Professional Documents

Culture Documents

Shaft and Housing Tolerances - Nodes Bearing

Uploaded by

Morteza ShakerienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft and Housing Tolerances - Nodes Bearing

Uploaded by

Morteza ShakerienCopyright:

Available Formats

Search ...

HOME PRODUCTS BRAND TECHNOLOGY GUIDE ABOUT CONTACT

Home / TECHNOLOGY GUIDE / Bearing data

/ Shaft and housing tolerances

Technology Guide Bearing data

Bearing basics

Shaft and housing tolerances

Selection of bearing

Friction The fit is determined by the ISO tolerances for shafts and housings (ISO 286) in conjunction with the tolerances Δdmp for the bore

and ΔDmp for the outside diameter of the bearings (DIN 620).

Speeds

Tolerance zones

Lubrication

The ISO tolerances are defined in the form of tolerance zones. They are determined by their position relative to the zero line (=

tolerance position) and their size (= tolerance grade, see ISO 286). The tolerance position is indicated by letters (upper case for

Bearing data

housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits.

Design of bearing

arrangements

Fitting and dismantling

Product search

Partial or full part number

Search

Fits for rolling bearings

(1)Zero line

(2)Nominal diameter

(3)Medias/00016412_mei_in_0k_0k.gif Loose fit

(4)Transition fit

(5)Tight fit

(6)Shaft diameter

(7)Housing bore

ΔDmp = tolerance for bearing outside diameter

Δdmp = tolerance for bearing bore

Reference to tables of shaft and housing tolerances

The tables as below contain recommendations for the selection of shaft and housing tolerances that are valid for normal fitting and

operating conditions.

Deviations are possible if particular requirements apply, for example in relation to running accuracy, smooth running or operating

temperature. Increased running accuracies thus require closer tolerances such as tolerance grade 5 instead of 6. If the inner ring is

warmer than the shaft during operation, the seating may loosen to an impermissible extent. A tighter fit must then be selected, for

example m6 instead of k6.

In such cases, the question of fits can only be resolved by a compromise. The individual requirements must be weighed against each

other and those fulfilled that give the best overall solution.

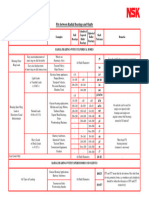

Shaft tolerances for radial bearings with cylindrical bore

Condition of rotation Bearing type Shaft Displacement facility

Tolerance

diameter

Load zone

mm

Point load on inner ring Ball bearings, All sizes Inner ring easily displaced g6 (g5)

roller bearings

Inner ring not easily displaced, angular contact ball h6 (j6)

bearings and tapered roller bearings with adjusted inner

ring

Needle roller All sizes Non-locating bearing h6 (g6)1)

bearings

Circum‑ ferential load Ball bearings up to 50 Normal loads2) j6 (j5)

on inner ring or indeter-

minate load direction 50 to 100 Low loads3) j6 (j5)

Normal and high loads4) k6 (k5)

100 to 200 Low loads2) k6 (m6)

Normal and high loads5) m6 (m5)

over 200 Low loads m6 (m5)

Normal and high loads n6 (n5)

Roller up to 60 Low loads j6 (j5)

bearings

Normal and high loads k6 (k5)

60 to 200 Low loads k6 (k5)

Normal loads m6 (m5)

High loads n6 (n5)

200 to 500 Normal loads m6 (n6)

High loads, shocks p6

over 500 Normal loads n6 (p6)

High loads p6

Needle roller up to 50 Low loads k6

bearings

Normal and high loads m6

50 to 120 Low loads m6

Normal and high loads n6

120 to 250 Low loads n6

Normal and high loads p6

250 to 400 Low loads p6

Normal and high loads r6

400 to 500 Low loads r6

Normal and high loads s6

over 500 Low loads r6

Normal and high loads s6

1. For easier fitting.

2. C/P > 10

3. C/P > 12

4. C/P < 12

5. C/P < 10

Shaft tolerances for axial bearings

Load Bearing type Shaft Operating conditions Tolerance

diameter zone

Axial load Axial deep groove ball bearings All sizes - j6

Axial deep groove ball bearings, double - k6

direction

Axial cylindrical roller bearings with shaft - h6 (j6)

locating washer

Axial cylindrical roller and cage assemblies - h8

Combined Axial spherical roller bearings All sizes Point load on shaft locating washer j6

load

up Circumferential load on shaft j6 (k6)

to 200 mm locating washer

over 200 mm k6 (m6)

Housing tolerances radial bearings

Condition of rotation Displacement facility Load Operating conditions Tolerance

zone

Point load on outer ring Outer ring easily displaced, housing unsplit The tolerance grade is H7 (H6)1)

determined by the running

Outer ring easily displaced, housing split accuracy required H8 (H7)

Outer ring not easily displaced, housing unsplit High running accuracy required H6 (J6)

Outer ring not easily displaced, angular contact Normal running accuracy H7 (J7)

ball bearings and tapered roller bearings with

adjusted outer ring Housing split

Outer ring easily displaced Heat input via shaft G72)

Circum‑ ferential load on Low loads, outer ring cannot be displaced For high running accuracy K7 (K6)

outer ring or indeter- requirements: K6, M6, N6 and P6

minate load direction Normal loads, shocks, outer ring cannot be M7 (M6)

displaced

High loads, shocks (C/P < 6), outer ring cannot be N7 (N6)

displaced

High loads, severe shocks, thin-walled housing, P7 (P6)

outer ring cannot be displaced

1, G7 for housings made from flake graphite cast iron GG, if bearing outside diameter D > 250 mm and temperature difference

between outer ring and housing > 10 K.

2, F7 for housings made from flake graphite cast iron GG, if bearing outside diameter D > 250 mm and temperature difference

between outer ring and housing > 10 K.

Housing tolerances for axial bearings

Load Bearing type Operating conditions Tolerance

zone

Axial load Axial deep groove ball bearings Normal running accuracy E8

High running accuracy H6

Axial cylindrical roller bearings with - H7 (K7)

housing locating washer

Axial cylindrical roller and cage - H10

assemblies

Axial spherical roller bearings Normal loads High loads E8

G7

Combined loads Point load on housing Axial spherical roller bearings - H7

locating washer

Combined loads Circumferential load on Axial spherical roller bearings - K7

housing locating washer

Related article

Tables of shaft and housing f

RELATED PRODUCTS

© 2016 Nodes Technology Co., Ltd. | Contact Us

No. 98 Argyle Street, Mongkok, KL, Hong Kong

Phone: +852-5136-3000

E-mail: service@nodeshk.com

You might also like

- Rothe Erde Slewing BearingDocument194 pagesRothe Erde Slewing BearingRafael FurquimNo ratings yet

- Antifriction Bearings - 2Document2 pagesAntifriction Bearings - 2MahmoudKamalElshazlyNo ratings yet

- 71 ShaftDocument1 page71 ShafterezerezerezNo ratings yet

- Tolerancias de RodamientosDocument3 pagesTolerancias de Rodamientospaolo88No ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- Required running accuracy and bearing fit factorsDocument1 pageRequired running accuracy and bearing fit factorsMorteza ShakerienNo ratings yet

- Bearing TolerancesDocument4 pagesBearing TolerancesShazdeh HosseinNo ratings yet

- 5) Bearing Fundamentals PDFDocument123 pages5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Thrust Bearings: 53210 29430 E U210 M 81110 TN P5Document20 pagesThrust Bearings: 53210 29430 E U210 M 81110 TN P5Ismael RiosNo ratings yet

- Introduction To Antifriction BearingsDocument39 pagesIntroduction To Antifriction BearingsTalha AhmadNo ratings yet

- Bearing Maintenance Technology: Er Prateek Gupta Er Ranjeet SinghDocument56 pagesBearing Maintenance Technology: Er Prateek Gupta Er Ranjeet SinghsamirsabatNo ratings yet

- H006 011Document7 pagesH006 011Guilherme FleschNo ratings yet

- ASKUBALDocument64 pagesASKUBALDarkedgeNo ratings yet

- 71 HousingDocument1 page71 HousingerezerezerezNo ratings yet

- Cat173ex - RHR SRBsDocument5 pagesCat173ex - RHR SRBsTiago AnaniasNo ratings yet

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- BearingsDocument30 pagesBearingsIhsan AhmedNo ratings yet

- Bearings and Selection of Bearing From Manufacturers CatalogDocument29 pagesBearings and Selection of Bearing From Manufacturers CatalogUddhav S100% (1)

- Tapered Roller BearingsDocument37 pagesTapered Roller Bearingskhairul ardyNo ratings yet

- L6 RollerBearings 16-12 v2Document58 pagesL6 RollerBearings 16-12 v2Ugo PetrusNo ratings yet

- Lecture #4 - Iso Tolerances (2018) - Part IIDocument44 pagesLecture #4 - Iso Tolerances (2018) - Part IIakinhaciNo ratings yet

- RKB Bearing Designation SystemDocument48 pagesRKB Bearing Designation SystemFurqan ShabbirNo ratings yet

- The Importance of Properly Mounting Thin Section Bearings: An SKF Group BrandDocument8 pagesThe Importance of Properly Mounting Thin Section Bearings: An SKF Group BrandTony CasillaNo ratings yet

- TDocument33 pagesTTheodoros AtheridisNo ratings yet

- Catalogo Acoples OmegaDocument172 pagesCatalogo Acoples OmegaDiego Aramando LizcanoNo ratings yet

- Fits Between Radial Bearings and ShaftsDocument1 pageFits Between Radial Bearings and Shaftsmohamed bakryNo ratings yet

- Bearing Types, Specs & ApplicationsDocument41 pagesBearing Types, Specs & ApplicationsTejesh ShamiNo ratings yet

- PG 209-215Document7 pagesPG 209-215filkeNo ratings yet

- 5 BearingDocument13 pages5 Bearingarbazkhan13218980No ratings yet

- BearingsDocument35 pagesBearingsmahendra babu mekalaNo ratings yet

- Bearing FitsDocument9 pagesBearing FitsPPMNo ratings yet

- Tapered+Roller+Bearing Detail SuffixDocument20 pagesTapered+Roller+Bearing Detail SuffixDeni SuhayaNo ratings yet

- Split Tapered Bearings Mini CatalogueDocument16 pagesSplit Tapered Bearings Mini CataloguekrutesNo ratings yet

- Tolerances For Bearing Seats and Abutments - SKF - SKFDocument1 pageTolerances For Bearing Seats and Abutments - SKF - SKFKamer YıldızNo ratings yet

- Bearing Fits PDFDocument9 pagesBearing Fits PDFMujahidin AhmadNo ratings yet

- Gene PDFDocument75 pagesGene PDFZaidiNo ratings yet

- Tapered Roller BearingsDocument42 pagesTapered Roller Bearingsmohammed barghothiNo ratings yet

- Double Row Cylindrical Roller Bearings GuideDocument5 pagesDouble Row Cylindrical Roller Bearings Guidehengki wibowoNo ratings yet

- Module 5: Bearing Materials and TypesDocument126 pagesModule 5: Bearing Materials and TypesArjun LalitNo ratings yet

- 2009 Balineras de Bola y Rodillo GMBDocument46 pages2009 Balineras de Bola y Rodillo GMBKESAVANNo ratings yet

- Bearing FitsDocument9 pagesBearing Fitstaekwangkim4907No ratings yet

- Rolling Element Bearings Childs2014Document53 pagesRolling Element Bearings Childs2014joshuaNo ratings yet

- FKL - Steel-MillDocument20 pagesFKL - Steel-MillThái PhiNo ratings yet

- RKB Bearing Tolerances and Radial Internal ClearancesDocument36 pagesRKB Bearing Tolerances and Radial Internal ClearancesCAT CYLINDERNo ratings yet

- Tpi183 de en PDFDocument40 pagesTpi183 de en PDFAGNALDOJULIONo ratings yet

- Everything You Need to Know About Linear BearingsDocument11 pagesEverything You Need to Know About Linear BearingsTesco toolsNo ratings yet

- 5 - G - Aguila Shaft DesignDocument7 pages5 - G - Aguila Shaft DesignJonas M. MagbooNo ratings yet

- Drive TrainDocument2 pagesDrive Trainatlanticblue98No ratings yet

- Tilting Pas Radial BearingsDocument28 pagesTilting Pas Radial Bearingskamran kainporNo ratings yet

- Bearing SelectionDocument22 pagesBearing SelectionAbhishek ShindeNo ratings yet

- Rulmenti KoyoDocument83 pagesRulmenti KoyoLucyan IonescuNo ratings yet

- Bearing Fits PDFDocument9 pagesBearing Fits PDFanilNo ratings yet

- CHAPTER 6 Bearings UpdatedDocument26 pagesCHAPTER 6 Bearings UpdatedMuhammad Azrul100% (1)

- Notes On Ball Bearings: Bearing NomenclatureDocument9 pagesNotes On Ball Bearings: Bearing NomenclatureSalman KhanNo ratings yet

- Rolling Contact BearingDocument31 pagesRolling Contact Bearingpotnuru JaivanthNo ratings yet

- 3 Bearing Tolerance Class and Measurement MethodsDocument6 pages3 Bearing Tolerance Class and Measurement Methodstsrinivasan5083100% (1)

- PG 049-061 PDFDocument13 pagesPG 049-061 PDFfilkeNo ratings yet

- Bearing PropertiesDocument14 pagesBearing Propertieshengki wibowoNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- O-Ring Seal Sizes: From Micro To Macro, We Have Every Size You NeedDocument36 pagesO-Ring Seal Sizes: From Micro To Macro, We Have Every Size You NeedMorteza ShakerienNo ratings yet

- KEC General PresentarionDocument6 pagesKEC General PresentarionMorteza ShakerienNo ratings yet

- O-Ring Groove Design Extrusion Limits - Seal & Design, IncDocument2 pagesO-Ring Groove Design Extrusion Limits - Seal & Design, IncMorteza ShakerienNo ratings yet

- NDT Procedure For Dye Penetrant Inspection: 1 Scope Qualification of Testing PersonnelDocument4 pagesNDT Procedure For Dye Penetrant Inspection: 1 Scope Qualification of Testing PersonnelMorteza ShakerienNo ratings yet

- Gland Dimensions Industrial Static SealDocument1 pageGland Dimensions Industrial Static SealMorteza ShakerienNo ratings yet

- RESL Catalogue StandardDocument8 pagesRESL Catalogue StandardMorteza ShakerienNo ratings yet

- Fundamental of O-RingDocument32 pagesFundamental of O-RingMorteza ShakerienNo ratings yet

- Gland Dimensions Industrial Reciprocating SealDocument1 pageGland Dimensions Industrial Reciprocating SealMorteza ShakerienNo ratings yet

- O-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierDocument4 pagesO-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierMorteza ShakerienNo ratings yet

- Magneto-Electric Transmitter MEM / MEM-PPA Operating InstructionDocument11 pagesMagneto-Electric Transmitter MEM / MEM-PPA Operating InstructionMorteza ShakerienNo ratings yet

- 4eys / 4eyt: Installation/Operating ManualDocument28 pages4eys / 4eyt: Installation/Operating ManualMorteza ShakerienNo ratings yet

- Compact elastomer bellows seal technical specificationsDocument2 pagesCompact elastomer bellows seal technical specificationsMorteza ShakerienNo ratings yet

- Catalog Burgmann mg1Document8 pagesCatalog Burgmann mg1Morteza ShakerienNo ratings yet

- Catalog Burgmann mg9Document7 pagesCatalog Burgmann mg9Morteza ShakerienNo ratings yet

- Beyond Ra - Why Surface Finish Matters in Seal Performance - Fluid Power JournalDocument7 pagesBeyond Ra - Why Surface Finish Matters in Seal Performance - Fluid Power JournalMorteza ShakerienNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)Morteza ShakerienNo ratings yet

- Abravan Pumps CatalogueDocument143 pagesAbravan Pumps CatalogueMorteza ShakerienNo ratings yet

- Drawing 2Document1 pageDrawing 2Morteza ShakerienNo ratings yet

- Study of The Trapping of Fluid A Gear: Yanada, Meng and T Icbikawa, Itsuji, MengDocument7 pagesStudy of The Trapping of Fluid A Gear: Yanada, Meng and T Icbikawa, Itsuji, MengMorteza ShakerienNo ratings yet

- TEPZZ 5 9 - B - T: European Patent SpecificationDocument34 pagesTEPZZ 5 9 - B - T: European Patent SpecificationMorteza ShakerienNo ratings yet

- NII-Electronic Library ServiceDocument9 pagesNII-Electronic Library ServiceMorteza ShakerienNo ratings yet

- Design and Performance of Gear Pumps With A Non-Involute Tooth ProfileDocument13 pagesDesign and Performance of Gear Pumps With A Non-Involute Tooth ProfileMorteza ShakerienNo ratings yet

- Parker CFD Analysis PGP 640 ModelDocument18 pagesParker CFD Analysis PGP 640 ModelsudharsanNo ratings yet

- PDF QCF Start ActionDocument2 pagesPDF QCF Start ActionMorteza ShakerienNo ratings yet

- VC Flow Meter Construction and OperationDocument20 pagesVC Flow Meter Construction and OperationMorteza ShakerienNo ratings yet

- Analysis of Mechanical Engineering Design and Quality ControlDocument4 pagesAnalysis of Mechanical Engineering Design and Quality ControlMorteza ShakerienNo ratings yet

- Robustnessday - GPS-challenges and opportunities-JD-16-9 PDFDocument34 pagesRobustnessday - GPS-challenges and opportunities-JD-16-9 PDFMorteza ShakerienNo ratings yet

- Selection of FAG Bearing Arrangement - Nodes BearingDocument2 pagesSelection of FAG Bearing Arrangement - Nodes BearingMorteza ShakerienNo ratings yet

- Fits and Tolerances On Gearbox Shaft and Housing - The Engineering BlogDocument1 pageFits and Tolerances On Gearbox Shaft and Housing - The Engineering BlogMorteza ShakerienNo ratings yet

- Ana MirandaDocument8 pagesAna Mirandaapi-26075761No ratings yet

- Prahlad ChhabriaDocument3 pagesPrahlad ChhabriaYogesh Jagpal SharmaNo ratings yet

- Morning MessageDocument11 pagesMorning MessageymarksmithNo ratings yet

- Writing Verb List 40Document2 pagesWriting Verb List 40Alvin Jay GarciaNo ratings yet

- HQE2R Diagnostics & PrioritésDocument205 pagesHQE2R Diagnostics & PrioritéssusCitiesNo ratings yet

- Peace Corps Volunteer Advisory Council - Council StructureDocument4 pagesPeace Corps Volunteer Advisory Council - Council StructureAccessible Journal Media: Peace Corps DocumentsNo ratings yet

- Combined-Move and FreezeDocument4 pagesCombined-Move and Freezeapi-505036826No ratings yet

- Test 4: Mic Ho Use Agency - RepairsDocument4 pagesTest 4: Mic Ho Use Agency - Repairsandi ariNo ratings yet

- Ecpm 1514 - Efcp 2514 Schedule 2021Document4 pagesEcpm 1514 - Efcp 2514 Schedule 2021Dieketseng Deborah MohlakoanaNo ratings yet

- Optimize Volleyball Serve in Minimal TimeDocument20 pagesOptimize Volleyball Serve in Minimal Timejason jenningsNo ratings yet

- Me Lab Report 1 SilvaDocument18 pagesMe Lab Report 1 SilvaEthan SilvaNo ratings yet

- Biosystamtics and Taxonomy First UnitDocument13 pagesBiosystamtics and Taxonomy First UnitDr Estari Mamidala88% (8)

- 5.2 Theory of ProductionDocument10 pages5.2 Theory of ProductionMissDangNo ratings yet

- Ergonomics in The Workplace PDFDocument2 pagesErgonomics in The Workplace PDFDanielNo ratings yet

- Add Field in COOIS 2 SAPDocument12 pagesAdd Field in COOIS 2 SAPaprian100% (1)

- Bourdieu FoucaultDocument33 pagesBourdieu FoucaultChristie DanielsNo ratings yet

- Kigali Report - Web Version (Oct 2014)Document64 pagesKigali Report - Web Version (Oct 2014)HarisNeophytouNo ratings yet

- Research Paper With ReferencesDocument7 pagesResearch Paper With Referencesc9q0c0q7100% (1)

- On The Job TrainingDocument3 pagesOn The Job TrainingNica X AportoNo ratings yet

- Product Presentation PowerPoint TemplatesDocument19 pagesProduct Presentation PowerPoint TemplatesTuyet PhamNo ratings yet

- Solubility and dissolution factorsDocument20 pagesSolubility and dissolution factorsYuppie RajNo ratings yet

- Erpia PDFDocument316 pagesErpia PDFJosuéLMNo ratings yet

- Introduction To Neural Networks: Revision Lectures: © John A. Bullinaria, 2004Document24 pagesIntroduction To Neural Networks: Revision Lectures: © John A. Bullinaria, 2004basela2010No ratings yet

- Beard & Ragheb (1983) - Measuring Leisure MotivationDocument11 pagesBeard & Ragheb (1983) - Measuring Leisure MotivationHuyen T. T. NguyenNo ratings yet

- Kath Murdoch S Inquiry Cycle PDFDocument1 pageKath Murdoch S Inquiry Cycle PDFSneha MishraNo ratings yet

- Formulation and in Vitro Evaluation of Minoxidil Topical GelDocument10 pagesFormulation and in Vitro Evaluation of Minoxidil Topical GelHelenMonicaNo ratings yet

- The Importance of Business CorrespondenceDocument2 pagesThe Importance of Business Correspondencealberto2santos-4No ratings yet

- Effective Academic Writing 1Document164 pagesEffective Academic Writing 1KYAW SOE100% (1)

- Maths in Focus Chapter 11Document52 pagesMaths in Focus Chapter 11eccentricftw450% (2)

- Recorder SysInfra GuideDocument202 pagesRecorder SysInfra Guidekrstep2No ratings yet