Professional Documents

Culture Documents

Integrated Dual-Axis Gyro IDG-1215: Features General Description

Uploaded by

samsonit1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated Dual-Axis Gyro IDG-1215: Features General Description

Uploaded by

samsonit1Copyright:

Available Formats

Integrated Dual-Axis Gyro

IDG-1215

FEATURES GENERAL DESCRIPTION

• Integrated X- and Y-axis gyros on a single chip The IDG-1215 is an integrated dual-axis angular rate

• ±67°/s full-scale range sensor (gyroscope). It uses InvenSense’s proprietary and

• 15mV/°/s sensitivity patented MEMS technology with vertically driven,

• Integrated amplifiers and low-pass filter vibrating masses to make a functionally complete, low-

• Auto Zero function cost, dual-axis angular rate sensor. All required

electronics are integrated onto a single chip with the

• Integrated reset switch for high-pass filters

sensor.

• On-chip temperature sensor

• High vibration rejection over wide frequency range The IDG-1215 gyro uses two sensor elements with novel

• High cross-axis isolation by proprietary MEMS design vibrating dual-mass bulk silicon configurations that sense

• 3V single-supply operation the rate of rotation about the X- and Y-axis (in-plane

• Hermetically sealed for temp and humidity resistance sensing). This results in a unique, integrated dual-axis

• 10,000g Shock Tolerant gyro with guaranteed-by-design vibration rejection and

• Smallest dual axis gyro package at 4 x 5 x 1.2mm high cross-axis isolation. It is specifically designed for

• RoHS and Green Compliant demanding consumer applications requiring low cost,

small size and high performance.

APPLICATIONS

The IDG-1215 gyro includes integrated electronics

• GPS Navigation Devices necessary for application-ready functionality. It

• Robotics incorporates X- and Y-axis low-pass filters, pins for user

• Electronic Toys definable high-pass filters, user controlled integrated

• Platform Stabilization switches for resetting the high-pass filters and an

EEPROM for on-chip factory calibration of the sensor.

Factory trimmed scale factors eliminate the need for

external active components and end-user calibration.

This product is lead-free and Green Compliant.

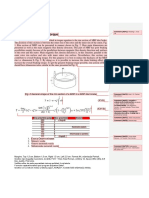

VDD

IDG-1215 300kΩ

24 AZ

Oscillator Coriolis Output

Demodulator

Sense Gain

7 X-RATEOUT

XAGC 6 X-Rate Low-Pass

Sensor Filter

0.22µF X-HP2

5

Auto Zero

650Ω

Oscillator Coriolis VREF X-HP1 750

Sense Demodulator 1

Gain

Y-Rate Low-Pass 0.1µF

YAGC 15 Sensor Filter Output

0.22µF Gain

14 Y-RATEOUT

Auto Zero

Supply Y-HP2

16

2.2Ω

9 VDD Charge Pump Memory Reference

Regulator Trim 650Ω

1.0µF LDO 0.1µF 19 VDD

VREF Y-HP1 750

20

CPOUT GND 0.1µF

12 2 26 27 28 22 23

VREF PTAT

0.1µF/25V

Sensor

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 1 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

SPECIFICATIONS

All parameters specified are @ VDD = 3.0 V and Ta = 25°C.

Specifications are measured with the circuit on the first page. All specifications apply to both axes.

PARAMETER CONDITIONS MIN TYP MAX UNITS

SENSITIVITY

Full-Scale Range Factory Set ±67 °/s

Sensitivity 15 mV/°/s

Initial Calibration Tolerance ±6 %

Over Specified Temperature ±5 %

Nonlinearity Best Fit Straight Line <1 % of FS

Cross-axis Sensitivity ±1 %

REFERENCE

Voltage Value Factory set 1.35 V

Tolerance ±50 mV

Load Drive 100 µA

Capacitive Load Drive Load directly connected to VREF 100 pF

Power Supply Rejection VDD= 2.7V to 3.3V 1 mV/V

Over Specified Temperature ±5 mV

ZERO-RATE OUTPUT

Static Output (Bias) Factory Set 1.35 V

Relative With Auto Zero ±2 °/sec

Initial Calibration Tolerance

to VREF Without Auto Zero ±50 °/sec

Relative

Over Specified Temperature Without Auto Zero ±30 °/sec

to VREF

Power Supply Sensitivity @ 50 Hz 10 °/sec/V

FREQUENCY RESPONSE

High Frequency Cutoff Internal LPF -90° 140 Hz

LPF Phase Delay 10Hz -4.5 °

MECHANICAL FREQUENCIES

X-Axis Resonant Frequency 20 24 28 kHz

Y-Axis Resonant Frequency 23 27 31 kHz

Frequency Separation X and Y Gyroscopes 3 kHz

NOISE PERFORMANCE

Total RMS Noise Bandwidth 1Hz to 1kHz 3 mV rms

OUTPUT DRIVE CAPABILITY

Output Voltage Swing Load = 100kΩ to Vdd/2 0.05 Vdd-0.05 V

Capacitive Load Drive 100 pF

Output Impedance 100 Ω

POWER ON-TIME

Zero-rate Output Settling to ±3°/s 50 200 ms

HPF RESET SWITCH / AUTO ZERO

On-Resistance X-HP2, Y-HP2 650 Ω

AZ Logic High Rising Input 1.9 V

AZ Logic Low Falling Input 0.9 V

HPF Reset Pulse Duration 3 µsec

Auto Zero Pulse Duration 2 1500 µsec

Offset Settle Time After Auto Zero 7 msec

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 2 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

PARAMETER CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY (VDD)

Operating Voltage Range 2.7 3.0 3.3 V

Quiescent Supply Current 7 9.5 mA

Over Specified Temperature ±0.5 mA

TEMPERATURE SENSOR

Sensitivity Range -20 to +85°C 4 mV/°C

Offset 1.25 V

Output Impedance 12 kΩ

TEMPERATURE RANGE

Specified Temperature Range -20 +85 °C

RECOMMENDED OPERATING CONDITIONS

Parameter Min Typical Max Unit

Power Supply Voltage (VDD) 2.7 3.0 3.3 V

Power Supply Voltage (VDD) 20 ms

Rise Time (10% - 90%)

ABSOLUTE MAXIMUM RATINGS

Stress above those listed as “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress

rating only and functional operation of the device under these conditions is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

Parameter Rating

Power Supply Voltage (VDD) -0.3V to +6.0V

Acceleration (Any Axis, unpowered) 10,000g for 0.3ms

Operating Temperature Range -40 to +105°C

Storage Temperature Range -40 to +125°C

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 3 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

PACKAGE DIMENSIONS (all dimensions in mm)

TOP VIEW BOTTOM VIEW

2X

A

D 0.15 C

2X

D2 0.15 C

E2

Chamfer,

0.10mm

B e L

DETAIL

SIDE VIEW

S COMMON

Y

0.10 C M

DIMENSIONS MILLIMETERS DIMENSIONS INCH

B

O MIN. NOM. MAX. MIN. NOM. MAX

A L

A 1.10 1.15 1.20 0.042 0.044 0.046

SEATING

A3 0.203 BSC 0.008 BSC

PLANE b

A3 b 0.18 0.25 0.30 0.007 0.009 0.011

C D 3.85 4.00 4.15 0.150 0.156 0.161

0.10 M C B A D2 2.65 2.80 2.95 0.103 0.109 0.115

E 4.85 5.00 5.15 0.189 0.195 0.200

E2 3.50 3.65 3.80 0.137 0.142 0.148

e 0.50 BSC 0.019 BSC

L 0.30 0.35 0.40 0.011 0.013 0.015

L1 0.00 0.08 0.15 0.000 0.003 0.006

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 4 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

PIN DESCRIPTION

Number Pin Description

2, 26, 27, 28 GND Ground

9, 19 VDD Positive supply voltage: 2.7V to 3.3V

1 XHP1 Filter input for X-axis

5 XHP2 Filter output for X-axis

6 XAGC Amplitude control capacitor connection

7 X-RATE OUT Rate output for rotation about the X-axis

12 CPOUT Charge pump capacitor connection

14 Y-RATE OUT Rate output for rotation about the Y-axis

15 YAGC Amplitude control capacitor connection

16 YHP2 Filter output for Y-axis

20 YHP1 Filter input for Y-axis

22 VREF Precision reference output

23 PTATS Proportional to Absolute Temperature Sensor Output

24 AZ X & Y Auto Zero control pin

8, 10, 11, 13, 21, 25 RESV Reserved. Do not connect. Used for factory trimming

3, 4, 17, 18 NC Not internally connected. May be used for PCB trace routing

PIN CONNECTION (TOP VIEW) RATE SENSITIVE AXIS

This is a dual-axis rate sensing device. It produces a

PTATS

VREF

RESV

RESV

GND

positive output voltage for rotation about the X- or Y-axis,

GND

GND

AZ

as shown in the figure below.

28 27 26 25 24 23 22 21

XHP1 1 20 YHP1

GND 2 19 VDD

IDG-1215

NC 3 18 NC

IDG-1215 +X

NC 4 17 NC +Y

XHP2 5 16 YHP2

XAGC 6 15 YAGC

7 8 9 10 11 12 13 14

CPOUT

RESV

VDD

RESV

RESV

RESV

X-RATE OUT

Y-RATE OUT

28-pin, 4mm x 5mm x 1.2mm

QFN Package

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 5 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

DESIGN NOTES

4. High-Pass Filter

1. Overview

If not using Auto Zero, high-pass filters are required in

The IDG-1215 gyro is a dual-axis gyroscope consisting of order to eliminate DC rate offset and any potential

two independent vibratory MEMS gyroscopes. One temperature dependence thereof.

detects rotation about the X-axis; the other detects

rotation about the Y-axis. Each structure is fabricated The high-pass filters are implemented by connecting an

using InvenSense’s proprietary bulk silicon technology. RC combination between X-HP1 and X-HP2, and Y-HP1

The structures are covered and hermetically sealed at the and Y-HP2. The cut-off frequency for the filters is defined

wafer-level. The cover shields the gyro from EMI. by fcutoff = 1/2πRC. The following table shows examples of

RC combinations corresponding with the desired cut-off

The gyroscope’s proof-masses are electrostatically frequency.

oscillated at resonance. An internal automatic gain

control circuit precisely sets the oscillation of the proof Cut-off

masses. When the sensor is rotated about the X- or Y- Resistor Capacitor

Frequency

(kΩ) (μF)

axis, the Coriolis effect causes a vibration that can be (Hz)

detected by a capacitive pickoff. The resulting signal is

0.03 1000 4.7

amplified, demodulated, and filtered to produce an analog

voltage that is proportional to the angular rate. 0.07 1000 2.2

0.1 330 4.7

2. Amplitude Control

0.3 100 4.7

The scale factor of the gyroscope depends on the

amplitude of the mechanical motion and the trim setting 5. High-Pass Filter Reset Switch

of the internal programmable gain stages. The oscillation

circuit precisely controls the amplitude to maintain The IDG-1215 gyroscope circuitry includes integrated

constant sensitivity over the temperature range. The switches to reset the external high-pass filters. The

capacitors (0.22μF, ±10%) connected to Pin 6 (XAGC) switches are activated by bringing the AZ pin (Pin 24)

and Pin 15 (YAGC) are compensation capacitors for the high. This closes the switches and shorts the capacitors

amplitude control loops. to VREF, allowing the high-pass filter capacitors to charge

up quickly. Without the high-pass filter reset switch, the

3. Internal Low-Pass Filter high-pass filters can take several seconds to initialize. It

is recommended to reset the high-pass filters at startup

After the demodulation stage, there is a low-pass filter and during overload conditions. The AZ Pin has an

that limits noise and high frequency artifacts from the internal pull-up resistor of 300kΩ. During normal

demodulator before final amplification. The typical filter operation, the HPS Pin should be pulled low. Note that

characteristics are shown below. the AZ input buffer is a Schmitt buffer with approximately

1.0V of hysteresis.

LPF and Gain

10 10

6. Gyro Outputs

5 5

Gain

0 0

The IDG-1215 gyro has X- and Y-outputs, with

sensitivities and full-scale ranges as summarized below.

Filter Response (dB)

-5 -5

Phase (deg)

Sensitivity Full-Scale

-10 -10 Axis Gyro Output

(mV/º/s) Range (±º/s)

-15 Phase -15

X X-RATEOUT 15 67

-20 -20

Y Y-RATEOUT 15 67

-25 -25

-30 -30 The IDG-1215 gyro outputs are independent of supply

1 10 100 1000 voltage (i.e. they are not ratiometric).

Nominal

Frequency (Hz) Limits

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 6 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

IDG-1215

Gyro rotation rate is calculated as: output can be externally buffered with a low offset-drift

buffer, and optionally a low-pass filter to minimize noise.

(Gyro Output Voltage – Gyro Zero-Rate Out) / Sensitivity

9. High Impedance Nodes

where the Zero-Rate Output (ZRO) is nominally VREF.

There is a temperature dependence to ZRO, and an initial

XAGC (pin 6) and YAGC (pin 15) pins are high

accuracy to ZRO.

impedance (>1Mohm) nodes. Any coating, glue or epoxy

on these pins or on the capacitors connected to these

7. Auto Zero pins, will affect part performance and should be avoided.

Auto Zero (AZ) is a function that reduces the effect of 10. Proper Interface Cleaning

Zero-Rate Offset (ZRO) drift without requiring the use of

an external high-pass filter. If the Auto Zero function is Proper cleaning of PCB solder pads prior to assembly is

used, a high-pass filter should not be used. recommended. PCB surface contaminants at XAGC (pin

6), YAGC (pin 15), X-HP2 (Pin 5) or YHP2 (pin 16) device

AZ works by keeping the gyro’s Zero-Rate Output (ZRO) interface may affect part performance.

close to VREF, and thus allows the user to achieve a

wider usable signal range, without using external analog 11. Power Supply Filtering

high pass filters.

When activated, the Auto Zero circuit internally nulls the NOTE: Power supply Voltage (VDD) rise time

ZRO to VREF. The typical usage of Auto Zero is in (10% - 90%) must be less than 20 ms, at VDD (pins 9

conditions where: and 19), for proper device operation.

1. The gyro’s motion is known, such as when: The IDG-1215 gyro should be isolated from system

a. The gyro is stationary. power supply noise by a combination of an RC filter that

b. Other sensors can report angular rotation attenuates high frequency noise and a Low Drop Out

rate. power supply regulator (LDO) that attenuates low

frequency noise. The figure below shows a typical

2. The DC value of the gyro output is not important,

configuration.

but only the AC value is. In this case, a digital ac

filter may be used to extract the gyro data, which

Supply

provides a higher-quality output than is possible VIN VOUT

with an analog R-C filter. 9

2.2Ω LDO 0.1µF

The Auto Zero function is initiated on the rising edge of En 19 IDG-1215

GND

the AZ pin. The Auto Zero settling time is typically 7ms. 1.0µF

This time includes the time required for nulling the ZRO

and for the settling of the internal low pass filter (LPF). If

the external LPF bandwidth is less than 200Hz, the Auto

Zero settling time will be longer than specified. The low-pass RC filter should be chosen such that it

The AZ pulse width should meet the specified minimum provides significant attenuation of system noise at high

time requirement of 2µs to start the Auto Zero function, frequencies. The LDO should be a low noise regulator

and should be shorter than the maximum specified time (<100μV/rtHz) that exhibits good noise rejection at low

of 1500µs. The Auto Zero pulse should occur after the frequencies.

start-up period to cancel any initial calibration error.

8. Temperature Sensor

A built-in Proportional-To-Absolute-Temperature (PTAT)

sensor provides temperature information on Pin 23

(PTATS). The temperature sensor output signal is

analog, and has a bias of approximately 1.25V at room

o

temperature, and increases at a rate of 4mV/ C. The

output impedance is nominally 12kΩ and is therefore not

designed to drive low impedance loads. If necessary, the

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 7 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

Integrated Dual-Axis Gyro

IDG-1215

This information furnished by InvenSense is believed to be accurate and reliable. However, no responsibility is assumed by InvenSense for its use, or for any infringements of patents or

other rights of third parties that may result from its use. Specifications are subject to change without notice. InvenSense reserves the right to make changes to this product, including its

circuits and software, in order to improve its design and/or performance, without prior notice. InvenSense makes no warranties, neither expressed nor implied, regarding the information

and specifications contained in this document. InvenSense assumes no responsibility for any claims or damages arising from information contained in this document, or from the use of

products and services detailed therein. This includes, but is not limited to, claims or damages based on the infringement of patents, copyrights, mask work and/or other intellectual property

rights.

Certain intellectual property owned by InvenSense and described in this document is patent protected. No license is granted by implication or otherwise under any patent or patent rights of

InvenSense. This publication supersedes and replaces all information previously supplied. Trademarks that are registered trademarks are the property of their respective companies.

InvenSense sensors should not be used or sold in the development, storage, production or utilization of any conventional or mass-destructive weapons or any other weapons or life

threatening applications, as well as in any other life critical applications such as medical equipment, transportation, aerospace and nuclear instruments, undersea equipment, power plant

equipment, disaster prevention and crime prevention equipment.

©2008 InvenSense, Inc. All rights reserved.

InvenSense, Inc., 1197 Borregas Ave., Sunnyvale, CA 94089, USA 8 DS-IDG-1215B-00-01

Tel: +1 (408) 988-7339 Fax: +1 (408) 988-8104 ©2008 InvenSense, Inc. All rights reserved.

Website: http//www.invensense.com

You might also like

- Mercedes Atego PDF Service ManualDocument70 pagesMercedes Atego PDF Service ManualAnderson Luiz65% (17)

- Battery Technology Crash Course A Concise Introduction by Slobodan PetrovicDocument123 pagesBattery Technology Crash Course A Concise Introduction by Slobodan Petrovicsamsonit1100% (3)

- Ism 330 DLCDocument116 pagesIsm 330 DLCebbys89No ratings yet

- AVAGO Motion Control Selection Guide 2013Document64 pagesAVAGO Motion Control Selection Guide 2013Dante CastroNo ratings yet

- High CMR Isolation Amplifiers: HCPL-7800 HCPL-7800A HCPL-7800BDocument17 pagesHigh CMR Isolation Amplifiers: HCPL-7800 HCPL-7800A HCPL-7800BRobert AguilarNo ratings yet

- N61 1524 000 004 HG1120 MEMS Inertial Measurement Unit BroDocument2 pagesN61 1524 000 004 HG1120 MEMS Inertial Measurement Unit Bro贾翼洲No ratings yet

- ADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningDocument12 pagesADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningFargham SandhuNo ratings yet

- ADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningDocument12 pagesADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningFargham SandhuNo ratings yet

- Multi-Purpose Intelligent Robot R-2000iA: Fanuc LTDDocument50 pagesMulti-Purpose Intelligent Robot R-2000iA: Fanuc LTDJuan FernandezNo ratings yet

- DR-M Optical Sorter Flyer enDocument2 pagesDR-M Optical Sorter Flyer enEngr Waqar Ahmed RajputNo ratings yet

- ATS625 DatasheetDocument22 pagesATS625 Datasheetkarthik4096No ratings yet

- Iris TgsDocument2 pagesIris Tgs김도희No ratings yet

- IS620 BR EN Spreads Web V4.1Document17 pagesIS620 BR EN Spreads Web V4.1Firman SyahNo ratings yet

- Heading Motion Sensor Intelligent Gyro Compass IgcDocument2 pagesHeading Motion Sensor Intelligent Gyro Compass IgcjaliltaghdarehNo ratings yet

- Hitbot Catalogue - V 20230613Document117 pagesHitbot Catalogue - V 20230613guwniarzykNo ratings yet

- XVC-1x00e Datasheet 20220427Document2 pagesXVC-1x00e Datasheet 20220427Alexandar MarinkovicNo ratings yet

- Electronics and Sensors CatalogDocument16 pagesElectronics and Sensors CatalogSuresh JKNo ratings yet

- Ds 000347 Icm 42688 P v1.2Document109 pagesDs 000347 Icm 42688 P v1.2longcasey90No ratings yet

- 12-Bit Programmable Contactless Potentiometer: General DescriptionDocument43 pages12-Bit Programmable Contactless Potentiometer: General DescriptionAndre PauloNo ratings yet

- AS - MCD.08.066 SuccessStory Sigma5 EuropeRFIDInlayPerfDocument1 pageAS - MCD.08.066 SuccessStory Sigma5 EuropeRFIDInlayPerfi.ozNo ratings yet

- Adcole Model 1100Document5 pagesAdcole Model 1100Ankush BhardwajNo ratings yet

- Datasheetumix U5Document2 pagesDatasheetumix U5AlexNo ratings yet

- Two-Wire End-of-Line Programmable Hall-Effect Switch/Latch: Description Features and BenefitsDocument21 pagesTwo-Wire End-of-Line Programmable Hall-Effect Switch/Latch: Description Features and Benefitsmario230991No ratings yet

- FI01 e SIPART PS2 2005 PDFDocument21 pagesFI01 e SIPART PS2 2005 PDFSofian NasrNo ratings yet

- SKF Sensor Bearings - Motor Encoder Unit - Feb 2015Document2 pagesSKF Sensor Bearings - Motor Encoder Unit - Feb 2015rominaDnNo ratings yet

- Siemens 2017Document26 pagesSiemens 2017Varun PatelNo ratings yet

- Vibxpert-II Brochure Lit.53.400.EnDocument4 pagesVibxpert-II Brochure Lit.53.400.EnMoustafa HelmyNo ratings yet

- Mitutoyo - Mikrometry Laserowe Laser Scan Micrometer - E13004 - 2016 ENDocument40 pagesMitutoyo - Mikrometry Laserowe Laser Scan Micrometer - E13004 - 2016 END.T.No ratings yet

- Fixturlaser ECO Wind BrochureDocument4 pagesFixturlaser ECO Wind BrochureCleydson Vieira GomesNo ratings yet

- Sipartps2 Ps2 Fi01 enDocument27 pagesSipartps2 Ps2 Fi01 enJose Luiz QuerubinNo ratings yet

- AEXQ2825 Advantage Cat 336 GC Vs SK350LC-10 LRC - ENDocument2 pagesAEXQ2825 Advantage Cat 336 GC Vs SK350LC-10 LRC - ENArvind Harry0% (1)

- Siemens SipartPS2 Cat2008Document24 pagesSiemens SipartPS2 Cat2008Andy HeruNo ratings yet

- Mitsubishi Electric Industrial Robot Melfa Rv-8CrlDocument8 pagesMitsubishi Electric Industrial Robot Melfa Rv-8CrlMelike KısmetNo ratings yet

- ILT 1500 DatasheetDocument2 pagesILT 1500 DatasheetcerconsNo ratings yet

- HG4930 MEMS Inertial Measurement Unit: Aerospace Performance. Industrial Prices. Possibilities of Navigation. Made EasyDocument2 pagesHG4930 MEMS Inertial Measurement Unit: Aerospace Performance. Industrial Prices. Possibilities of Navigation. Made EasyNitish SharmaNo ratings yet

- Xmotion Catalog en 202306Document164 pagesXmotion Catalog en 202306corazzaedwardNo ratings yet

- DS 000347 ICM 42688 P v1.7Document110 pagesDS 000347 ICM 42688 P v1.7aleruedaNo ratings yet

- Mitsubishi Electric Industrial Robot Melfa Rv-8Crl: Factory AutomationDocument8 pagesMitsubishi Electric Industrial Robot Melfa Rv-8Crl: Factory Automationleonardo morenoNo ratings yet

- Bonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterDocument12 pagesBonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterCAT MINING SHOVELNo ratings yet

- WWE Hyundai N700E Variable Frequency Drives JECDocument8 pagesWWE Hyundai N700E Variable Frequency Drives JECmasterdesign1978No ratings yet

- Windrock 6320 Diesel BrochureDocument4 pagesWindrock 6320 Diesel BrochureLazzarus Az GunawanNo ratings yet

- GP 180Document2 pagesGP 180yousufNo ratings yet

- Abb Acs550 Catalog en 3afe64792857 Revr 2705Document16 pagesAbb Acs550 Catalog en 3afe64792857 Revr 2705Jove MultisystemsNo ratings yet

- GEIT 20056EN Usm Go Flaw DetectorDocument4 pagesGEIT 20056EN Usm Go Flaw DetectorDaniel OscarNo ratings yet

- Tds 0005Document2 pagesTds 0005computerparadise1993No ratings yet

- Infoscan FV105DatasheetDocument2 pagesInfoscan FV105DatasheetHasaan HussainNo ratings yet

- GeoMax Zipp02 Data SheetDocument2 pagesGeoMax Zipp02 Data Sheetbbutros_317684077No ratings yet

- Motion Sensing and Control ProductsDocument64 pagesMotion Sensing and Control Productsekitani6817No ratings yet

- Sipartps2 Ps2 Fi01 enDocument25 pagesSipartps2 Ps2 Fi01 enadw0804No ratings yet

- Flyer Controller YRC1000 E 07.2020Document8 pagesFlyer Controller YRC1000 E 07.2020ALSAMAD V MNo ratings yet

- Siemens SiPart PS2 PositionerDocument21 pagesSiemens SiPart PS2 Positionermohamed abourayaNo ratings yet

- 6 4prainbowVA1103Document2 pages6 4prainbowVA1103Marco AvilaNo ratings yet

- Small Engine Control Module: ApplicationsDocument2 pagesSmall Engine Control Module: Applicationsashraf abdelrahmanNo ratings yet

- Tsop 48Document8 pagesTsop 48Uziel Olivares JaraNo ratings yet

- ATS668 DatasheetDocument13 pagesATS668 DatasheetsumanthrgowdaNo ratings yet

- ABB General Purpose Drives: ACS550 0.75 To 355 kW/1 To 500 HP CatalogDocument16 pagesABB General Purpose Drives: ACS550 0.75 To 355 kW/1 To 500 HP Catalogavijit dasNo ratings yet

- Mod 941Document2 pagesMod 941J. M.No ratings yet

- CCTV - Advert - Adl 5302H SeriesDocument2 pagesCCTV - Advert - Adl 5302H SeriesCV CIPTA KARYA GEMILANGNo ratings yet

- G120X - PresentationDocument16 pagesG120X - PresentationAyman ElotaifyNo ratings yet

- Flow Between Parallel Plates - Comsol2008Document22 pagesFlow Between Parallel Plates - Comsol2008Lakshmi BarathiNo ratings yet

- Brand Carbonyl Iron Powder-Brochure - Magnetorheological Fluids Basonetic-EnglishDocument4 pagesBrand Carbonyl Iron Powder-Brochure - Magnetorheological Fluids Basonetic-Englishgurudev001No ratings yet

- Technical Data Basonetic 4035 051010 PDFDocument8 pagesTechnical Data Basonetic 4035 051010 PDFsamsonit1100% (1)

- Technical Data Basonetic 5030 PDFDocument8 pagesTechnical Data Basonetic 5030 PDFsamsonit1No ratings yet

- Basonetic 5030 MRF - Clutch PDFDocument4 pagesBasonetic 5030 MRF - Clutch PDFsamsonit1No ratings yet

- Basonetic 2040 - DamperDocument4 pagesBasonetic 2040 - Dampersamsonit1100% (1)

- Lekcija 4Document1 pageLekcija 4samsonit1No ratings yet

- Internet Use in Agriculture, Remote Service, and Maintenance: E-Commerce, E-Business, E-Consulting, E-SupportDocument12 pagesInternet Use in Agriculture, Remote Service, and Maintenance: E-Commerce, E-Business, E-Consulting, E-SupportAkanksha Nagar-RM 20RM903No ratings yet

- 6.4 Information Technologies in Water ManagementDocument14 pages6.4 Information Technologies in Water Managementsamsonit1No ratings yet

- 4 Mechantronics and ApplicationsDocument11 pages4 Mechantronics and Applicationssamsonit1No ratings yet

- Management and Decision Support SystemsDocument13 pagesManagement and Decision Support Systemssamsonit1No ratings yet

- PrefaceDocument2 pagesPrefacesamsonit1No ratings yet

- Features General Description: DE-ACCM3D Buffered 3g Tri-Axis AccelerometerDocument5 pagesFeatures General Description: DE-ACCM3D Buffered 3g Tri-Axis Accelerometersamsonit1No ratings yet

- Magnetic Sensors Product Catalog: Sensing Earth's Magnetic FieldDocument224 pagesMagnetic Sensors Product Catalog: Sensing Earth's Magnetic Fieldsamsonit1No ratings yet

- Cover Exhibition Reference Learning Hardware Download About Feed Forum Wiki Code Tutorials Basics Library Topics BooksDocument3 pagesCover Exhibition Reference Learning Hardware Download About Feed Forum Wiki Code Tutorials Basics Library Topics Bookssamsonit1No ratings yet

- A Review of Current Sensro Technologies and Applications Within Automtive and Traffic Control SystemsDocument26 pagesA Review of Current Sensro Technologies and Applications Within Automtive and Traffic Control Systemssamsonit1No ratings yet

- PMMA High Sensitive Capacitive Micro Accelerometer Fabricated Based On Hot EmbossingDocument4 pagesPMMA High Sensitive Capacitive Micro Accelerometer Fabricated Based On Hot Embossingsamsonit1No ratings yet

- FlexRay and ISOBUS Integration For Off-RDocument9 pagesFlexRay and ISOBUS Integration For Off-Rsamsonit1No ratings yet

- IDG-1215 Dual-Axis Gyro Product SpecificationDocument25 pagesIDG-1215 Dual-Axis Gyro Product Specificationsamsonit1No ratings yet

- Control Problems in A Turbocharged Spark-Ignition EngineDocument10 pagesControl Problems in A Turbocharged Spark-Ignition Enginesamsonit1No ratings yet

- RTU Training Course Description 2014Document760 pagesRTU Training Course Description 2014Đồng Nai CTNo ratings yet

- Honda Insight Hybrid Electric Car: (EV) That Use Motors For The Driving Source Hybrid Vehicles (HV) ThatDocument24 pagesHonda Insight Hybrid Electric Car: (EV) That Use Motors For The Driving Source Hybrid Vehicles (HV) Thatmail2975682No ratings yet

- MDF-C8V1: Operating InstructionsDocument40 pagesMDF-C8V1: Operating InstructionsHi ParphNo ratings yet

- Amted399086en (Web)Document180 pagesAmted399086en (Web)aleksandaralNo ratings yet

- DSAZIHA100080735Document2 pagesDSAZIHA100080735AbdNo ratings yet

- Hi-Target V60 GNSS RTK Receiver: User GuideDocument55 pagesHi-Target V60 GNSS RTK Receiver: User GuidealgebraikoNo ratings yet

- S4CPlus-Repair Manual Part 1 IRB6600Document220 pagesS4CPlus-Repair Manual Part 1 IRB6600martinimartiiniNo ratings yet

- JM JTManualDocument23 pagesJM JTManualcuongNo ratings yet

- Icl 8211Document14 pagesIcl 8211mencomputerNo ratings yet

- DTC CodeDocument2 pagesDTC CodetataeNo ratings yet

- FichaTecnica Promonitor NRF560Document13 pagesFichaTecnica Promonitor NRF560Charles MartinNo ratings yet

- Datasheet RSR110Document2 pagesDatasheet RSR110Shree Kumar MishraNo ratings yet

- Af0zp0ba (COMBIAC2-ing) PDFDocument65 pagesAf0zp0ba (COMBIAC2-ing) PDFtaurusNo ratings yet

- VEGA II Electronic Flow Computer Blending Version 2.0 - Ds - Ve - 0019 - enDocument6 pagesVEGA II Electronic Flow Computer Blending Version 2.0 - Ds - Ve - 0019 - enRoronoa ZorroNo ratings yet

- Incubadora NatalCare ST-LXDocument103 pagesIncubadora NatalCare ST-LXcecilia molinaNo ratings yet

- Getting Started Manuel Cadence 2017-18Document32 pagesGetting Started Manuel Cadence 2017-18陳景裕No ratings yet

- Cutting Machine GroundingDocument24 pagesCutting Machine GroundingMarco TorresNo ratings yet

- Important!: All Sales Force Dan Maslic BDTECB204Document2 pagesImportant!: All Sales Force Dan Maslic BDTECB204Ing. Alejandro NarvaezNo ratings yet

- Air Fryer SilverCrestDocument112 pagesAir Fryer SilverCrestSzabadosMariannaNo ratings yet

- Hypnotic PDFDocument888 pagesHypnotic PDFSATISHGOKULNo ratings yet

- ToshibaDocument316 pagesToshibaRitesh SharmaNo ratings yet

- NUX MG-30 Versatile Modeler User Manual: Manuals+Document11 pagesNUX MG-30 Versatile Modeler User Manual: Manuals+JasperMelNo ratings yet

- P900RM (En) 05Document242 pagesP900RM (En) 05inclumarhNo ratings yet

- VA CarparkManagementSysDocument22 pagesVA CarparkManagementSysmerkermanNo ratings yet

- So4203 2aDocument17 pagesSo4203 2aanhufriendNo ratings yet

- Sony Xm-255exDocument14 pagesSony Xm-255exsamuel ancesquiNo ratings yet

- PB 502 ManualDocument16 pagesPB 502 ManualArio FitriantoNo ratings yet

- 05 - Time Switches Digital & AnalougeDocument21 pages05 - Time Switches Digital & AnalougePhaniNo ratings yet

- Basler BE1-851 - 9289900990PDocument364 pagesBasler BE1-851 - 9289900990Pap00100% (1)

- 3KC90008TL40 enDocument5 pages3KC90008TL40 enElmer MendozaNo ratings yet