Professional Documents

Culture Documents

(Rpo, 2) in The Case

Uploaded by

SvapneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Rpo, 2) in The Case

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608 : 2005

ISO 6892: 1998

In tables K.1 and K.2, these three kinds of error are expressed in terms of a relative uncertainty

coefficient:

where

x is the general average;

sr is the estimated repeatability standard deviation within laboratories;

'\"l.. is the estimated variability between laboratories;

sR is the estimated precision of the test method: reproducibility standard deviation.

These quantities are close to the 95 % confidence interval of x. They are calculated for each material

tested. and each property.

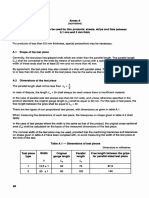

K.3 Results of programme A

Details can be found in the report, reference [7]. The materials are a soft aluminium, a heat-treated

aluminium alloy, a low alloy steel, an austenitic stainless steel, a nickel-base alloy and a high-alloy heat

treated steel. For each material, six tests were carried out by the six participants. In all cases, 12,5 mm

diameter cylindrical test pieces were used. The results are summarized in table K.1. In the case of the

low-alloy steel having a yield point behaviour, only the 0,2 % proof strength is reported. The elongation

values are relative to a gauge length equal to five diameters.

K.4 Results of programme B

Details can be found in the report, reference [8]. The materials are:

two sheet materials: a low carbon malleable steel and an austenitic stainless steel (thickness

2,5 mm);

three grades of bars: a constructional steel, an austenitic stainless steel, a heat treated high

strength steel (diameter 20 mm).

Tests were carried out using flat test pieces for the first two materials (18 participants, 5 tests for each

material) and 10 mm diameter cylindrical test pieces for the bars (18 participants, 5 tests for each

material). The width of the flat test piece was 20 mm and the initial gauge length 80 mm. The results are

summarized in table K.2. No distinction is made between lower yield strength (ReL) and proof strength

(RpO,2) in the case of materials with yield points. For the cylindrical test pieces, the elongation values

correspond to a gauge length equal to five diameters.

40

You might also like

- ASTM A 681-08 Standard Specification For Tool Steels AlloyDocument14 pagesASTM A 681-08 Standard Specification For Tool Steels AlloyTeodoroNo ratings yet

- Testing Guidence For Duplex Stainless Steel PDFDocument183 pagesTesting Guidence For Duplex Stainless Steel PDFtjt4779No ratings yet

- IS 1079 Hot Rolled Carbon Steel SheetsDocument12 pagesIS 1079 Hot Rolled Carbon Steel Sheetssdmel75% (8)

- ASTM A681-08 - Standard Specification For Tool Steels AlloyDocument14 pagesASTM A681-08 - Standard Specification For Tool Steels Alloyhand42100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsFrom EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Astm A633 1979Document6 pagesAstm A633 1979ingmichaelgarcia100% (1)

- 343 3khbDocument35 pages343 3khbshimic32000100% (1)

- Lab Description For Hardness Testing Procedures: Applicable StandardsDocument11 pagesLab Description For Hardness Testing Procedures: Applicable StandardsJaymin PatelNo ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNo ratings yet

- Edd Fuel Tank ApplicationDocument11 pagesEdd Fuel Tank ApplicationZubair AhmadNo ratings yet

- The Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCBDocument5 pagesThe Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCB78858799No ratings yet

- Quantitative MetallographyDocument14 pagesQuantitative MetallographyMhd. Didi Endah PranataNo ratings yet

- Structures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangDocument12 pagesStructures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangNasarKhanNo ratings yet

- High-Carbon Anti-Friction Bearing Steel: Standard Specification ForDocument4 pagesHigh-Carbon Anti-Friction Bearing Steel: Standard Specification Fornelwan_topanNo ratings yet

- Astm b649 1995Document6 pagesAstm b649 1995Greg YeeNo ratings yet

- Ruukki Technical Article Local Buckling of Plates Made of High Strength Steel - AshxDocument5 pagesRuukki Technical Article Local Buckling of Plates Made of High Strength Steel - AshxIsuru Indrajith PereraNo ratings yet

- Evaluation of MechanicalDocument5 pagesEvaluation of MechanicalPatil HemantNo ratings yet

- Evaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardDocument9 pagesEvaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardwalkerbhoNo ratings yet

- Energy Conservation in Foundry Industry by Modeling and Experimental Investigation of Induction Furnace Process ParametersDocument4 pagesEnergy Conservation in Foundry Industry by Modeling and Experimental Investigation of Induction Furnace Process ParametersEngr Farrukh RehanNo ratings yet

- Testing of The Mechanical Properties For 15mo3 SteelDocument2 pagesTesting of The Mechanical Properties For 15mo3 SteelavenclNo ratings yet

- Effect of Oxide Particles On The Stabilization and Final Microstructure in AluminiumDocument7 pagesEffect of Oxide Particles On The Stabilization and Final Microstructure in AluminiumEidelsayedNo ratings yet

- 03 JTE Astm Tensile Stress ConcentrationDocument6 pages03 JTE Astm Tensile Stress ConcentrationTanu RdNo ratings yet

- NIST Correlation Full-Size and Sub-Size or Miniaturized Charpy Specimens and Verification of Machines ELucon - PVT February 2016 PDFDocument42 pagesNIST Correlation Full-Size and Sub-Size or Miniaturized Charpy Specimens and Verification of Machines ELucon - PVT February 2016 PDFcehamos882No ratings yet

- Libroduplex PDFDocument183 pagesLibroduplex PDFHugo PeñaNo ratings yet

- Local Buckling Studies of Cold-Formed Steel Compression Members at Elevated TemperaturesDocument47 pagesLocal Buckling Studies of Cold-Formed Steel Compression Members at Elevated TemperaturesAlaa AssiNo ratings yet

- Abstract Exp1Document5 pagesAbstract Exp1wan nur mursyidahNo ratings yet

- 2015-5.9 SleevesDocument28 pages2015-5.9 SleevesLuis CanoNo ratings yet

- Testing Strategies To Evaluate Non-Oriented ElectrDocument12 pagesTesting Strategies To Evaluate Non-Oriented ElectrSadeeskumar NilNo ratings yet

- Torsional Buckling of Composite Cylindrical ShellsDocument108 pagesTorsional Buckling of Composite Cylindrical Shellsjunjie yiNo ratings yet

- Thin-Walled Structures: Yuner Huang, Ben YoungDocument10 pagesThin-Walled Structures: Yuner Huang, Ben YoungDr-Riya MondalNo ratings yet

- A618 PDFDocument4 pagesA618 PDFSadashiva sahooNo ratings yet

- The Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentsDocument23 pagesThe Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentspkguptaqaqcNo ratings yet

- Chem Lab 1 (1st Year Gen Chem Uottawa)Document10 pagesChem Lab 1 (1st Year Gen Chem Uottawa)MagicalC0wNo ratings yet

- 10 - Ravichandran Et AlDocument13 pages10 - Ravichandran Et AlAdam Al AufaNo ratings yet

- Effect of Variation in Magnesium and Copper On MecDocument9 pagesEffect of Variation in Magnesium and Copper On MecTaTayosNo ratings yet

- B 211 - 00 - Qjixms0wmaDocument10 pagesB 211 - 00 - Qjixms0wmamercab15No ratings yet

- Is 15961 - 2012Document12 pagesIs 15961 - 2012riverwilliamsNo ratings yet

- Galvanic Corrosion Behavior of Orthodontic Archwire Alloys Coupled To Bracket Alloys.Document7 pagesGalvanic Corrosion Behavior of Orthodontic Archwire Alloys Coupled To Bracket Alloys.maparmerNo ratings yet

- Effects of Post Weld Heat Treatment (PWHT) Temperature On Mechanical Properties of Weld Metals For High-Cr Ferritic Heat-Resistant SteelDocument7 pagesEffects of Post Weld Heat Treatment (PWHT) Temperature On Mechanical Properties of Weld Metals For High-Cr Ferritic Heat-Resistant SteelShanmuga NavaneethanNo ratings yet

- Is 5082 1998Document11 pagesIs 5082 1998dipenkhandhediyaNo ratings yet

- Thermo-Mechanical Analysis of Wire and Arc Additive Layer Manufacturing Process On Large Multi-Layer PartsDocument11 pagesThermo-Mechanical Analysis of Wire and Arc Additive Layer Manufacturing Process On Large Multi-Layer Partsrizkboss8312No ratings yet

- CIVE 265 - Lab 2 - Tensile Testing of MeDocument6 pagesCIVE 265 - Lab 2 - Tensile Testing of MeRebecca ChungNo ratings yet

- Brinell TestDocument8 pagesBrinell TestAddrien DanielNo ratings yet

- 1079Document12 pages1079Akhileshkumar PandeyNo ratings yet

- Leakage Rate Measurement and Durability Testing of Field-Made MecDocument11 pagesLeakage Rate Measurement and Durability Testing of Field-Made MecAndrei AtofaneiNo ratings yet

- Study On The Performance of Electroless Nickel Coating On Aluminium For Cylinder LinersDocument8 pagesStudy On The Performance of Electroless Nickel Coating On Aluminium For Cylinder LinersBharat Vinjamuri100% (1)

- Design, Fabrication and Performance Evaluation of A Hardness Testing MachineDocument6 pagesDesign, Fabrication and Performance Evaluation of A Hardness Testing MachineIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 2013-5.2 Riser SleeveDocument18 pages2013-5.2 Riser SleeveDavindRa Soni100% (1)

- Formabilities of Steel/aluminium Alloy Laminated Composite SheetsDocument7 pagesFormabilities of Steel/aluminium Alloy Laminated Composite SheetsgligamsnNo ratings yet

- Self Piercing RivetDocument11 pagesSelf Piercing RivetyomansahajNo ratings yet

- B 211m - 02 - Qjixmu0tmdiDocument10 pagesB 211m - 02 - Qjixmu0tmdimercab15No ratings yet

- Study On The Correlation of Toughness With ChemicaDocument7 pagesStudy On The Correlation of Toughness With ChemicaarvindNo ratings yet

- An Experimental Study of The Local Heat Transfer Characteristics in Automotive Louvered FinsDocument8 pagesAn Experimental Study of The Local Heat Transfer Characteristics in Automotive Louvered FinsAmnur AkhyanNo ratings yet

- Steel Fibers For Fiber-Reinforced ConcreteDocument4 pagesSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNo ratings yet

- Cobem 2225 FinalDocument7 pagesCobem 2225 FinalSérgio Fernando LajarinNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Is 1608 - 2005 - 11Document1 pageIs 1608 - 2005 - 11SvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 14Document1 pageIs 1608 - 2005 - 14SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inDocument1 pageIS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthDocument1 pageIS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthSvapneshNo ratings yet