Professional Documents

Culture Documents

Is 1608 - 2005 - 36

Uploaded by

SvapneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1608 - 2005 - 36

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608: 2005

ISO 6892: 1998

Annex J

(informative)

An "Error Budget" approach to the estimation of the uncertainty of measurement

In tensile testing

J.1 Introduction

An approach for estimating the uncertainty of measurements is outlined based upon the "error budget"

concept using the measurement tolerances specified in the testing and calibration standards. It should

be noted that it is not possible to calculate a single value for the measurement uncertainty for all

materials since different materials exhlbit different response characteristics to some of the specified

control parameters, e.g. straining rate or stressing rate [3). The error budget presented here could be

regarded as an upper limit to the measurement uncertainty for a laboratory undertaking testing in

compliance with this International Standard (class 1 machine and extensometer). .

It should be noted that when evaluating the total scatter in experimental results the uncertainty in

measurement should be considered in addition to the inherent scatter due to material inhomogeneity.

The statistical approach to the analysis of intercomparison exercises (Round Robin experiments) given

in appendix K does not separate out the two contributing causes of the scatter. Another useful approach

for estimating interlaboratory scatter is to employ a Certified Reference Material (CAM) which has

certified material properties. The selection of candidate materials for use as a room temperature tensile

CAM has been discussed elsewhere [3) and a 1 tonne batch of a material (Nimonic 75) in the form of

14 mm diameter bar is in the process of being certified in a project under the supervision of the

Community Bureau of Reference (SCA).

J.2 Estimation of uncertainty

J.2.1 Material Independent parameters

The manner in which errors from a variety of sources should be added together has been treated in

considerable detail (4) and more recently guidance has been given on assessing precision and

uncertainty in two ISO documents, ISO 5725-2 and the Guide to the expression of uncertainty in

measurement.

In the following analysis the conventional least mean squares approach has been used.

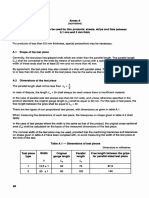

The tolerances for the various testing parameters for tensile properties are given in table J.1 together

with expected uncertainty. Because of the shape of the stress-strain curve, some of the tensile

properties in principle can be determined with a higher degree of precision than others, e.g., the upper

yield strength ReH is only dependent on the tolerances for measurement of force and cross sectional

area, whilst proof strength, Rp ' is dependent on force, strain (displacement), gauge length and

cross-sectional area. In the case of reduction in area, Z, the measurement tolerance for cross-sectional

area both before and after fracture needs to be considered.

34

You might also like

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Engineering Surveying: Theory and Examination Problems for StudentsFrom EverandEngineering Surveying: Theory and Examination Problems for StudentsRating: 4.5 out of 5 stars4.5/5 (8)

- The Estimation of Uncertainties in Hardness Measurements - GABAUERDocument18 pagesThe Estimation of Uncertainties in Hardness Measurements - GABAUERSuta VijayaNo ratings yet

- Uncert Cop 04 2000Document26 pagesUncert Cop 04 2000arbab_taghaviNo ratings yet

- The Determination of Uncertainties in Plane Strain Fracture Toughness (K) TestingDocument23 pagesThe Determination of Uncertainties in Plane Strain Fracture Toughness (K) TestingAnkur gaurNo ratings yet

- The Determination of Uncertainties in Critical Crack Tip Opening Displacement (CTOD) TestingDocument26 pagesThe Determination of Uncertainties in Critical Crack Tip Opening Displacement (CTOD) Testinganouar82No ratings yet

- Uncertainty Mech TestDocument9 pagesUncertainty Mech TestChong NeoyeahNo ratings yet

- Uncertainties in Fatigue Crack Growth MeasurementsDocument25 pagesUncertainties in Fatigue Crack Growth MeasurementsdilrangiNo ratings yet

- The Determination of Uncertainties in Compression TestingDocument18 pagesThe Determination of Uncertainties in Compression TestingMuhammadFaizalNo ratings yet

- Expression of Uncertainty in EMCDocument40 pagesExpression of Uncertainty in EMCDev Kumar Sil50% (2)

- The Determination of Uncertainties in High Cycle Fatigue Testing (For Plain and Notch-Sensitive Specimens)Document33 pagesThe Determination of Uncertainties in High Cycle Fatigue Testing (For Plain and Notch-Sensitive Specimens)Awan AJaNo ratings yet

- The Determination of Uncertainties in Charpy Impact TestingDocument19 pagesThe Determination of Uncertainties in Charpy Impact TestingAfriandiBayuNo ratings yet

- CookBook 08 Determination of Conformance - 09-2018Document4 pagesCookBook 08 Determination of Conformance - 09-2018Carlos LópezNo ratings yet

- Measurement Techniques and EvaluationDocument25 pagesMeasurement Techniques and Evaluationyaman saddikNo ratings yet

- M&MS 2007 453Document17 pagesM&MS 2007 453vijayaNo ratings yet

- An Introduction To Quality Assurance in Analytical Science: DR Irene Mueller-Harvey MR Richard Baker MR Brian WoodgetDocument17 pagesAn Introduction To Quality Assurance in Analytical Science: DR Irene Mueller-Harvey MR Richard Baker MR Brian WoodgetEddy TeranNo ratings yet

- Intermidiate Check Vâlcu - 2018 - J. - Phys. - Conf. - Ser. - 1065 - 042033Document5 pagesIntermidiate Check Vâlcu - 2018 - J. - Phys. - Conf. - Ser. - 1065 - 042033AAAbbbNo ratings yet

- Measurement Uncertainty in Material Testing: Differences and Similarities Between ISO, CEN and ASTM ApproachesDocument6 pagesMeasurement Uncertainty in Material Testing: Differences and Similarities Between ISO, CEN and ASTM ApproachesGustavo SánchezNo ratings yet

- 325-Article Text-912-1-10-20190610 PDFDocument10 pages325-Article Text-912-1-10-20190610 PDFR JNo ratings yet

- Uncertainty EmcDocument36 pagesUncertainty EmcHimma FirdausNo ratings yet

- To The Expression of Uncertainty in MeasurementDocument4 pagesTo The Expression of Uncertainty in MeasurementimeqingenieriaNo ratings yet

- GMP 11 Mar 2003 PDFDocument6 pagesGMP 11 Mar 2003 PDFFërnando Rodrîguëz HerreräNo ratings yet

- Experimental Stress AnalysisDocument19 pagesExperimental Stress Analysisrishith0% (1)

- G118 - Guidance For Defining The Scope of Accreditation For Calibration Laboratories-10225-2Document28 pagesG118 - Guidance For Defining The Scope of Accreditation For Calibration Laboratories-10225-2walterNo ratings yet

- Cálculos A Partir de Un Ensayo de Tracción (Inglés)Document18 pagesCálculos A Partir de Un Ensayo de Tracción (Inglés)Richard_xpNo ratings yet

- Verifying Measurement UncertaintyDocument5 pagesVerifying Measurement UncertaintySylab InstrumentsNo ratings yet

- Expanded Uncertainty U. The Purpose of The Expanded Uncertainty Is For Each MeasurementDocument21 pagesExpanded Uncertainty U. The Purpose of The Expanded Uncertainty Is For Each MeasurementErick Leonardo Valle MendozaNo ratings yet

- Nabl 141Document78 pagesNabl 141Saptarshi Das100% (3)

- Vol18 2 01Document7 pagesVol18 2 01PUPUT PUJIANTINo ratings yet

- IncertidumbreDocument7 pagesIncertidumbreLaura GuarguatiNo ratings yet

- Iacoviello,+Numero 50 Art 32Document12 pagesIacoviello,+Numero 50 Art 32MuhammadFaizalNo ratings yet

- Verifying Measurement Uncertainty Using A Control Chart With Dynamic Control LimitsDocument6 pagesVerifying Measurement Uncertainty Using A Control Chart With Dynamic Control LimitsFrancisco BacilioNo ratings yet

- Uncertainity Measurement Requirements of ISO IEC 17025 2005Document28 pagesUncertainity Measurement Requirements of ISO IEC 17025 2005ahkiaenaaaaNo ratings yet

- Measurement Uncertainty and Traceability Issues: A Standards Activity UpdateDocument9 pagesMeasurement Uncertainty and Traceability Issues: A Standards Activity UpdateLaffineur EricNo ratings yet

- Section 1Document12 pagesSection 1Christos PougiasNo ratings yet

- Determination of Measurement Uncertainty of StrainDocument16 pagesDetermination of Measurement Uncertainty of StrainAbdul AhadNo ratings yet

- 8.2.2 LAP Guidance On The Estimation of Uncertainty of Measurement - R1Document18 pages8.2.2 LAP Guidance On The Estimation of Uncertainty of Measurement - R1Catalina CiocanNo ratings yet

- SOP-Procedure Calibration of Metal TapesDocument12 pagesSOP-Procedure Calibration of Metal Tapeshaharamesh100% (1)

- 8.0 Determination of Conformance With Specifications or Limit Values With Particular Reference To Measurement Uncertainties - Possible StrategiesDocument3 pages8.0 Determination of Conformance With Specifications or Limit Values With Particular Reference To Measurement Uncertainties - Possible Strategiesjrlr65No ratings yet

- Final Lab Report 212-1Document16 pagesFinal Lab Report 212-1Dipak RajputNo ratings yet

- EURAMET CG 18 02 Non Automatic Weighing InstrumentsDocument83 pagesEURAMET CG 18 02 Non Automatic Weighing InstrumentsPurwanto NugrohoNo ratings yet

- EURAMET cg-18 v.02.1Document84 pagesEURAMET cg-18 v.02.1Renato LameraNo ratings yet

- Guide IncertitudesDocument117 pagesGuide IncertitudesIbtissam LabsirNo ratings yet

- Concept and Assessment of The Novel Design of Tribological TesterDocument7 pagesConcept and Assessment of The Novel Design of Tribological TesterBittu Kumar SinghNo ratings yet

- The Changes in ISO 6892-1:2016 Metallic Materials Tensile Testing StandardDocument5 pagesThe Changes in ISO 6892-1:2016 Metallic Materials Tensile Testing StandardCaline NunesNo ratings yet

- Top Down Evaluation of Matrix Effects UncertaintyDocument34 pagesTop Down Evaluation of Matrix Effects UncertaintyAngel GarciaNo ratings yet

- Vi. 2002, Praha/Prague, Czech Republic: Radovan Novotný - Josef BradíkDocument6 pagesVi. 2002, Praha/Prague, Czech Republic: Radovan Novotný - Josef Bradíkdil_6333No ratings yet

- Introduction To Linear MetrologyDocument71 pagesIntroduction To Linear MetrologyDivakaran MullathNo ratings yet

- Comparison of The GUM and Monte Carlo Methods For The Uncertainty Estimation in Electromagnetic CompDocument21 pagesComparison of The GUM and Monte Carlo Methods For The Uncertainty Estimation in Electromagnetic CompEleanor AlonzoNo ratings yet

- Dimensional Verification Test Report TempDocument5 pagesDimensional Verification Test Report TempMarianna GofmanNo ratings yet

- Astm G213 - 17Document16 pagesAstm G213 - 17Black MambaNo ratings yet

- The Determination of Uncertainties in Creep Testing To European Standard Pren 10291Document37 pagesThe Determination of Uncertainties in Creep Testing To European Standard Pren 10291viverefeliceNo ratings yet

- Uncertainty Analysis of Positional Deviations of CNC Machine ToolsDocument8 pagesUncertainty Analysis of Positional Deviations of CNC Machine ToolsAgustin Brau AvilaNo ratings yet

- Standard Test Method For Impact Testing of Miniaturized Charpy V-Notch SpecimensDocument7 pagesStandard Test Method For Impact Testing of Miniaturized Charpy V-Notch SpecimensMyles StapelbergNo ratings yet

- 5 Preparation For Determining Instrument Channel SetpointsDocument12 pages5 Preparation For Determining Instrument Channel SetpointsMauricio Javier DuranNo ratings yet

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- Experimentation, Validation, and Uncertainty Analysis for EngineersFrom EverandExperimentation, Validation, and Uncertainty Analysis for EngineersNo ratings yet

- A New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeFrom EverandA New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeNo ratings yet

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Is 1608 - 2005 - 11Document1 pageIs 1608 - 2005 - 11SvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 14Document1 pageIs 1608 - 2005 - 14SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inDocument1 pageIS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthDocument1 pageIS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthSvapneshNo ratings yet

- Metallic Medical Bone Screws: Standard Specification and Test Methods ForDocument18 pagesMetallic Medical Bone Screws: Standard Specification and Test Methods ForDiego MarchioriNo ratings yet

- Engine Block ReportDocument11 pagesEngine Block ReportLouis Fernandez100% (1)

- MTO Indowater 2019Document5 pagesMTO Indowater 2019Muhammad Ilham Al FaizNo ratings yet

- 8 Torsion Spring Fatigue PerformanceDocument2 pages8 Torsion Spring Fatigue PerformancestevemwilliamsNo ratings yet

- Factors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and OutletDocument4 pagesFactors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and Outletbibekananda sahooNo ratings yet

- Brinell& Rockwell User's ManualDocument37 pagesBrinell& Rockwell User's ManualBharath TrichyNo ratings yet

- CurveDocument19 pagesCurveSheryll de GuzmanNo ratings yet

- SC-01 Safety Code On Storage, Handling & Use of Gas CylindersDocument8 pagesSC-01 Safety Code On Storage, Handling & Use of Gas CylindersSandeep ShettyNo ratings yet

- Facility Manager - Updated Resume KhalidDocument3 pagesFacility Manager - Updated Resume KhalidimadNo ratings yet

- 6stroke EngineDocument5 pages6stroke EngineMitesh KumarNo ratings yet

- Multi Spindle Drilling Machine Project FileDocument28 pagesMulti Spindle Drilling Machine Project FileRoyalAryans100% (5)

- Dumper Caterpillar 772Document32 pagesDumper Caterpillar 772Foromaquinas100% (2)

- Checklist For Painting Work of Structural SteelDocument3 pagesChecklist For Painting Work of Structural Steelajit karandikar78% (9)

- Kruger Tunnel Ventilation Products BrochureDocument12 pagesKruger Tunnel Ventilation Products BrochureMarino AyalaNo ratings yet

- Aircraft Materials and Processes - 2017 PDFDocument36 pagesAircraft Materials and Processes - 2017 PDFDan Keith Mina DuadNo ratings yet

- Sunfolding Pneumatics White Paper 2020 07Document8 pagesSunfolding Pneumatics White Paper 2020 07Hilmi Dhiya UlhaqNo ratings yet

- Manual 6a32Document24 pagesManual 6a32Buho FielNo ratings yet

- Utility Consumption (IA+Nitrogen)Document7 pagesUtility Consumption (IA+Nitrogen)WickyNo ratings yet

- CIP HeaterDocument2 pagesCIP HeaterTutoriais 2.0No ratings yet

- Twin Steel Helix Fiber Reinforced Concrete: P. Alekhya, R. Prashanth Kumar, N. Murali KrishnaDocument8 pagesTwin Steel Helix Fiber Reinforced Concrete: P. Alekhya, R. Prashanth Kumar, N. Murali KrishnaSumair LoneNo ratings yet

- Energetic and Exergetic Analysis of A Multi-Stage Turbine, Coal-Fired 173 MW Power PlantDocument18 pagesEnergetic and Exergetic Analysis of A Multi-Stage Turbine, Coal-Fired 173 MW Power PlantDr-Aditya ChauhanNo ratings yet

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionDocument57 pagesPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaNo ratings yet

- Class 12 - Mathematical Modeling of Hydraulic SystemDocument14 pagesClass 12 - Mathematical Modeling of Hydraulic Systemapi-26676616No ratings yet

- RH - Em9seDocument6 pagesRH - Em9seJefa DanarNo ratings yet

- Black Holes, Singularities and Information Loss - Richard P DolanDocument5 pagesBlack Holes, Singularities and Information Loss - Richard P DolancolordiamondsNo ratings yet

- Qut EN01 32720 Int Cms UnitDocument40 pagesQut EN01 32720 Int Cms UnitMohammed RizwanNo ratings yet

- Grasso Screw Compressor Package Pi - tcm11 38504Document84 pagesGrasso Screw Compressor Package Pi - tcm11 38504Twfeek AhmedNo ratings yet

- Pneumatic Vulcanizing MachineDocument50 pagesPneumatic Vulcanizing MachineANAND KRISHNANNo ratings yet

- Structural Analysis Jan 2023Document11 pagesStructural Analysis Jan 2023harshavenna04No ratings yet

- ENGINEER'S Report For Generator Set of LaundryDocument3 pagesENGINEER'S Report For Generator Set of LaundryNathan Esteban79% (14)