Professional Documents

Culture Documents

X7R Dielectric: General Specifications

Uploaded by

akshay rajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X7R Dielectric: General Specifications

Uploaded by

akshay rajCopyright:

Available Formats

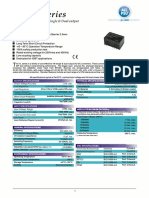

X7R Dielectric

General Specifications

X7R formulations are called “temperature stable” ceramics and fall into EIA Class II materials. X7R is the most popular

of these intermediate dielectric constant materials. Its temperature variation of capacitance is within ±15% from -55°C to

+125°C. This capacitance change is non-linear.

Capacitance for X7R varies under the influence of electrical operating con-ditions such as voltage and frequency.

X7R dielectric chip usage covers the broad spectrum of industrial applications where known changes in capacitance due

to applied voltages are acceptable.

PART NUMBER (SEE PAGE 4 FOR COMPLETE PART NUMBER EXPLANATION)

0805 5 С 103 M A T 2 A

Size Voltage Dielectric Capacitance Capacitance Failure Terminations Packaging Special

(L” x W”) 4V = 4 X7R = C Code (In pF) Tolerance Rate T = Plated Ni and Sn 2 = 7” Reel Code

6.3V = 6 2 Sig. Digits + J = ± 5%* A = Not Z= FLEXITERM®** 4 = 13” Reel A = Std.

10V = Z Number of Zeros K = ±10% Applicable *Optional termination Product

16V = Y M = ± 20% Contact

25V = 3 **See FLEXITERM® Factory For

50V = 5 X7R section Multiples

*≤1μF only,

100V = 1 contact factory for

200V = 2 additional values

500V = 7

NOTE: Contact factory for availability of Termination and Tolerance Options for Specific Part Numbers.

Contact factory for non-specified capacitance values.

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order. 19

100819

– surface mount ceramic capacitor products –

X7R Dielectric

Specifications and Test Methods

Parameter/Test X7R Specification Limits Measuring Conditions

Operating Temperature Range -55ºC to +125ºC Temperature Cycle Chamber

Capacitance Within specified tolerance

≤ 10% for ≥ 50V DC rating≤ 12.5% for 25V DC rating Freq.: 1.0 kHz ± 10%

≤ 12.5% for 25V and 16V DC rating Voltage: 1.0Vrms ± .2V

Dissipation Factor

≤ 12.5% for ≤ 10V DC rating For Cap > 10µF, 0.5Vrm @ 120Hz

Contact Factory for DF by PN

10,000MΩ or 500MΩ - µF, Charge device with rated voltage for

Insulation Resistance

whichever is less 120 ± 5 secs @ room temp/humidity

Charge device with 250% of rated voltage for 1-5 seconds, w/

Dielectric Strength No breakdown or visual defects charge and discharge current limited to 50 mA (max)

Note: Charge device with 150% of rated voltage for 500V devices.

Appearance No defects

Capacitance

≤ ±12%

Resistance to Variation Deflection: 2mm

Flexure Dissipation Test Time: 30 seconds

Meets Initial Values (As Above)

Stresses Factor

Insulation

≥ Initial Value x 0.3

Resistance

≥ 95% of each terminal should be covered with Dip device in eutectic solder at 230 ± 5ºC

Solderability

fresh solder for 5.0 ± 0.5 seconds

Appearance No defects, <25% leaching of either end terminal

Capacitance

≤ ±7.5%

Variation

Dissipation Dip device in eutectic solder at 260ºC for 60 seconds. Store at

Resistance to Meets Initial Values (As Above)

Factor room temperature for 24 ± 2hours before measuring electrical

Solder Heat

Insulation properties.

Meets Initial Values (As Above)

Resistance

Dielectric

Meets Initial Values (As Above)

Strength

Appearance No visual defects Step 1: -55ºC ± 2º 30 ± 3 minutes

Capacitance

≤ ±7.5% Step 2: Room Temp ≤ 3 minutes

Variation

Dissipation

Meets Initial Values (As Above) Step 3: +125ºC ± 2º 30 ± 3 minutes

Thermal Shock Factor

Insulation

Meets Initial Values (As Above) Step 4: Room Temp ≤ 3 minutes

Resistance

Dielectric Repeat for 5 cycles and measure after 24 ± 2 hours at room

Meets Initial Values (As Above)

Strength temperature

Appearance No visual defects Pre-treatment: After mounting, perform heat treatment 150+0/-

Capacitance 10C for 2 hour, then stabilise for 24+/-2 hour at room temp,

≤ ±12.5% then measure.

Variation

Dissipation

≤ Initial Value x 2.0 (See Above) Charge device with ≥ rated voltage in test chamber set at

Factor

Insulation 125ºC ± 2ºC for 1000 hours (+48, -0).

Load Life ≥ Initial Value x 0.3 (See Above)

Resistance

Pre-treatment: After remove from test chamber, perform heat

treatment 150+0/-10C for 2 hour, then stabilise for 24+/-2 hour

Dielectric at room temp, then measure.

Meets Initial Values (As Above)

Strength

Contact KYOCERA AVX for datasheet of specific parts.

Appearance No visual defects Pre-treatment: After mounting, perform heat treatment 150+0/-

Capacitance 10C for 2 hour, then stabilise for 24+/-2 hour at room temp,

≤ ±12.5% then measure.

Variation

Dissipation

Load ≤ Initial Value x 2.0 (See Above) Store in a test chamber set at 85ºC ± 2ºC/ 85% ± 5% relative

Factor

Humidity humidity for 1000 hours (+48, -0) with rated voltage applied.

Insulation

≥ Initial Value x 0.3 (See Above)

Resistance

Pre-treatment: After remove from test chamber, perform heat

Dielectric treatment 150+0/-10C for 2 hour, then stabilise for 24+/-2 hour

Meets Initial Values (As Above)

Strength at room temp, then measure.

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

20 online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

051222

– surface mount ceramic capacitor products –

X7R Dielectric

Capacitance Range

PREFERRED SIZES ARE SHADED

SIZE 0101* 0201 0402 0603 0805 1206

Soldering Reflow Only Reflow Only Reflow/Wave Reflow/Wave Reflow/Wave Reflow/Wave

Paper/

Packaging All Paper All Paper All Paper Paper/Embossed Paper/Embossed

Embossed

mm 0.40 ± 0.02 0.60 ± 0.03 1.00 ± 0.10 1.60 ± 0.15 2.01 ± 0.20 3.20 ± 0.30

(L) Length

(in.) (0.016 ± 0.0008) (0.024 ± 0.001) (0.040 ± 0.004) (0.063 ± 0.006) (0.079 ± 0.008) (0.126 ± 0.012)

mm 0.20 ± 0.02 0.30 ± 0.03 0.50 ± 0.10 0.81 ± 0.15 1.25 ± 0.20 1.60 ± 0.30

W) Width

(in.) (0.008 ± 0.0008) (0.011 ± 0.001) (0.020 ± 0.004) (0.032 ± 0.006) (0.049 ± 0.008) (0.063 ± 0.012)

mm 0.10± 0.04 0.15 ± 0.05 0.25 ± 0.15 0.35 ± 0.15 0.50 ± 0.25 0.50 ± 0.25

(t) Terminal

(in.) (0.004 ± 0.0016) (0.006 ± 0.002) (0.010 ± 0.006) (0.014 ± 0.006) (0.020 ± 0.010) (0.020 ± 0.010)

WVDC 16 6.3 10 16 25 50 6.3 10 16 25 50 100 6.3 10 16 25 50 100 200 250 6.3 10 16 25 50 100 200 250 6.3 10 16 25 50 100 200 250 500

Cap 100 101 B A A A A A C C C C C C G G G G G G J J G G N N N

(pF) 150 151 B A A A A A C C C C C C G G G G G G J J G G G G G G N N N

220 221 B A A A A A C C C C C C G G G G G G J J E E E E E E E J J J J J J J N N P

330 331 B A A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

470 471 B A A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

680 681 B A A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

1000 102 B A A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

1500 152 A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

2200 222 A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

3300 332 A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

3900 392 A A A A

4700 472 A A A A C C C C C C G G G G G G J J J J J J J J J J J J J J J N N P

5600 562 A A A A

6800 682 A A A A C C C C C C G G G G G G J J J J J J J P P J J J J J J N N P

Cap 0.01 103 A A A A C C C C C C G G G G G G J J J J J J J P P J J J J J J N N P

(μF) 0.012 123

0.015 153 C C C C E G G G G G J J J J J J J J P P J J J J J J N N Q

0.018 183

0.022 223 A A A C C C C E G G G G G J J J J J J J J P P J J J J J J P P Q

0.027 273

0.033 333 C C C C E G G G G J J J J J J P P P J J J J J J Q Q Q

0.039 393

0.047 473 C C C C E G G G G J J J J J J P P P J J J J J J Q Q Q

0.068 683 C C C C E G G G G J J J J J J P P J J J J J P Q Q

0.082 823

0.1 104 A C C C C E G G G G J J J J J J P P J J J J J P Q Q

0.12 124

0.15 154 G G G J J N N N N P K K K K K Q Q Q

0.22 224 C C C C G G J J J N N N N P K K K K K Q Q Q

0.33 334 J J J J J P P P P P K K K K N Q

0.47 474 C C J J J J J P P P P P M M M M X X

0.68 684 J J J P P P M M M M X X

1.0 105 C J J J J K P P P P M M M M X X

2.2 225 J J K P P P P M M M X X X

4.7 475 K P P P X X X X Z

10 106 P P P X X X X

22 226 X X

47 476

100 107

WVDC 16 6.3 10 16 25 50 6.3 10 16 25 50 100 6.3 10 16 25 50 100 200 250 6.3 10 16 25 50 100 200 250 6.3 10 16 25 50 100 200 250 500

SIZE 0101* 0201 0402 0603 0805 1206

Letter A B C E G J K M N P Q X Y Z

Max. 0.33 0.22 0.56 0.71 0.90 0.94 1.02 1.27 1.40 1.52 1.78 2.29 2.54 2.79

Thickness (0.013) (0.009) (0.022) (0.028) (0.035) (0.037) (0.040) (0.050) (0.055) (0.060) (0.070) (0.090) (0.100) (0.110)

PAPER EMBOSSED

NOTE: Contact factory for non-specified capacitance values

*EIA 01005

**Contact Factory for Specifications

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order. 21

022222

– surface mount ceramic capacitor products –

X7R Dielectric

Capacitance Range

PREFERRED SIZES ARE SHADED

SIZE 1210 1812 1825 2220 2225

Soldering Reflow Only Reflow Only Reflow Only Reflow Only Reflow Only

Packaging Paper/Embossed All Embossed All Embossed All Embossed All Embossed

mm 3.30 ± 0.4 4.50 ± 0.40 4.50 ± 0.40 5.70 ± 0.50 5.70 ± 0.40

(L) Length

(in.) (0.130± 0.016) (0.177 ± 0.016) (0.177 ± 0.016) (0.224 ± 0.020) (0.224 ± 0.016)

mm 2.50 ± 0.30 3.20 ± 0.40 6.40 ± 0.40 5.00 ± 0.40 6.30 ± 0.40

W) Width

(in.) (0.098 ± 0.012) (0.126 ± 0.016) (0.252 ± 0.016) (0.197 ± 0.016) (0.248 ± 0.016)

mm 0.50 ± 0.25 0.61 ± 0.36 0.61 ± 0.36 0.64 ± 0.39 0.64 ± 0.39

(t) Terminal

(in.) (0.020 ± 0.010) (0.024 ± 0.014) (0.024 ± 0.014) (0.025 ± 0.015) (0.025 ± 0.015)

WVDC 10 16 25 50 100 200 500 16 25 50 100 200 500 50 100 200 25 50 100 200 500 50 100 200

Cap 100 101

(pF) 150 151

220 221 K K K M

330 331 K K K M N N N N

470 471 K K K M N N N N

680 681 K K K M N N N N

1000 102 K K K K K K M N N N N N N X X X X X X X X X X

1500 152 K K K K K K M N N N N N N X X X X X X X X X X

2200 222 K K K K K K M N N N N N N X X X X X X X X X X

3300 332 K K K K K K P N N N N N N X X X X X X X X X X

4700 472 K K K K K K P N N N N N P X X X X X X X X X X

6800 682 K K K K K K P N N N N N P X X X X X X X X X X

Cap 0.01 103 K K K K K K P N N N N N P X X X X X X X X X X

(μF) 0.015 153 K K K K K K P N N N N N P X X X X X X X X X X

0.022 223 K K K K K P Q N N N N N P X X X X X X X X X X

0.033 333 K K K K K P X N N N N N X X X X X X X X X X X

0.047 473 K K K K K P X N N N N P X X X X X X X X X X X

0.068 683 K K K K K P X N N N N P X X X X X X X X X X X

0.1 104 K K K K K P X N N N P P X X X X X X X X X X X

0.15 154 K K K M P Z Z N N N P P Z X X X X X X X X X X

0.22 224 K K K M P Z N N N P Q Z X X X X X X X X X X

0.33 334 K K K M Q Z N N N P X Z X X X X X X X X X X

0.47 474 M M M P Q Z N N N Q X Z X X X X X X X X X X

0.68 684 M M P X X Z Q Q Q Q Z X X X X X X Z X X X

1.0 105 P P P X Z Q Q Q X Z X X X X X X 7 X X X

1.5 155 N N Z Z Z Z Z Z X X Z X X Z X X Z

2.2 225 X X Z Z Z Z Z Z X X Z X X Z X X Z

3.3 335 X X Z Z Z Z Z Z X X X Z X X

4.7 475 Z Z Z Z Z Z Z Z X X Z Z X X

10 106 Z Z Z Z Z Z Z Z Z Z Z Z Z

22 226 Z Z Z Z

47 476 Z

100 107

WVDC 10 16 25 50 100 200 500 16 25 50 100 200 500 50 100 200 25 50 100 200 500 50 100 200

SIZE 1210 1812 1825 2220 2225

Letter A B C E G J K M N P Q X Y Z 7

Max. 0.33 0.22 0.56 0.71 0.90 0.94 1.02 1.27 1.40 1.52 1.78 2.29 2.54 2.79 3.30

Thickness (0.013) (0.009) (0.022) (0.028) (0.035) (0.037) (0.040) (0.050) (0.055) (0.060) (0.070) (0.090) (0.100) (0.110) (0.130)

PAPER EMBOSSED

NOTE: Contact factory for non-specified capacitance values

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

22 online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

080221

– surface mount ceramic capacitor products –

You might also like

- X7R Dielectric: General SpecificationsDocument4 pagesX7R Dielectric: General SpecificationsnkswarunNo ratings yet

- KGM X7RDocument4 pagesKGM X7RerikaNo ratings yet

- Specification Sheet for Samsung Multi-layer Ceramic CapacitorDocument3 pagesSpecification Sheet for Samsung Multi-layer Ceramic Capacitorelias rangelNo ratings yet

- 7pg17 XR Catalogue SheetDocument16 pages7pg17 XR Catalogue SheetkarthikNo ratings yet

- Vl-1 W Series: Lwunregulated SingleDocument4 pagesVl-1 W Series: Lwunregulated SingleMr.K chNo ratings yet

- Cement Coated Wirewound Resistors: Electrical DataDocument2 pagesCement Coated Wirewound Resistors: Electrical DataTanay ShahNo ratings yet

- T491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument24 pagesT491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumSebastian ChaileNo ratings yet

- Multitek Synchronising Check Relay m200Document2 pagesMultitek Synchronising Check Relay m200Gomgom SiagianNo ratings yet

- X5R Dielectric: General SpecificationsDocument6 pagesX5R Dielectric: General SpecificationsDinesh ThevanNo ratings yet

- PDC 500 Encapsulated Convection Cooled DC DCDocument1 pagePDC 500 Encapsulated Convection Cooled DC DCKislan MislaNo ratings yet

- D121_24V_TO_12V_10A_120WDocument3 pagesD121_24V_TO_12V_10A_120WrujanacNo ratings yet

- R.46 X2 CLASS METALLIZED POLYPROPYLENE FILM CAPACITOR TECHNICAL DATADocument2 pagesR.46 X2 CLASS METALLIZED POLYPROPYLENE FILM CAPACITOR TECHNICAL DATAวรพงษ์ กอชัชวาลNo ratings yet

- DC-DC Converter 10 Watt: 10T6AW4 - 1.5 SeriesDocument5 pagesDC-DC Converter 10 Watt: 10T6AW4 - 1.5 SeriesSero StivNo ratings yet

- SPECIFICATION SHEET FOR SAMSUNG MULTI-LAYER CERAMIC CAPACITORDocument3 pagesSPECIFICATION SHEET FOR SAMSUNG MULTI-LAYER CERAMIC CAPACITORcometNo ratings yet

- Tantalum Surface Mount CapacitorsDocument24 pagesTantalum Surface Mount CapacitorsgausscanaveaNo ratings yet

- Insulation Resistance Value Insulation Level: Ohmmeter. This Is How The Test Works: DC Voltage of 500Document4 pagesInsulation Resistance Value Insulation Level: Ohmmeter. This Is How The Test Works: DC Voltage of 500Anonymous XXyhgBhDy3100% (1)

- Reverse Power: Technical SpecificationDocument2 pagesReverse Power: Technical SpecificationOMi MeHarNo ratings yet

- Manual 3300Document6 pagesManual 3300stafarob2022No ratings yet

- HOHIHT03E MSR R500 - UT33D - Digital Multimeter Manual US A4 - WEBDocument20 pagesHOHIHT03E MSR R500 - UT33D - Digital Multimeter Manual US A4 - WEBproust73No ratings yet

- SMD Aluminium Electrolytic Capacitors: FeaturesDocument6 pagesSMD Aluminium Electrolytic Capacitors: FeaturesManny DionedaNo ratings yet

- Operation Manual: 1. SummarizeDocument2 pagesOperation Manual: 1. SummarizeRizaldyNo ratings yet

- Cl05a104ka5nnnc PDFDocument2 pagesCl05a104ka5nnnc PDFdusk dawnNo ratings yet

- Digital Multimeter User ManualDocument10 pagesDigital Multimeter User ManualGyarmati László100% (1)

- 2S7B 3upDocument5 pages2S7B 3upJlavieraNo ratings yet

- Packaging Code: Only Reflow SolderingDocument24 pagesPackaging Code: Only Reflow SolderingLuís GuerreiroNo ratings yet

- Samsung 0805 1uF 50V X7R MLCC SpecificationDocument2 pagesSamsung 0805 1uF 50V X7R MLCC Specificationelias rangelNo ratings yet

- Aluminum Single-Point Load Cell Aluminum Single-Point Load CellDocument3 pagesAluminum Single-Point Load Cell Aluminum Single-Point Load CellMakhis RifaiNo ratings yet

- Datasheet_AVXDocument6 pagesDatasheet_AVXDavid HernándezNo ratings yet

- Monitoring RelayDocument20 pagesMonitoring RelayarmskoteNo ratings yet

- Componete ElectronicoDocument5 pagesComponete ElectronicoStuxnetNo ratings yet

- Voltage Transducer DVL 1000 V 1000 VDocument8 pagesVoltage Transducer DVL 1000 V 1000 Vnaveen kumarNo ratings yet

- Safety 1.1. Safety InformationDocument8 pagesSafety 1.1. Safety InformationdthibodeNo ratings yet

- Specification: CL 21 F 223 Z B A N N N CDocument3 pagesSpecification: CL 21 F 223 Z B A N N N Csam2976No ratings yet

- Resistor Kit: CFR 1/4 W 5% (2.5 X 6.8)Document9 pagesResistor Kit: CFR 1/4 W 5% (2.5 X 6.8)saif habibNo ratings yet

- Paladin Transducers (Class 0.5)Document11 pagesPaladin Transducers (Class 0.5)heri fauziNo ratings yet

- 250 VAC, +85 °C: - RC Unit, Class X1, Metallized Paper With Integrated Resistor - 0.022 - 0.1 F, 100Document2 pages250 VAC, +85 °C: - RC Unit, Class X1, Metallized Paper With Integrated Resistor - 0.022 - 0.1 F, 100alonso leonNo ratings yet

- Voltamp Transformers Limited: SR. NODocument2 pagesVoltamp Transformers Limited: SR. NOrohitshetyeNo ratings yet

- Pib1025 Esd1000 1Document5 pagesPib1025 Esd1000 1soliscristopher1310No ratings yet

- Res Non InductivesDocument3 pagesRes Non InductiveszaxmavNo ratings yet

- VJ X8R Surface Mount Multilayer Ceramic Chip Capacitors For High Temperature Applications Up To 150 °CDocument6 pagesVJ X8R Surface Mount Multilayer Ceramic Chip Capacitors For High Temperature Applications Up To 150 °Critchie ritchieNo ratings yet

- Analogue Meters With Moving - Iron Movement: Data SheetDocument4 pagesAnalogue Meters With Moving - Iron Movement: Data SheetSreegith ChelattNo ratings yet

- ESD Protection Diode for SRAM ModulesDocument3 pagesESD Protection Diode for SRAM Modulesshijith. ppNo ratings yet

- NIC Components NRE-HL SeriesDocument8 pagesNIC Components NRE-HL SeriesNICCompNo ratings yet

- DSA00116625Document7 pagesDSA00116625Ricardo Campos LandaetaNo ratings yet

- Rotative Position Transducer Features and SpecificationsDocument2 pagesRotative Position Transducer Features and SpecificationsSathish J EceNo ratings yet

- Carbon Composition Resistor: Rating and DimensionsDocument5 pagesCarbon Composition Resistor: Rating and DimensionsEbuka DanielNo ratings yet

- m830b 600v Hys004369Document8 pagesm830b 600v Hys004369ursuletzu72No ratings yet

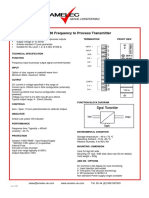

- AHM 780 Frequency To Process Transmitter: Termination Front ViewDocument2 pagesAHM 780 Frequency To Process Transmitter: Termination Front Viewهيثم أزرقةNo ratings yet

- Aluminum Electrolytic Capacitors: SpecificationsDocument1 pageAluminum Electrolytic Capacitors: SpecificationsMichael KovalNo ratings yet

- NIC Components NMC X7R SeriesDocument3 pagesNIC Components NMC X7R SeriesNICCompNo ratings yet

- SMDDocument6 pagesSMDJose SCNo ratings yet

- Datasheet s1 Pressure TransducerDocument6 pagesDatasheet s1 Pressure TransducerAlexander BerbinNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- Packaging Code: Only Reflow SolderingDocument24 pagesPackaging Code: Only Reflow SolderingAndri AwanNo ratings yet

- Model Number Structure: Relays With Forcibly Guided ContactsDocument22 pagesModel Number Structure: Relays With Forcibly Guided Contactselkin mezaNo ratings yet

- dubilier-resistor-networks-datasheetDocument2 pagesdubilier-resistor-networks-datasheetGhalielectrosoft GesNo ratings yet

- High Voltage CapacitorsDocument6 pagesHigh Voltage CapacitorsMahmoud Digital-DigitalNo ratings yet

- MP725 Surface Mount Power Film ResistorsDocument1 pageMP725 Surface Mount Power Film ResistorsAroon BhagwandinNo ratings yet

- General Information: Varistor Plus Single Layer Technology Varistor Glossary of Terms and DefinitionsDocument3 pagesGeneral Information: Varistor Plus Single Layer Technology Varistor Glossary of Terms and DefinitionsIgor PNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument3 pagesPart Number: Status: Overview: Description:: Documentsakshay rajNo ratings yet

- Series: Multilayer Ceramic Chip CapacitorsDocument57 pagesSeries: Multilayer Ceramic Chip Capacitorsakshay rajNo ratings yet

- Data Sheet: Surface-Mount Ceramic Multilayer CapacitorsDocument20 pagesData Sheet: Surface-Mount Ceramic Multilayer CapacitorsMae MegumiNo ratings yet

- Chip Multilayer Ceramic Capacitors Specifications and Test MethodsDocument26 pagesChip Multilayer Ceramic Capacitors Specifications and Test Methodsakshay rajNo ratings yet

- SL32C thru SL310C Surface Mount Schottky Rectifier Spec SheetDocument3 pagesSL32C thru SL310C Surface Mount Schottky Rectifier Spec Sheetakshay rajNo ratings yet

- Murata Products For AutomotiveDocument48 pagesMurata Products For Automotiveakshay rajNo ratings yet

- D/CRCW E3: VishayDocument10 pagesD/CRCW E3: VishayBenyamin Farzaneh AghajarieNo ratings yet

- Asco Series 300 Ats Operators ManualDocument20 pagesAsco Series 300 Ats Operators ManualGera Ortiz Martinez100% (1)

- Presentation On BEAMEX MC5 CalibratorDocument29 pagesPresentation On BEAMEX MC5 Calibratoranu prakashNo ratings yet

- Wong Uma Ure 01-01-03 TechnicalDocument5 pagesWong Uma Ure 01-01-03 TechnicalinquillayNo ratings yet

- 2022 Bss Physics Paper II Msce MockDocument6 pages2022 Bss Physics Paper II Msce MockMalack Chagwa100% (1)

- Mechanical Characteristics of Overhead LinesDocument13 pagesMechanical Characteristics of Overhead LinesMizanur RahmanNo ratings yet

- Separating Suspensions and ColloidsDocument11 pagesSeparating Suspensions and ColloidsGenna CuencaNo ratings yet

- R4815N1 Rectifier: FeaturesDocument2 pagesR4815N1 Rectifier: FeaturesDanny AvilésNo ratings yet

- 02 Introduction To Sample PreparationDocument53 pages02 Introduction To Sample PreparationAri YusliandiNo ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Principles of Helicopter Aerodynamics Chapter 4Document37 pagesPrinciples of Helicopter Aerodynamics Chapter 4Kim MittendorfNo ratings yet

- Motovario MaintenanceDocument72 pagesMotovario Maintenancearachman297988No ratings yet

- Coiled TubingDocument87 pagesCoiled TubingBoedi Syafiq100% (1)

- Urdaneta City University College of Engineering and ArchitectureDocument10 pagesUrdaneta City University College of Engineering and Architecturezed cozNo ratings yet

- BERE1013 Lab 2 - Hooke's LawDocument12 pagesBERE1013 Lab 2 - Hooke's LawAina BalqisNo ratings yet

- Los Tres ModelosDocument7 pagesLos Tres ModelosRicardo CortezNo ratings yet

- OPSS 791 Nov2014Document6 pagesOPSS 791 Nov2014Muhammad UmarNo ratings yet

- Four conic sections explainedDocument20 pagesFour conic sections explainedWendell ReyesNo ratings yet

- Sharif International Offers Solar Grid Hybrid System for Jinnah ParkDocument2 pagesSharif International Offers Solar Grid Hybrid System for Jinnah ParkMuhammad SajidNo ratings yet

- Karta - FTL33Document36 pagesKarta - FTL33Adam MazurekNo ratings yet

- Temporal Stability of Inviscid Incompressible Flows: SabhileshDocument34 pagesTemporal Stability of Inviscid Incompressible Flows: SabhileshSabhilesh SinghNo ratings yet

- Bil Jax 36XTDocument50 pagesBil Jax 36XTDuynamndk100% (1)

- Lab 02Document4 pagesLab 02CookiesNo ratings yet

- 3 - Formation Pressures For Well DesignDocument20 pages3 - Formation Pressures For Well DesignSlim.BNo ratings yet

- NMAT Physics Practice Questions Set 3Document10 pagesNMAT Physics Practice Questions Set 3Nurshayma JalilNo ratings yet

- Sedimentation: Engr. Nadeem Karim BhattiDocument23 pagesSedimentation: Engr. Nadeem Karim BhattiEngr Sarang Khan100% (1)

- JC2 Math Test Solutions Minimum Cone VolumeDocument13 pagesJC2 Math Test Solutions Minimum Cone VolumeTimothy HandokoNo ratings yet

- Reinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDocument18 pagesReinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDivy JainNo ratings yet

- Nexion 300 IcpmsDocument9 pagesNexion 300 IcpmsAhmad HamdounNo ratings yet

- C0636A×1000 Bench LatheDocument2 pagesC0636A×1000 Bench LatheAlireza KazemiNo ratings yet