Professional Documents

Culture Documents

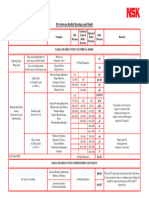

Required running accuracy and bearing fit factors

Uploaded by

Morteza ShakerienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Required running accuracy and bearing fit factors

Uploaded by

Morteza ShakerienCopyright:

Available Formats

SiteMap FAQ Contact 中文 |

ENGLISH

Other Languages

About us Product Application Research & Development Manufacturing & Quality Sales & Service Technical Contact us

Sales & Service >Required running accuracy and fit

Sales & Service

Main Clients and markets select

Customer Service

Bearing Selection services

Bearing Handling Service

Bearing Fitting Service

select

Fitting surface pressure

Shaft and housing

requirements Required running accuracy and fit

Conditions of rotation and fit Bearing fits are also related to the required operating accuracy and easiness of mounting and dismounting. For

Interference minimum and example, to reduce resilience and vibration, clearance fits should generally not be used for bearings where high

demands are placed on running accuracy. Bearings seating on the shaft and in the housing should be made to

maximum values

narrow dimensional tolerances, corresponding at least to grade 5 for the shaft and at least to grade 6 for the

Required running accuracy and

housing.

fit

Lubrication Service

Preload

Bearing cleanliness

● Fits of radial bearings with solid steel shafts

Bore Diameter (mm) Tolerance

Load Conditions Examples Remarks

of Shaft

Ball bearing Tapered roller bearing

Easy axial Use g5 and

displacement Wheels on h5 where

of inner ring stationary g6 accuracy is

on shaft axles required. In

Rotating desirable case of large

Outer Ring All shaft diameters

bearings, f6

Load Easy axial

can be used

displacement Tension

to allow

of inner ring pulleys, Rope h6

easy axial

on shaft sheaves

movement.

unnecessary

Electrical

appliances, <18 - js5

Pumps,

Blowers,

Light loads

Transport 18 to 100 < 40 js6 (j6)

(<0.06 Cr1))

vehicles,

Precision

machinery, 100 to 200 40 to 140 k6

Machine tools k6 and m6

can be used

Rotating

General for single-

Inner Ring

applications, js5~6 row tapered

Load or <18 -

Medium and (j5-6) roller

Load

large motors, bearings

Indeterminate

Turbines, instead of k5

Pumps, and m5.

Normal loads

Engines, 18 to 100 < 40 k5 or 6

(0.06 to 0.13

Gears,

Cr)

Woodworking

machines, 100 to 140 40 to 100 m5 or 6

Vehicles,

Construction

equipment, 140 to 200 100 to 140 m6

Crushers

● Fits of radial bearings with housing

Tolerance

for

Load Conditions Examples Remarks

housing

bores

Automotive wheel

Normal or

hubs, Vibrating N7

Rotating heavy loads

screens

outer

Solid ring load Light or Conveyor roller,

In the case of K7 or JS7(J7) is an

Housings variable Rope sheaves, M7

alternative. If axial displacement of

loads Tension pulleys

the outer ring is not required, K7 is

Heavy applied.If axial displacement of

Traction motors M7

shock loads outer ring is necessary, JS7 (J7) is

Direction of applied

Normal or

load

heavy loads Pumps, Medium K7

Indeterminate

and large motors JS7(J7)

Normal or

Solid or

light loads

Split

Housing General bearing

Loads of all application,

H7

kinds Railway axle

boxes

Rotating

Inner Grinding Spindle

ring load rear ball bearings,

high Speed

JS6(J6)

Accurate Centrifugal For heavy loads, interference

running Compressor free fit tighter than K is used. When

Desirable bearings high accuracy is required,

under very strict tolerances should

Grinding spindle

Solid normal and be used for fitting.

front ball bearings,

Housing Direction of light loads

High speed

load K6

centrifugal

Indeterminate

compressor fixed

bearings

Rotating Minimum

Electrical home

inner noise is H6

appliance

ring load required

Notes: The above form is for steel housing, if alnico housing, the interference shall be bigger than the above.

● Tolerances for Shaft Diameters

Shaft tolerances and resultant fits

Shaft Bearing

Diameter Broe diameter g6 h6 j5 j6 js5

mm tolerance Δdmp

Over Incl. Low High High Low High Low High Low High Low High Low

Deviations (shaft diameter)

Theoretical interference (+) / clearance (-)

Probable interference (+) / clearance (-)

1 3 -8 0 -2 -8 0 -6 +2 -2 +4 -2 +2 -2

+6 -8 +8 -6 +10 -2 +12 -2 +10 -2

+4 -6 +6 -4 +9 -1 +10 0 +9 -1

3 6 -8 0 -4 -12 0 -8 +3 -2 +6 -2 +2,5 -2,5

+4 -12 +8 -8 +11 -2 +14 -2 +10,5 -2,5

+2 -10 +6 -6 +10 -1 +12 0 +9 -1

6 10 -8 0 -5 -14 0 -9 +4 -2 +7 -2 +4 -4

+3 -14 +8 -9 +12 -2 +15 -2 +11 -3

+1 -12 +6 -7 +10 0 +13 0 +9 -1

10 18 -8 0 -6 -17 0 -11 +5 -3 +8 -3 +4 -4

+2 -17 +8 -11 +13 -3 +16 -3 +12 -4

0 -15 +6 -9 +11 -1 +14 -1 +10 -2

18 30 -10 0 -7 -20 0 -13 +5 -4 +9 -4 +4,5 -4,5

+3 -20 +10 -13 +15 -4 +19 -4 +14,5 -4,5

0 -17 +7 -10 +13 -2 +16 -4 +12 -2

30 50 -12 0 -9 -25 0 -16 +6 -5 +11 -5 +5,5 -5,5

+3 -25 +12 -16 +18 -5 +23 -5 +15,5 -5,5

-1 -21 +8 -12 +15 -2 +19 -1 +15 -3

50 80 -15 0 -10 -29 0 -19 +6 -7 +12 -7 +6,5 -6,5

+5 -29 +15 -19 +21 -7 +27 -7 +21.5 -6,5

+1 -25 +11 -15 +17 -3 +23 -3 +18 -3

80 120 -20 0 -12 -34 0 -22 +6 -9 +13 -9 +7,5 -7,5

+8 -34 +20 -22 +26 -9 +33 -9 +27,5 -7,5

+2 -28 +14 -16 +21 -4 +27 -3 +23 -3

120 180 -25 0 -14 -39 0 -25 +7 -11 +14 -11 +9 -9

+11 -39 +25 -25 +32 -11 +39 -11 +34 -9

+4 -32 +18 -18 +26 -5 +32 -4 +28 -3

Shaft Bearing

Diameter Broe diameter js6 k5 k6 m5 m6

mm tolerance Δdmp

Over Incl. Low High High Low High Low High Low High Low High Low

Deviations (shaft diameter)

Theoretical interference (+) / clearance (-)

Probable interference (+) / clearance (-)

1 3 -8 0 +3 -3 +4 0 +6 0 +6 +2 +8 +2

+11 -3 +12 0 +14 0 +14 +2 +16 +2

+9 -1 +11 +1 +12 +2 +13 +3 +14 +4

3 6 -8 0 +4 -4 +6 +1 +9 +1 +9 +4 +12 +4

+12 -4 +14 +1 +17 +1 +17 +4 +20 +4

+10 -2 +13 +2 +15 +3 +16 +5 +18 +6

6 10 -8 0 +4,5 -4,5 +7 +1 +10 +1 +12 +6 +15 +6

+12,5 -4,5 +15 +1 +18 +1 +20 +6 +23 +6

+11 -3 +13 +3 +16 +3 +18 +8 +21 +8

10 18 -8 0 +5,5 -5,5 +9 +1 +12 +1 +15 +7 +18 +7

+13,5 -5,5 +17 +1 +20 +1 +23 +7 +26 +7

+11 -3 +15 +3 +18 +3 +21 +9 +24 +9

18 30 -10 0 +6,5 -6,5 +11 +2 +15 +2 +17 +8 +21 +8

+16,5 -6,5 +21 +2 +25 +2 +27 +8 +31 +8

+14 -4 +19 +4 +22 +5 +25 +10 +28 +11

30 50 -12 0 +8 -8 +13 +2 +18 +2 +20 +9 +25 +9

+20 -8 +25 +2 +30 +2 +32 +9 +25 +9

+16 -4 +22 +5 +26 +6 +29 +12 +25 +9

50 80 -15 0 +9,5 -9,5 +15 +2 +21 +2 +24 +11 +30 +11

+24.5 -9,5 +25 +2 +30 +2 +32 +9 +45 +11

+20 -5 +26 +6 +32 +6 +35 +15 +41 +15

80 120 -20 0 +11 -11 +18 +3 +25 +3 +28 +13 +35 +13

+31 -11 +38 +3 +45 +3 +48 +13 +55 +13

+25 -5 +33 +8 +39 +9 +43 +18 +49 +19

120 180 -25 0 +12,5 -12,5 +21 +3 +28 +3 +33 +15 +40 +15

+37,5 -12,5 +46 +3 +53 +3 +58 +15 +65 +15

+31 -6 +40 9 +46 +10 +52 +21 +58 +22

● Tolerances for Housing Bore Diameters

Housing tolerances and resultant fits

Housing Bearing

Diameter Outside diameter H6 H7 J6 J7 JS6

mm tolerance Δdmp

Over Incl. Low High High Low High Low High Low High Low High Low

Deviations (shaft diameter)

Theoretical interference (+) / clearance (-)

Probable interference (+) / clearance (-)

6 10 0 -8 0 +9 0 +15 -4 -5 -7 +8 -4,5 +4,5

0 -17 0 -23 +4 -13 +7 -16 +4,5 -12,5

-2 -15 -3 -20 +2 -11 +4 -13 +3 -11

10 18 0 -8 0 +11 0 +18 -5 +6 -8 +10 -5,5 +5,5

0 -19 0 -26 +5 -14 +8 -18 +5,5 -13.5

-2 -17 -3 -23 +3 -12 +5 -15 +3 -11

18 30 0 -9 +0 +13 0 +21 -5 +8 -9 +12 -6.5 +6.5

0 -22 0 -30 +5 -17 +9 -21 +6.5 -15.5

-3 -19 -3 -27 +2 -14 +6 -18 +4 -13

30 50 0 -11 +0 +16 0 +25 -6 +10 -11 +14 -8 +8

0 -27 0 -36 +6 -21 +11 -25 +8 -19

-3 -24 -4 -32 +3 -18 +7 -21 +5 -16

50 80 0 -13 0 +19 0 30 -6 +13 -12 +18 -9.5 +9.5

0 -32 0 -43 +6 -31 +12 -31 +9.5 -22.5

-4 -28 -5 -38 +2 -22 +7 -26 +6 -19

80 120 0 -15 0 +22 0 +35 -6 +16 -13 +22 -11 +11

0 -37 0 -50 +6 -31 +13 -37 +11 -26

-5 -32 -5 -45 +1 -26 +8 -32 +6 -21

120 150 0 -18 0 +25 0 +40 -7 +18 -14 +26 -12,5 +12,5

0 -43 0 -58 +7 -36 +14 -44 +12,5 -30,5

-6 -37 -7 -51 +1 -30 +7 -37 +7 -25

150 180 0 -25 0 +25 0 +40 -7 +18 -14 +26 -12,5 +12,5

0 -50 0 -65 +7 -43 +14 -51 +12,5 -37,5

-7 -43 -8 -57 0 -36 +6 -43 +6 -31

180 250 0 -30 0 +29 0 +46 -7 +22 -16 +30 -14,5 +14,5

0 -59 0 -76 +7 -52 +16 -60 +14,5 +14,5

-8 -51 -10 -66 -1 -44 +6 -50 +6 -36

Housing Bearing

Diameter Outside diameter JS7 K6 K7 M7 N7

mm tolerance Δdmp

Over Incl. Low High High Low High Low High Low High Low High Low

Deviations (shaft diameter)

Theoretical interference (+) / clearance (-)

Probable interference (+) / clearance (-)

6 10 0 -8 -7,5 +7,5 -7 +2 -10 +5 -15 0 -19 -4

+7,5 -15,5 +7 -10 +10 -13 +15 -8 +19 -4

+5 -13 +5 -8 +7 -10 +12 -5 +16 -1

10 18 0 -8 -9 +9 -9 +2 -12 +6 -18 0 -23 -5

+9 -17 +9 -10 +12 -14 +18 -8 +23 -3

+6 -14 +7 -8 +9 -11 +15 -5 +20 0

18 30 0 -9 -10.5 +10.5 -11 +2 -15 +6 -21 0 -28 -7

+10.5 -19.5 +11 -11 +15 -15 +21 -9 +28 -2

+7 -16 +8 -8 +12 -12 +18 -6 +25 +1

30 50 0 -11 -12.5 +12.5 -13 +3 -18 +7 -25 0 -33 -8

+12.5 -23.5 +13 -14 +18 -18 +25 -11 +33 -3

+9 -20 +10 -11 +14 -14 +21 -7 +29 +1

50 80 0 -13 -15 +15 -15 +4 -21 +9 -30 0 -39 -9

+15 -28 +15 -17 +21 -22 +30 -13 +39 -4

+10 -23 +11 -13 +16 -17 +25 -8 +34 +1

80 120 0 -15 -17.5 +17.5 -18 +4 -25 +10 -35 0 -45 -10

+17.5 -32.5 +18 -19 +25 -25 +35 -15 +45 -5

+12 -27 +13 -14 +20 -20 +30 -10 +40 0

120 150 0 -18 -20 +20 -21 +4 -28 +12 -40 0 -52 -12

+20 -38 +21 -22 +28 -30 +40 -18 +52 -6

+13 -31 +15 -16 +21 -23 +33 -11 +45 +1

150 180 0 -25 -20 +20 -21 +4 -28 +12 -40 0 -52 -12

+20 -45 +21 -29 +28 -37 +40 -25 +52 -13

+12 -37 +14 -22 +20 -29 +32 -17 +44 -5

180 250 0 -30 -23 +23 -24 +5 -33 +13 -46 0 -60 -14

+23 -53 +24 -35 +33 -43 +46 -30 +60 -16

+13 -43 +16 -27 +23 -33 +36 -20 +50 +6

@2013 China•Huanchi Bearing Group Terms and Conditions | Sitemap |

Privacy Policy

浙公网安备 33028202000255号

You might also like

- Shaft and Housing Tolerances - Nodes BearingDocument1 pageShaft and Housing Tolerances - Nodes BearingMorteza ShakerienNo ratings yet

- Bearing Tolerances PDFDocument13 pagesBearing Tolerances PDFkeyur1109No ratings yet

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDocument16 pagesClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyAxel DominiqueNo ratings yet

- Turntables Specification JostDocument6 pagesTurntables Specification JostYãbeçk MâmNo ratings yet

- Kaydon 390 MTDocument7 pagesKaydon 390 MTExpertum99No ratings yet

- Split Tapered Bearings Mini CatalogueDocument16 pagesSplit Tapered Bearings Mini CataloguekrutesNo ratings yet

- Engineering Tolerancing: Chapter OutlineDocument36 pagesEngineering Tolerancing: Chapter OutlineZir BexehenNo ratings yet

- General Information: Wire Rope SheavesDocument2 pagesGeneral Information: Wire Rope SheavesFayyaz NadeemNo ratings yet

- Design of Shafts and Housings For Optimum Operation and PerformanceDocument2 pagesDesign of Shafts and Housings For Optimum Operation and Performancemichaeltichon3No ratings yet

- Fits Si Tables Ansi b4.2-1978 r1994 0Document10 pagesFits Si Tables Ansi b4.2-1978 r1994 0SebastiánGarcíaNo ratings yet

- HP 50-65 FIXED ROTARY TILLER SPECIFICATIONS AND PRICINGDocument1 pageHP 50-65 FIXED ROTARY TILLER SPECIFICATIONS AND PRICINGVishwanathanNo ratings yet

- Involute Spline Shafts & Bushings: FeaturesDocument4 pagesInvolute Spline Shafts & Bushings: FeaturesSunilNo ratings yet

- Easy to mount cartridge spindles and precision grinding headsDocument11 pagesEasy to mount cartridge spindles and precision grinding headsstallone21No ratings yet

- NSK CAT E1102m A58-81-1Document12 pagesNSK CAT E1102m A58-81-1tepu msosaNo ratings yet

- UCFC 215: Round Flange Ball Bearing Unit With Extended Inner Ring and Set Screw Locking, Cast Iron Housing, JISDocument6 pagesUCFC 215: Round Flange Ball Bearing Unit With Extended Inner Ring and Set Screw Locking, Cast Iron Housing, JISJhon Jairo Arango MarquezNo ratings yet

- Link-Thyssenkrupp Rothe Erde Turntables BrochureDocument9 pagesLink-Thyssenkrupp Rothe Erde Turntables BrochureBang TwoNo ratings yet

- 2030 Catalog PDFDocument15 pages2030 Catalog PDFAmanush KoolNo ratings yet

- HSM Brochure PDFDocument4 pagesHSM Brochure PDFBerinssonScottHernandezSucsoNo ratings yet

- Standard grating installation clearancesDocument1 pageStandard grating installation clearancesnalzackNo ratings yet

- Flexible Disc Couplings: TB Wood's Form-FlexDocument44 pagesFlexible Disc Couplings: TB Wood's Form-Flexraj_kr1078No ratings yet

- Fits Between Radial Bearings and Housing BoresDocument1 pageFits Between Radial Bearings and Housing Boresmohamed bakryNo ratings yet

- 2985 6085 1 PBDocument7 pages2985 6085 1 PBDinizNo ratings yet

- Sundwig 2HI Skinpass CounterbendingDocument2 pagesSundwig 2HI Skinpass Counterbendingsmc07No ratings yet

- Link BeltDocument6 pagesLink Beltnelson santosNo ratings yet

- HSS Handbook 2018 DigitalDocument16 pagesHSS Handbook 2018 DigitalChris van RensburgNo ratings yet

- 02IDPT Drill Bits #2Document48 pages02IDPT Drill Bits #2AboZaidNo ratings yet

- HSM Catalog EngDocument68 pagesHSM Catalog EngFernando MéndezNo ratings yet

- Cilindros RLSDocument1 pageCilindros RLSErnesto El LokoNo ratings yet

- Fits Between Radial Bearings and ShaftsDocument1 pageFits Between Radial Bearings and Shaftsmohamed bakryNo ratings yet

- FL4012Document2 pagesFL4012Leonardo Infante VargasNo ratings yet

- SP-0702 RF-12-611 MilitarDocument2 pagesSP-0702 RF-12-611 Militarafaba5No ratings yet

- Dura LubeDocument4 pagesDura LubemoisespolancoNo ratings yet

- Straightening and Guide RollsDocument7 pagesStraightening and Guide Rollsa04205No ratings yet

- The Importance of Properly Mounting Thin Section Bearings: An SKF Group BrandDocument8 pagesThe Importance of Properly Mounting Thin Section Bearings: An SKF Group BrandTony CasillaNo ratings yet

- Carb Toroidal Roller Bearings Can Improve The Performance and Reliability of Bearing ArrangementsDocument4 pagesCarb Toroidal Roller Bearings Can Improve The Performance and Reliability of Bearing ArrangementsAsela BandaraNo ratings yet

- SKF WSTU 215-SRB-CRE SpecificationDocument5 pagesSKF WSTU 215-SRB-CRE SpecificationGuess VaughnNo ratings yet

- Bearing Basics: SKF Reliability Maintenance InstituteDocument49 pagesBearing Basics: SKF Reliability Maintenance Institutepurav_patel20079232No ratings yet

- NSK CAT E1102m A20-23 PDFDocument2 pagesNSK CAT E1102m A20-23 PDFChetan PrajapatiNo ratings yet

- Radial Clearance Reduction CardDocument2 pagesRadial Clearance Reduction Cardmh100% (1)

- Everything Under Control... : Rotolok UsaDocument4 pagesEverything Under Control... : Rotolok UsaJimmy BallonNo ratings yet

- Manual Reductor Faja de 24Document15 pagesManual Reductor Faja de 24yan100% (1)

- Tpi183 de en PDFDocument40 pagesTpi183 de en PDFAGNALDOJULIONo ratings yet

- E1 Lozyska Barylkowe FAGDocument26 pagesE1 Lozyska Barylkowe FAGnoregisteredNo ratings yet

- 2018-07-01 No-B1031e-6 BRG Precision Bro en WebDocument49 pages2018-07-01 No-B1031e-6 BRG Precision Bro en WebFernando EmanuelNo ratings yet

- Drylin R Round Shaft Guide SystemsDocument29 pagesDrylin R Round Shaft Guide SystemsAdelson MartinsNo ratings yet

- Bearing MS 51961-35Document2 pagesBearing MS 51961-35Moutaz IsmailNo ratings yet

- Overview Bearing ElementsDocument1 pageOverview Bearing ElementsPatrick BrilhanteNo ratings yet

- Timber Purlin Screw Armourcoat Blue 2020Document2 pagesTimber Purlin Screw Armourcoat Blue 2020alive stayNo ratings yet

- Fit Tolerances and Applications - Mec Engineering SpreadsheetsDocument14 pagesFit Tolerances and Applications - Mec Engineering Spreadsheetstemu ShashNo ratings yet

- Tapered Roller BearingsDocument37 pagesTapered Roller Bearingskhairul ardyNo ratings yet

- BB 1 - 1 Estapa - Pump WorksDocument2 pagesBB 1 - 1 Estapa - Pump WorksMarco Pompa ReyesNo ratings yet

- SKF fitsDocument42 pagesSKF fitsNitu Vasile VirgilNo ratings yet

- Horizontal Split CasingDocument6 pagesHorizontal Split CasingvivekpecNo ratings yet

- Gear Pump KRACHT KF3 - 63 PDFDocument11 pagesGear Pump KRACHT KF3 - 63 PDFDimitrijs Silins100% (1)

- Brochure OTR KOMATSU PDFDocument16 pagesBrochure OTR KOMATSU PDFAdityanath DasNo ratings yet

- FCV PlugValve 5000RDocument12 pagesFCV PlugValve 5000RtestNo ratings yet

- Type of Fit Symbol of Fit Examples of Application Interference FitDocument1 pageType of Fit Symbol of Fit Examples of Application Interference FitDharmesh patelNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Fundamental of O-RingDocument32 pagesFundamental of O-RingMorteza ShakerienNo ratings yet

- KEC General PresentarionDocument6 pagesKEC General PresentarionMorteza ShakerienNo ratings yet

- O-Ring Groove Design Extrusion Limits - Seal & Design, IncDocument2 pagesO-Ring Groove Design Extrusion Limits - Seal & Design, IncMorteza ShakerienNo ratings yet

- NDT Procedure For Dye Penetrant Inspection: 1 Scope Qualification of Testing PersonnelDocument4 pagesNDT Procedure For Dye Penetrant Inspection: 1 Scope Qualification of Testing PersonnelMorteza ShakerienNo ratings yet

- Gland Dimensions Industrial Static SealDocument1 pageGland Dimensions Industrial Static SealMorteza ShakerienNo ratings yet

- RESL Catalogue StandardDocument8 pagesRESL Catalogue StandardMorteza ShakerienNo ratings yet

- O-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierDocument4 pagesO-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierMorteza ShakerienNo ratings yet

- Gland Dimensions Industrial Reciprocating SealDocument1 pageGland Dimensions Industrial Reciprocating SealMorteza ShakerienNo ratings yet

- O-Ring Seal Sizes: From Micro To Macro, We Have Every Size You NeedDocument36 pagesO-Ring Seal Sizes: From Micro To Macro, We Have Every Size You NeedMorteza ShakerienNo ratings yet

- Magneto-Electric Transmitter MEM / MEM-PPA Operating InstructionDocument11 pagesMagneto-Electric Transmitter MEM / MEM-PPA Operating InstructionMorteza ShakerienNo ratings yet

- 4eys / 4eyt: Installation/Operating ManualDocument28 pages4eys / 4eyt: Installation/Operating ManualMorteza ShakerienNo ratings yet

- Compact elastomer bellows seal technical specificationsDocument2 pagesCompact elastomer bellows seal technical specificationsMorteza ShakerienNo ratings yet

- Catalog Burgmann mg1Document8 pagesCatalog Burgmann mg1Morteza ShakerienNo ratings yet

- Catalog Burgmann mg9Document7 pagesCatalog Burgmann mg9Morteza ShakerienNo ratings yet

- Beyond Ra - Why Surface Finish Matters in Seal Performance - Fluid Power JournalDocument7 pagesBeyond Ra - Why Surface Finish Matters in Seal Performance - Fluid Power JournalMorteza ShakerienNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)Morteza ShakerienNo ratings yet

- Abravan Pumps CatalogueDocument143 pagesAbravan Pumps CatalogueMorteza ShakerienNo ratings yet

- Drawing 2Document1 pageDrawing 2Morteza ShakerienNo ratings yet

- Study of The Trapping of Fluid A Gear: Yanada, Meng and T Icbikawa, Itsuji, MengDocument7 pagesStudy of The Trapping of Fluid A Gear: Yanada, Meng and T Icbikawa, Itsuji, MengMorteza ShakerienNo ratings yet

- TEPZZ 5 9 - B - T: European Patent SpecificationDocument34 pagesTEPZZ 5 9 - B - T: European Patent SpecificationMorteza ShakerienNo ratings yet

- NII-Electronic Library ServiceDocument9 pagesNII-Electronic Library ServiceMorteza ShakerienNo ratings yet

- Design and Performance of Gear Pumps With A Non-Involute Tooth ProfileDocument13 pagesDesign and Performance of Gear Pumps With A Non-Involute Tooth ProfileMorteza ShakerienNo ratings yet

- Parker CFD Analysis PGP 640 ModelDocument18 pagesParker CFD Analysis PGP 640 ModelsudharsanNo ratings yet

- PDF QCF Start ActionDocument2 pagesPDF QCF Start ActionMorteza ShakerienNo ratings yet

- VC Flow Meter Construction and OperationDocument20 pagesVC Flow Meter Construction and OperationMorteza ShakerienNo ratings yet

- Analysis of Mechanical Engineering Design and Quality ControlDocument4 pagesAnalysis of Mechanical Engineering Design and Quality ControlMorteza ShakerienNo ratings yet

- Robustnessday - GPS-challenges and opportunities-JD-16-9 PDFDocument34 pagesRobustnessday - GPS-challenges and opportunities-JD-16-9 PDFMorteza ShakerienNo ratings yet

- Fits and Tolerances On Gearbox Shaft and Housing - The Engineering BlogDocument1 pageFits and Tolerances On Gearbox Shaft and Housing - The Engineering BlogMorteza ShakerienNo ratings yet

- Selection of FAG Bearing Arrangement - Nodes BearingDocument2 pagesSelection of FAG Bearing Arrangement - Nodes BearingMorteza ShakerienNo ratings yet

- Accounting & Finance Professional: Uzair Ahmed KhanDocument5 pagesAccounting & Finance Professional: Uzair Ahmed KhanmedicotNo ratings yet

- Image Processing Methods For Food InspectionDocument69 pagesImage Processing Methods For Food InspectionFemilNo ratings yet

- D3E804F51B6-02T 5-Speed Manual GearboxDocument133 pagesD3E804F51B6-02T 5-Speed Manual GearboxjorgebautistagarciaNo ratings yet

- (CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static LoadingDocument156 pages(CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static Loading_at_to_75% (4)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- Isee Nses2023 BrochureDocument12 pagesIsee Nses2023 BrochurehksachinNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- Arduino ReportDocument3 pagesArduino ReportarunNo ratings yet

- Client Contract1Document4 pagesClient Contract1Jeysi MartinezNo ratings yet

- Curses, Foiled Again, and AgainDocument68 pagesCurses, Foiled Again, and AgainPete TaltonNo ratings yet

- Dielectric Properties Analysis of Gas Turbine Synchronous Generator by Polarization and Depolarization Current MeasuremenDocument4 pagesDielectric Properties Analysis of Gas Turbine Synchronous Generator by Polarization and Depolarization Current MeasuremenAriNo ratings yet

- Datasheet Uni M QNB NS enDocument2 pagesDatasheet Uni M QNB NS enLinh dươngNo ratings yet

- Condor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) ADocument2 pagesCondor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) AEldar IsgenderovNo ratings yet

- In Southeast Asia Poised For Rapid Growth: AUGUST 2019Document8 pagesIn Southeast Asia Poised For Rapid Growth: AUGUST 2019Nguyễn Vũ HoàngNo ratings yet

- Rcra Online: Howdoiuse Advanced Search?Document2 pagesRcra Online: Howdoiuse Advanced Search?Franklin Crespo AmoresNo ratings yet

- IntR 09 2012 0199Document23 pagesIntR 09 2012 0199Hazel Bianca GabalesNo ratings yet

- Load Banks CatalogDocument10 pagesLoad Banks CatalogMehmet Cem AteşNo ratings yet

- Chapter 3 - Overview of Manufacturing - UpdateDocument58 pagesChapter 3 - Overview of Manufacturing - Updatethinhtruong17092003No ratings yet

- Histograms Answers MMEDocument5 pagesHistograms Answers MMEEffNo ratings yet

- Urban Transit For Livable Cities: ReferencesDocument3 pagesUrban Transit For Livable Cities: ReferencesVismitha RamaiahNo ratings yet

- Factor Quadratic TrinomialsDocument23 pagesFactor Quadratic TrinomialsMaegan Eunice VirayNo ratings yet

- Clone WarsDocument30 pagesClone Warsapi-652369770No ratings yet

- PartnerDocument14 pagesPartnerLeo van GorkumNo ratings yet

- MTM800增强型控制头Document308 pagesMTM800增强型控制头1012268087No ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- GNSS Processing Report for TDTV MarkerDocument9 pagesGNSS Processing Report for TDTV MarkerJoshua Paskah NugrahaNo ratings yet

- English H I Tho I Tatm5Document14 pagesEnglish H I Tho I Tatm5Anh Nguyễn TuấnNo ratings yet

- A General Contingency Theory of ManagementDocument16 pagesA General Contingency Theory of ManagementlucasNo ratings yet

- Endterm Algebra 2019 TT01Document1 pageEndterm Algebra 2019 TT01khang nguyễnNo ratings yet

- How Does Night Vision Work Research PaperDocument4 pagesHow Does Night Vision Work Research Paperafeenylsy100% (1)