Professional Documents

Culture Documents

Sop 10 Procedure For Preservation of Products

Uploaded by

vaishnaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop 10 Procedure For Preservation of Products

Uploaded by

vaishnaviCopyright:

Available Formats

SOP 10 PROCEDURE FOR PRESERVATION OF PRODUCTS

PURPOSE

To establish and maintain a uniform and controlled method of handling, storage,

packing preservation & delivery of product. To determine the use of devices to prevent

product contamination.

SCOPE

This quality system procedure applies to all raw materials and finished goods as

defined.

RESPONSIBILITIES

All personnel are responsible for maintained procedure

Director/ Merchandiser in coordination are responsible for ensuring all products

described in above scope are purchased timely and required Q-C is carried out.

Unaccepted goods if any are to be sent to the supplier as per the decisions taken

respectively.

Threads are preserve by packing in Plastic sacks against moisture loss.

Production Manager is responsible for any product supplied by the job workers.

Authorizing unaccepted goods to be returned to the Job worker.

Procedure

To avoid raw material contamination while unloading, storage material covered with

plastic as required and on the pallets, the labour should use clean hand & portable

trolley for pulling / lifting.

Person should use clean hands & as required gloves while handling of material in

processing station

Person entering in the plant should wash hands properly.

In process, contamination is only possible when the running material to contamination

of other foreign material. The person doing cleaning & preventive suitable method used

for avoid contamination.

To control the contamination of the finished product at the time of final inspection of

the material & while packaging.

The person doing the packaging must check, packing material for any damage to avoid

while packing & stitching.

The person must wear the hat & mask involved in packaging.

The person involved in packaging must use clean hand while packaging.

In case the packing of material found is of any non-conformity, it can be collected and

stored separately as rejected material.

The packed material must be stored on the pallets in multiple stacking to avoid any

slippage of these stocked bags.

The packed material must be used for packaging as mentioned in the order. The packed

should be marked with meeting buyers requirements.

Storage: The raw material purchased as per specific orders and is randomly checked at

the time of delivery and than stored in respective stores. Fabric is purchased as per

requirement of specific buyer order. These materials are checked on delivery by the

respective departments. They are checked for defects and measurements and are

stored as per order in respective stores.

Processed material received from job works are checked by the Passing master as per

the standard defects and special quality instructions referred by the buyer.

Clipped and finished goods are covered with large sheets to protect from dust and

damage.

Packaging& Product Preservation

Packing is done as per instructions form the buyer for specific orders. The material is

normally packed in the following sequence:

Individual Poly bags, Master Poly Bags & Cartons.

The preservative granules (Silica gel) are put in every Carton to preserve the product from

moisture and insects.

You might also like

- OBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Document4 pagesOBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Andy RojasNo ratings yet

- SOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesDocument2 pagesSOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesMosub Al.Dirdiry100% (1)

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- Material Handling and Preservation ProcedureDocument2 pagesMaterial Handling and Preservation ProcedureIman ZNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Sop For in - Process Fill Weight DeterminationDocument1 pageSop For in - Process Fill Weight DeterminationPrince MoniNo ratings yet

- SOP handling control prohibitedDocument4 pagesSOP handling control prohibitedSolomon GamanuelNo ratings yet

- SOP-07 Supplier Selection, Evaluation & PurchasingDocument5 pagesSOP-07 Supplier Selection, Evaluation & Purchasingtrivesh100% (1)

- Batch Packing RecordDocument1 pageBatch Packing RecordGBL 22100% (1)

- Sop - F-P StorageDocument3 pagesSop - F-P Storagekundanrana0% (1)

- Outsourced Processes 9001 2015Document2 pagesOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- SOP For Handling of Market ComplaintDocument32 pagesSOP For Handling of Market Complaintsubbu_281No ratings yet

- Quality Assurance Incoming Raw Materials Inspection PlanDocument2 pagesQuality Assurance Incoming Raw Materials Inspection PlanAlvin NodaNo ratings yet

- Materials Receivig Work Instruction in A Manufacturing UnitDocument2 pagesMaterials Receivig Work Instruction in A Manufacturing Unitdeiveeganv411591% (11)

- WH006-02 Sop For Receipt of Raw and Packing MaterialDocument6 pagesWH006-02 Sop For Receipt of Raw and Packing MaterialBRIJENDRA KUMAR SINGHNo ratings yet

- Vendor Audit SOP GuideDocument9 pagesVendor Audit SOP Guiderana_ehsan1163100% (2)

- SOP 08 Batch Process ControlDocument2 pagesSOP 08 Batch Process ControlKrishna Rameshrao Ambilwade0% (1)

- Calibration and Maintenance of Measuring and Monitoring Devices SOPDocument3 pagesCalibration and Maintenance of Measuring and Monitoring Devices SOPBPG Service100% (1)

- Control and Monitoring Measuring and Testing EquipmentDocument3 pagesControl and Monitoring Measuring and Testing EquipmentRohit VishwakarmaNo ratings yet

- ASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal HygieneDocument5 pagesASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal Hygienesunny mgxNo ratings yet

- Sop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateDocument17 pagesSop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateSreelakshmi RakeshNo ratings yet

- Sample Shipping SOP SummaryDocument6 pagesSample Shipping SOP SummaryMahayudin SaadNo ratings yet

- Procedure For Emergency PreparenessDocument4 pagesProcedure For Emergency PreparenessNaizil KareemNo ratings yet

- SOP065RMSD - 04 Raw Material Specification Development FormDocument4 pagesSOP065RMSD - 04 Raw Material Specification Development FormGrace ChenNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- SOP For IQADocument25 pagesSOP For IQAMuhammad As'adNo ratings yet

- Operating Procedure for Internal & External CommunicationDocument4 pagesOperating Procedure for Internal & External CommunicationnomanNo ratings yet

- Ipca Laboratories batch approvalDocument4 pagesIpca Laboratories batch approvalmarkandey gupta100% (1)

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- Calibration Policy SOPDocument3 pagesCalibration Policy SOPYousifNo ratings yet

- Batch ReleaseDocument12 pagesBatch Releasemarkandey gupta50% (2)

- LGT - WHD - QP03-Material Handling and Storage Control ProcedureDocument7 pagesLGT - WHD - QP03-Material Handling and Storage Control ProcedureGregorNo ratings yet

- Department: M.R. & Quality Control Document Title: Control of Non-Conforming ProductDocument3 pagesDepartment: M.R. & Quality Control Document Title: Control of Non-Conforming ProductJamil VoraNo ratings yet

- Quality Planning SopDocument4 pagesQuality Planning SopSaravana kumar NagarajanNo ratings yet

- Supplier Approval ProcedureDocument2 pagesSupplier Approval ProcedureJobaer100% (2)

- Prepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCDocument2 pagesPrepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCMhammad NaveedNo ratings yet

- Material Review Board (MRB) Form: B-E Supplier OtherDocument1 pageMaterial Review Board (MRB) Form: B-E Supplier OtherImam MansyurNo ratings yet

- 1635 - 03 Control of Non Conforming Products Rev. 01Document5 pages1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNo ratings yet

- Warranty Management and Claims Processing SystemDocument2 pagesWarranty Management and Claims Processing SystemAnkurNo ratings yet

- SOP For DespatchDocument7 pagesSOP For DespatchKishan Maurya0% (1)

- Procedure Preservation SOP-011Document4 pagesProcedure Preservation SOP-011Justin Terry100% (1)

- Batch Release For Goods: 1. ObjectiveDocument2 pagesBatch Release For Goods: 1. ObjectivePrince MoniNo ratings yet

- QA Procedure for Inspection and TestingDocument6 pagesQA Procedure for Inspection and TestingdwarakababuNo ratings yet

- Production SOP - RIODocument8 pagesProduction SOP - RIOabu naym100% (1)

- SOP of Glassware HandlingDocument1 pageSOP of Glassware HandlingPrince Moni100% (2)

- Sample, Labeling, Packing, ShippingDocument12 pagesSample, Labeling, Packing, ShippingAnonymous ggRTHDKe6No ratings yet

- SOP On Artwork Design and Approval - Pharmaceutical GuidanceDocument41 pagesSOP On Artwork Design and Approval - Pharmaceutical GuidancePrashun Shekhar Srivastava100% (1)

- Non-Conforming Material ProcedureDocument1 pageNon-Conforming Material ProcedureMd.Akidul Islam AkidNo ratings yet

- Change Control Form: Page 1 of 5 F1/Qa-Xxx/NnDocument5 pagesChange Control Form: Page 1 of 5 F1/Qa-Xxx/NnLatesh Hole100% (1)

- SOP of Release or Rejection of Finished ProductDocument1 pageSOP of Release or Rejection of Finished ProductPrince MoniNo ratings yet

- Preventive Maintenance PlanDocument7 pagesPreventive Maintenance PlanCuyapo Infirmary Lying-In HospitalNo ratings yet

- SOP On Monitoring of Temperature and Relative Humidity.Document2 pagesSOP On Monitoring of Temperature and Relative Humidity.RainMan75100% (2)

- JAGSONPAL HOLD TIME STUDYDocument3 pagesJAGSONPAL HOLD TIME STUDYAshok Lenka100% (2)

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Annual Product Quality Review (APQR) SOP - PharmaBDocument14 pagesAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Vendor Qualification ProcDocument3 pagesVendor Qualification ProcSa Ra100% (1)

- WPPDC-QMD-001-Material Control and Werehousing ProcedureDocument4 pagesWPPDC-QMD-001-Material Control and Werehousing ProcedureSimbu ArasanNo ratings yet

- Zaiqa Foods handling, storage, packing, delivery procedureDocument3 pagesZaiqa Foods handling, storage, packing, delivery proceduregmbyNo ratings yet

- CSSD CPT Manual-1Document4 pagesCSSD CPT Manual-1thirsal2003No ratings yet

- SOP 6: Procedure for Purchasing <40Document2 pagesSOP 6: Procedure for Purchasing <40vaishnaviNo ratings yet

- SOP 9 IDENTIFICATION AND TRACEABILITYDocument3 pagesSOP 9 IDENTIFICATION AND TRACEABILITYvaishnavi100% (5)

- SOP 5 Design DevlopementDocument2 pagesSOP 5 Design DevlopementvaishnaviNo ratings yet

- Sop 7 Procedure For Verification of Purchased ProductDocument1 pageSop 7 Procedure For Verification of Purchased ProductvaishnaviNo ratings yet

- Sop 3: Procedure For Awareness and Training of Personnel PurposeDocument6 pagesSop 3: Procedure For Awareness and Training of Personnel PurposevaishnaviNo ratings yet

- Participants Handouts-AUDIT PLAN Assessment Plan Date: 15 December 2015Document1 pageParticipants Handouts-AUDIT PLAN Assessment Plan Date: 15 December 2015vaishnaviNo ratings yet

- Food Defense Plan: B G A in N N S I A T L Ea Industries Limited / 1 Aug 2022 / KanavDocument4 pagesFood Defense Plan: B G A in N N S I A T L Ea Industries Limited / 1 Aug 2022 / Kanavvaishnavi100% (1)

- ISO 9001-2015 Documented InformationDocument2 pagesISO 9001-2015 Documented InformationvaishnaviNo ratings yet

- BATCH Bat Matrix OriginalDocument5 pagesBATCH Bat Matrix OriginalBarangay NandacanNo ratings yet

- Use VCDS with PC lacking InternetDocument1 pageUse VCDS with PC lacking Internetvali_nedeleaNo ratings yet

- IN SUNNY SPAIN, 1882-85: "My Country, My Love, My People, I Leave You Now, You Disappear, I Lose Sight of You"Document4 pagesIN SUNNY SPAIN, 1882-85: "My Country, My Love, My People, I Leave You Now, You Disappear, I Lose Sight of You"Mary Claire ComalaNo ratings yet

- Diseñadores Del Siglo XX - Las Figuras Clave Del Diseño y - Dormer, Peter - 1993 - Barcelona - Ceac - 9780747202684 - Anna's ArchiveDocument264 pagesDiseñadores Del Siglo XX - Las Figuras Clave Del Diseño y - Dormer, Peter - 1993 - Barcelona - Ceac - 9780747202684 - Anna's ArchiveSilvina RodríguezNo ratings yet

- FS1-Episode 10Document4 pagesFS1-Episode 10Mark Gerald Lagran82% (11)

- Business Process AnalysisDocument64 pagesBusiness Process AnalysisPanko MaalindogNo ratings yet

- Written Work 1 Q1 Science 10Document6 pagesWritten Work 1 Q1 Science 10JOEL MONTERDENo ratings yet

- Tsu m7 Practice Problems Integral CalculusDocument1 pageTsu m7 Practice Problems Integral CalculusJAMNo ratings yet

- SALICYLATE POISONING SIGNS AND TREATMENTDocument23 pagesSALICYLATE POISONING SIGNS AND TREATMENTimmortalneoNo ratings yet

- Organization Structure in SAP Plant Maintenance: CommentsDocument3 pagesOrganization Structure in SAP Plant Maintenance: CommentsMarco Antônio Claret TeixeiraNo ratings yet

- Surio vs. ReyesDocument3 pagesSurio vs. ReyesAdrian FranzingisNo ratings yet

- Ap Finance Go PDFDocument3 pagesAp Finance Go PDFSuresh Babu ChinthalaNo ratings yet

- Bradley Et Al. 1999. Goal-Setting in Clinical MedicineDocument12 pagesBradley Et Al. 1999. Goal-Setting in Clinical MedicineFelipe Sebastián Ramírez JaraNo ratings yet

- Down Syndrome Research PaperDocument11 pagesDown Syndrome Research Paperapi-299871292100% (1)

- SYLLABUS FYUP-PoliticalScience PDFDocument105 pagesSYLLABUS FYUP-PoliticalScience PDFIshta VohraNo ratings yet

- India-An Underdeveloped Economy: (Contd )Document6 pagesIndia-An Underdeveloped Economy: (Contd )Amrita Prashant IyerNo ratings yet

- Anne Frank Halloween Costume 2Document5 pagesAnne Frank Halloween Costume 2ive14_No ratings yet

- Credit As A Means of Investment in Medieval Islamic TradDocument6 pagesCredit As A Means of Investment in Medieval Islamic TradIfanaNo ratings yet

- Guide To Kulchur 1938Document374 pagesGuide To Kulchur 1938Jonathan CarsonNo ratings yet

- KluberDocument20 pagesKluberJako MishyNo ratings yet

- Window On The Wetlands BrochureDocument2 pagesWindow On The Wetlands BrochureliquidityNo ratings yet

- RetailMarketinginIndia 1Document158 pagesRetailMarketinginIndia 1RamanNo ratings yet

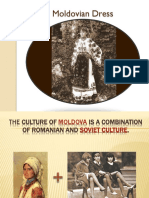

- Moldavian DressDocument16 pagesMoldavian DressAnastasia GavrilitaNo ratings yet

- You Write, It Types!: Quick Start GuideDocument21 pagesYou Write, It Types!: Quick Start Guidejean michelNo ratings yet

- Review of Esu Yoruba God Power and The IDocument7 pagesReview of Esu Yoruba God Power and The IBoris MilovicNo ratings yet

- Inducting - Orientation, Socialisation & Placing New HiresDocument17 pagesInducting - Orientation, Socialisation & Placing New HiresJaskiran KaurNo ratings yet

- 09 Egyptian Architecture PDFDocument107 pages09 Egyptian Architecture PDFIra PecsonNo ratings yet

- Samsung C&T AuditDocument104 pagesSamsung C&T AuditkevalNo ratings yet

- Skills Test Unit 1 Test A EmailDocument4 pagesSkills Test Unit 1 Test A EmailЛиза ОмельченкоNo ratings yet

- Form of SpesDocument2 pagesForm of SpesMark Dave SambranoNo ratings yet