Professional Documents

Culture Documents

Tabel Hitung Effiensi Boiler Samson - 1 - R1

Uploaded by

AndriZi0 ratings0% found this document useful (0 votes)

10 views1 pageThis proposal discusses a control system board for a steam boiler system at an Unilever plant in Indonesia. It analyzes how operating conditions that differ from catalog specifications, such as higher water temperatures and pressures, impact the efficiency of the boiler system. While these conditions lower the efficiency of individual boilers, the overall efficiency of the system may actually improve due to increased steam production outweighing the effects of reduced boiler efficiencies.

Original Description:

Original Title

Tabel hitung Effiensi boiler samson_1_R1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis proposal discusses a control system board for a steam boiler system at an Unilever plant in Indonesia. It analyzes how operating conditions that differ from catalog specifications, such as higher water temperatures and pressures, impact the efficiency of the boiler system. While these conditions lower the efficiency of individual boilers, the overall efficiency of the system may actually improve due to increased steam production outweighing the effects of reduced boiler efficiencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageTabel Hitung Effiensi Boiler Samson - 1 - R1

Uploaded by

AndriZiThis proposal discusses a control system board for a steam boiler system at an Unilever plant in Indonesia. It analyzes how operating conditions that differ from catalog specifications, such as higher water temperatures and pressures, impact the efficiency of the boiler system. While these conditions lower the efficiency of individual boilers, the overall efficiency of the system may actually improve due to increased steam production outweighing the effects of reduced boiler efficiencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

PROPOSAL

Submission destination

: Unilever Indonesia

CONTROL SYSTEM BOARD

Operating conditions Catalog data conditions

System configuration Water Temp : 99 ℃ ・・・ 15 ℃

Required pressure : 0.8 MPa ・・・ 0.48 MPa

Concentrated water blow rate : 0 % ・・・ 0 %

Average steam consumption : 11.3 t/h ・・・ MAX POWER

Total amount of steam Impact on efficiency

11.5 t/h

Water temp : 99 ℃ Catalog conditions = 15℃

Boiler1 : - 3.4 %

※The higher the value,

Boiler2 : - 3.4 %

the lower the efficiency However,

Chemical feed pump Boiler3 : - 3.4 % as steam production increases,

Boiler4 : - 3.4 % fuel efficiency actually improves.

Boiler5 : -

Rwquired pressure : 0.8 MPa Catalog conditions = 0.48MPa

2.88t/h 2.88t/h 2.88t/h 2.88t/h Water softner Boiler1 : - 0.8 %

Boiler2 : - 0.8 % ※The higher the value,

Boiler3 : - 0.8 % the lower the efficiency

Boiler4 : - 0.8 %

Boiler5 : - %

Concentrated water blow rate : 0 % Catalog conditions = 0%

Boiler1 : - 0 % ※The higher the value,

Boiler2 : - 0 % the lower the efficiency

Boiler3 : - 0 % Not considered because

90℃ water tank Boiler4 : - 0 % the water quality is undecided

Warm up Boiler5 : - 0 %

System overview

Average steam consumption : 10 t/h

Maximum evaporarion(actual) : 11.5 t/h Boiler1 : - 0 %

Steam when one unit is stopped : 8.6 t/h Boiler2 : - 0 %

Lower limit load to stop all units : 411 kg/h Under Boiler3 : - 0 % Not considered because

Boiler4 : - 0 % load fluction is unknown

Efficiency of each boiler(actual) Catalog spec Boiler5 : - 0 %

1) SE-3000APG : 93.8 % ← 98 %

2) SE-3000APG : 93.8 % ← 98 % Remarks

3) SE-3000APG : 93.8 % ← 98 % It seems that the boiler efficiency is greatly reduced by the water supply temp.

4) SE-3000APG : 93.8 % ← 98 % In reality, the amount of steam that can be produced is increasing,

5) : and the amount of fuel consumed per kg of steam is being reduced.

System efficiency : 93.8 %

※When operating under the conditions on the right

You might also like

- Attack From Atlantis (1953) Lester Del Rey PDFDocument222 pagesAttack From Atlantis (1953) Lester Del Rey PDFAndrei Mihailescu100% (1)

- American Red Cross Disaster Preparation TipsDocument24 pagesAmerican Red Cross Disaster Preparation TipsStatesman JournalNo ratings yet

- CHP5361DL ChungHo Iguassu Sparkling Tiny Instrukcja Obsługi ENDocument32 pagesCHP5361DL ChungHo Iguassu Sparkling Tiny Instrukcja Obsługi ENSalon ParkieciarniaNo ratings yet

- Experiment 5B Types of Chemical ReactionsDocument8 pagesExperiment 5B Types of Chemical ReactionsNicole ZhangNo ratings yet

- Process Data Sheet For Main Air Compressor Rev00Document4 pagesProcess Data Sheet For Main Air Compressor Rev00mahan moradiNo ratings yet

- Biodiversity EssayDocument10 pagesBiodiversity EssayWong Sun100% (2)

- Construction Estimates - Electrical and Plumbing Labor Cost and EstimatesDocument4 pagesConstruction Estimates - Electrical and Plumbing Labor Cost and EstimatesLyn Garcia80% (30)

- Croda How To LoVOCoatDocument6 pagesCroda How To LoVOCoatkarla100% (1)

- Basic Theory PumpDocument37 pagesBasic Theory PumpkunkzNo ratings yet

- Productos de CementaciónDocument43 pagesProductos de CementaciónPaola Giron100% (2)

- Isobutylene PresentationDocument50 pagesIsobutylene PresentationMissQiah0% (1)

- Pump EfficiencyDocument10 pagesPump EfficiencyArunkumarNo ratings yet

- Calculated Primary AirDocument1 pageCalculated Primary AirIrfan AhmedNo ratings yet

- Offshore World - Track Record - Swiber LimitedDocument9 pagesOffshore World - Track Record - Swiber LimitedTip RendahNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Pump Selection - Teluk Kabung (07.10.2015) - With CommentDocument15 pagesPump Selection - Teluk Kabung (07.10.2015) - With CommentPriyo Jati WahyonoNo ratings yet

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir GangarNo ratings yet

- Hydraulic Lab Manual 2017Document48 pagesHydraulic Lab Manual 2017Muhammad AdilNo ratings yet

- Scrubber Design For Phosphoric Acid Production FacilityDocument57 pagesScrubber Design For Phosphoric Acid Production FacilityAndres Rodriguez Herrera100% (2)

- 5350 RamjetDocument24 pages5350 RamjetkkonthenetNo ratings yet

- MINI STEAM POWER PLANT - Lab ManualDocument20 pagesMINI STEAM POWER PLANT - Lab Manualmelanie japay50% (6)

- Project:: 2800TPD Burning System CalculationDocument7 pagesProject:: 2800TPD Burning System CalculationOUSSAMA LAKHILINo ratings yet

- The Sizing Boiler Feed Pumps CalculationDocument3 pagesThe Sizing Boiler Feed Pumps CalculationArun Kumar DeyNo ratings yet

- 11OBDGS1 Engine DiagnosticsDocument59 pages11OBDGS1 Engine DiagnosticsMandy MoalemNo ratings yet

- EnerpacDocument1 pageEnerpachenry vegaNo ratings yet

- Practice Result (Ref)Document5 pagesPractice Result (Ref)Manuel ParreñoNo ratings yet

- 250kw Biogas Generator SpecDocument6 pages250kw Biogas Generator Spectannl220788No ratings yet

- 4 Lecture (Reheat Rankine Cycle)Document5 pages4 Lecture (Reheat Rankine Cycle)Ali Haider RizviNo ratings yet

- Sizing and Selection Chart 25T, 25TE, 25E, 25PT, 25PTE: How To Select and SizeDocument2 pagesSizing and Selection Chart 25T, 25TE, 25E, 25PT, 25PTE: How To Select and SizePaul Andre Cruz MolinaNo ratings yet

- Problem Sheet # 5 (Turbofan)Document3 pagesProblem Sheet # 5 (Turbofan)Muhammad JamilNo ratings yet

- Sizing Selection Chart-25T 25TE 25E 25PT 25PTE-TI-1-1124-USDocument2 pagesSizing Selection Chart-25T 25TE 25E 25PT 25PTE-TI-1-1124-USDiegoNo ratings yet

- Genset Caterpillar 200 kVADocument5 pagesGenset Caterpillar 200 kVAridho kusumaNo ratings yet

- Experiment No.3: Exp Name: Boiler (Steam Generator) Description and ApplicationDocument7 pagesExperiment No.3: Exp Name: Boiler (Steam Generator) Description and ApplicationAywb Kh HamadNo ratings yet

- SELECTED Case Studies On BFW Pump and Steam TurbinesDocument9 pagesSELECTED Case Studies On BFW Pump and Steam TurbinesVijayNo ratings yet

- Centrifugal Pressure Boosting Pumps: Techical DataDocument2 pagesCentrifugal Pressure Boosting Pumps: Techical DataCarlos CetinaNo ratings yet

- 6 Pompy Obiegowe ENDocument24 pages6 Pompy Obiegowe ENCosty LcpNo ratings yet

- Process Data Sheet For Booster Air Compressor Rev00Document4 pagesProcess Data Sheet For Booster Air Compressor Rev00mahan moradiNo ratings yet

- Energy Cost of Pump MotorDocument16 pagesEnergy Cost of Pump MotorkapilNo ratings yet

- Summary of Vapor Power SystemDocument7 pagesSummary of Vapor Power SystemAgung Dwi SaptoNo ratings yet

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- Engine For Power Generation Applications: EU 2002/88/EC Stage 2Document4 pagesEngine For Power Generation Applications: EU 2002/88/EC Stage 2Владислав ЛеоновNo ratings yet

- Sheet 4Document2 pagesSheet 4Mustafa AymanNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- BP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVADocument5 pagesBP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVARobet PrasetyoNo ratings yet

- W2 MAN 9L2738 Main EngineDocument13 pagesW2 MAN 9L2738 Main EngineHisyammudin RoslanNo ratings yet

- HP-LP Bypass FDocument16 pagesHP-LP Bypass FSolaiNo ratings yet

- Relavant MIT Questions With SolutionsDocument27 pagesRelavant MIT Questions With SolutionsRehman UllahNo ratings yet

- EP1 With Bayonett Connector DescriptionDocument13 pagesEP1 With Bayonett Connector DescriptionSutec Hungária Kft.No ratings yet

- 4045HF485 154hp@2400rpmDocument4 pages4045HF485 154hp@2400rpmKazim AlrefaiNo ratings yet

- Chery A21 Service Manual Mechanism of 2.0nalc EngineDocument45 pagesChery A21 Service Manual Mechanism of 2.0nalc Enginehusnihameed74No ratings yet

- Demu Specification & SystemsDocument37 pagesDemu Specification & SystemsSourabh SaxenaNo ratings yet

- BP40 Diesel Generating Set: Standby Power 50Hz 35KW / 44KVA Prime Power 50Hz 32KW / 40KVADocument5 pagesBP40 Diesel Generating Set: Standby Power 50Hz 35KW / 44KVA Prime Power 50Hz 32KW / 40KVAAhmad ZikriNo ratings yet

- VRLA Batteries PBQ 3.5-4: 3.5ah - 4voltDocument2 pagesVRLA Batteries PBQ 3.5-4: 3.5ah - 4volterewrwerNo ratings yet

- Scrubbing CirculationDocument2 pagesScrubbing Circulation511231103No ratings yet

- RVL013HDocument1 pageRVL013Hsergiohc7No ratings yet

- Sulphuric Acid TransferDocument2 pagesSulphuric Acid Transfer511231103No ratings yet

- Diesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- Fuel Savings and Efficiency CalculatorDocument6 pagesFuel Savings and Efficiency CalculatorFaizan YousufNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Diesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- First Basis Vaccum Requirements Pressure RequirementsDocument1 pageFirst Basis Vaccum Requirements Pressure RequirementssohaibNo ratings yet

- Man v32 44crDocument2 pagesMan v32 44crKeshav Shrivastava KSNo ratings yet

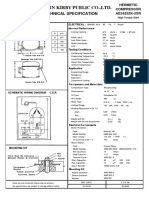

- Kulthorn Kirby Public Co.,Ltd.: Technical SpecificationDocument2 pagesKulthorn Kirby Public Co.,Ltd.: Technical SpecificationPradhish RejiNo ratings yet

- Whirlpool Adp 533 WHDocument12 pagesWhirlpool Adp 533 WHGustavo ValdezNo ratings yet

- Method and Configuration H2S Online AnalyzerDocument2 pagesMethod and Configuration H2S Online AnalyzerNicola MargarelliNo ratings yet

- Sem 3 Tad-Pt Turbo Eng 2020Document69 pagesSem 3 Tad-Pt Turbo Eng 2020S Vd VoetNo ratings yet

- BCM280 Nta855 G1BDocument9 pagesBCM280 Nta855 G1BAGUS PURWANTONo ratings yet

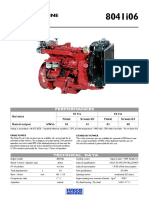

- 8041i06 (Catalog)Document2 pages8041i06 (Catalog)Worapol KaewyingNo ratings yet

- 16 - Mortuary Freezer PDFDocument19 pages16 - Mortuary Freezer PDFWan Arif Wan NasirNo ratings yet

- Standby Power 50Hz Prime Power 50Hz - : Standard FeaturesDocument5 pagesStandby Power 50Hz Prime Power 50Hz - : Standard FeaturesMrShaz ZainalNo ratings yet

- CNC Turning MachineDocument78 pagesCNC Turning MachineAndriZiNo ratings yet

- 4.3-Furnace Rear SideDocument1 page4.3-Furnace Rear SideAndriZiNo ratings yet

- 11 Tertiary SuperheaterDocument1 page11 Tertiary SuperheaterAndriZiNo ratings yet

- 4.4-Furnace Right SideDocument1 page4.4-Furnace Right SideAndriZiNo ratings yet

- 4.2-Furnace Left SideDocument1 page4.2-Furnace Left SideAndriZiNo ratings yet

- 3-LP Water HeaterDocument1 page3-LP Water HeaterAndriZiNo ratings yet

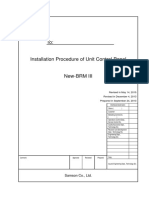

- Installation Manual NEW-BRMDocument17 pagesInstallation Manual NEW-BRMAndriZiNo ratings yet

- BB Solar Catalog SeriesDocument1 pageBB Solar Catalog SeriesAndriZiNo ratings yet

- Company Profile Indo Prawita Sekawan 2015Document11 pagesCompany Profile Indo Prawita Sekawan 2015AndriZiNo ratings yet

- Se 3000apg (Eng)Document16 pagesSe 3000apg (Eng)AndriZiNo ratings yet

- Manual Data Sheet Gaode China Refractory Tools Dibeli IB 2020 Dumai ProjectDocument4 pagesManual Data Sheet Gaode China Refractory Tools Dibeli IB 2020 Dumai ProjectAndriZiNo ratings yet

- Brochure Ceramic Fiber FINEFLEXDocument5 pagesBrochure Ceramic Fiber FINEFLEXAndriZiNo ratings yet

- Circulation in The Philippine ArchipelagoDocument20 pagesCirculation in The Philippine ArchipelagoGrace PatagocNo ratings yet

- Nursery EsteblishmentDocument154 pagesNursery EsteblishmentRoy PelegNo ratings yet

- Greater Mumbai Eastern Coast CZMPDocument4 pagesGreater Mumbai Eastern Coast CZMPSonali TelangNo ratings yet

- Chem - Rev-WS-01Document4 pagesChem - Rev-WS-01DhivegaNo ratings yet

- Practice Test 2: PASSAGE 1 Questions 1-10Document12 pagesPractice Test 2: PASSAGE 1 Questions 1-1003- Trịnh Thị Ngọc BíchNo ratings yet

- EarthingDocument13 pagesEarthingipraoNo ratings yet

- WRD - Performance Budget 2022-23Document43 pagesWRD - Performance Budget 2022-23Neil AgshikarNo ratings yet

- Manuale VT Cimex Eradicator Na M0S11829 1S10 PDFDocument60 pagesManuale VT Cimex Eradicator Na M0S11829 1S10 PDFZac RiegoNo ratings yet

- Nitoproof 10Document2 pagesNitoproof 10Balasubramanian Ananth67% (3)

- Objective of The VisitDocument4 pagesObjective of The VisitAwes OmarNo ratings yet

- Analysis of Flow Structure Over Ogee Spillway in Consideration of Scale and Roughness Effects by Using CFD ModelDocument9 pagesAnalysis of Flow Structure Over Ogee Spillway in Consideration of Scale and Roughness Effects by Using CFD ModelPashupati MandalNo ratings yet

- Stripcote 35SDocument1 pageStripcote 35SMaverikbjNo ratings yet

- The Global Pinch Point in Water Reuse NetworksDocument4 pagesThe Global Pinch Point in Water Reuse Networkscarlosalfredo35No ratings yet

- Blue Green Algae Bio Fertilizer TechnologyDocument3 pagesBlue Green Algae Bio Fertilizer TechnologySurendra Hota100% (4)

- Drawings For Plumbing and DrainageDocument31 pagesDrawings For Plumbing and DrainageKISUJA MADUHUNo ratings yet

- Cetol WF 965 5188-045401-XXX: Product Description Drying TimeDocument2 pagesCetol WF 965 5188-045401-XXX: Product Description Drying TimeMed ManNo ratings yet

- Landforms 3d AssignmentDocument2 pagesLandforms 3d Assignmentapi-77017198No ratings yet

- Waterless Tanning Chrome Tanning in Ethanol and Its DerivativesDocument32 pagesWaterless Tanning Chrome Tanning in Ethanol and Its DerivativesJosé Carlos Vilca AlarcónNo ratings yet