Professional Documents

Culture Documents

Supporting Every Stage of The Geoscience and Mining Life Cycle

Uploaded by

VerioskaCarreño0 ratings0% found this document useful (0 votes)

6 views1 pageHh

Original Title

a39ac9740152494d8c0a6756cd9506ef

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageSupporting Every Stage of The Geoscience and Mining Life Cycle

Uploaded by

VerioskaCarreñoHh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

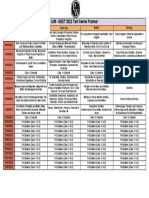

Supporting Every Stage of the

Geoscience and Mining Life Cycle

X-ray Fluorescence (XRF) | X-ray Diffraction (XRD) | Microscopy | Nondestructive Testing (NDT) Technology

Geological Surveys and

Academia: Earth Sciences and

Mineral Processing Research

• Field work

• Teaching

• Lab and research activities Exploration

Greenfields and Brownfields

• Optimize exploration budgets and fast track

projects with real-time data in the field

• Rapidly delineate mineralogical controls

Mining • Optical mineralogy/petrology of host rock

materials

• Grade control and lithogeochemistry—real-time

geochemistry and mineralogy

• Use NDT technology, like phased array, eddy

current, and remote visual inspection, to inspect

fixed and heavy mobile plant equipment

Mineral Processing

and Extractive Metallurgy

• Fast analysis to optimize process, recovery,

and extraction

• Near real-time process control

Onsite and Commercial • Optical mineralogy/petrology of host rock

materials

Laboratories

• Inexpensive, near real-time multi-element

geochemistry

• Easily collect quantitative mineralogy

• Optical mineralogy/petrology of host rock materials Plant Maintenance

Fixed and Mobile Equipment

• Alloy PMI, weld testing, and oil/lubricant wear

analysis

• Corrosion ID and classification

Environmental Remediation • Measure the thickness of conveyor belts and

other wear surfaces

and Mine Closure • Use remote video to visually inspect hard-to-

• Soil, rock, and dust monitoring; site remediation; reach places

contamination mapping; waste and tailing • Use microscopes to view welds at high

classification, including acid-mine drainage (AMD) magnification

• Mineralogical phase ID of waste and tails materials

www.olympus-ims.com

You might also like

- Prospecting and Exploration of Mineral DepositsFrom EverandProspecting and Exploration of Mineral DepositsRating: 4.5 out of 5 stars4.5/5 (3)

- Research Center: Minerals TestingDocument16 pagesResearch Center: Minerals TestingFIORELLA GIANINA CHIPANA OCHOANo ratings yet

- Vanta XRF BrochureDocument5 pagesVanta XRF Brochurericardo cruzNo ratings yet

- Vanta Handheld XRF Analyzer: Rugged. Revolutionary. ProductiveDocument5 pagesVanta Handheld XRF Analyzer: Rugged. Revolutionary. ProductiveVerioskaCarreñoNo ratings yet

- Enduring Excellence Enduring Excellence Enduring Excellence Enduring ExcellenceDocument8 pagesEnduring Excellence Enduring Excellence Enduring Excellence Enduring ExcellenceansarNo ratings yet

- Tech RUDN EurasiaDocument11 pagesTech RUDN EurasiaSeyed Hadi AhmadiNo ratings yet

- Industry - Minerals Processing 2022Document23 pagesIndustry - Minerals Processing 2022Prabhat MishraNo ratings yet

- Drilling and LoggingDocument42 pagesDrilling and Loggingjose2911100% (1)

- Base Metal LeachingDocument4 pagesBase Metal LeachingRa kannanNo ratings yet

- Mewbourne School: of Petroleum and Geological EngineeringDocument27 pagesMewbourne School: of Petroleum and Geological EngineeringGhassen LaouiniNo ratings yet

- SGS MIN WA013 Flotation EN 11 PDFDocument3 pagesSGS MIN WA013 Flotation EN 11 PDFPaul Acosta MamaniNo ratings yet

- Introduction Well LoggingDocument40 pagesIntroduction Well LoggingTajuddin MohammedNo ratings yet

- EpsilonDocument7 pagesEpsilonL Fernando Melo PNo ratings yet

- Terra Search Services BrochureDocument4 pagesTerra Search Services BrochureAgus BudiluhurNo ratings yet

- Services For The Industry: Iron Ore & SteelDocument2 pagesServices For The Industry: Iron Ore & SteelPramod SinghNo ratings yet

- 04 - Eksplorasi - Iwan MunajatDocument23 pages04 - Eksplorasi - Iwan MunajatdadqwdNo ratings yet

- Prospecting and ExplorationDocument24 pagesProspecting and ExplorationGerald PaglinawanNo ratings yet

- Chapter 2 Investigation for Bridge DesignDocument8 pagesChapter 2 Investigation for Bridge DesignAsfaw BelayNo ratings yet

- RPM Course Overview Mining For Non Miners Advanced Underground Coal.v1Document1 pageRPM Course Overview Mining For Non Miners Advanced Underground Coal.v1Prakash RajakNo ratings yet

- METALLURGICAL ANALYSIS GUIDEDocument4 pagesMETALLURGICAL ANALYSIS GUIDEIrah Antonniette SagutNo ratings yet

- DNFM ServicesDocument1 pageDNFM ServicesJohn M. CavoteNo ratings yet

- The Importance of Understanding The Field Geomatics For UTHM PackDocument19 pagesThe Importance of Understanding The Field Geomatics For UTHM PackElisanoor2No ratings yet

- Programme in Technical and Operational Surface Mining ExcellenceDocument4 pagesProgramme in Technical and Operational Surface Mining Excellencezvishavane zvishNo ratings yet

- SPE Peer-Reviewed Journals: Other PeriodicalsDocument2 pagesSPE Peer-Reviewed Journals: Other PeriodicalsAli MahammedNo ratings yet

- 18ctce CFP BrochureDocument6 pages18ctce CFP Brochurefebri siregarNo ratings yet

- Well LoggingDocument46 pagesWell LoggingReddy Setyawan100% (1)

- Comminution CourseDocument413 pagesComminution CourseNataniel Linares100% (1)

- Nickel Laterite WebinarDocument44 pagesNickel Laterite Webinarherryadi.wachyudinNo ratings yet

- Brazil Onshore - 2011 - FinalDocument32 pagesBrazil Onshore - 2011 - FinalDiego D. LasalleNo ratings yet

- Company BrochureDocument20 pagesCompany BrochureQoudar RamdhaniNo ratings yet

- Chapter 7 - Surface MiningDocument43 pagesChapter 7 - Surface MiningKajal Nayak100% (1)

- Chapter 7 - Surface MiningDocument43 pagesChapter 7 - Surface MiningLobsang MatosNo ratings yet

- Cast MaterialsDocument20 pagesCast MaterialsLoru GomezNo ratings yet

- AusencoDocument20 pagesAusencoloisNo ratings yet

- Non Destructive TestingDocument24 pagesNon Destructive TestingLipika GayenNo ratings yet

- SGS MIN WA108 An Overview of Coal Capabilities EN 11Document2 pagesSGS MIN WA108 An Overview of Coal Capabilities EN 11Reonki ReonkiNo ratings yet

- NDT MethodsDocument29 pagesNDT Methodskabilan kumarNo ratings yet

- Screenshot 2023-06-14 at 15.19.17Document27 pagesScreenshot 2023-06-14 at 15.19.17Amir ShahzadNo ratings yet

- Mineral Processing ChallengesDocument23 pagesMineral Processing ChallengesrodmonsalNo ratings yet

- Integrating Bulk Ore Sorting Into A Mining OperationDocument16 pagesIntegrating Bulk Ore Sorting Into A Mining OperationEduardo CandelaNo ratings yet

- Programme in Technical and Operational Surface Mining ExcellenceDocument3 pagesProgramme in Technical and Operational Surface Mining Excellenceantonio rodriguesvieiraNo ratings yet

- Vanta Mining EN Letter 202312 WebDocument8 pagesVanta Mining EN Letter 202312 WebJohn SmitgNo ratings yet

- Mineral Exploration Drilling TechniquesDocument17 pagesMineral Exploration Drilling TechniquesanamagicoNo ratings yet

- New CV AdilDocument2 pagesNew CV AdilEngr.Tanveer KhanNo ratings yet

- Comminution Course 2016 - CompressDocument392 pagesComminution Course 2016 - CompressThibaut LeconteNo ratings yet

- Drilling Process PresentationDocument13 pagesDrilling Process PresentationCharlzandyNo ratings yet

- Geochemical Analysis of Iron Ore - SGSDocument2 pagesGeochemical Analysis of Iron Ore - SGSAnton De la ruaNo ratings yet

- Geochemical Analysis of Iron Ore - SGSDocument2 pagesGeochemical Analysis of Iron Ore - SGSAnton De la ruaNo ratings yet

- RPM Course Overview Mining For Non Miners Coal MetalsDocument1 pageRPM Course Overview Mining For Non Miners Coal MetalsRyan BahariNo ratings yet

- Site Investigation Methods and TechniquesDocument3 pagesSite Investigation Methods and TechniquesDivine LlorenteNo ratings yet

- Ore & Host Rock Characterization Using Televiewer DataDocument26 pagesOre & Host Rock Characterization Using Televiewer DataalenmeNo ratings yet

- Oil & Gas Industry Cycle: Where Are The Hydrocarbons?Document38 pagesOil & Gas Industry Cycle: Where Are The Hydrocarbons?ahza hanifNo ratings yet

- Geometallurgy: Sgs Minerals Services - T3 Sgs 354 09-2013Document3 pagesGeometallurgy: Sgs Minerals Services - T3 Sgs 354 09-2013Edwin Velásquez100% (1)

- Terkelin Purba - Penerapan Teknologi Digital Dalam Peningkatan Pertumbuhan Eksplorasi Dan Produksi PertambanganDocument18 pagesTerkelin Purba - Penerapan Teknologi Digital Dalam Peningkatan Pertumbuhan Eksplorasi Dan Produksi PertambanganSabarNo ratings yet

- 1.1 - Mine LifecycleDocument23 pages1.1 - Mine LifecycleSaeda NajafizadaNo ratings yet

- SGS Min Wa370Document2 pagesSGS Min Wa370anggiaNo ratings yet

- Thrust Areas of Research Offered For PHDocument2 pagesThrust Areas of Research Offered For PHadityamduttaNo ratings yet

- Metallurgical Considerations in Mine Feasibility StudiesDocument52 pagesMetallurgical Considerations in Mine Feasibility StudiesLud PasNo ratings yet

- Waste Management For Offshore Decommissioning: Caroline White BPDocument18 pagesWaste Management For Offshore Decommissioning: Caroline White BPChristian BarNo ratings yet

- Chinook-Services-Wellsite GeologyDocument6 pagesChinook-Services-Wellsite Geologyincharge geologistNo ratings yet

- Fit For Purpose - Things To Know in GeoChem Testing (Evident)Document56 pagesFit For Purpose - Things To Know in GeoChem Testing (Evident)VerioskaCarreñoNo ratings yet

- Online Geology Resources For Portable XRF and XRD: Rugged. Revolutionary. ProductiveDocument2 pagesOnline Geology Resources For Portable XRF and XRD: Rugged. Revolutionary. ProductiveVerioskaCarreñoNo ratings yet

- Vanta XRF ExplorationDrilling AppNote 201608 WebDocument2 pagesVanta XRF ExplorationDrilling AppNote 201608 WebVerioskaCarreñoNo ratings yet

- Sample Cup SolutionsDocument11 pagesSample Cup SolutionsVerioskaCarreñoNo ratings yet

- MapuDocument1 pageMapuVerioskaCarreñoNo ratings yet

- Las Últimas NoticiasDocument1 pageLas Últimas NoticiasVerioskaCarreñoNo ratings yet

- A Review of The Handheld X-Ray Fluorescence SpectrometerDocument11 pagesA Review of The Handheld X-Ray Fluorescence SpectrometerDaniele QuinnNo ratings yet

- FDocument8 pagesFFatissam La LionneNo ratings yet

- XRF Analysis of Rocks and Minerals PDFDocument154 pagesXRF Analysis of Rocks and Minerals PDFCristián Ignacio Zuilt Zúñiga100% (1)

- Part I-Surface MiningDocument75 pagesPart I-Surface MiningVerioskaCarreñoNo ratings yet

- A Review of The Handheld X-Ray Fluorescence SpectrometerDocument11 pagesA Review of The Handheld X-Ray Fluorescence SpectrometerDaniele QuinnNo ratings yet

- FDocument1 pageFVerioskaCarreñoNo ratings yet

- 38-Character Cryogenic Rocket Engine Document SummaryDocument23 pages38-Character Cryogenic Rocket Engine Document SummaryDebanjan LahiriNo ratings yet

- Passive Energy Dissipation Systems For StructuralDocument12 pagesPassive Energy Dissipation Systems For StructuralMichael Jhoan Rodriguez RomeroNo ratings yet

- Gas MigrationDocument42 pagesGas Migrationmoussa mrzg100% (1)

- CH 90Document14 pagesCH 90NishanNo ratings yet

- Manual On Design of DamsDocument35 pagesManual On Design of DamsTamilselvanNo ratings yet

- Electrostatic 6Document5 pagesElectrostatic 6Hammad MustafaNo ratings yet

- Logbook Ctu 07 (Arif SB 2023) - 1Document240 pagesLogbook Ctu 07 (Arif SB 2023) - 1Arief Setia budiNo ratings yet

- AIM - NEET 2022 Test Series PlannerDocument1 pageAIM - NEET 2022 Test Series Planner6 months AgoNo ratings yet

- Refsys PDFDocument2 pagesRefsys PDFtae walaNo ratings yet

- Phy PPT FinalDocument29 pagesPhy PPT FinalReck OnNo ratings yet

- Surge CalcsDocument29 pagesSurge CalcsThamotharanNo ratings yet

- Aircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITDocument32 pagesAircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITAida Brkić - BurićNo ratings yet

- 21 A-Classical-Perturbation-Technique-Which-Is-Valid-For-Large-Parameters PDFDocument4 pages21 A-Classical-Perturbation-Technique-Which-Is-Valid-For-Large-Parameters PDFAnonymous zXVPi2PlyNo ratings yet

- GG 6 (1-3) 53-80 1987 by Rowe and Soderman PDFDocument28 pagesGG 6 (1-3) 53-80 1987 by Rowe and Soderman PDFpabulumzengNo ratings yet

- PDFDocument2 pagesPDFbhavesh patelNo ratings yet

- Physics 1 Code PH-101 Contacts 3+1 Credits 4Document2 pagesPhysics 1 Code PH-101 Contacts 3+1 Credits 4Dr. Pradeep Kumar SharmaNo ratings yet

- Class 11 and 12 Biology, Chemistry and Physics NotesDocument4 pagesClass 11 and 12 Biology, Chemistry and Physics NotesADARSHRAJ MOHAPATRANo ratings yet

- Design of RCC Chimney in HyderabadDocument84 pagesDesign of RCC Chimney in Hyderabadhemantkle2u100% (1)

- Mach ZenderDocument4 pagesMach ZenderGreeshmani GreeshNo ratings yet

- Chapter 5 Wind Energy SystemDocument71 pagesChapter 5 Wind Energy SystemMohammad Irfan AliNo ratings yet

- Chapter 19Document30 pagesChapter 19d4rkne5sNo ratings yet

- Drosera MSDocument1 pageDrosera MStribolasNo ratings yet

- Finite Element Analysis of Delamination of NanocompositesDocument7 pagesFinite Element Analysis of Delamination of NanocompositesArjunNo ratings yet

- 03Document34 pages03Gagan JainNo ratings yet

- Troubleshooting - Brgs.Document6 pagesTroubleshooting - Brgs.Sanjoy deyNo ratings yet

- Cairo University Metallurgy Lecture on Metal Drawing ProcessDocument20 pagesCairo University Metallurgy Lecture on Metal Drawing Processيوسف عادل حسانينNo ratings yet

- CHM 3103 Lab # 3.1 ReportDocument5 pagesCHM 3103 Lab # 3.1 ReportRaja GokhulNo ratings yet

- API Plan 11 12 23 52 PDFDocument18 pagesAPI Plan 11 12 23 52 PDFAkhmad Zaenudin100% (1)

- Physics ProjectDocument25 pagesPhysics Projectaryan sharrma100% (1)

- Schroedinger EssayDocument19 pagesSchroedinger EssayMark MoodyNo ratings yet