Professional Documents

Culture Documents

11 Determination of Percentage Elongation After Fracture

Uploaded by

SvapneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 Determination of Percentage Elongation After Fracture

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608: 2005

ISO 6892: 1998

The test pieces shall be held by suitable means such as wedges, screwed grips, shouldered holders,

etc.

Every endeavour shall be made to ensure that test pieces are held in such a way that the force is

applied as axially as possible. This is of particular importance when testing brittle materials or when

determining proof stress (non-proportional elongation) or proof stress (total elongation) or yield stress.

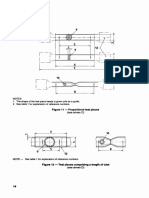

11 Determination of percentage elongation after fracture (A)

11.1 Percentage elongation after fracture shall be determined in accordance with the definition given

in 4.4.2.

For this purpose, the two broken pieces of the test piece are carefully fitted back together so that their

axes lie in a straight line.

Special precautions shall be taken to ensure proper contact between the broken parts of the test piece

when measuring the final gauge length. This is particularly important in the case of test pieces of small

cross-section and test pieces having low elongation values.

Elongation after fracture (L u - L o> shall be determined to the nearest 0,25 mm with a measuring device

with 0,1 mm resolution and the value of percentage elongation after fracture shall be rounded to the

nearest 0,5 % . If the specified minimum percentage elongation is less than 5 % , it is recommended that

special precautions be taken when determining elongation (see annex E).

This measurement is, in principle, valid only if the distance between the fracture and the nearest gauge

mark is no less than one third of the original gauge length (/Jo). However, the measurement is valid,

irrespective of the position of the fracture, if the percentage elongation after fracture is equal to or

greater than the specified value.

11.2 For machines capable of measuring extension at fracture using an extensometer, it is not

necessary to mark the gauge lengths. The elongation is measured as the total extension at fracture, and

it is therefore necessary to deduct the elastic extension in order to obtain percentage elopgation after

fracture.

In principle, this measurement is only valid if fracture occurs within the extensometer gauge length (L e ).

The measurement is valid regardless of the position of the fracture cross-section if the percentage

elongation after fracture is equal to or greater than the specified value.

NOTE - If the product standard specifies the determination of percentage elongation after rupture for a given

gauge length, the extensometer gauge length shall be equal to this length.

11.3 If elongation is measured over a given fixed length, it can be converted to proportional gauge

length, using conversion formulae or tables as agreed before the commencement of testing (for example

as in ISO 2566-1 and ISO 2566-2).

NOTE - Comparisons of percentage elongation are possible only when the gauge length or extensometer gauge

length, the shape and area of the cross-section are the same or when the coefficient of proportionality (k) is the

same.

10

You might also like

- Ass 05 Tension in Circular RoodsDocument11 pagesAss 05 Tension in Circular RoodsMia HussainNo ratings yet

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- E83-10a Standard Practice For Verification and Classification of Extensometer SystemsDocument14 pagesE83-10a Standard Practice For Verification and Classification of Extensometer SystemsislamakthamNo ratings yet

- Unit - IIIDocument215 pagesUnit - IIINishigandha Bansode100% (1)

- Tensile Strength TestDocument2 pagesTensile Strength TestJanice VaflorNo ratings yet

- 0.5 % Eul! 5 52 000 Psi 360 Mpa!: Fig. 9 Stress-Strain Diagram For Determination of Yield Strength by The Offset MethodDocument1 page0.5 % Eul! 5 52 000 Psi 360 Mpa!: Fig. 9 Stress-Strain Diagram For Determination of Yield Strength by The Offset Methodkaveh-bahiraeeNo ratings yet

- Bending Stiffness of FiberboardDocument6 pagesBending Stiffness of FiberboardBobKatNo ratings yet

- Estimating Uncertainty in Poisson's Ratio from Tension TestingDocument18 pagesEstimating Uncertainty in Poisson's Ratio from Tension TestingRichard_xpNo ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- Barkatullah University Tensile Test PresentationDocument20 pagesBarkatullah University Tensile Test PresentationSalman KhanNo ratings yet

- C 273-00Document4 pagesC 273-00Khan ShahzebNo ratings yet

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankNo ratings yet

- C 120 - 90 r94 Qzeymc1sruqDocument4 pagesC 120 - 90 r94 Qzeymc1sruqJason RogersNo ratings yet

- Torsion Testing of Wire: Standard Test Method ForDocument2 pagesTorsion Testing of Wire: Standard Test Method Foribnu.asad984No ratings yet

- Steel TestsDocument4 pagesSteel TestsSaradhiJannNo ratings yet

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- ASTM C293-1-Flexural Strebgth Test-Centre PointDocument3 pagesASTM C293-1-Flexural Strebgth Test-Centre PointAnnur Kamarudin100% (3)

- Tensile Strength or Tension TestDocument3 pagesTensile Strength or Tension TestJun VarNo ratings yet

- Astm C 393Document4 pagesAstm C 393Arash Aghagol0% (1)

- Bending StiffnessDocument6 pagesBending StiffnessMark Samsel RohanNo ratings yet

- Experiment 1Document7 pagesExperiment 1waseemjuttNo ratings yet

- Tensile TestDocument6 pagesTensile TestMohamed EmadNo ratings yet

- 2015.12.08 Material Models EN10002Document6 pages2015.12.08 Material Models EN10002Herman AucampNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Tensile Testing of Mild Steel Circular Bar: Marisha Bhatti 19AE30010Document11 pagesTensile Testing of Mild Steel Circular Bar: Marisha Bhatti 19AE30010Marisha BhattiNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- Evaluating Mobile Bearing Knee Dislocation: Standard Test Method ForDocument3 pagesEvaluating Mobile Bearing Knee Dislocation: Standard Test Method ForBetsy WiedenfeldNo ratings yet

- C 78 - 94 QZC4LTK0Document3 pagesC 78 - 94 QZC4LTK0Rufo CascoNo ratings yet

- Chapter-V Testing of MaterialsDocument4 pagesChapter-V Testing of Materialsmurali thathaNo ratings yet

- Flexural Strength ConcreteDocument3 pagesFlexural Strength ConcreteShantanu DuttaNo ratings yet

- Astm F 606 PDFDocument15 pagesAstm F 606 PDFLajkoNo ratings yet

- D 747 - 99 - Rdc0ny1sruqDocument9 pagesD 747 - 99 - Rdc0ny1sruqChristian HinostrozaNo ratings yet

- E83 16 PDFDocument14 pagesE83 16 PDFMiguel BazalduaNo ratings yet

- Tensile Testing Asm StandardDocument13 pagesTensile Testing Asm StandardNinad PawarNo ratings yet

- Astm D1621-00Document4 pagesAstm D1621-00hegiro1974No ratings yet

- Plastic Strain Ratio MethodDocument6 pagesPlastic Strain Ratio MethodNok MudahNo ratings yet

- Tensile TestDocument9 pagesTensile Testonkod1No ratings yet

- F2183Document4 pagesF2183Gustavo SuarezNo ratings yet

- Unevenness of Textile Strands Using Capacitance Testing EquipmentDocument5 pagesUnevenness of Textile Strands Using Capacitance Testing EquipmentTuran Eren GülNo ratings yet

- Yarn Testing in ShortDocument4 pagesYarn Testing in ShortRezaul Karim TutulNo ratings yet

- Tensile TestingDocument13 pagesTensile TestingAric NgNo ratings yet

- Astm e 488 PDFDocument8 pagesAstm e 488 PDFJavier Bada100% (1)

- Elastic Modulus MeasurementDocument3 pagesElastic Modulus MeasurementCarlos BustamanteNo ratings yet

- D790 - 10 PDFDocument11 pagesD790 - 10 PDFShanaka Jayasekara67% (3)

- GE Bolt Mike III Owner's Manual20160519666133Document3 pagesGE Bolt Mike III Owner's Manual20160519666133Brenno GonçalvesNo ratings yet

- Measuring The Change in Length of Fasteners Using The Ultrasonic Pulse-Echo TechniqueDocument4 pagesMeasuring The Change in Length of Fasteners Using The Ultrasonic Pulse-Echo TechniquetuanNo ratings yet

- Tex-448-A, Flexural Strength of Concrete Using Simple Beam Third-Point LoadingDocument4 pagesTex-448-A, Flexural Strength of Concrete Using Simple Beam Third-Point LoadingDanny Zuan AfrizalNo ratings yet

- Edge Crush TestDocument7 pagesEdge Crush TestJaiprakash SainiNo ratings yet

- ASTM c78Document7 pagesASTM c78Miyamura IzumiNo ratings yet

- C 120 - 00 - QzeymaDocument3 pagesC 120 - 00 - QzeymaMorched TounsiNo ratings yet

- C 651Document4 pagesC 651Asep TheaNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- ISO 6892:1998 and IS 1608:2005 tensile test data uncertaintyDocument1 pageISO 6892:1998 and IS 1608:2005 tensile test data uncertaintySvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- ISO 6892 and ISO 1608 mechanical property standardsDocument1 pageISO 6892 and ISO 1608 mechanical property standardsSvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 34Document1 pageIs 1608 - 2005 - 34SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- Measurement Uncertainty Calculation for Room Temperature Tensile TestingDocument1 pageMeasurement Uncertainty Calculation for Room Temperature Tensile TestingSvapneshNo ratings yet

- ISO tube test standardsDocument1 pageISO tube test standardsSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- Figure 13 - Test Piece Cut From A TubeDocument1 pageFigure 13 - Test Piece Cut From A TubeSvapneshNo ratings yet

- Is 1608 - 2005 - 20Document1 pageIs 1608 - 2005 - 20SvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- ISO 6892 test report requirementsDocument1 pageISO 6892 test report requirementsSvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Assignment 2 AST-451 PDFDocument8 pagesAssignment 2 AST-451 PDFPriya SinghNo ratings yet

- VibrationDocument28 pagesVibrationhari tubagusNo ratings yet

- Seismic Analysis of A Reinforced Concrete Building by Response Spectrum MethodDocument10 pagesSeismic Analysis of A Reinforced Concrete Building by Response Spectrum MethodRahul KumarNo ratings yet

- Applications of Comsol Multiphysics Software To Heat Transfer ProcessesDocument64 pagesApplications of Comsol Multiphysics Software To Heat Transfer ProcessesMatan ZittounNo ratings yet

- Design of Gantry GirderDocument15 pagesDesign of Gantry Girdervineetkothari1No ratings yet

- CH16: Adsorption and Ion ExchangeDocument5 pagesCH16: Adsorption and Ion Exchangeangel matienzoNo ratings yet

- Concrete Dam Design Analysis Assignment PG 2013 HyEngDocument1 pageConcrete Dam Design Analysis Assignment PG 2013 HyEngHabtamu Hailu100% (1)

- Prelim Quiz 1 20Document16 pagesPrelim Quiz 1 20Simoun Angelo DimabogteNo ratings yet

- ProceedingsDocument111 pagesProceedingsSalma SherbazNo ratings yet

- Tyre As Car ComponentDocument113 pagesTyre As Car ComponenttsegayNo ratings yet

- Department of Civil Engineering Course Number: ARC 2129 Course Name: Structure and Architecture-IDocument2 pagesDepartment of Civil Engineering Course Number: ARC 2129 Course Name: Structure and Architecture-Iঅভ্রদীপ দাসNo ratings yet

- Compression Testing of Metallic Materials at Room TemperatureDocument10 pagesCompression Testing of Metallic Materials at Room TemperatureAngel Ardila ArdilaNo ratings yet

- Chapter 4 Shear Force Bending Moment and Deflection of Beams 28012015 For StudentsDocument26 pagesChapter 4 Shear Force Bending Moment and Deflection of Beams 28012015 For StudentsccipNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityD VNo ratings yet

- Chapter 7 General Energy EquationDocument56 pagesChapter 7 General Energy EquationPhilip Lionel PeterNo ratings yet

- Rudolf ClausiusDocument2 pagesRudolf ClausiusAndruşa IoanaNo ratings yet

- LAS Gen - Chem2 - MELC - 2 3 - Q4 Week 1Document10 pagesLAS Gen - Chem2 - MELC - 2 3 - Q4 Week 1Bjai MedallaNo ratings yet

- Chapter 20 Sol. Bedford DinamicaDocument88 pagesChapter 20 Sol. Bedford DinamicaOrlando Chirinos50% (2)

- AirfoilAnalysisDocument24 pagesAirfoilAnalysisShashank Sharma100% (1)

- Ch07 Homework Solutions PDFDocument118 pagesCh07 Homework Solutions PDFLEONARDO VIVANCOSNo ratings yet

- Gravity and Motion: Understanding Main IdeasDocument2 pagesGravity and Motion: Understanding Main IdeasFernando MateoNo ratings yet

- WBPSC JE Civil 2018 (English)Document12 pagesWBPSC JE Civil 2018 (English)Biki Rawdy DasNo ratings yet

- DRILLING OdtDocument4 pagesDRILLING Odtperiya salehNo ratings yet

- Chapter 4&5 Review and Chapter 7 IntroductionDocument22 pagesChapter 4&5 Review and Chapter 7 IntroductionJunyi JiNo ratings yet

- Tutorial On How To Do Fea in Proe: 1. IntroductionDocument13 pagesTutorial On How To Do Fea in Proe: 1. Introductiongreg1212No ratings yet

- EGR 100 Hovercraft Design Project IIDocument16 pagesEGR 100 Hovercraft Design Project IInaveenNo ratings yet

- Renewable Energy Harvesting by Vortex-Induced Motions: Review and Benchmarking of TechnologiesDocument22 pagesRenewable Energy Harvesting by Vortex-Induced Motions: Review and Benchmarking of Technologiesr_filizadehNo ratings yet

- Liberty ShipsDocument37 pagesLiberty Ships2K19/ME/041 ANSH JININo ratings yet

- Geotechnical Examples Using: OpenseesDocument79 pagesGeotechnical Examples Using: OpenseesAngga Fajar SetiawanNo ratings yet

- Iso 1940 - 1Document11 pagesIso 1940 - 1Kaushik Sengupta100% (2)