Professional Documents

Culture Documents

G5 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test Checklist

Uploaded by

Mohammad SolaimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G5 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test Checklist

Uploaded by

Mohammad SolaimanCopyright:

Available Formats

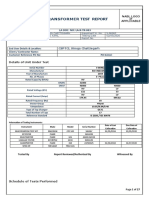

Aggreko Power Projects

Form

Project Number:

Revision: 1

Diesel Inspection and Test

Page 1 of 3

The purpose of this document is to ensure that Aggreko’s fleet of Diesel generators are setup correctly before hand over to the site Operations

manager.

Equipment Identification

Generator No. (Site) 05 (BRAHMANGAON 100MW)

Generator Plant No. XAAB 140

SMR 43

Serial No. 25320736

Engine CPL 2227

Date of manufacture 3-2007

Type P.E734C2

Alternator Serial No. X17B0837324

Date of manufacture

Installed Calibration

Gempac (AGC)

Engine control system

Installed Calibration

Checks Result

Transformer Site ID 01

Transformer Plant No. XASS214001-4

LV Isolator ID Q10B

Nominal Settings (GEMPAC) As per protection document

Voltage 415V

Frequency 50Hz

Current 1798A

Pre-Commissioning Tests Power 1034kW

Power Factor 0.90pf

Operation mode GRID

Checks

Oil and coolant

Oil level

HT circuit coolant level

LT circuit coolant level (QSK Only)

Cables and entry

Cable entry sealed

Cables are torque to 75nM

Pre-Commissioning Tests AVR Setup

Continued Droop% 80%

Printed on: September 22, 2013 Project Name: Page 1 of 3

Document No: AGK-ALL-ALL-EG-005-FO-5 Document Name: 608000833.docx

Aggreko Power Projects

Form

Project Number:

Revision: 1

Diesel Inspection and Test

Page 2 of 3

Trim% 100%

Type MX321 R448

Generator Output Circuit Breaker As per Protection document

Long time setting – Ir 0.7

Long time delay setting– tr 2 sec @ 6x Ir

Short time setting- Isd 2.5

Short time delay setting–tsd 0.3 sec ON

Instantaneous setting –Inst 4

Engine Shutdown switches (Danfoss) Standard set point

Low oil pressure shutdown ü 30PSI (2BAR)

Low coolant pressure shutdown ü 7PSI (0.5BAR)

High coolant temperature ü 1000C

Auxiliary supplies

Batteries / Charger Measured value

Battery volts (Range 24-28VDC) 23.9

Charger output volts (Range 24-28VDC) 27.8

Fan protection and trip test Note/GEMPAC display

Radiator fan over load F6 set to 31A

Room fan over load F7 set to 17 A

Trip F6 HT radiator fan supply Fan Tripped

Trip F7room fan supply Fan Tripped

Engine sensors Note/GEMPAC display

Push RH external emergency stops Emergency Stop

Disconnect coolant temperature wire L19 in engine JB N/A High Coolant Temp

Disconnect coolant pressure wire L27 in engine JB N/A Low Coolant Pressure

Disconnect oil pressure wire L31 in engine JB N/A Low Oil pressure

Off/ Local/ Remote switch operational

Alarm Reset push button operational

Push LH external emergency stops Emergency Stop

Auto Fuel

Turn and hold switch to manual, solenoid opens

Fill Tank until High alarm lights at 85%

Fill tank until High-High alarm lights at 90% and solenoid

shuts

Generator Output Checks

Zero the GEMPAC voltage trim in menu # 4740 adjust the

voltage using the AVR volts dial to set the voltage to nominal. Min=414 Max=416

Use the Voltage raise lower switch to test the AVR swing

No Load Run Checks Metering Measured GEMPAC

Circuit breaker in test position GEMPAC Voltage display matches measured 414Vac 415Vac

GEMPAC in Island mode

GEMPAC Frequency display matches measured 50Hz 50Hz

Front Panel Notes

Speed Control Lower/ Raise switch operational

Volts Control Lower/ Raise switch operational

No Load Run Checks Fans Notes

HT radiator fans rotating in clockwise direction.

Circuit breaker in test position

(air drawn throw radiator and expelled from top)

GEMPAC in Island mode Room fans rotating in clockwise direction

Notes

(air drawn from container and expelled from top)

Printed on: September 22, 2013 Project Name: Page 2 of 3

Document No: AGK-ALL-ALL-EG-005-FO-5 Document Name: 608000833.docx

Aggreko Power Projects

Form

Project Number:

Revision: 1

Diesel Inspection and Test

Page 3 of 3

Generator synchronises to live bus after selecting auto

Main circuit breaker opens after pressing manual control

button

Generator Stop

Cool down for 300secs after stop button pressed

Shut GEMPAC

Circuit breaker and shutdown test CB Trip

down Display

Test CB close inhibit by opening low voltage isolator

N/A

on transformer.

No Load Run Checks Disconnect ESD plug located in generator CB

Emergency Stop

enclosure.

Circuit breaker in test position Trip Generator ACB with Micrologic test unit N/A CB Trip

GEMPAC in Island mode

Adjust AVR volts pot to increase volts by 10% Gen Volts high

Adjust AVR volts pot to decrease volts by 10% Gen Volts Low

Disconnect oil pressure wire L31 in engine JB ü N/A Oil Pressure

Increase speed to 1650RPM (55Hz) Over-speed

Load governing Notes

Generator ramps to load level at 1% per second

Generator maintains power factor between 0.8-1.0 lag while

ramping on load

Engine governs to set kW level (850kW)

Alternator governs to set power factor

kW load governing is stable

Load running test

kVAr load governing is stable

Phase currents are balanced

Phase voltages are balanced

Generator ramps off load at 2% per second

Generator maintain power factor between 0.8-1.0lag during

ramping off load

Generator breaker opens at <116kW during ramp off

NOTES:

I have carried out all the inspection and tests as above

Job Title:

Name:

6/19/2018

Signature: X

Signe d by: Paul va n de Graa f

Date:

Printed on: September 22, 2013 Project Name: Page 3 of 3

Document No: AGK-ALL-ALL-EG-005-FO-5 Document Name: 608000833.docx

You might also like

- G2 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test ChecklistDocument3 pagesG2 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test ChecklistMohammad SolaimanNo ratings yet

- G4 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test ChecklistDocument3 pagesG4 - AGK-ALL-ALL-EG-005-FO-05 Diesel Inspection and Test ChecklistMohammad SolaimanNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- ECPM4407T 4 InfoPacketDocument11 pagesECPM4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Scan 16 Jun 2022Document1 pageScan 16 Jun 2022pirates kingNo ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- EM3714T-5 Customer Information PacketDocument9 pagesEM3714T-5 Customer Information Packetandrade2158No ratings yet

- Motogenerador A GasDocument9 pagesMotogenerador A GasPablo AguileraNo ratings yet

- ECP4404T Customer Information BALDORDocument9 pagesECP4404T Customer Information BALDOREduleofNo ratings yet

- ITP-Line Hardware - Type TestDocument3 pagesITP-Line Hardware - Type TestPrabhakar SvNo ratings yet

- ECP4407T 4 InfoPacketDocument10 pagesECP4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- ECP4400T 4 InfoPacketDocument9 pagesECP4400T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- ECPM4406T 4 InfoPacketDocument11 pagesECPM4406T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Customer Information PacketDocument10 pagesCustomer Information PacketIsaac Rodríguez BetancourtNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetMed CHNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetNsma AlaaNo ratings yet

- Generac Stand ByeDocument5 pagesGenerac Stand ByeMiguel Angel Pavon CarbonellNo ratings yet

- Test Report Rev.02 Doosan BobcatDocument1 pageTest Report Rev.02 Doosan BobcatHamoda HananNo ratings yet

- Valves CutsheetDocument1 pageValves CutsheetAntony PrabhakaranNo ratings yet

- TM PZ88 3 Phase/1500RPM PM 80 KVA Generating Set SpecificationsDocument2 pagesTM PZ88 3 Phase/1500RPM PM 80 KVA Generating Set SpecificationsAnamta KhanNo ratings yet

- Specification table for 3-phase squirrel cage induction motorDocument1 pageSpecification table for 3-phase squirrel cage induction motorHary FadlyNo ratings yet

- AREVA Relay Test Format ModifDocument97 pagesAREVA Relay Test Format ModifAUHEBEZNo ratings yet

- CECP4115T InfoPacket 50HP 1800RPMDocument11 pagesCECP4115T InfoPacket 50HP 1800RPMrrobles011No ratings yet

- Motor TC ForDocument1 pageMotor TC Forshelkeaba4No ratings yet

- 6090HFC95 325HP 2200RPMDocument4 pages6090HFC95 325HP 2200RPMMarcelo FloresNo ratings yet

- DTC Generator Inverter Performance: Circuit DescriptionDocument8 pagesDTC Generator Inverter Performance: Circuit DescriptionbakriramziNo ratings yet

- AHU - With Recovery Fan Startup ChecklistDocument2 pagesAHU - With Recovery Fan Startup Checklisttekken123joNo ratings yet

- VHECP2333T InfoPacketDocument10 pagesVHECP2333T InfoPacketFagner Senna Fagner SennaNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- Field Inspection and Test ReportDocument10 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- TM PZ650 3-Phase Generator SetDocument2 pagesTM PZ650 3-Phase Generator SetHasan RaufNo ratings yet

- Maintenance Transaction Record: Aircraft Identification and StatusDocument1 pageMaintenance Transaction Record: Aircraft Identification and StatusAlejandro BarradasNo ratings yet

- The 10mta Beneficiation Plant Project of Shougang Hierro Peru S.A.ADocument4 pagesThe 10mta Beneficiation Plant Project of Shougang Hierro Peru S.A.AYinder Vega OsorioNo ratings yet

- ECPM4115T 4 InfoPacketDocument13 pagesECPM4115T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- 09F321X763G1 Customer Information PacketDocument8 pages09F321X763G1 Customer Information Packetrrobles011No ratings yet

- Engine Performance CurveDocument4 pagesEngine Performance CurveOGNo ratings yet

- ReportDocument3 pagesReportService FTPLNo ratings yet

- Ficha Tecnica C32Document6 pagesFicha Tecnica C32mauricio.areveyNo ratings yet

- Mop For 142011Document2 pagesMop For 142011kassa hilemnehNo ratings yet

- Himoinsa HPW 60 PDFDocument2 pagesHimoinsa HPW 60 PDFJhonattan Hugo Portugal MorunoNo ratings yet

- 160 Kva Factory Joint Test Report InternalDocument2 pages160 Kva Factory Joint Test Report InternalDebdulal DuttaNo ratings yet

- Kirloskar: Diesel Generating Sets KG365W / KG365WSDocument4 pagesKirloskar: Diesel Generating Sets KG365W / KG365WSnam phạmNo ratings yet

- 1.3.1. LEHE1448-02r - G3512HDocument7 pages1.3.1. LEHE1448-02r - G3512HJuan Valdivieso100% (2)

- Actuator Test CertificateDocument1 pageActuator Test CertificateravigurajapuNo ratings yet

- AUIRFR8405Document12 pagesAUIRFR8405nithinmundackal3623No ratings yet

- 112 Specs 380V 50Hz 250kVA 6SL8800TA Rev00Document4 pages112 Specs 380V 50Hz 250kVA 6SL8800TA Rev00nam phạmNo ratings yet

- Kirloskar Diesel Generators Offer Reliable Power, Low CostsDocument4 pagesKirloskar Diesel Generators Offer Reliable Power, Low Costsnam phạmNo ratings yet

- Transformer Test Report: LA DOC. NO: LA-R-TR-003Document27 pagesTransformer Test Report: LA DOC. NO: LA-R-TR-003mayur dhandeNo ratings yet

- JMM4109T Customer Information PacketDocument8 pagesJMM4109T Customer Information PacketGabriel NogueiraNo ratings yet

- Pm-Tune Up Service: SEPD3076Document5 pagesPm-Tune Up Service: SEPD3076Aulia NafarinNo ratings yet

- 2500KW CM20171024-07485-48285Document4 pages2500KW CM20171024-07485-48285Tam SykesNo ratings yet

- M2333T InfoPacketDocument10 pagesM2333T InfoPacketroalNo ratings yet

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- SS 10278979 1000028914 155Document12 pagesSS 10278979 1000028914 155Mohit electricalsNo ratings yet

- Generator HTMLDocument5 pagesGenerator HTMLInstrumentistas de Turno ARCO MezclasNo ratings yet

- BOQ For Qatar Plant1 20-Jan-24Document134 pagesBOQ For Qatar Plant1 20-Jan-24Engineer Atif Rasul ChoudhryNo ratings yet

- FC113X-C Cummins - Leroy GRDocument7 pagesFC113X-C Cummins - Leroy GRIsrael GomezNo ratings yet

- Cat G3516H: 50 HZ Continuous Gas Generator SetsDocument7 pagesCat G3516H: 50 HZ Continuous Gas Generator SetsReal IDNo ratings yet

- 200kW Generator Gas Canopy Data SheetDocument2 pages200kW Generator Gas Canopy Data SheetWilliam AlvaradoNo ratings yet

- Chapter 3 DiodeDocument246 pagesChapter 3 DiodeLittle VoiceNo ratings yet

- Calculation of Enthalpy ChangesDocument18 pagesCalculation of Enthalpy ChangesYulia T RahkadimaNo ratings yet

- 1 Soalan 1Document7 pages1 Soalan 1Radziah MohamedNo ratings yet

- Baumüller - Three-Phase Synchronous MotorsDocument72 pagesBaumüller - Three-Phase Synchronous MotorsraduroNo ratings yet

- BMS Flair Mss2707a-TbDocument1 pageBMS Flair Mss2707a-Tbjulian vargasNo ratings yet

- Power Electronics XMV66FPM001AI XMV Comm ChecklistDocument15 pagesPower Electronics XMV66FPM001AI XMV Comm ChecklistrafaelcbscribdNo ratings yet

- 6.6 (Barello)Document2 pages6.6 (Barello)buildwithlegos23No ratings yet

- M o D U L e 0 4 - 0 1 - 0 1 A Electronic Fundamentals: DiodesDocument33 pagesM o D U L e 0 4 - 0 1 - 0 1 A Electronic Fundamentals: DiodesИлларион ПанасенкоNo ratings yet

- Magrini Galileo Cat GenDocument55 pagesMagrini Galileo Cat GenCata Catalin100% (2)

- MS IB Physics SL Summative Test Topics A. (1,2,3) and D.1Document34 pagesMS IB Physics SL Summative Test Topics A. (1,2,3) and D.1gvicentiniNo ratings yet

- 3W Datasheet-FinalDocument5 pages3W Datasheet-FinalMorteza JafarzadehNo ratings yet

- Electrostatic 1 Shot DPP 1Document8 pagesElectrostatic 1 Shot DPP 1Ayush JainNo ratings yet

- Meralco RatesDocument1 pageMeralco RatesnkeilNo ratings yet

- Pioro 2005Document25 pagesPioro 2005Thamil ThedalNo ratings yet

- Building and Environment: Mosha Zhao, Schew-Ram Mehra, Hartwig M. KünzelDocument16 pagesBuilding and Environment: Mosha Zhao, Schew-Ram Mehra, Hartwig M. KünzelAsmita ManharNo ratings yet

- C 0024 - TLZ THLZ - 04 08Document46 pagesC 0024 - TLZ THLZ - 04 08Oscar Alvitez DominguezNo ratings yet

- Lecture 5 Electric CircuitDocument20 pagesLecture 5 Electric CircuitAeron KimNo ratings yet

- 10390001-2-3 h1748 As Built DocumentsDocument768 pages10390001-2-3 h1748 As Built Documentsbatizap batizapNo ratings yet

- Carrier Serie 50TC (15-27.5 Ton) PDFDocument98 pagesCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoNo ratings yet

- J249 04 Paper Dec 17Document24 pagesJ249 04 Paper Dec 17yufm2008No ratings yet

- RAC ProblemsDocument12 pagesRAC ProblemsIts meNo ratings yet

- Study of Helium Diffusion in Different Types of Balloons (Autosaved)Document29 pagesStudy of Helium Diffusion in Different Types of Balloons (Autosaved)hhzuNo ratings yet

- REGENT UNIVERSITY ELECTROMAGNETIC THEORY SECTIONDocument5 pagesREGENT UNIVERSITY ELECTROMAGNETIC THEORY SECTIONeyyzeyyNo ratings yet

- Data Sheet 79-koyo-TRD-NDocument6 pagesData Sheet 79-koyo-TRD-NVALCICLEINo ratings yet

- Type VTT 11, 12: Definite Time Delay RelayDocument6 pagesType VTT 11, 12: Definite Time Delay RelayArun KumarNo ratings yet

- Soalan Sains No 10 Latihan Dan JawapanDocument10 pagesSoalan Sains No 10 Latihan Dan JawapanroroyaakopNo ratings yet

- Tagukon National High School: Second Grading ExaminationDocument2 pagesTagukon National High School: Second Grading ExaminationArnel AbatonNo ratings yet

- Physics ActivitiesDocument12 pagesPhysics ActivitiesAnurag Verma 12th MedNo ratings yet

- SCH 3W RMU GDDocument16 pagesSCH 3W RMU GDadityasmartiNo ratings yet

- Unit-IV Renewable Energy Sources (MCQ)Document10 pagesUnit-IV Renewable Energy Sources (MCQ)Sourabh SinghNo ratings yet