Trung DuongNo ratings yet

- C0M-37 Sump PumpDocument2 pagesC0M-37 Sump PumpHong Trung DuongNo ratings yet

- 2Document3 pages2Hong Trung DuongNo ratings yet

- C0M-07 FRP Tank-VesselDocument2 pagesC0M-07 FRP Tank-VesselHong Trung DuongNo ratings yet

- WPP-ME-305 - DISTRIBUTION PUMP DETAIL-Layout1Document1 pageWPP-ME-305 - DISTRIBUTION PUMP DETAIL-Layout1Hong Trung DuongNo ratings yet

- Centrifugal Pump DB6, 6H, 7, 8, 9, 10 SeriesDocument16 pagesCentrifugal Pump DB6, 6H, 7, 8, 9, 10 SeriesHong Trung DuongNo ratings yet

- Forged Steel FittingsDocument12 pagesForged Steel FittingsHong Trung DuongNo ratings yet

- Catalog PK Hàn HuaxinDocument27 pagesCatalog PK Hàn HuaxinHong Trung DuongNo ratings yet

- Instruction Manual (Model B Pump Series G)Document23 pagesInstruction Manual (Model B Pump Series G)Hong Trung DuongNo ratings yet