Professional Documents

Culture Documents

Preliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data Sheet

Uploaded by

Mohamed RaafatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data Sheet

Uploaded by

Mohamed RaafatCopyright:

Available Formats

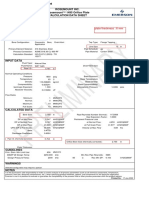

*This is a Preliminary Report

ROSEMOUNT INC.

Rosemount™ 1495 Orifice Plate

CALCULATION DATA SHEET

GENERAL DATA

Customer:

P. O. No:

S. O. No: plate thickness : 6 mm

Sizing Name: FE-00400

Product Advisor ID: R115507

Calculation Date: 17-Jan-2022

Model No:

PRODUCT DESCRIPTION

Bore Configuration: Concentric Bore, Drain/Vent Tap Type: Flange Tapping

Application

Line Size: 8 in

Primary Element Material: 316 Stainless Steel Pipe Schedule: 80

Process Connection: ASME B16.36 CL 900 RF Pipe Material: Carbon Steel

Calculation Standard ISO-5167-2 (2003) / TR

15377

RY

INPUT DATA

Fluid Type: Natural Gas

Fluid Name: WET GAS Drain/Vent Size: 0.118 in

Pipe I.D.: 7.625 in

Normal Operating Conditions

Pressure: 1850 psig Base Pressure: 14.730 psia

Temperature:

Density:

Compressibility:

Isentropic Exponent:

Absolute Viscosity:

110.298265

65

0.825241

1.300

0.010268

C

kg/m3

cP

NA Base Temperature:

Base Density:

Base Compressibility:

Atmospheric Pressure:

60.0

0.844848

14.696

F

kg/m3

psia

Flow Rates

IMI

Minimum: 10 MMSCFD

Normal: 20 MMSCFD

Maximum: 25 MMSCFD

Full Scale: 30 MMSCFD

CALCULATED DATA

EL

Bore Size: 3.875 in Pipe Reynolds Number (Normal): 3543695

Gas Expansion Factor: 0.9999

DP at Min Flow: 6.170 inH2O@60F Permanent Pressure Loss

DP at Normal Flow: 24.679 inH2O@60F at Normal Flow: 17.896 inH2O@60F

DP at Max Flow: 38.561 inH2O@60F at Full Scale Flow: 40.267 inH2O@60F

URV (DP at Full Scale): 55.527 inH2O@60F Velocity at Max Flow 6.98 ft/s

PR

Beta: 0.5086

Discharge Coefficient: 0.6026

Pipe I.D. (thermally corrected): 7.629 in

Orifice Bore Size (thermally corrected): 3.880 in

Plate Thickness:

GUIDELINES

Prim. Elem. Min Limit Use: 1.273 MMSCFD

MAWP @ Design Temp: 2250.000 psig Min Rec Pipe Reynolds: 8520

Design Pressure/Temp: 2000 psig 85 C Rec Min DP: 0.100 inH2O@60F

WARNINGS

Selected configuration may require a special

NOTES

It is the purchaser's sole responsibility to make a careful analysis of all process parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives,contaminants, etc.), when specifying product materials, options, and components for the particular application.

Emerson is not in a position to evaluate or guarantee the compatibility of the process fluid or other process parameters with the product options.

Printed On: 17-Jan-2022

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Preliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data SheetDocument1 pagePreliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data SheetMohamed RaafatNo ratings yet

- Rosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetDocument1 pageRosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetMamta DeshmukhNo ratings yet

- Rosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetDocument1 pageRosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetMamta DeshmukhNo ratings yet

- Orifice Plate ReportDocument1 pageOrifice Plate ReportdsdeNo ratings yet

- Calc Report EMERSONDocument2 pagesCalc Report EMERSONMuhammad SalmanNo ratings yet

- Rosemount Inc. Restriction Orifice Plate Calculation Data SheetDocument1 pageRosemount Inc. Restriction Orifice Plate Calculation Data SheetJulian Camilo Segura BermudezNo ratings yet

- Orifice Plate Flowmeter: Rosemount IncDocument1 pageOrifice Plate Flowmeter: Rosemount IncJulian Camilo Segura BermudezNo ratings yet

- Rosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetDocument2 pagesRosemount Inc. 1495 - Standard Orifice ISO 5167 (2003) Calculation Data SheetArvinderSinghNo ratings yet

- Fe-103, Fe-104 8''Document2 pagesFe-103, Fe-104 8''Vikram JitNo ratings yet

- Rosemount Inc. ASME Venturi Tube Calculation Data SheetDocument1 pageRosemount Inc. ASME Venturi Tube Calculation Data SheethaisamsarwarNo ratings yet

- Flow Element: Base Maximum Flow Min Flow Property MethodDocument4 pagesFlow Element: Base Maximum Flow Min Flow Property Methodscploperation.2x50 CommonNo ratings yet

- Fe-7151 Case 3 PDFDocument1 pageFe-7151 Case 3 PDFSureshNo ratings yet

- Fe-7151 Case 1 PDFDocument1 pageFe-7151 Case 1 PDFSureshNo ratings yet

- fLOW 3265 PDFDocument1 pagefLOW 3265 PDFSureshNo ratings yet

- Flow Element: Base Maximum Flow Normal Flow Property MethodDocument1 pageFlow Element: Base Maximum Flow Normal Flow Property MethodSureshNo ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Sina Control Co. Designer & Manufacturer CoDocument2 pagesSina Control Co. Designer & Manufacturer Cohcsharma1967No ratings yet

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNo ratings yet

- Grundfos PacoDocument1 pageGrundfos PacoRifan ActNo ratings yet

- Backflush Pump Capacity & Rated CurrentDocument7 pagesBackflush Pump Capacity & Rated Currentsaikat_das_meNo ratings yet

- Pumpset 2Document3 pagesPumpset 2Docu CenterNo ratings yet

- NB 50-160-169 (167) - 74m3-h. 36m. 11KW PDFDocument4 pagesNB 50-160-169 (167) - 74m3-h. 36m. 11KW PDFViệt Đặng XuânNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNo ratings yet

- 511-CP02 KPD 25-16QFDocument3 pages511-CP02 KPD 25-16QFNitin KurupNo ratings yet

- Data Sheet: Item N°: Curv e Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curv e Tolerance According To ISO 9906SergioNo ratings yet

- 2curva Preliminar 2LLR 2 STGDocument3 pages2curva Preliminar 2LLR 2 STGRafael PlazasNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument2 pagesDescription Value: Printed From Grundfos CAPSHemanth RajshekarNo ratings yet

- 2005 PDFDocument5 pages2005 PDFMihai-Eugen PopaNo ratings yet

- 2500 GPM X 180 Psi - VTP ULFMDocument7 pages2500 GPM X 180 Psi - VTP ULFMFELNo ratings yet

- Flow Element SizingDocument4 pagesFlow Element SizingAbraham Osarenkhoe PatrickNo ratings yet

- Ducts Pressure Losses Board: Project: Site: Unit - No.: Building: Airflow (CFM) ESP (Pa)Document12 pagesDucts Pressure Losses Board: Project: Site: Unit - No.: Building: Airflow (CFM) ESP (Pa)Karthy GanesanNo ratings yet

- CM 3-2Document7 pagesCM 3-2hatkaraokequamangNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument3 pagesPump Performance Datasheet: Operating Conditions LiquidNitin KurupNo ratings yet

- Performance Data CurveDocument57 pagesPerformance Data Curveedwin nolberto100% (1)

- 01.datasheet For FCV 200324A-05-01Document2 pages01.datasheet For FCV 200324A-05-01Nguyễn Văn SơnNo ratings yet

- Sliding Stem Valve Specification: Each PartDocument1 pageSliding Stem Valve Specification: Each PartHoan HoNo ratings yet

- Roof Tank 315 LPM @90m (Set)Document4 pagesRoof Tank 315 LPM @90m (Set)infonetsmgNo ratings yet

- Mercer Valve Pilot Sizing v6.4CUSTDocument5 pagesMercer Valve Pilot Sizing v6.4CUSTFaizan AhmedNo ratings yet

- Scrubbing CirculationDocument2 pagesScrubbing Circulation511231103No ratings yet

- Ficha Técnica Electrobomba Jockey, Mod. GCR1-19, 2HP, FitFlowDocument4 pagesFicha Técnica Electrobomba Jockey, Mod. GCR1-19, 2HP, FitFlowSUPERVISOR PROYECTOS BCI & RCI (EDUARDO VILLANUEVA)No ratings yet

- NB 80-160-169 (167) - 135m3-h. 34.7m. 22KW PDFDocument4 pagesNB 80-160-169 (167) - 135m3-h. 34.7m. 22KW PDFViệt Đặng XuânNo ratings yet

- NB 80-160-169 (167) - 135m3-h. 34.7m. 22KW PDFDocument4 pagesNB 80-160-169 (167) - 135m3-h. 34.7m. 22KW PDFViệt Đặng XuânNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions LiquidAquib HaiderNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions LiquidmarcoaqmNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document7 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- North Side Spectral Noise LoggingDocument7 pagesNorth Side Spectral Noise LoggingSusin LimNo ratings yet

- Abb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussDocument32 pagesAbb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussAbdessalem BougoffaNo ratings yet

- Proportional Pressure Relief Valve Poppet Type, Direct-Acting, Metric Cartridge - 350 BarDocument4 pagesProportional Pressure Relief Valve Poppet Type, Direct-Acting, Metric Cartridge - 350 BarSakahi SharmaNo ratings yet

- Tag Number: 10-FG - 3020CDocument1 pageTag Number: 10-FG - 3020CtalangocdayNo ratings yet

- CurvasDocument30 pagesCurvasArturo Morales LinaresNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidRicardo PereiraNo ratings yet

- Diaphragm - Pumps - 7011 Thomas PDFDocument2 pagesDiaphragm - Pumps - 7011 Thomas PDFcalejandrotgNo ratings yet

- Ebara 3PF 32-160 PDFDocument6 pagesEbara 3PF 32-160 PDFEddie GuillénNo ratings yet

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDocument6 pagesCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNo ratings yet

- Applicator Sizing - FlowDocument3 pagesApplicator Sizing - FlowJocker GreickNo ratings yet

- Sizing CalculationDocument13 pagesSizing CalculationDaniel DuongNo ratings yet

- Curva Bomba 3K8X6-16 ARV M3ST Con 100Hp Imp. 13.0 inDocument5 pagesCurva Bomba 3K8X6-16 ARV M3ST Con 100Hp Imp. 13.0 ineduinNo ratings yet

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- General Service Solenoid Valves: FeaturesDocument6 pagesGeneral Service Solenoid Valves: FeaturesMohamed RaafatNo ratings yet

- Goval-IT PIPINGDocument50 pagesGoval-IT PIPINGMohamed RaafatNo ratings yet

- Flanges Technical Catalog: Catálogo Técnico FlangesDocument9 pagesFlanges Technical Catalog: Catálogo Técnico FlangesMohamed RaafatNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Stud Bolt ItalyDocument58 pagesStud Bolt ItalyMohamed RaafatNo ratings yet

- Ball Valves Rk-Proball: KH 3T S (NC), " - 4", PN63/100 Casting LeverDocument3 pagesBall Valves Rk-Proball: KH 3T S (NC), " - 4", PN63/100 Casting LeverMohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- Preliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data SheetDocument1 pagePreliminary Preliminary: Rosemount Inc. Rosemount 1495 Orifice Plate Calculation Data SheetMohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- Relief Valves: SRVL SeriesDocument2 pagesRelief Valves: SRVL SeriesMohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- WNRF 2 MFF ItalyDocument1 pageWNRF 2 MFF ItalyMohamed RaafatNo ratings yet

- WN RF Flanges SCH 40 CL 150 19Document1 pageWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNo ratings yet

- مصايدDocument1 pageمصايدMohamed RaafatNo ratings yet

- 1953 Flipbook PDFDocument1 page1953 Flipbook PDFMohamed RaafatNo ratings yet

- Pressure Gauges: Used For Pressure Measurement of Liquids and GasesDocument1 pagePressure Gauges: Used For Pressure Measurement of Liquids and GasesMohamed RaafatNo ratings yet

- Awo, Part I by Awo Fa'lokun FatunmbiDocument7 pagesAwo, Part I by Awo Fa'lokun FatunmbiodeNo ratings yet

- Boeing SWOT AnalysisDocument3 pagesBoeing SWOT AnalysisAlexandra ApostolNo ratings yet

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDocument13 pagesGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutNo ratings yet

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningDocument8 pagesINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedNo ratings yet

- Introduction To Human MovementDocument5 pagesIntroduction To Human MovementNiema Tejano FloroNo ratings yet

- Internship (1) FinalDocument12 pagesInternship (1) FinalManak Jain50% (2)

- Dekker V Weida Amicus Brief by 17 AGsDocument35 pagesDekker V Weida Amicus Brief by 17 AGsSarah WeaverNo ratings yet

- Actara (5 24 01) PDFDocument12 pagesActara (5 24 01) PDFBand Dvesto Plus CrepajaNo ratings yet

- Simple Past and Past Perfect TensesDocument13 pagesSimple Past and Past Perfect TensesSincerly RevellameNo ratings yet

- Mastering American EnglishDocument120 pagesMastering American Englishmarharnwe80% (10)

- Glory in The Cross - Holy Thursday - Schutte PDFDocument1 pageGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyNo ratings yet

- 4.1.1.6 Packet Tracer - Explore The Smart Home - ILM - 51800835Document4 pages4.1.1.6 Packet Tracer - Explore The Smart Home - ILM - 51800835Viet Quoc100% (1)

- - Анализ текста The happy man для ФЛиС ЮФУ, Аракин, 3 курсDocument2 pages- Анализ текста The happy man для ФЛиС ЮФУ, Аракин, 3 курсJimmy KarashNo ratings yet

- Idoc - Pub - Pokemon Liquid Crystal PokedexDocument19 pagesIdoc - Pub - Pokemon Liquid Crystal PokedexPerfect SlaNaaCNo ratings yet

- Agile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)Document67 pagesAgile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)j.paulo.mcNo ratings yet

- 0n9) O6..,w48j-GDocument14 pages0n9) O6..,w48j-GMocha FurrerNo ratings yet

- Dehydration AssessmentDocument2 pagesDehydration AssessmentzaheerbdsNo ratings yet

- Integrated Management System 2016Document16 pagesIntegrated Management System 2016Mohamed HamedNo ratings yet

- Trading Rules To Successful ProfitsDocument89 pagesTrading Rules To Successful ProfitsOuattaraNo ratings yet

- Fractional Differential Equations: Bangti JinDocument377 pagesFractional Differential Equations: Bangti JinOmar GuzmanNo ratings yet

- Angeles City National Trade SchoolDocument7 pagesAngeles City National Trade Schooljoyceline sarmientoNo ratings yet

- CIVE2304 C1-1 Hydrological CycleDocument54 pagesCIVE2304 C1-1 Hydrological CyclenaserNo ratings yet

- EffectivenessDocument13 pagesEffectivenessPhillip MendozaNo ratings yet

- Invenio Flyer enDocument2 pagesInvenio Flyer enErcx Hijo de AlgoNo ratings yet

- Millennium Development GoalsDocument6 pagesMillennium Development GoalsSasha Perera100% (2)

- Know Your TcsDocument8 pagesKnow Your TcsRocky SinghNo ratings yet

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDocument9 pagesJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidNo ratings yet

- Technology in Society: SciencedirectDocument10 pagesTechnology in Society: SciencedirectVARGAS MEDINA ALEJANDRANo ratings yet

- Week1 TutorialsDocument1 pageWeek1 TutorialsAhmet Bahadır ŞimşekNo ratings yet

- Week 1-2 Module 1 Chapter 1 Action RseearchDocument18 pagesWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNo ratings yet