Professional Documents

Culture Documents

Is 1608 - 2005 - 25

Uploaded by

SvapneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1608 - 2005 - 25

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608: 2005

ISO 6892: 1998

Annex C

(normative)

Types of test piece to be used for sheets a~,d flats of thickness equal to or greater than 3 mm,

and wire, bars and sections of diameter or thickness equal to or greater than 4 mm

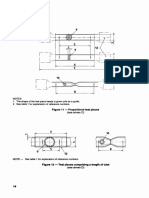

C.1 Shape of the test piece

In general, the test piece is machined and the parallel length shall be connected by means of transition

curves to the gripped ends which may be of any suitable shape for the grips of the test machine (see

figure 11). The minimum transition radius between the gripped ends and the parallel length shall be:

0,75 d (d being the diameter of the gauge length) for the cylindrical test pieces;

12 mm for the prismatic test pieces.

Sections, bars, etc., may be tested unmachined, if required.

The cross-section of the test piece may be circular, square, rectangular or, in special cases, of another

shape.

For test pieces with a rectangular cross-section it is recommended that the width to thickness ratio

should not exceed 8: 1.

In general, the diameter of the parallel length of machined cyli"drical test pieces shall be not less than

4mm.

C.2 Dimensions of the test piece

C.2.1 Parallel length of machined test piece

The parallel length (Lc) shall be at least equal to:

a) L o + ~ in the case of test pieces with circular cross-section;

b) Lo + 1 ,5~ in the case of prismatic test pieces.

Depending on the type of test piece, the length Lo + 2d or Lo + 2 ~ shall be used in cases of dispute,

unless there is insufficient material.

C.2.2 Length of unmachlned test piece

The free length between the grips of the machine shall be adequate for the gauge marks to be at a

reasonable distance from these grips.

23

You might also like

- Unit 1 MetrologDocument145 pagesUnit 1 MetrologPavan TejaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- TG1 Scala Dynamic Cone Penetrometer Cone CalibrationDocument4 pagesTG1 Scala Dynamic Cone Penetrometer Cone Calibrationanthony100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Radiographic Examination of Piping Welds According To EN: IssueDocument6 pagesRadiographic Examination of Piping Welds According To EN: Issuebth8320No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Standards of MeasurementDocument18 pagesStandards of Measurementvarn_op10No ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Metrology and Quality Control PracticalDocument53 pagesMetrology and Quality Control PracticalDIPAK VINAYAK SHIRBHATE75% (4)

- Chapter 1: Standards of MeasurementDocument18 pagesChapter 1: Standards of MeasurementStelwin FernandezNo ratings yet

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDocument16 pagesManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukdarouichNo ratings yet

- Standards of Measurement.Document14 pagesStandards of Measurement.Muhammad Sohag HussainNo ratings yet

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- Unit I Sprx1003 Metrology and InstrumentationDocument31 pagesUnit I Sprx1003 Metrology and InstrumentationBHOOMINo ratings yet

- Manual Ultrasonic Inspection of Thin Metal WeldsDocument16 pagesManual Ultrasonic Inspection of Thin Metal WeldsSimon LeeNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingFrom EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingNo ratings yet

- 10 Me 42 BDocument144 pages10 Me 42 BdineshNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF Asme CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF Asme CodesDiego HenriqueNo ratings yet

- Mech311 Midterm 2009, 2011 and 2012Document9 pagesMech311 Midterm 2009, 2011 and 2012Parvinder SinghNo ratings yet

- Standards of Measurement Presented by Dr.P.R. Venkatesh Professor Dept of Mechanical Engineering Rvce Bangalore-54Document18 pagesStandards of Measurement Presented by Dr.P.R. Venkatesh Professor Dept of Mechanical Engineering Rvce Bangalore-54Blue DarkNo ratings yet

- D 1052 - 85 R99 - RdewntiDocument4 pagesD 1052 - 85 R99 - RdewntimanthandevNo ratings yet

- Test Specimens and Mechanical Testing Procedures For Materials W2Document10 pagesTest Specimens and Mechanical Testing Procedures For Materials W2utsmanheruNo ratings yet

- UT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithDocument21 pagesUT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithAZAZ AHMADNo ratings yet

- ASME Sec VIII Div 1Document120 pagesASME Sec VIII Div 1kanchanabalaji96% (23)

- Wear of Coated and Uncoated Carbides in Turning Tool SteelDocument6 pagesWear of Coated and Uncoated Carbides in Turning Tool Steelking9sunNo ratings yet

- 1.length StandardsDocument23 pages1.length StandardsBala Sundar M100% (1)

- Weld Spec 2Document3 pagesWeld Spec 2spstainless316No ratings yet

- IS 1079 Hot Rolled Carbon Steel SheetsDocument12 pagesIS 1079 Hot Rolled Carbon Steel Sheetssdmel75% (8)

- Ut ProcedureDocument4 pagesUt Procedureأحمد صبحىNo ratings yet

- ESAB - PipelinesDocument65 pagesESAB - PipelinesLigia114100% (2)

- UT of TKY Connections PDFDocument14 pagesUT of TKY Connections PDFreiazh0% (1)

- Chapter 1Document5 pagesChapter 1Gaurav AgarwalNo ratings yet

- R024-E75 Standard One Metre Bar For Verification OfficersDocument7 pagesR024-E75 Standard One Metre Bar For Verification OfficerselrojoerikNo ratings yet

- Tensile Calculation PDFDocument2 pagesTensile Calculation PDFWendimagen Meshesha FantaNo ratings yet

- Astm C490Document5 pagesAstm C490Horacio ApolayoNo ratings yet

- Astm D1654 08 New PDFDocument7 pagesAstm D1654 08 New PDFAlek Abek ANo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- Lecture 3Document10 pagesLecture 3Abhishek SinhaNo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- Module 2Document7 pagesModule 2sathiaNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- C 559Document2 pagesC 559Asep TheaNo ratings yet

- Slip GaugesDocument17 pagesSlip GaugesUday ThulaNo ratings yet

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Specimen BlankingDocument3 pagesSpecimen BlankingAguayo JavierNo ratings yet

- En 10045-1Document9 pagesEn 10045-1Elton Sanchez100% (2)

- Pipelines Welding HandbookDocument64 pagesPipelines Welding HandbookSixto GerardoNo ratings yet

- Engg Metrology (C-1 Answers)Document11 pagesEngg Metrology (C-1 Answers)Mohammed AseerNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 34Document1 pageIs 1608 - 2005 - 34SvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- Figure 13 - Test Piece Cut From A TubeDocument1 pageFigure 13 - Test Piece Cut From A TubeSvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 20Document1 pageIs 1608 - 2005 - 20SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEFrom EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATERating: 4 out of 5 stars4/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Building Construction and DrawingFrom EverandBuilding Construction and DrawingRating: 2.5 out of 5 stars2.5/5 (3)

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)