Professional Documents

Culture Documents

Is 1608 - 2005 - 14

Uploaded by

SvapneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1608 - 2005 - 14

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608: 2005

ISO 6892: 1998

13.2 The property may be obtained without plotting the force-extension curve by using automatic

devices (ag. microprocessor).

14 Determination of proof strength, total extension (Rt )

14.1 The proof strength (total extension) is determined on the force-extension diagram by drawing a

line parallel to the ordinate axis (force axis) and at a distance from this equivalent to the prescribed total

percentage extension. The point at which this line intersects the curve gives the force corresponding to

the desired proof strength. The latter is obtained by dividing this force by the original cross-sectional

area of the test piece (So) (see figure 4).

14.2 The property may be obtained without plotting the force-extension diagram by using automatic

devices.

15 Method of verification of permanent set strength (Rr)

The test piece is subjected to a force for 10 s to 12 s corresponding to the specified stress and it is then

confirmed, after removing the force, that the permanent set extension or elongation is not more than the

percentage specified for the original gauge length.

16 Determination of percentage reduction of area (Z)

Percentage reduction of area shall be determined in accordance with the definition given in 4.7.

The two. broken pieces of the test piece are carefully fitted back together so that their axes lie in a

straight line. The minimum cross-sectonial area after fracture (Su) shall be measured to an accuracy of

± 2 % (see annexes A to D). The diftere.tce between the area (Su) and the original cross-sectional area

(So) expressed as a percentage of the original area gives the percentage reduction of area.

17 Accuracy of the results

The accuracy of results is dependent on various parameters which may be separated into two

categories:

metrological parameters such as class of machine and extensometer and the accuracy of specimen

dimensional measurements;

material and testing parameters such as nature of material, test piece geometry and preparation,

testing rate, temperature. data acquisition and analysis technique.

In the absence of sufficient data on all types of materials it is not possible, at present, to fix values of

accuracy for the different properties measured by the tensile test.

Annex J provides a guideline for the determination of uncertainty related to metrological parameters.

Annex K provides values obtained from interlaboratory tests on a group of steels and aluminium alloys.

12

You might also like

- 5) Method of N, R-ValueDocument6 pages5) Method of N, R-Valuesatish_trivediNo ratings yet

- Lab C - Torsion - Mech - MRPDocument5 pagesLab C - Torsion - Mech - MRPIdaam Abdulla SaaidNo ratings yet

- (Received 4 June 1985) : 1. Direct Method - Where 2. Indirect Method - WhereDocument13 pages(Received 4 June 1985) : 1. Direct Method - Where 2. Indirect Method - Wheremichael_dinh_6No ratings yet

- Cad 4 1-4 35Document12 pagesCad 4 1-4 35mtdestaNo ratings yet

- MD Robotic DeburringDocument6 pagesMD Robotic DeburringAldo BustamanteNo ratings yet

- Optical Interferometry For Measurement of The Geometric Dimensions of Industrial PartsDocument8 pagesOptical Interferometry For Measurement of The Geometric Dimensions of Industrial PartsTin ManejeroNo ratings yet

- Structural Analysis With Strain Gage Measurements: Experiment 1Document7 pagesStructural Analysis With Strain Gage Measurements: Experiment 1Yılmaz GürpınarNo ratings yet

- Tensile Test of Brass SpecimenDocument7 pagesTensile Test of Brass SpecimenmanmathkNo ratings yet

- DynamometerDocument21 pagesDynamometerHussam El'SheikhNo ratings yet

- Lab - Strain Measurement SystemDocument8 pagesLab - Strain Measurement SystemscribdkimNo ratings yet

- Modul 3 Strain Measurement v2 PDFDocument11 pagesModul 3 Strain Measurement v2 PDFFachrudin HanafiNo ratings yet

- Impact Hammer Product DataDocument4 pagesImpact Hammer Product DatasadettinorhanNo ratings yet

- Predicting High-Speed Machining Dynamics by Substructure AnalysisDocument6 pagesPredicting High-Speed Machining Dynamics by Substructure AnalysisAkhileshwar_singh88No ratings yet

- Engineering Review J-Integral Fracture Toughness AssessmentDocument6 pagesEngineering Review J-Integral Fracture Toughness AssessmentavenashaNo ratings yet

- 0.5 % Eul! 5 52 000 Psi 360 Mpa!: Fig. 9 Stress-Strain Diagram For Determination of Yield Strength by The Offset MethodDocument1 page0.5 % Eul! 5 52 000 Psi 360 Mpa!: Fig. 9 Stress-Strain Diagram For Determination of Yield Strength by The Offset Methodkaveh-bahiraeeNo ratings yet

- Experimental Stress AnalysisDocument19 pagesExperimental Stress Analysisrishith0% (1)

- Fatigue-Striation Counting MethodDocument8 pagesFatigue-Striation Counting MethodObeydullahKhanNo ratings yet

- Torsion Test Experiment 2Document5 pagesTorsion Test Experiment 2Ryan Hasnan HNo ratings yet

- Torsion Test Experiment 2Document5 pagesTorsion Test Experiment 2Ryan Hasnan HNo ratings yet

- 05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsDocument7 pages05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsAli KhalfallahNo ratings yet

- Advanced Signal Processing Algorithms in Structural Integrity Monitoring 2014 Procedia EngineeringDocument13 pagesAdvanced Signal Processing Algorithms in Structural Integrity Monitoring 2014 Procedia EngineeringalkhiatNo ratings yet

- Eee 207 - Chapter 3Document18 pagesEee 207 - Chapter 3Naija RonaldoNo ratings yet

- Steel Torsion TestDocument9 pagesSteel Torsion TestPattarawat NakkumNo ratings yet

- Vibration and acoustic data for a punch press: mode shapes, radiation ratios and dampingDocument12 pagesVibration and acoustic data for a punch press: mode shapes, radiation ratios and dampingKamrul HasanNo ratings yet

- Hybrid Experimental-Numerical Concept of Residual Stress Analysis in Laser WeldmentsDocument8 pagesHybrid Experimental-Numerical Concept of Residual Stress Analysis in Laser WeldmentscarlofilippinNo ratings yet

- A Parameter Study of A Machine Tool With Multiple BoundariesDocument18 pagesA Parameter Study of A Machine Tool With Multiple Boundariestina1augmentosNo ratings yet

- Dynamic Analysis Large Vibrating ScreenDocument4 pagesDynamic Analysis Large Vibrating ScreenZiggy GregoryNo ratings yet

- Experimental and Numerical Analysis of An In-Plane Shear - PRDocument30 pagesExperimental and Numerical Analysis of An In-Plane Shear - PRPranab Kumar PradhanNo ratings yet

- Derivation of torsion theory formulaDocument9 pagesDerivation of torsion theory formulasayerzNo ratings yet

- Finite Element Analysis of A Synchronous Permanent Magnet Micromotor Through Axisymmetric and Transverse Planar SimulationsDocument4 pagesFinite Element Analysis of A Synchronous Permanent Magnet Micromotor Through Axisymmetric and Transverse Planar Simulationsarnika33No ratings yet

- EEG383 Measurement - Chapter 2 - Characteristics of Measuring InstrumentsDocument26 pagesEEG383 Measurement - Chapter 2 - Characteristics of Measuring Instrumentsايهاب غزالة100% (1)

- Experimental Verification of Modal Test Analysis of Circular Plate Using EMADocument8 pagesExperimental Verification of Modal Test Analysis of Circular Plate Using EMAABHISHEK CHAUHANNo ratings yet

- Strain Measurement and Analysis On The Load in Universal Testing MachineDocument7 pagesStrain Measurement and Analysis On The Load in Universal Testing MachineInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Di Benedetti1 Et Al - 2015 - 3D-DIC For Strain Measurement in Small Scale GFRP RC SpecimensDocument9 pagesDi Benedetti1 Et Al - 2015 - 3D-DIC For Strain Measurement in Small Scale GFRP RC Specimensukyo0801No ratings yet

- Characterization of Welding DiscontinuitDocument19 pagesCharacterization of Welding DiscontinuitERONo ratings yet

- Testing of SteelDocument7 pagesTesting of Steelmushroom0320No ratings yet

- Effects of Fracture Area Measurement Method and Tension Test Specimen Type On Fracture Strain Values of 980 Class AHSSDocument11 pagesEffects of Fracture Area Measurement Method and Tension Test Specimen Type On Fracture Strain Values of 980 Class AHSSHenrique SeverianoNo ratings yet

- Optimization of The Welding Parameters in Resistance Spot WeldingDocument6 pagesOptimization of The Welding Parameters in Resistance Spot WeldingIAEME PublicationNo ratings yet

- Lab 9 - Schmidt Hammer Rebound HardnessDocument7 pagesLab 9 - Schmidt Hammer Rebound HardnessankeshNo ratings yet

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- Calculation Techniques of Two-Dimensional Residual Stress Field For Mechanical Engineering ApplicationDocument4 pagesCalculation Techniques of Two-Dimensional Residual Stress Field For Mechanical Engineering Applicationjperdigon9634No ratings yet

- Sheet Metal FormingDocument7 pagesSheet Metal FormingHussien EbrhimNo ratings yet

- ISO 6892:1 998 and IS 1608:2005Document1 pageISO 6892:1 998 and IS 1608:2005SvapneshNo ratings yet

- FM and SM Lab ManualDocument87 pagesFM and SM Lab ManualGeorge OliverNo ratings yet

- How Strain Gages Work.: Strain, Stress, and Poisson's RatioDocument8 pagesHow Strain Gages Work.: Strain, Stress, and Poisson's RatiokittisunNo ratings yet

- 3-Exp#03 Tensile TestDocument7 pages3-Exp#03 Tensile TestD7ooM_612No ratings yet

- Compensation of Friction and Backlash Effects in An Electrical Actuator by MerzoukiDocument10 pagesCompensation of Friction and Backlash Effects in An Electrical Actuator by MerzoukijacobwatsonNo ratings yet

- Tensile Properties of AluminumDocument47 pagesTensile Properties of AluminumksNo ratings yet

- Paper PublishDocument5 pagesPaper PublishMuzammil KhanNo ratings yet

- Ductile Fracture by NotchDocument8 pagesDuctile Fracture by Notch多如No ratings yet

- 10 NDTP05 05Document7 pages10 NDTP05 05Savinda SenevirathneNo ratings yet

- Evaluation of The Materials Damage in Gas TurbineDocument9 pagesEvaluation of The Materials Damage in Gas TurbineThanapaet RittirutNo ratings yet

- A Simple Method To Determine Ductile Fracture Strain in A Tensile Test of Plane Specimen'SDocument5 pagesA Simple Method To Determine Ductile Fracture Strain in A Tensile Test of Plane Specimen'SksNo ratings yet

- Residual Stress Measurements of Cast Aluminum Engine Blocks Using DiffractionDocument7 pagesResidual Stress Measurements of Cast Aluminum Engine Blocks Using Diffractionsarafil123No ratings yet

- Jamech: Numerical and Experimental Analysis and Optimization of Process Parameters of AA1050 Incremental Sheet FormingDocument11 pagesJamech: Numerical and Experimental Analysis and Optimization of Process Parameters of AA1050 Incremental Sheet FormingCarlos ArenasNo ratings yet

- J-Resistance Results From Multi-Specimen and Single-Specimen SurfaceDocument6 pagesJ-Resistance Results From Multi-Specimen and Single-Specimen SurfaceMarcelo Varejão CasarinNo ratings yet

- Microscopic View of Flank Wear AreaDocument4 pagesMicroscopic View of Flank Wear Areajacobian1810No ratings yet

- Relationship Between Tool Flank Wear Area and Component Forces in Single Point TurningDocument6 pagesRelationship Between Tool Flank Wear Area and Component Forces in Single Point TurningAniruddha GuptaNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- ISO 6892 and ISO 1608 mechanical property standardsDocument1 pageISO 6892 and ISO 1608 mechanical property standardsSvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Measurement Uncertainty Calculation for Room Temperature Tensile TestingDocument1 pageMeasurement Uncertainty Calculation for Room Temperature Tensile TestingSvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- Is 1608 - 2005 - 34Document1 pageIs 1608 - 2005 - 34SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

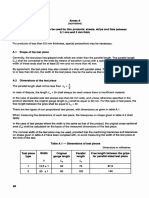

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- ISO 6892:1998 and IS 1608:2005 tensile test data uncertaintyDocument1 pageISO 6892:1998 and IS 1608:2005 tensile test data uncertaintySvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

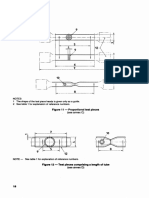

- Figure 13 - Test Piece Cut From A TubeDocument1 pageFigure 13 - Test Piece Cut From A TubeSvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- ISO 6892 test report requirementsDocument1 pageISO 6892 test report requirementsSvapneshNo ratings yet

- Is 1608 - 2005 - 20Document1 pageIs 1608 - 2005 - 20SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- ISO tube test standardsDocument1 pageISO tube test standardsSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- Evaluation of Different Grains Used For ProductionDocument7 pagesEvaluation of Different Grains Used For ProductionAmin TaleghaniNo ratings yet

- En Eco-Drive Panel ConnectionDocument4 pagesEn Eco-Drive Panel ConnectionElectroventica ElectroventicaNo ratings yet

- MAXScript EssentialsDocument20 pagesMAXScript EssentialsSebastián Díaz CastroNo ratings yet

- Levitator Ino - InoDocument2 pagesLevitator Ino - InoSUBHANKAR BAGNo ratings yet

- Sales Manager or Regional Manager or Senior Sales ExecutiveDocument3 pagesSales Manager or Regional Manager or Senior Sales Executiveapi-77473806No ratings yet

- RGB PDFDocument35 pagesRGB PDFGestion Medios Zamba ColorsNo ratings yet

- Picture DescriptionDocument7 pagesPicture DescriptionAida Mustafina100% (3)

- BonBonB What Map ReviewsDocument396 pagesBonBonB What Map Reviewstoyi kamiNo ratings yet

- NOC Status for UPPCB in October 2017Document6 pagesNOC Status for UPPCB in October 2017Jeevan jyoti vnsNo ratings yet

- Unit 2 GEC 106Document132 pagesUnit 2 GEC 106fernando.gl559No ratings yet

- From Verse Into A Prose, English Translations of Louis Labe (Gerard Sharpling)Document22 pagesFrom Verse Into A Prose, English Translations of Louis Labe (Gerard Sharpling)billypilgrim_sfeNo ratings yet

- New Life in Christ by Wilson HerreraDocument18 pagesNew Life in Christ by Wilson Herreralesantiago100% (1)

- DS - 20190709 - E2 - E2 198S-264S Datasheet - V10 - ENDocument13 pagesDS - 20190709 - E2 - E2 198S-264S Datasheet - V10 - ENCristina CorfaNo ratings yet

- 1814 d01 PDFDocument20 pages1814 d01 PDFteletrabbiesNo ratings yet

- Edu Mphil SyllabusDocument27 pagesEdu Mphil Syllabussollu786_889163149No ratings yet

- Between Empire and GlobalizationDocument5 pagesBetween Empire and Globalizationazert yuiopNo ratings yet

- 01-RH124 Red Hat System Administration IIDocument4 pages01-RH124 Red Hat System Administration IIpimentel-diogo2056No ratings yet

- Installation Manual MSP DUCT - SLIM DUCT PDFDocument31 pagesInstallation Manual MSP DUCT - SLIM DUCT PDFutaiuliancatalinNo ratings yet

- Philo Q1module 4Document18 pagesPhilo Q1module 4Abygiel Salas100% (1)

- ECN 202 Final AssignmentDocument10 pagesECN 202 Final AssignmentFarhan Eshraq JeshanNo ratings yet

- Flyer Radar Based Floating Roof Monitoring Flyer Rosemount en 586140Document2 pagesFlyer Radar Based Floating Roof Monitoring Flyer Rosemount en 586140Patricio UretaNo ratings yet

- EngM6 TB WebDocument161 pagesEngM6 TB WebNong BillNo ratings yet

- Interpersonal Skills RubricDocument1 pageInterpersonal Skills RubricJason Stammen100% (1)

- A Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoDocument12 pagesA Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoSansa LauraNo ratings yet

- The Effect of Online Game Addiction To TheDocument5 pagesThe Effect of Online Game Addiction To TheRafuell Amper CablasNo ratings yet

- Batch Op LOPA WorksheetDocument35 pagesBatch Op LOPA WorksheetShruti JoshiNo ratings yet

- Basic Sciences: Home MCQ's DiscussionsDocument10 pagesBasic Sciences: Home MCQ's Discussionsdileep9002392No ratings yet

- Thermodynamics efficiency calculationsDocument3 pagesThermodynamics efficiency calculationsInemesit EkopNo ratings yet

- 05-Program Design and AnalysisDocument78 pages05-Program Design and AnalysisTarq AbdullahNo ratings yet

- Kenya Dieticians License ApplicationDocument5 pagesKenya Dieticians License ApplicationGrace NdutaNo ratings yet