Professional Documents

Culture Documents

Caf-03 Cma Theory Notes Prepared by Fahad Irfan

Uploaded by

iamneonkingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caf-03 Cma Theory Notes Prepared by Fahad Irfan

Uploaded by

iamneonkingCopyright:

Available Formats

CAF-03 CMA THEORY NOTES

CHAPTER 1 – INVENTORY VALUATION

1) Advantages & Disadvantages of FIFO

Advantages

Logical (probably represents physical reality)

Easy to understand and explain to managers

Gives a value near to replacement cost

Disadvantages

Can be cumbersome to operate

Managers may find it difficult to compare costs and make decisions when they are charged with

varying prices for the same materials

In a period of high inflation, inventory issue prices will lag behind current market value

2) Advantages & Disadvantages of AVCO

Advantages

Smoothens out price fluctuations

Easier to administer than FIFO and LIFO (Last in First Out)

Disadvantages

Issue price is rarely what has been paid

Prices tend to lag a little behind current market values when there is gradual inflation

CHAPTER 2 - INVENTORY MANAGEMENT

1) Definitions

(i) Stock out Costs:

These costs result from not having enough inventories in stock to meet customers' needs. These costs

include lost sales, customers’ ill will, and the costs of expediting orders for goods not in stock.

(ii) Lead Time:

The time period between placing an order till the receipt of the goods from suppliers is called lead time.

(iii) Reorder Point:

The point of time when an order is required to be placed or production to be initiated to replenish

depleted stocks is called reorder point. It is determined by multiplying the lead time and average usage.

(iv) Safety Stock:

To minimize stock outs on account of increased demand or delays in delivery etc., a buffer stock is often

maintained. Such a buffer stocks is called Safety stock.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

(v) Inventory control:

Inventory control can be defined as the system used in an organization to control its investment in

inventory/stocks. I.e. the overall objective of inventory control is to minimize, in total, the costs

associated with stock. This includes; the recording and monitoring of stock levels, forecasting future

demands and deciding

when and how many to order.

(vi) Maximum inventory level:

A company will set a maximum level for inventory. Inventory held above this would incur extra holding

cost without adding any benefit to the company.

The inventory level should never exceed a maximum level. If it does, something unusual has happened

to either the supply lead time or demand during the supply lead time. The company would investigate

this and take action perhaps adjusting purchasing behavior.

(vii) Minimum inventory level:

The inventory level could be dangerously low if it falls below a minimum warning level. When inventory

falls below this amount, management should check that a new supply will be delivered before all the

inventory is used up, so that there will be no stock-out.

2) The method of stock valuation which should be used in times of fluctuating prices:

Weighted Average stock valuation method should be used in times of fluctuating prices because this

method is rational, systematic and not subject to manipulation. It is representative of the prices that

prevailed during the entire period rather than the price at any particular point in time. It is because of

this smoothening effect that this method should be used for stock valuation in times of fluctuating

prices.

3) The practical Assumptions of EOQ

EOQ model is valid only as per the following assumptions:

The holding cost per unit will be constant.

The average inventory is equal to one half of the order quantity as the stock is consumed at a

constant rate throughout the period. (discussed in above sections)

The cost per order is constant.

There are no quantity discounts available.

The demand for its inputs and outputs can be predicted with perfect certainty.

4) The practical limitations of EOQ

It is assumed that annual demand of material is known and constant, which in fact not. The demand

will be based on sales which may vary.

It is also assumed that per order cost and holding cost per unit shall not change. In practice, it is not

possible as some of these costs are not controllable. For example, increase in prices of petrol by

Government will enhance transportation cost.

Another limitation of EOQ model is its assumption in connection to non-availability of discounts

which is not possible in practice.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

In seasonal variation situation, the demand will be higher during season while it will be declined in

off season. Therefore, it will not justify the assumption that demand can be predicted with perfect

certainty.

5) Reasons of maintaining the safety stock:

(i) Protect against unforeseen variation in supply and/or demand.

(ii) Prevent disruption in manufacturing or deliveries.

(iii) Avoid stock-outs to keep customer service and satisfaction levels high.

6) Costs associated with holding of inventory:

(i) Cost of capital tied up

(ii) Insurance costs

(iii) Cost of warehousing

(iv) Obsolescence, deterioration and theft

7) situations in which EOQ model for determining optimum level of stocks becomes invalid:

The EOQ model becomes invalid in the following situations:

The holding cost per unit is not constant.

The stock is not consumed at a constant rate throughout the period due to which average inventory

is not equal to one half of the order quantity.

The cost per order is not constant.

There are quantity discounts available.

CHAPTER 3 - ACCOUNTING FOR OVERHEADS

1) Treatment of under-absorbed and over-absorbed factory overheads.

The under or over applied overhead may be:

treated as period cost by closing it to Cost of Goods Sold Account or directly to Income Statement.

apportioned between inventories and cost of goods sold.

2) Reasons for under-absorbed / over absorbed factory overheads

The actual hours worked may be more or less than the estimated hours.

The estimates may not be accurate.

Actual overhead costs and actual activity levels are different from budgeted costs and activity levels.

Changes in the methods of production.

Abnormal changes in the component prices of factory overheads.

Extraordinary expenses might have been incurred during the accounting period.

Major changes might have taken place. For example, replacement of general purpose machine with

automatic high speed machines.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

3) Factors affecting the predetermined overhead rate:

In addition to the selection of bases, the following more factors are also considered:

1. Activity level selection

2. Inclusion or exclusion of fixed overheads

3. Single rate or several rates

4) Definitions

Normal Capacity

The company expects that there is no change in the demand and therefore, the same number of units

shall be produced. This is called Normal Capacity.

Expected Actual Capacity.

If the company expects that the demand will increase or decrease and estimates a level at 90% or 70%,

this is called Expected Actual Capacity.

Direct expenses

Expenses that are fully traceable to the product, service or department that is being costed.

Examples:

Raw Materials that are specifically used for the product in consideration,

Labor which is directly involved in converting the raw material

Other expenses that are specifically incurred for the product.

Indirect expenses (Production overheads)

Indirect expenses are those expenses that incur in the course of making a product, providing of service

or running department but which cannot be traced directly and fully to the product, service or

department.

Examples:

Labor which is not directly involved in the conversion of raw material but indirectly involved in

making of the product. Such as supervisor who is responsible to supervise the production

process is not directly involved and therefore treated as indirect cost,

Tools, spares and materials that are used in the machinery or equipment used in the production,

Factory rent if the factory premises are hired,

Depreciation of machinery and equipment.

Electricity and other utility expenses incurred for the production facilities

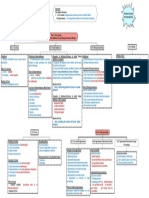

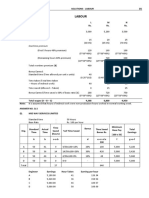

CHAPTER 4 – LABOUR COSTING

1) Types of labor cost:

a) Direct Labor Cost: Direct labor cost is any cost that is specifically incurred for or can be readily

charged to or recognized with any specific contract, job or work order. In cost accounting it is classified

as direct labor cost which becomes part of prime cost. For example: In a watch manufacturing factory, a

worker operating molding machine to produce a part of wrist watch.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

b) Indirect Labor Cost: Where the direct labor can be recognized with and charged to the job, the

indirect labor cannot be so charged and hence is treated as part of the factory overheads. For example:

Wages paid to supervisor of a factory or salary paid to driver of delivery van used for distribution of the

product.

2) Effective labor cost control

Effective labor cost control is achieved through different tools including;

analyzing the targeted production,

preparing labor budget and standardizing labor cost per unit,

monitoring output, quality, wastage ratios, rework cost due to bad workmanship

wage incentive systems

3) High Day Rate system

Advantages

It is easier to calculate and understand.

It assures the employee a consistently high wage.

Disadvantages

Employees cannot go beyond the fixed hourly rate for the extra effort they put in. In the example

given above if the employee makes 280 units instead of 240 units in a 40 hours week, the cost per

unit would decrease even further but all the savings would go to the benefit of the employer and

none would go to the employee.

The high wages might become the accepted wage level for normal working. Management might

need to keep checks on the productivity and efficiency levels of the employees.

4) Group Bonus Scheme

Advantages

Group schemes reduce the clerical efforts to be put in for the calculations of individual incentive

schemes.

They are easy to be administered.

Group schemes improve the team cohesion.

Disadvantages

Employees might demand for minimum targets for accepting the scheme.

Employees doing the best and the worst might fall victim to team’s politics

5) Profit sharing scheme

Advantages

The biggest advantage is that the organization will pay only what it can afford to pay out of the

actual profits earned.

Such schemes can be offered to indirect labor as well.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

Disadvantages

Employees may be putting in best of their efforts yet the organization might still incur losses on

account of issues beyond the control of the employees.

It is a long term commitment that the organization is asking for. The employees have to wait for the

bonus until the year ends. The reward is not an immediate one

CHAPTER 9 – MARGINAL COSTING AND ABSORPTION COSTING

1) Advantages and disadvantages of absorption costing

Advantages of absorption costing

Inventory values include an element of fixed production overheads. This is consistent with the

requirement in financial accounting that (for the purpose of financial reporting) inventory should include

production overhead costs.

Calculating under/over absorption of overheads may be useful in controlling fixed overhead

expenditure.

By calculating the full cost of sale for a product and comparing it will the selling price, it should be

possible to identify which products are profitable and which are being sold at a loss.

Disadvantages of absorption costing

Absorption costing is a more complex costing system than marginal costing.

Absorption costing does not provide information that is useful for decision making (like marginal

costing does).

Assigning of Production overheads always include an element of discretion; and

It might led to sub-optimal decision-making as a product might be discontinued due to loss which

might be caused by fixed production over head.

2) Advantages and disadvantages of marginal costing

Advantages of marginal costing

It is easy to account for fixed overheads using marginal costing. Instead of being apportioned they

are treated as period costs and written off in full as an expense the income statement for the period

when they occur.

There is no under/over-absorption of overheads with marginal costing, and therefore no adjustment

necessary in the income statement at the end of an accounting period.

Marginal costing provides useful information for decision making.

Disadvantages of marginal costing

Marginal costing does not value inventory in accordance with the requirements of financial

reporting. (However, for the purpose of cost accounting and providing management information,

there is no reason why inventory values should include fixed production overhead, other than

consistency with the financial accounts.)

Marginal costing can be used to measure the contribution per unit of product, or the total

contribution earned by a product, but this is not sufficient to decide whether the product is

profitable enough. Total contribution has to be big enough to cover fixed costs and make a profit.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

CHAPTER 10 – STANDARD COSTING

1) Types of standard

Ideal standards.

These assume perfect operating conditions. No allowance is made for wastage, labour inefficiency or

machine breakdowns. The ideal standard cost is the cost that would be achievable if operating

conditions and operating performance were perfect. In practice, the ideal standard is not achieved.

Attainable standards.

These assume efficient but not perfect operating conditions. An allowance is made for waste and

inefficiency. However, the attainable standard is set at a higher level of efficiency than the current

performance standard, and some improvements will therefore be necessary in order to achieve the

standard level of performance

Current standards.

These are based on current working conditions and what the entity is capable of achieving at the

moment. Current standards do not provide any incentive to make significant improvements in

performance, and might be considered unsatisfactory when current operating performance is

considered inefficient.

Basic standards.

These are standards which remain unchanged over a long period of time. Variances are calculated by

comparing actual results with the basic standard, and if there is a gradual improvement in performance

over time, this will be apparent in an improving trend in reported variances.

CHAPTER 11 – VARIANCE ANALYSIS

1) Comments on the difference between overhead variances under marginal and absorption costing:

All variable and fixed overhead variances under marginal and absorption costing are same, except for

the fixed overhead volume (efficiency and capacity) variances which can be calculated only under

absorption costing.

In absorption costing, fixed overheads are allocated to the products and these are included in the

inventory valuations. Therefore, fixed overhead volume variances can be computed under absorption

costing only.

In marginal costing, only variable overheads are assigned to the product; fixed overheads are regarded

as period costs and written off as a lump sum to the profit and loss account.

Therefore, fixed overhead volume variances cannot be computed under marginal costing.

CHAPTER 12 – TRAGET COSTING

1) Definitions

Target cost:

Target cost is an estimate of a product cost which is determined by subtracting a desired profit margin

from a competitive selling / market price. This target cost may be less than the planned initial product

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

cost but it is expected to be achieved by the time the product reaches the maturity stage of the product

life cycle.

Cost gap:

Cost gap is the difference between the expected cost and the target cost. It can only be arising when

expected cost to produce one unit exceeds the target cost. It can be calculated as:

Cost gap = Expected cost – Target cost

2) Common methods of closing the target cost gap are:

To re-design products to make use of common processes and components that are already used in

the manufacture of other products by the company.

To discuss with key supplier’s methods of reducing materials costs. Target costing involves the entire

‘value chain’ from original suppliers of raw materials to the customer for the end-product, and

negotiations and collaborations with suppliers might be an appropriate method of finding important

reductions in cost.

To eliminate non-value added activities or non-value added features of the product design.

Something is ‘non-value added’ if it fails to add anything in value for the customer. The cost of non-

value added product features or activities can therefore be saved without any loss of value for the

customer. Value analysis may be used to systematically examine all aspects of a product cost to

provide the product at the required quality at the lowest possible cost. This is the crux of target

costing.

Using standardized components will reduce the cost but it might impact the innovation element for

the product

To train staff in more efficient techniques and working methods. Improvements in efficiency will

reduce costs.

3) Advantages of Target Costing

There are several possible advantages from the use of target costing.

It helps to improve the understanding within a company of product costs.

It recognizes that the most effective way of reducing costs is to plan and control costs from the

product design stage onwards.

It helps to create a focus on the final customer for the product or service, because the concept of

‘value’ is important: target costs should be achieved without loss of value for the customer.

It is a multi-disciplinary approach, and considers the entire supply chain. It could therefore help to

promote co-operation, both between departments within a company and also between a company

and its suppliers and customers.

Target costing can be used together with recognized methods for reducing costs, such as value

analysis, value engineering, just in time purchasing and production, Total Quality Management and

continuous improvement i.e. Kaizen costing.

Target costing recognizes that process improvement and cost cutting is not a top down process but

rather one where workers who actually work on the product could come up with valuable

suggestions

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

CHAPTER 14 – RELEVANT COSTING

1) Definitions

Opportunity cost:

An opportunity cost is a cost that measures the opportunity that is lost or sacrificed when the choice of

one course of action requires that an alternative course of action be given up.

Example

A company has an opportunity to obtain a contract for the production of Z which will require processing

on machine X which is already working at full capacity. The contract can only be fulfilled by reducing the

present output of machine X which will result in reduction of profit contribution by Rs. 200,000.

If the company accepts the contract, it will sacrifice a profit contribution of Rs. 200,000 from the lost

output of product Z. This loss of Rs. 200,000 represents an opportunity cost of accepting the contract.

Sunk cost

A sunk cost is a historical or past cost that the company has already incurred. These costs cannot be

changed/recovered in any case and are ignored while making a decision.

Example

A company mistakenly purchased a machine that does not completely suit its requirements. The price of

the machine already paid is a sunk cost and will not be considered while deciding whether to sell the

machine or use it.

Relevant cost:

The predicted future costs that would differ depending upon the alternative courses of action, are called

relevant costs.

Example

A company purchased a raw material few years ago for Rs. 100,000. A customer is prepared to purchase

it for Rs. 60,000. The material is not otherwise saleable but can be sold after further processing at a cost

of Rs. 30,000.

In this case, the additional conversion cost of Rs. 30,000 is relevant cost whereas the raw material cost

of Rs. 100,000 is irrelevant.

Incremental cost

An incremental cost is the additional cost that will occur if a particular decision is taken. Provided that

this additional cost is a cash flow.

Example:

To produce 1,000 units, a company incurred variable cost of Rs. 1.2 million. At a normal capacity of

2,000 units, fixed cost incurred was Rs. 0.6 million.

The incremental cost of making one extra unit would be Rs. 1,200 and it would not affect the fixed cost.

Avoidable and unavoidable costs

An avoidable cost could be saved (avoided), depending whether or not a particular decision is taken. An

unavoidable cost is a cost that will be incurred anyway.

Example:

A company is paying Rs. 0.5 million annually for a warehouse on a short term lease and incurring an

annual cost of Rs. 0.4 million on maintenance and security of the warehouse. One year of the lease is

remaining and the warehouse is no more required.

PREPARED BY FAHAD IRFAN

CAF-03 CMA THEORY NOTES

The rental cost of the warehouse is unavoidable cost; therefore, it should be ignored while taking any

decision. However, by closing down the warehouse the company can avoid annual maintenance and

security costs of Rs. 0.4 million.

PREPARED BY FAHAD IRFAN

You might also like

- Caf-03 Cma Theory Notes Prepared by Fahad IrfanDocument16 pagesCaf-03 Cma Theory Notes Prepared by Fahad IrfanHadeed HafeezNo ratings yet

- Chapter 1 - Inventory Valuation: Caf-08 Cma Complete TheoryDocument8 pagesChapter 1 - Inventory Valuation: Caf-08 Cma Complete TheoryShehrozSTNo ratings yet

- Theory PortionDocument6 pagesTheory Portioncontact.samamaNo ratings yet

- Topics Covered in This ChapterDocument12 pagesTopics Covered in This ChapterManisha NagdaNo ratings yet

- Compiled Cma TheoryDocument8 pagesCompiled Cma TheoryTooba MaqboolNo ratings yet

- 21 Chapter 13Document25 pages21 Chapter 13Fajar Pitarsi DharmaNo ratings yet

- Standard Costs Measure Business PerformanceDocument17 pagesStandard Costs Measure Business Performancepam pamNo ratings yet

- Chapter - 13: Inventory ManagementDocument11 pagesChapter - 13: Inventory ManagementSsilent SsoulNo ratings yet

- Essay Los 2015 Section D. Cost Management 20 %Document18 pagesEssay Los 2015 Section D. Cost Management 20 %lassaadNo ratings yet

- Process Costing TermsDocument27 pagesProcess Costing TermsJon Jan CronicoNo ratings yet

- Ch03 - Predetermined OH Rates & Absorption-Variable CostingDocument10 pagesCh03 - Predetermined OH Rates & Absorption-Variable CostingNicole ValentinoNo ratings yet

- Inventory ManagementDocument24 pagesInventory Managementnishi27777No ratings yet

- Manage inventory efficientlyDocument25 pagesManage inventory efficientlyanitikaNo ratings yet

- Advances in Inventory ManagementDocument42 pagesAdvances in Inventory ManagementNaeem Ul HassanNo ratings yet

- Advantages of FIFODocument8 pagesAdvantages of FIFOVictoria NadarNo ratings yet

- Chapter 11 - Inventory ManagementDocument7 pagesChapter 11 - Inventory Managementhello_khayNo ratings yet

- 157 37325 EA435 2013 4 2 1 Chap013Document43 pages157 37325 EA435 2013 4 2 1 Chap013Lee JNo ratings yet

- MCC 202 Advanced Cost AccountingDocument4 pagesMCC 202 Advanced Cost AccountingNeoHoodaNo ratings yet

- Stores 1Document12 pagesStores 1James BoruNo ratings yet

- Inventory ManagementDocument12 pagesInventory ManagementArya UtamaNo ratings yet

- E12 en Part 3 Session 16 IMDocument36 pagesE12 en Part 3 Session 16 IMAhmad Al-abdulghaniNo ratings yet

- TB Addatu - Standard Costs and Variable AnalysisDocument15 pagesTB Addatu - Standard Costs and Variable AnalysisJean Fajardo Badillo0% (3)

- Inventory Management and ControlDocument52 pagesInventory Management and ControlAshish MalhanNo ratings yet

- MASB2 Inventories Pg2Document2 pagesMASB2 Inventories Pg2hyraldNo ratings yet

- Coppergate Educare Costing Theory NotesDocument106 pagesCoppergate Educare Costing Theory Notespratikjai100% (1)

- I) What Does Controllable Cost Mean?Document14 pagesI) What Does Controllable Cost Mean?Deco DewNo ratings yet

- Inventory ControlDocument40 pagesInventory ControlSidda ReddyNo ratings yet

- Costing MaterialsDocument123 pagesCosting Materialsanon_672065362No ratings yet

- Project Management Ii: Inventory ModelsDocument17 pagesProject Management Ii: Inventory ModelsmpagiNo ratings yet

- Inventory Control (Management) : 1. Raw Materials 2. ComponentsDocument21 pagesInventory Control (Management) : 1. Raw Materials 2. ComponentsWondmageneUrgessaNo ratings yet

- Topic 5 DPLM 0211Document10 pagesTopic 5 DPLM 0211julian chepkongaNo ratings yet

- A Study On Inventory ManagementDocument22 pagesA Study On Inventory ManagementMehul Panchal100% (1)

- Chapter 2 Cost and Management AcctDocument18 pagesChapter 2 Cost and Management AcctDebebe DanielNo ratings yet

- CMA CAF-8 Important TheoryDocument14 pagesCMA CAF-8 Important TheoryShehrozSTNo ratings yet

- CA Final AMA Theory Complete R6R7GKB0 PDFDocument143 pagesCA Final AMA Theory Complete R6R7GKB0 PDFjjNo ratings yet

- CHAPTER 4 - Inventory MGT MMDocument25 pagesCHAPTER 4 - Inventory MGT MMhailegebreselassie24No ratings yet

- MAS Variable and Absorption CostingDocument11 pagesMAS Variable and Absorption CostingGwyneth TorrefloresNo ratings yet

- New Invt MGT KesoramDocument69 pagesNew Invt MGT Kesoramtulasinad123No ratings yet

- Accounting Theory of CostingDocument2 pagesAccounting Theory of CostingOmerSyedNo ratings yet

- Inventory ControlDocument48 pagesInventory ControlvijiNo ratings yet

- Overhead and AbsorptionDocument22 pagesOverhead and AbsorptionJaokumar JaoNo ratings yet

- Chapter 10Document27 pagesChapter 10Nayomi_DNo ratings yet

- Overhead Rates, Flexible Budgets, Absorption and Variable CostingDocument17 pagesOverhead Rates, Flexible Budgets, Absorption and Variable CostingSalvador CpsNo ratings yet

- Predetermined Overhead RatesDocument16 pagesPredetermined Overhead RatesjangjangNo ratings yet

- Accounting 1 Accounting For InventoryDocument12 pagesAccounting 1 Accounting For InventoryAshraf AminNo ratings yet

- Operations Research 2Document132 pagesOperations Research 2Cesar Amante TingNo ratings yet

- Inventory StrategyDocument27 pagesInventory Strategyut123No ratings yet

- CAT T7 Key NotesDocument30 pagesCAT T7 Key NotesSeah Chooi KhengNo ratings yet

- Manage inventory costs with optimal order quantitiesDocument27 pagesManage inventory costs with optimal order quantitiesBittuNo ratings yet

- Coursework header sheet defines inventory types and purposesDocument6 pagesCoursework header sheet defines inventory types and purposesGalib TalukderNo ratings yet

- LSCM Project Mp16009Document11 pagesLSCM Project Mp16009Ankit KumarNo ratings yet

- Chapter 9 Inventory Management Teaching StudentDocument62 pagesChapter 9 Inventory Management Teaching StudentMUHAMMAD SYAFIQ ABDUL HALIMNo ratings yet

- Quantity Standards: Lecture Note ACCTBA3-Fundamentals of Accounting 3 Chapter 12: Standard CostingDocument20 pagesQuantity Standards: Lecture Note ACCTBA3-Fundamentals of Accounting 3 Chapter 12: Standard CostingAndrew MirandaNo ratings yet

- Ca Final - Ama (Costing) Theory Notes: Amogh Ashtaputre @amoghashtaputre Amogh Ashtaputre Amogh AshtaputreDocument143 pagesCa Final - Ama (Costing) Theory Notes: Amogh Ashtaputre @amoghashtaputre Amogh Ashtaputre Amogh AshtaputreB GANAPATHY100% (1)

- Chapter 8 Standard Cost Accounting CompressDocument13 pagesChapter 8 Standard Cost Accounting CompressJohn Kenneth Jarce CaminoNo ratings yet

- Nventory Anagement: Unit 2 Module OneDocument18 pagesNventory Anagement: Unit 2 Module OneOckouri BarnesNo ratings yet

- Standard Costing vs Absorption Costing ProjectDocument21 pagesStandard Costing vs Absorption Costing ProjectMukesh ManwaniNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Chapter 4 Free Consent and Void Agreements (Vol - 2)Document12 pagesChapter 4 Free Consent and Void Agreements (Vol - 2)iamneonkingNo ratings yet

- Lecture 2 97Document1 pageLecture 2 97iamneonkingNo ratings yet

- Ratios explainedDocument2 pagesRatios explainediamneonkingNo ratings yet

- Lecture 3 98Document1 pageLecture 3 98iamneonkingNo ratings yet

- Lecture 1 96Document1 pageLecture 1 96iamneonkingNo ratings yet

- Chapter 04 MindMapDocument1 pageChapter 04 MindMapiamneonkingNo ratings yet

- Business Law: Certificate in Accounting and Finance Stage ExaminationDocument3 pagesBusiness Law: Certificate in Accounting and Finance Stage ExaminationiamneonkingNo ratings yet

- Chapter 4 Free Consent and Void AgreementsDocument20 pagesChapter 4 Free Consent and Void AgreementsiamneonkingNo ratings yet

- Business Laws MCQ AnswersDocument2 pagesBusiness Laws MCQ AnswersiamneonkingNo ratings yet

- Q-5 Spr-20 SOLUTIONDocument2 pagesQ-5 Spr-20 SOLUTIONiamneonkingNo ratings yet

- QPL Labor Practice (Q A)Document3 pagesQPL Labor Practice (Q A)iamneonkingNo ratings yet

- Labor (Solutions)Document7 pagesLabor (Solutions)iamneonkingNo ratings yet

- Q-3 Spr-17 SOLUTIONDocument2 pagesQ-3 Spr-17 SOLUTIONiamneonkingNo ratings yet

- Q-6 Aut-12 SOLUTIONDocument1 pageQ-6 Aut-12 SOLUTIONiamneonkingNo ratings yet

- Q-3 Spr-10 SOLUTIONDocument3 pagesQ-3 Spr-10 SOLUTIONiamneonkingNo ratings yet

- Q-1 Aut-17 SOLUTIONDocument3 pagesQ-1 Aut-17 SOLUTIONiamneonkingNo ratings yet

- Q-3 Aut-16 SOLUTION (Lec#39 HW)Document2 pagesQ-3 Aut-16 SOLUTION (Lec#39 HW)iamneonkingNo ratings yet

- Test 6 (QP)Document4 pagesTest 6 (QP)iamneonkingNo ratings yet

- Q-4 Aut-11 SOLUTIONDocument1 pageQ-4 Aut-11 SOLUTIONiamneonkingNo ratings yet

- 15 Term Test 1 (QP)Document6 pages15 Term Test 1 (QP)iamneonkingNo ratings yet

- Suggested Solution Assessment Test 01: Rise School of AccountancyDocument3 pagesSuggested Solution Assessment Test 01: Rise School of AccountancyiamneonkingNo ratings yet

- Q-4 Aut-21 SOLUTIONDocument2 pagesQ-4 Aut-21 SOLUTIONiamneonkingNo ratings yet

- Rise of AccountancyDocument1 pageRise of AccountancyiamneonkingNo ratings yet

- Test 4 (QP)Document2 pagesTest 4 (QP)iamneonkingNo ratings yet

- Test 5 (QP)Document4 pagesTest 5 (QP)iamneonkingNo ratings yet

- Depreciation calculation and gain on disposalDocument3 pagesDepreciation calculation and gain on disposaliamneonkingNo ratings yet

- Rise School of Accountancy: Suggested Solution Test 04Document2 pagesRise School of Accountancy: Suggested Solution Test 04iamneonkingNo ratings yet

- Test-7 (Sol.)Document4 pagesTest-7 (Sol.)iamneonkingNo ratings yet

- Term Test 1 (Sol.)Document5 pagesTerm Test 1 (Sol.)iamneonkingNo ratings yet

- PropensityModels PDFDocument4 pagesPropensityModels PDFSarbarup BanerjeeNo ratings yet

- Year 10 Maths PlaneDocument62 pagesYear 10 Maths Planehal wangNo ratings yet

- School of Public Health: Haramaya University, ChmsDocument40 pagesSchool of Public Health: Haramaya University, ChmsRida Awwal100% (1)

- The Unbounded MindDocument190 pagesThe Unbounded MindXtof ErNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Virtio-Fs - A Shared File System For Virtual MachinesDocument21 pagesVirtio-Fs - A Shared File System For Virtual MachinesLeseldelaterreNo ratings yet

- Airs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayDocument19 pagesAirs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayRamil J. Merculio100% (1)

- Hanwha Engineering & Construction - Brochure - enDocument48 pagesHanwha Engineering & Construction - Brochure - enAnthony GeorgeNo ratings yet

- Bal - 2011 - The New HRM in The 21st Century - A Strategic ViewDocument15 pagesBal - 2011 - The New HRM in The 21st Century - A Strategic ViewJoaquínMartínezMiñoNo ratings yet

- Handbook of Zen, Mindfulness and Spiritual Health PDFDocument324 pagesHandbook of Zen, Mindfulness and Spiritual Health PDFMatthew Grayson100% (3)

- Abbreviation Meaning Notes: Cibo ("With Food")Document4 pagesAbbreviation Meaning Notes: Cibo ("With Food")TantriNo ratings yet

- Solutions: Spheres, Cones and CylindersDocument13 pagesSolutions: Spheres, Cones and CylindersKeri-ann MillarNo ratings yet

- Corporate Governance in SMEsDocument18 pagesCorporate Governance in SMEsSana DjaanineNo ratings yet

- Continuous Sampling PlanDocument2 pagesContinuous Sampling PlanAnonymous wA6NGuyklDNo ratings yet

- EPISIOTOMYDocument17 pagesEPISIOTOMYKaye Arriane TenorioNo ratings yet

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocument28 pagesLiquid Analysis v3 Powell-Cumming 2010 StanfordgwErfanNo ratings yet

- Software Client Linux 21 01Document81 pagesSoftware Client Linux 21 01BronskyNo ratings yet

- Basic LCI To High LCIDocument3 pagesBasic LCI To High LCIIonut VladNo ratings yet

- Business Analysis FoundationsDocument39 pagesBusiness Analysis FoundationsPriyankaNo ratings yet

- Oral Medication PharmacologyDocument4 pagesOral Medication PharmacologyElaisa Mae Delos SantosNo ratings yet

- Kltdensito2 PDFDocument6 pagesKltdensito2 PDFPutuWijayaKusumaNo ratings yet

- Characteristics and Guidelines of PublicspaceDocument3 pagesCharacteristics and Guidelines of PublicspaceJanani SurenderNo ratings yet

- True False Survey FinalDocument2 pagesTrue False Survey Finalwayan_agustianaNo ratings yet

- Getting the Most from Cattle Manure: Proper Application Rates and PracticesDocument4 pagesGetting the Most from Cattle Manure: Proper Application Rates and PracticesRamNocturnalNo ratings yet

- Administracion Una Perspectiva Global Y Empresarial Resumen Por CapitulosDocument7 pagesAdministracion Una Perspectiva Global Y Empresarial Resumen Por Capitulosafmqqaepfaqbah100% (1)

- Grade 8 Lily ExamDocument3 pagesGrade 8 Lily ExamApril DingalNo ratings yet

- Variables in Language Teaching - The Role of The TeacherDocument34 pagesVariables in Language Teaching - The Role of The TeacherFatin AqilahNo ratings yet

- 20ME901 Automobile Engineering Unit 3Document74 pages20ME901 Automobile Engineering Unit 36044 sriramNo ratings yet

- Membandingkan Recall 24 Jam Nutri Survey Dengan TkpiDocument7 pagesMembandingkan Recall 24 Jam Nutri Survey Dengan TkpiFransisca SihotangNo ratings yet

- Serendipity - A Sociological NoteDocument2 pagesSerendipity - A Sociological NoteAmlan BaruahNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)