Professional Documents

Culture Documents

Acknowledgement: Induction Training Report - Naa Koshie Lamptey

Uploaded by

asamselaseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acknowledgement: Induction Training Report - Naa Koshie Lamptey

Uploaded by

asamselaseCopyright:

Available Formats

Induction Training Report – Naa Koshie lamptey

ACKNOWLEDGEMENT

My humble appreciation goes to the Almighty God for the wonderful opportunity given me to

undertake my training successfully in the Materials Division. I also thank the Director of

Materials, Mr. BonneyAcquah,and his Managers; Mr. Odai, Mr. Klu, Mr. Matrevi and Nana for

the various lectures they took me through my training period at the Materials’ Division. Further

thanks and appreciation goes to Mr. Atsu,, Mr Mensah and Mr Ofotsu for their help in taking me

through the lab works in the various sections under the materials Division.

Materials Division Page i

Induction Training Report – Naa Koshie lamptey

TABLE OF CONTENT

ACKNOWLEDGEMENT............................................................................................................i

TABLE OF CONTENT...............................................................................................................ii

CHAPTER 1....................................................................................................................................1

1. INTRODUCTION................................................................................................................1

1.1 Organisational Structure.....................................................................................................2

CHAPTER 2....................................................................................................................................4

2. BITUMINOUS PRODUCTS...............................................................................................4

2.1 Types and Grades of Bitumen............................................................................................4

2.2 Physical Tests on Bitumen.................................................................................................4

2.3 Mix Design of Hot Mix Asphalt (HMA)............................................................................5

2.4 Mix Design Methods.........................................................................................................6

3. SOILS AND AGGREGATES..............................................................................................7

3.1 Sample Preparation.............................................................................................................7

3.2 Laboratory Tests on sample...............................................................................................7

3.3 Properties of Concrete and Concrete Mix Design..............................................................8

3.4 Laboratory test on Concrete Constituents..........................................................................8

3.5 Properties of Concrete........................................................................................................9

3.6 Relevance of Tests to MRT Standard Specifications.......................................................10

CHAPTER 4..................................................................................................................................11

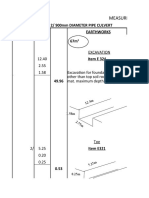

4. FOUNDATION..................................................................................................................11

4.1. Types of Foundations..................................................................................................11

4.2 Tests conducted at the Foundation Laboratory................................................................12

4.3 Soil Description................................................................................................................13

Materials Division Page ii

Induction Training Report – Naa Koshie lamptey

CHAPTER 5..................................................................................................................................14

5. PAVEMENT.......................................................................................................................14

5.1 Types of Highway Pavement...........................................................................................14

5.2 Structural Component of a Flexible Pavement.................................................................14

5.3 Pavement Design Considerations.........................................................................................14

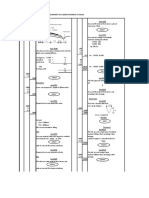

5.4 Pavement Design Procedure.............................................................................................16

5.5 Introduction to Pavement Evaluation and Monitoring.....................................................17

Materials Division Page iii

Induction Training Report – Naa Koshie lamptey

CHAPTER 1

1. INTRODUCTION

The Materials division is one of the Divisions under the Ghana Highway with

responsibilities including;:.

Develops specifications and inspection methods for use in construction and

maintenance of roads.

Mapping out Ghana soils and rocks and performing tests to determine their

suitability as base and sub-base materials.

Carrying out sub- surface investigation for the design of structural foundation for

bridges, culverts and buildings.

Provision of technical advice to other Divisions within GHA, Consultants,

Contractors, Ministries, Departments and agencies in infrastructural development.

Advices on airport runway pavement construction and maintenance.

All tests conducted in this division is in accordance with the standard specifications defined

in the Ministry of Transportation (MOT) Standard Specification for road and bridge works,

ASTM / AASHTO and the British (BS) standards.

As part of my training at the GHA, I was attached to the Materials Division for 4months

This report gives a brief account of my training period with the division.

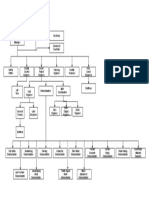

1.1 Organisational Structure

The materials Division is headed by a Director who is responsible for the smooth

administration and operation of the Division. The Director is supported by four (4)

Managers who are responsible for the sections listed below;

Soils and Aggregates

Foundations

Pavement

Bituminous Products

Materials Division Page 1

Induction Training Report – Naa Koshie lamptey

The mangers are assisted by other engineers, technicians and other staff.

Fig.1.1 shows the organisational structure of the Materials division.

Materials Division Page 2

Induction Training Report – Naa Koshie lamptey

Director of

Materials

Secretary

Soils and Aggt.

Manager Bituminous Foundations Pavement

Manager Research

Product Manager Manager and Dev.

Manager

Soils & Soils & (Vacant)

Aggt. Eng. Aggt. Eng.

(I) (II) Bituminous Foundations Pavement

Bituminous Engineer Pavement Eng.

Products Eng. Products Eng. Eng.

(II) (Monitoring & Research &

(I) Evaluation) Dev. Eng.

(Vacant)

Soils & Aggt. Soils &

Aggt. Tech. Foundations

Lab. Lab.

Supervisor Eng. Bitumen Lab. Bitumen

Supervisor Tech. Eng. Supervisor.

Pavement

Technician

Eng.

Technical Technical Foundations

Officers Officers Tech. Eng.

Technical

Officers

Fig.1.1Organisational Structure

Materials Division Page 3

Induction Training Report – Naa Koshie lamptey

CHAPTER 2

2. BITUMINOUS PRODUCTS

Bitumen is the by product obtained after the fractional distillation of crude oil. It is employed

in the construction of roads worldwide. Sampled bitumen which reflects the true nature and

conditions of the whole stock are presented to GHA’s material’s laboratory for testing.

2.1 Types and Grades of Bitumen

Bitumen is available in a variety of types and grades.

Types:

› Straight Run Bitumen

› Emulsion Bitumen

› Cut-back Bitumen

Grades of Bitumen:

› Penetration Grade:Examples include 40/50, 60/70, 80/100 etc.

› Viscosity Grade. Examples include AC 10, AC 20 etc.

› Performance Grade. Examples include PG 64-10, PG 70-10, PG 72-

10, etc.

2.2 Physical Tests on Bitumen

The physical tests conducted on bitumen includes::

Consistency Tests (degree of fluidity at any particular temperature)

› Penetration Test

To examine the consistency of a sample of bitumen by

determining the distance a standard needle vertically penetrates

the bitumen specimen under known conditions of loading, time

and temperature.

› Viscosity Test

Viscosity defines the fluid property of the bitumen. The degree

of fluidity at the application temperature greatly affects the ability

Materials Division Page 4

Induction Training Report – Naa Koshie lamptey

of the bituminous material to spread, penetrate into the voids and

also coat the aggregates.

› Softening Point Test

The test determines the temperature at which the bitumen sample

cannot support the weight off a steel ball and starts flowing.

› Ductility

The distance in centimeters (cm) that a standard briquette of

asphalt concrete will stretch before breaking at a specified

temperature of 25oC.

Safety Tests

› Flash Point Test

This test determines the temperature to which a bitumen sample

can be safely heated in the presence of an open flame

Stabiliy and Flow

› This test checks for the stability and flexibility of the mix. A

graph is plotted by the machine which shows this result

.

Other Tests

› Specific Gravity

› Distillation – to check if the right constituent of bitumen has been

used

2.3 Mix Design of Hot Mix Asphalt (HMA)

The process involves the combination of aggregates and bitumen

which are heated, proportioned, and mixed to produce the desired

paving mixture.

Some of the reasons for the design are:

Determine an economical blend and gradation of aggregate.

Provide sufficient asphalt to ensure a durable pavement.

Materials Division Page 5

Induction Training Report – Naa Koshie lamptey

Provide sufficient mix stability to satisfy the demands of traffic without

distortion or displacement.

Provide sufficient voids in compacted mix to allow slight amount of

additional compaction under traffic loading without flushing, bleeding

and loss of stability.

2.4 Mix Design Methods

Asphalt mix design methods include:

Marshall Method

Super Pave Method

Hveem Method

Materials Division Page 6

Induction Training Report – Naa Koshie lamptey

CHAPTER 3

3. SOILS AND AGGREGATES

Soil can be defined as the loose mass of mineral and organic materials that cover the

solid geology of the earth. Soil is mainly formed by weathering of solid rock at or near the

surface of the earth.

Aggregates are defined as inert, granular, and inorganic materials that normally

consist of stone or stone-like solids. Aggregates can be used alone (in road bases and

various types of fill) or can be used with cementing materials (such as Portland

cement or asphalt cement) to form composite materials or concrete.

Various tests are performed on soils and aggregates to determine their Engineering

properties which in effect determine its suitability for a specified work. As part my

training with the Soils and Aggregates section of the Materials Division, I sampled

material (lateritic) from a stockpile of the Dizengoff yard in Accra.

3.1 Sample Preparation

Drying and Riffling

The sample was air-dried to obtain the natural moisture content, (NMC). Samples to

be tested should be representative, i.e. they should be similar in characteristics to

most of the stock from which they come, or be an average of the range of materials

present. I therefore riffled the material under investigation.

3.2 Laboratory Tests on sample

The laboratory tests I conducted on the sample are as follows:

Index Property Tests

These tests are conducted for the purposes of classification or

characterization. They include:

› Atterberg Limits Test

Materials Division Page 7

Induction Training Report – Naa Koshie lamptey

Conducted to predict the behaviour of the material within the moisture

regime to determine its plasticity or the amount of clay. (Plasticity

Index, PI)

› Grading or Particle Size Distribution

This test enables a grading curve to be drawn which is a graphical

representation of the particle size distribution therefore useful in itself

for taking engineering decisions.

Strength Test

› California Bearing Ratio

The objective of the test is to determine the relative strength of the

material with respect to a well-graded crushed rock.

Compaction

The objective of the laboratory compaction is to determine an optimum

moisture content (OMC) and the corresponding maximum dry density (MDD)

of the material. The OMC and MDD are use to check relative compaction on

the field.

3.3 Properties of Concrete and Concrete Mix Design

Concrete is a composite material composed of coarse aggregate, fine aggregate ,

binder (cement), water and admixtures if required.The problem of designing a

concrete mix consists of selecting the correct proportions of cement, fine and coarse

aggregate and water to produce concrete having the specified properties. During my

training, I was involved in a concrete mix design process.

3.4 Laboratory test on Concrete Constituents

Prior to the mix, pre-qualification tests were conducted on the constituents of

concrete. The tests included:

Fine Aggregate

› Grading

› Specific Gravity

› Absorption

Materials Division Page 8

Induction Training Report – Naa Koshie lamptey

Coarse Aggregates

› Grading

› Absorption

› Flakiness Index

› Elongation Index

› Los Angeles Abrasion (LAA)

› Aggregate Impact Value (dry)

Water

The water used in the design should be potable water i.e. drinkable.

After conducting the pre-qualification tests, proportions of the constituents were

mixed together (trial and error) using the Concrete design manual as a guide till the

required concrete strength was reached.

3.5 Properties of Concrete

The properties of concrete most usually specified are:

The workability of the fresh concrete

The compressive strength at a specified age

The durability, by means of specifying the minimum cement content and/or

the maximum free-water/ cement ratio and, in some cases, requiring the use of

selected types of materials

Fig.2.3a Checking the workability of Fig.2.3b Preparing the concrete

the fresh concrete by means ofthe cubes for curing

Slump test

Materials Division Page 9

Induction Training Report – Naa Koshie lamptey

3.6 Relevance of Tests to MRT Standard Specifications

All the above mentioned tests were performed to check if the material meets the

specifications outlined in the Ministry of Roads and Transport Specifications for

Roads and Bridge Works. To mention a few, the section 12 of the MRT covers the

provision, laying and compacting of natural gravel material for subbase and base in

the pavement. In connection with the material under consideration;

Table 12.2 of section 12.4 clearly states that, for a natural material for base

course, the Average dry density should be 98% and the Minimum dry density

be 97%.

The maximum thickness of any layer compacted in one lift shall not exceed

200 mm after compaction.

Materials Division Page 10

Induction Training Report – Naa Koshie lamptey

CHAPTER 4

4. FOUNDATION

A foundation is defined as engineered system that supports the weight of a

structure and transmits the load to underlying soil or rock.

The foundation section of the materials division is responsible for the evaluation of

foundations to determine their bearing capacities. This is achieved by

conducting subsoil investigations. The goal of the subsurface investigation is to

obtain a detailed understanding of the engineeringand geologic properties of the soil,

rock strata and groundwater conditions that couldimpact the foundation.

Methods of conducting subsoil investigations include:

Trial Pits

Dynamic Cone Penetrometre Test

Auger Boring

Percussion Drilling

Rotary Drilling

Plate Loading Test

4.1. Types of Foundations

Foudations could be classified into two main categories. They are:

Deep foundations

These include:

› Pile foundation

› Caissons

› Piers

Shallow foundations

Examples include:

› Pad or column footings

Materials Division Page 11

Induction Training Report – Naa Koshie lamptey

› Strip footings

› Mat (raft) footings

4.2 Tests conducted at the Foundation Laboratory

Some of the tests that are been performed at the foundation laboratory are;

Consolidation

Resilient Modulus Test

Permeability Test

Shear Strength Tests

› Triaxial test

› Unconfined compression test

Consolidation

This test is performed to determine the magnitude and rate of volume decrease that a

laterally confined soil specimen undergoes when subjected to different vertical

pressures.

Resilient Modulus Test

The resilient modulus test is a measure of the elastic modulus of the soil. This

provides a means of characterizing pavement construction materials including

surface, base, and sub-base materials under a variety of repeated loads.

Permeability Test

This test determines the coefficient of permeability which is a measure of the

rate of flow of water through a soil.

Shear Strength Tests

The shear strength test is a measure of the soil resistance to deformation by

continuous displacement of its individual soil. It is used in analyzing stability

problems like lateral pressure on retaining structures, slope stability and bearing

capacity.

Materials Division Page 12

Induction Training Report – Naa Koshie lamptey

4.3 Soil Description

Soil descriptions are made from field observations and from disturbed and

undisturbed samples taken from cuttings, excavations and boreholes. The description

is a true representative of the material on paper. Soil description is usually based on

the other discussed below:

Consistency

Granular soils are described in varying terms of consistency as very loose,

loose, medium dense, dense or very dense.

Cohesive soils can also be described as very soft, soft, firm and stiff, very

stiff or hard.

Colour

The basiccolour of the sample is described with the dominantcolour being

mentioned last. Instances where the sample shows a mixture of colours, it is

described as mottled.

Texture

It is necessary to observe the physical 'feel' of the sample, i.e. worked in the

hand to determine the texture.

Subsidiary constituents/ associated soils

Associated soils/constituents are also mentioned upon observation.

Dominant soil name and additional features

The basic name of the predominant constituent and a single-word modifier

indicating any major subordinate constituent.

Materials Division Page 13

Induction Training Report – Naa Koshie lamptey

CHAPTER 5

5. PAVEMENT

A pavement is a layered structure designed to support vehicle wheel loads and to

distribute them to the roadbed safely. The designed layers are of varying strengths

and thickness to serve specific roles in the road pavement. The pavement section

of the materials division is responsible for the design and evaluation of trunk

road pavements.

5.1 Types of Highway Pavement

Highway pavement types include:

Flexible Pavement

Rigid Pavement

Composite Pavement

Pavement Blocks/Cobbles

5.2 Structural Component of a Flexible Pavement

The components of a flexible pavement are:

Subgrade or Prepared roadbed

Subbase

Base

Wearing surface

5.3 Pavement Design Considerations

Factors considered in the AASHTO procedure for the design of flexible pavement as

presented in the 1993 guide are:

Pavement performance

Primary factors considered are the structural and functional performance.

Structural performance include cracking, faulting, raveling, etc. Functional

Materials Division Page 14

Induction Training Report – Naa Koshie lamptey

performance considers the riding comfort. Pavement performance is

quantified by the Serviceability.

Traffic

Traffic load is determined in terms of the number of repetitions of a single

axle 80kN load applied to the pavement on a set of dual tires. This is also

known as the Equivalent Standard Axle Loads (ESALs). The axle loads are

converted to ESALs using load equivalent factors (LEFs) derived from the

AASHTO Road Test. ESAL is calculated as:

ESAL=f d ×G jt × AA DT ×365 × N i × F Ei

Where, f d = design lane factor

G jt = growth factor for a given growth rate j and design

period t

AADTi = first year annual average daily traffic for axle

category i

Ni = number of axleson each vehicle in category i

FEi= load equivalency factors for axle category i

Roadbed soils (subgrade material)

The AASHTO flexible pavement design procedure requires the input of an

effective roadbed soil resilient modulus, which is equivalent to the combined

effect of all seasonal modulus values.

Construction materials

The quality of materials used in constructing the subbase, base and wearing

course are determined. The appropriate layer coefficients are established by

deriving relationships based on material properties such as the resilient or

elastic modulus.

Materials Division Page 15

Induction Training Report – Naa Koshie lamptey

Environment

Temperature and rainfall are the two main environmental factors used in

evaluating pavement performance in the AASHTO method.

Drainage

The effect of drainage on all untreated layers below the road surface is

considered by multiplying each layer coefficient (ai) by a modifying factor

(mi). The structural number (SN)equation modified for drainage is shown

below:

SN=a1 D1 +a 2 D2 m2 +a 3 D3 m 3

Where, mi = drainage coefficient for layer i

a1, a2, a3 = layer coefficients representative of surface, base

and subbase course respectively.

D1, D2, D3 = actual thicknesss of surfacee , base and subbase

course respectively.

Reliability

The AASHTO guide proposes the use of reliability factor that considers the

possible uncertainties in traffic prediction as performance prediction. For a

given reliability level (R), the reliability factor is a function of the overall

standard deviation (So), that accounts for the standard variation in materials

and construction, the change in variation of traffic prediction and the normal

variation in pavement performance for a given number of ESAL applications.

5.4 Pavement Design Procedure

The procedure consists of five main steps:

Select or determine input data

Select surface and base materials

Determine minimum thickness required for input data

Materials Division Page 16

Induction Training Report – Naa Koshie lamptey

Evaluate feasibility of staged construction and prepare stage construction if

necessary

Carry out economic analyses of alternative designs and select the best design

5.5 Introduction to Pavement Evaluation and Monitoring

Pavement monitoring and evaluation involves techniques for monitoring the

structural and surface characteristics of pavement with the aim at improving

the durability of the road.

Some the evaluation techniques are the Falling Weight Deflectometer test and

the Dynamic Cone Penetration test.

The key pavement characteristics considered in an evaluation are:

Distress survey

Roughness evaluation

Structural testing

Skid Resistance

Monitoring is done to:

Prioritize maintenance activities

Prepare long range maintenance programs

Determine the effect of budget reduction and deferred maintenance

programs.

Materials Division Page 17

Induction Training Report – Naa Koshie lamptey

Materials Division Page 18

You might also like

- Manual English Volume 1 of 3 (Rev.01)Document120 pagesManual English Volume 1 of 3 (Rev.01)saudexecutiveNo ratings yet

- Construction Method Statement LOT2Document48 pagesConstruction Method Statement LOT2adetokunbo fapuroNo ratings yet

- Method Statement For A Construction Project PDFDocument114 pagesMethod Statement For A Construction Project PDFSyed Viqar Ahmed88% (8)

- Bale Ded Kick-Off Meeting-27march2018Document18 pagesBale Ded Kick-Off Meeting-27march2018DianNo ratings yet

- Visio 组织机构图(格鲁吉亚E60项目)Document1 pageVisio 组织机构图(格鲁吉亚E60项目)铁卫伟No ratings yet

- MS 005-Slope Protection Part 01Document12 pagesMS 005-Slope Protection Part 01Krishan RodrigoNo ratings yet

- Induction Training To Fresh Engineers: BY Er. Y.R.Balaji, Chief Engineer (H), ProjectsDocument39 pagesInduction Training To Fresh Engineers: BY Er. Y.R.Balaji, Chief Engineer (H), ProjectsSiva NatNo ratings yet

- MS 002 - Excavation and EmbankmentDocument19 pagesMS 002 - Excavation and EmbankmentKrishan RodrigoNo ratings yet

- PM Method Statement For A Construction ProjectDocument114 pagesPM Method Statement For A Construction ProjectXozan100% (1)

- 绘图2 2Document1 page绘图2 2Yuanj ZenNo ratings yet

- MS 002 - Excavation and EmbankmentDocument19 pagesMS 002 - Excavation and EmbankmentKrishan Rodrigo100% (2)

- Material / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectDocument1 pageMaterial / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectSiti Iyaroh dearni SaragihNo ratings yet

- Quality Assurance PlanDocument18 pagesQuality Assurance PlanANup GhiMire100% (12)

- Communication ProtocolDocument2 pagesCommunication ProtocolMohammed AffrozeNo ratings yet

- Material / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectDocument1 pageMaterial / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectSiti Iyaroh dearni SaragihNo ratings yet

- Organization StructureDocument1 pageOrganization StructureAndi Maghfirah Fitrah IINo ratings yet

- Material / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectDocument1 pageMaterial / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectSiti Iyaroh dearni SaragihNo ratings yet

- 绘图2Document1 page绘图2Yuanj ZenNo ratings yet

- Final Career Report For Submission On 1october in Jinja PDFDocument34 pagesFinal Career Report For Submission On 1october in Jinja PDFAnonymous CPEha1db7U100% (17)

- Site StructureDocument1 pageSite StructureEngineeri TadiyosNo ratings yet

- Visio 27 04 2015 PDFDocument2 pagesVisio 27 04 2015 PDFimran_ishaq75hotmailNo ratings yet

- Presentable Industrial Training Experience GabrielDocument15 pagesPresentable Industrial Training Experience GabrielOkortnne AyibaNo ratings yet

- Precast Box Culvert MethodologyDocument8 pagesPrecast Box Culvert Methodologyram kumarNo ratings yet

- Bheri Babai Diversion Multipurpose Project: Department of IrrigationDocument14 pagesBheri Babai Diversion Multipurpose Project: Department of IrrigationDEBASIS BARMANNo ratings yet

- Ogombo Method StatementDocument28 pagesOgombo Method Statementadetokunbo fapuroNo ratings yet

- Construction Project Organizational ChartDocument1 pageConstruction Project Organizational Chartzul67% (3)

- ASK - WO-22.2672-METHOD-SWC-001 - 1 Method Statement of Architecture WorkDocument13 pagesASK - WO-22.2672-METHOD-SWC-001 - 1 Method Statement of Architecture Workair separation unit plant swadaya ciptaNo ratings yet

- ProfileDocument3 pagesProfileMisango EmmanuelNo ratings yet

- Uwakima Akpan Technical Experience Report For CORENDocument36 pagesUwakima Akpan Technical Experience Report For CORENUWAKIMA AKPANNo ratings yet

- Quality Assurance Plan For Building ConstructionDocument18 pagesQuality Assurance Plan For Building ConstructionANup GhiMire100% (3)

- A1 - Organisation ChartDocument1 pageA1 - Organisation ChartEce TUĞRULÖZ100% (1)

- Assignment Organization ChartDocument2 pagesAssignment Organization ChartAhmed khushalNo ratings yet

- The Challenging Road Connectivity Project With A Project Outlay of Rs 329 Crore Has Been Awarded To On 18 May 2007Document23 pagesThe Challenging Road Connectivity Project With A Project Outlay of Rs 329 Crore Has Been Awarded To On 18 May 2007shijinkuttanNo ratings yet

- Nhai Act 1988Document43 pagesNhai Act 1988Munaganti KiranNo ratings yet

- MS 001 - Clearing - Ruwanpura ExpresswayDocument14 pagesMS 001 - Clearing - Ruwanpura ExpresswayKrishan RodrigoNo ratings yet

- G. Radhakrishnan Sr. Construction Engineer (Civil, Building & Structure) Mobile: - Sultanate of Oman +968 97768759 India +91 9003954578Document7 pagesG. Radhakrishnan Sr. Construction Engineer (Civil, Building & Structure) Mobile: - Sultanate of Oman +968 97768759 India +91 9003954578Vasanthan MohanNo ratings yet

- Road Construction MaterialsDocument98 pagesRoad Construction MaterialsFrimini BeatusNo ratings yet

- DPW Onshore Port Terminal: Project ManagerDocument1 pageDPW Onshore Port Terminal: Project Managerهيثم سميرNo ratings yet

- Method Statement For Earth WorksDocument26 pagesMethod Statement For Earth WorksReynaldo PruelNo ratings yet

- 3.2 Service - Engineering Department ChartDocument1 page3.2 Service - Engineering Department ChartKAREEEMNo ratings yet

- K3 Bore Pile PT KVCDocument326 pagesK3 Bore Pile PT KVCrhoewiebNo ratings yet

- PDF Waste To Energy ENGDocument4 pagesPDF Waste To Energy ENGpramods_8No ratings yet

- Ask - Wo-22.2672-Method-Swc-006 - Work Method of Asymmetric Pedestal RepairDocument8 pagesAsk - Wo-22.2672-Method-Swc-006 - Work Method of Asymmetric Pedestal Repairair separation unit plant swadaya ciptaNo ratings yet

- ០8. Club Study - - 008 - - BoQ PreparationDocument10 pages០8. Club Study - - 008 - - BoQ PreparationThean ThoeurnNo ratings yet

- Work Method Statement For Structure ErectionDocument12 pagesWork Method Statement For Structure ErectionMuhammad TeguhNo ratings yet

- PMCM Related Project - R7Document28 pagesPMCM Related Project - R7Achmad Firnanda FaisalNo ratings yet

- Method Statement For Random Rubble Masonry WorkDocument4 pagesMethod Statement For Random Rubble Masonry WorkarunaNo ratings yet

- Copy Model Engineering Organization Chart1Document1 pageCopy Model Engineering Organization Chart1guhlNo ratings yet

- Ask - Wo-22.2672-Method-Swc-005 - Work Method of Concrete Segretion Repair Rev 02Document8 pagesAsk - Wo-22.2672-Method-Swc-005 - Work Method of Concrete Segretion Repair Rev 02air separation unit plant swadaya ciptaNo ratings yet

- Epoxy Method StatementDocument8 pagesEpoxy Method StatementALLAN KIBIRIGENo ratings yet

- 0 - Doc 20190619 Wa0001Document32 pages0 - Doc 20190619 Wa0001Laxman HosamaniNo ratings yet

- Adiremets AuditfinalDocument14 pagesAdiremets AuditfinalMesafint lisanuNo ratings yet

- (Manual of Engineering Drawing) PDFDocument1 page(Manual of Engineering Drawing) PDFGrovertNo ratings yet

- (Manual of Engineering Drawing)Document1 page(Manual of Engineering Drawing)JaanaNo ratings yet

- CV Md. Shaha Ali Sheikh - Material - BSC - KUET - 20 Yr ExpDocument8 pagesCV Md. Shaha Ali Sheikh - Material - BSC - KUET - 20 Yr ExpMd. Juwel MondolNo ratings yet

- Syllabus Advt No 04 2016 PDFDocument33 pagesSyllabus Advt No 04 2016 PDFZafar Islam Zafar0% (1)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Computer-Aided Design TechniquesFrom EverandComputer-Aided Design TechniquesE. WolfendaleNo ratings yet

- Rainfall-Induced Slope Instability PRESENTATIONDocument15 pagesRainfall-Induced Slope Instability PRESENTATIONasamselaseNo ratings yet

- Rose S$DDocument22 pagesRose S$DasamselaseNo ratings yet

- Quantities Report - NAADocument13 pagesQuantities Report - NAAasamselaseNo ratings yet

- Induction Training Report - Planning Division: AcknowledgementDocument44 pagesInduction Training Report - Planning Division: AcknowledgementasamselaseNo ratings yet

- ACAD - 2DDDDDDo-GL-Model-GEN LAYOUTDocument1 pageACAD - 2DDDDDDo-GL-Model-GEN LAYOUTasamselaseNo ratings yet

- U-Drain 900Document2 pagesU-Drain 900asamselaseNo ratings yet

- Contracts Naa (Repaired)Document26 pagesContracts Naa (Repaired)asamselaseNo ratings yet

- Quant TTTTT TTTTTDocument10 pagesQuant TTTTT TTTTTasamselaseNo ratings yet

- Measurement Sheet: Project: EarthworksDocument57 pagesMeasurement Sheet: Project: EarthworksasamselaseNo ratings yet

- 2.4.7 Conclusion .. .6Document3 pages2.4.7 Conclusion .. .6asamselaseNo ratings yet

- Quant TTTTT TTTTTDocument10 pagesQuant TTTTT TTTTTasamselaseNo ratings yet

- Standard Test Method For Splitting Tensile Strength of Intact Rock Core SpecimensDocument4 pagesStandard Test Method For Splitting Tensile Strength of Intact Rock Core SpecimensasamselaseNo ratings yet

- Vehicle T-Atv1200 Mil Specs 2015 Tech DescrDocument22 pagesVehicle T-Atv1200 Mil Specs 2015 Tech DescrpeiyingongNo ratings yet

- Random Number GeneratorsDocument13 pagesRandom Number GeneratorsTassy Nokuthanda ChipofyaNo ratings yet

- ILSDocument35 pagesILSDawood waheedNo ratings yet

- Vanderbeck Solman ch01-10Document156 pagesVanderbeck Solman ch01-10Jelly AceNo ratings yet

- Hazard ManagementDocument18 pagesHazard Managementsthiyagu0% (1)

- UNIT V WearableDocument102 pagesUNIT V WearableajithaNo ratings yet

- Purposeful InnovationDocument6 pagesPurposeful InnovationKeith Tanaka MagakaNo ratings yet

- Least Used ProtocolsDocument3 pagesLeast Used ProtocolsJohn Britto0% (1)

- 6 - Designing Manufacturing Processes - Hill - Product ProfilingDocument20 pages6 - Designing Manufacturing Processes - Hill - Product ProfilingLalit S KathpaliaNo ratings yet

- Office of The Sangguniang Panlalawigan: Hon. Francisco Emmanuel "Pacoy" R. Ortega IiiDocument5 pagesOffice of The Sangguniang Panlalawigan: Hon. Francisco Emmanuel "Pacoy" R. Ortega IiiJane Tadina FloresNo ratings yet

- Smart Goals Rubric 2Document2 pagesSmart Goals Rubric 2api-338549230100% (2)

- Schindler's List Theme Sheet Music For Piano, Violin (Solo)Document1 pageSchindler's List Theme Sheet Music For Piano, Violin (Solo)Sara SzaboNo ratings yet

- PCAR Part 1 ReviewerDocument75 pagesPCAR Part 1 ReviewerMaybelyn ConsignadoNo ratings yet

- CCS0006L (Computer Programming 1) : ActivityDocument10 pagesCCS0006L (Computer Programming 1) : ActivityLuis AlcalaNo ratings yet

- IoscanDocument3 pagesIoscanTimNo ratings yet

- Chapter 6 Game Theory TwoDocument9 pagesChapter 6 Game Theory TwoMextli BarritaNo ratings yet

- Jungle Safari Booking Management System: Mini Project ReportDocument19 pagesJungle Safari Booking Management System: Mini Project ReportNIRAV SHAH100% (1)

- Promax Reference PDFDocument32 pagesPromax Reference PDFfarkli88No ratings yet

- Trench Infill Catalog Sheet Euro Version PDFDocument3 pagesTrench Infill Catalog Sheet Euro Version PDFricbxavierNo ratings yet

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- Oxy150 BrochureDocument2 pagesOxy150 BrochureSEC MachinesNo ratings yet

- Q No. Questions CO No.: C C W That Results in GDocument2 pagesQ No. Questions CO No.: C C W That Results in GSamarth SamaNo ratings yet

- Tutorial 3Document2 pagesTutorial 3AmrinaAkmal0% (1)

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- 18c Effective Telephone CommunicationDocument78 pages18c Effective Telephone CommunicationJan Cleo Cerdiña QuijanoNo ratings yet

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocument2 pagesSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNo ratings yet

- BBA - Study On Gold As A Safer Investment CommodityDocument94 pagesBBA - Study On Gold As A Safer Investment CommoditySANJU GNo ratings yet

- Vashi Creek Water Quality NaviMumbaiDocument27 pagesVashi Creek Water Quality NaviMumbairanucNo ratings yet

- Hira Gaurd HouseDocument14 pagesHira Gaurd HouseNagadevan GovindanNo ratings yet