Professional Documents

Culture Documents

DamageWeb Software Brochure

Uploaded by

Camilo NiñoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DamageWeb Software Brochure

Uploaded by

Camilo NiñoCopyright:

Available Formats

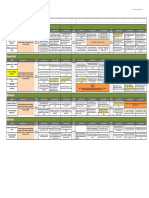

DamageWeb Software

PREDICT FUTURE OUTCOMES

SOFTWARE EXPERTISE

Proactively understand the maze of damage mechanisms found in your facility and select the CUSTOM DAMAGE MECHANISM DRAWINGS

best inspection method for each type of damage to reduce costly fixed equipment failures Improve communication and understanding throughout your organization with customized PFDs by process

and increase operational safety. unit or process. E²G will help import your custom PFDs into DamageWeb to streamline inspections and

E²G’s proprietary software is built

damage mechanism identification.

by industry experts and used by our DamageWeb, a cloud-based tool, is the only software created to specifically help inspection

consulting engineers on fitness-for- and maintenance personnel streamline the process of pinpointing damage mechanisms and • Organize drawings in folders by unit within a plant

service (FFS), damage mechanism identifying potential risk areas. With a technical basis in API RP 571 and WRC 489, • Identify different damage mechanisms using the legend or labels

reviews, RBI assessments, and other • Provide key plant personnel (inspection, operations, and reliability) with consistent damage mechanism

DamageWeb software is designed to help you quickly classify and understand the potential

asset lifecycle management projects. information

damage mechanisms. • Access corrosion rate and cracking susceptibility calculators for applicable damage mechanisms

E²G software is updated frequently

to meet the latest API and ASME

codes and standards. DAMAGE MECHANISMS SOLVER

Quickly identify and view critical factors affecting the applicable damage mechanisms in your process unit

with the built-in solver. Investigate each active or potential damage mechanism with the interactive sort and

380+ Develop maintenance

and inspection

Identify areas of

vulnerability

Extend the life of

equipment

Maximize damage

tolerance in process

filter functionality.

• Process unit

strategies units • Material of construction

years of combined industry experience

• Operating temperature

• Damage source or morphology

Pioneered development of • Diagrams & photos

PROCESS FLOW DIAGRAMS

FFS & RBI Easily access process flow diagrams (PFDs) to see where damage is likely to occur and cross-reference CALCULATION TOOLS

with API 571 for additional insight.

Accurately analyze corrosion rates for multiple materials using DamageWeb’s real-time display, interactive

Primary authors on sliding controls, and enhanced graphics.

• Read the code! All active damage mechanisms are hyperlinked to API 571

WRC 528 & 562 • Visualize and understand damage mechanisms with color-coded corrosion loops

• Access corrosion loops aligned to API 571 standard PFDs • High-Temperature Hydrogen Attack (HTHA)

• Sulfidation

Lead investigators on • H2/H2S corrosion

• Oxidation corrosion rates

API 579 & 571 • API 581 compatible susceptibility calculators (amine, sulfide stress, caustic cracking)

To learn more about the benefits of DamageWeb,

INDUSTRIES

Ammonia/Fertilizer

HERE’S HOW TO GET STARTED

SCHEDULE A DEMO

CL ICK H E R E

with an E²G Damage expert

Biofuels & Chemical &

Renewables Specialty Chemicals

© 2022 E²G | The Equity Engineering Group, Inc. ANSWERS FOR TODAY. INSIGHTS FOR TOMORROW.

Oil & Gas Petrochemicals

216.283.9519 // Software@E2G.com // www.E2G.com

You might also like

- Pigging ProcedureDocument11 pagesPigging ProcedureEndika Alfan100% (9)

- Workshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Document33 pagesWorkshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Ilie Viorel60% (5)

- Software Engineering 2Document4 pagesSoftware Engineering 2Michalcova Realisan JezzaNo ratings yet

- Invensys Foxboro IA Series Software ManualDocument18 pagesInvensys Foxboro IA Series Software ManualTeddy PahlewiNo ratings yet

- Frac ProDocument2 pagesFrac ProAbdullah Ishaq0% (1)

- Leica Geosystems: Release NotesDocument13 pagesLeica Geosystems: Release NotesCamilo NiñoNo ratings yet

- Device Security Assessment From Ge Digital DatasheetDocument4 pagesDevice Security Assessment From Ge Digital DatasheetSanchita RahadeNo ratings yet

- Data Sheet - Tenable - SC Continuous ViewDocument2 pagesData Sheet - Tenable - SC Continuous ViewCrystal PruebaNo ratings yet

- Tenable Io WasDocument2 pagesTenable Io WasJohn DoeNo ratings yet

- Questa VisualizerDocument2 pagesQuesta VisualizerVictor David SanchezNo ratings yet

- DPA Workstation Product BriefDocument2 pagesDPA Workstation Product Brieftest catNo ratings yet

- Cast@Ibm: Global Coe: Improved Quality and Faster Delivery With Accurate MeasurementDocument23 pagesCast@Ibm: Global Coe: Improved Quality and Faster Delivery With Accurate MeasurementGopu GaneshNo ratings yet

- ScanExpress OverviewDocument3 pagesScanExpress OverviewThein Htoon lwinNo ratings yet

- Engineering The Architecture of Distributed Control Systems: January 2002Document25 pagesEngineering The Architecture of Distributed Control Systems: January 2002shivabhaNo ratings yet

- Deep Dive SOAR 2Document22 pagesDeep Dive SOAR 2jesusmaitaNo ratings yet

- Release Fast. Respond FasterDocument2 pagesRelease Fast. Respond FasterramanujankNo ratings yet

- IVI 1982 en Patch For Endpoint ManagerDocument5 pagesIVI 1982 en Patch For Endpoint Managergtelictnt103No ratings yet

- Carestreamndtindustrexsoftware 5417600500202211 LetterenloresDocument2 pagesCarestreamndtindustrexsoftware 5417600500202211 LetterenloresMuthu PalanisamyNo ratings yet

- Maintain Integrity and Increase Reliability: Safely Ensure More Up-Time Productivity by Increasing Asset ReliabilityDocument2 pagesMaintain Integrity and Increase Reliability: Safely Ensure More Up-Time Productivity by Increasing Asset ReliabilityM ANo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Modern Vulnerability Management Key Benefits: Eliminate Blind SpotsDocument2 pagesModern Vulnerability Management Key Benefits: Eliminate Blind SpotsSantiago HuilcamaiguaNo ratings yet

- Retina Network Security Scanner Understanding CHAM - Common Hacking Attack MethodsDocument6 pagesRetina Network Security Scanner Understanding CHAM - Common Hacking Attack MethodsgynxNo ratings yet

- Websrvices Testing Issta04Document11 pagesWebsrvices Testing Issta04Uday KumarNo ratings yet

- Fundamentals of Continuous Integration: JenkinsDocument7 pagesFundamentals of Continuous Integration: JenkinsJavier MoralesNo ratings yet

- Dics b10123 00 7600 SMSCP Onepager Jobprofile 1 144Document2 pagesDics b10123 00 7600 SMSCP Onepager Jobprofile 1 144saeedNo ratings yet

- Outpost24's Vulnerability Management Solutions: Define Your Program Track ProgressDocument2 pagesOutpost24's Vulnerability Management Solutions: Define Your Program Track ProgressMarco Antonio GiaroneNo ratings yet

- ABS Groups Fixed Equipment Inspection ProgramsDocument1 pageABS Groups Fixed Equipment Inspection Programsghostforever0No ratings yet

- Software Engineering Index CardsDocument9 pagesSoftware Engineering Index Cardsghada alshabibNo ratings yet

- d0759xxxx XXXXXXXX 0enDocument2 pagesd0759xxxx XXXXXXXX 0enbgtNo ratings yet

- Attaka, On Demand Vulnerability AssessmentDocument6 pagesAttaka, On Demand Vulnerability AssessmentFederico SeinedinNo ratings yet

- Datasheet Apm 1Document2 pagesDatasheet Apm 1Muluken AlemuNo ratings yet

- TechTrend Journey To DevSecOpsDocument12 pagesTechTrend Journey To DevSecOpsKupusha CheteNo ratings yet

- FaultMaintananceFIN Correct2 PDFDocument5 pagesFaultMaintananceFIN Correct2 PDFNeeraj BhartiNo ratings yet

- Reliability Focused Maintenance: A Model To Facilitate RCM ConceptsDocument4 pagesReliability Focused Maintenance: A Model To Facilitate RCM ConceptsamiraautoNo ratings yet

- Citect SCADA Support-InfographicDocument1 pageCitect SCADA Support-Infographicatorresh090675No ratings yet

- Defineview Consulting: Expert Training, Verification Methodology AdvisoryDocument7 pagesDefineview Consulting: Expert Training, Verification Methodology AdvisoryRavi DixitNo ratings yet

- Naukri NeerajKumarJha (3y 0m)Document3 pagesNaukri NeerajKumarJha (3y 0m)Lal krishnanNo ratings yet

- CyberAlphaSecurity Mobile - Application PenTest Datasheet PDFDocument4 pagesCyberAlphaSecurity Mobile - Application PenTest Datasheet PDFTama OlanNo ratings yet

- The Power of Plant ManagerDocument2 pagesThe Power of Plant Manageringmetal9104100% (1)

- SE Unit-1Document84 pagesSE Unit-1Shiv PatelNo ratings yet

- 5ways: Fluid S YstemsDocument4 pages5ways: Fluid S YstemsAmar SheteNo ratings yet

- CH - 5 TestingDocument122 pagesCH - 5 Testingrautanushka13No ratings yet

- Core Impact Pro Data SheetDocument2 pagesCore Impact Pro Data Sheetmatlab engineerNo ratings yet

- SIPROTECDigitalTwin OmicronPresentationDocument56 pagesSIPROTECDigitalTwin OmicronPresentationKlong WarakronNo ratings yet

- DDocument6 pagesDYogastoNo ratings yet

- Rapid7 InsightAppSec Product BriefDocument2 pagesRapid7 InsightAppSec Product BriefJaimeNo ratings yet

- Reliabilityedge V12i1Document32 pagesReliabilityedge V12i1NdomaduNo ratings yet

- Digital Imaging Systems Process AnalysisDocument2 pagesDigital Imaging Systems Process AnalysisfimansurNo ratings yet

- GAMP5 Testing TypesDocument1 pageGAMP5 Testing Typesrnj1983No ratings yet

- Antaris II FT-NIR ProspektusDocument8 pagesAntaris II FT-NIR ProspektusMihaly JNo ratings yet

- Testing FrameworkDocument4 pagesTesting Frameworkbojam84386No ratings yet

- 1RE PDS AssetWise Strategy Development LTR EN LR 2015Document2 pages1RE PDS AssetWise Strategy Development LTR EN LR 2015Toby KuntaNo ratings yet

- Key Features BriefDocument2 pagesKey Features Briefhari_avar3793No ratings yet

- 7.0 PredictionDocument24 pages7.0 PredictionKushal DubeyNo ratings yet

- Brochure Brainwave en 2021 LRDocument3 pagesBrochure Brainwave en 2021 LRPavitra ShahNo ratings yet

- Making The Best of Application Security Solutions: Amit Ashbel Product EvangelistDocument47 pagesMaking The Best of Application Security Solutions: Amit Ashbel Product Evangelistcristian080989No ratings yet

- ASUG82900 - Securing SAP Software Systems From CyberattacksDocument38 pagesASUG82900 - Securing SAP Software Systems From CyberattacksFahri BaturNo ratings yet

- Chapter 5 - Software ArchitectureDocument11 pagesChapter 5 - Software ArchitectureFloyd LawtonNo ratings yet

- Verification vs. Validation: Unit 7Document23 pagesVerification vs. Validation: Unit 7Ms. Usha Kirana P, AL MACS NITKNo ratings yet

- Softeare EngDocument19 pagesSofteare EngSasuke UchihaNo ratings yet

- 2019 Summer Model Answer Paper (Msbte Study Resources)Document34 pages2019 Summer Model Answer Paper (Msbte Study Resources)arvi.sardarNo ratings yet

- Manage Architecture and Technical Debt at Agile SpeedDocument2 pagesManage Architecture and Technical Debt at Agile SpeedMuthusankaranarayanan ValliammalNo ratings yet

- Digitalizing The Chemical Industry of Tomorrow TodayDocument2 pagesDigitalizing The Chemical Industry of Tomorrow TodayCamilo NiñoNo ratings yet

- 2019 Master Schedule Inspection SummitDocument3 pages2019 Master Schedule Inspection SummitCamilo NiñoNo ratings yet

- Api Certification Exam Dates and Deadlines - 2014 Exam Window Program Schedule Application DeadlineDocument1 pageApi Certification Exam Dates and Deadlines - 2014 Exam Window Program Schedule Application DeadlineCamilo NiñoNo ratings yet

- Ccie DC Full Scale Labs PDFDocument185 pagesCcie DC Full Scale Labs PDFnaveedrana100% (2)

- Noli and El FiliDocument2 pagesNoli and El FiliGeramei Vallarta TejadaNo ratings yet

- IPS e El 110Document105 pagesIPS e El 110alinaghibNo ratings yet

- General Office Administration Level 1 (CVQ) PDFDocument129 pagesGeneral Office Administration Level 1 (CVQ) PDFddmarshall2838No ratings yet

- Space Policy SWAT Future Space Strategies 13 UnclassifiedDocument189 pagesSpace Policy SWAT Future Space Strategies 13 UnclassifiedSpaceStrategosNo ratings yet

- Fixed Asset Examples Excel TemplateDocument6 pagesFixed Asset Examples Excel TemplateHR BabitaNo ratings yet

- 1620 Ultra High Speed: Continuous Ink Jet PrinterDocument8 pages1620 Ultra High Speed: Continuous Ink Jet PrinterRudiNo ratings yet

- Msds 2342Document5 pagesMsds 2342Gabo TellezNo ratings yet

- User Defined FunctionsDocument67 pagesUser Defined Functionsmohamed aliNo ratings yet

- Pyneng Readthedocs Io en LatestDocument702 pagesPyneng Readthedocs Io en LatestNgọc Duy VõNo ratings yet

- (R) Nelson JB (2017) - Mindful Eating - The Art of Presence While You EatDocument4 pages(R) Nelson JB (2017) - Mindful Eating - The Art of Presence While You EatAnonymous CuPAgQQNo ratings yet

- Grammar Translation MethodDocument22 pagesGrammar Translation MethodCeyinNo ratings yet

- Global Business CH 2 2-MergedDocument58 pagesGlobal Business CH 2 2-MergedJace gunnerNo ratings yet

- Electronics by Gibilisco QandADocument22 pagesElectronics by Gibilisco QandAMary Rose AtendidoNo ratings yet

- Physical Storage: Data ONTAP 8.0 7-Mode AdministrationDocument71 pagesPhysical Storage: Data ONTAP 8.0 7-Mode AdministrationkurtenweiserNo ratings yet

- Karta Ronjenje en 163341Document2 pagesKarta Ronjenje en 163341mulalic_dNo ratings yet

- Civic Ass JolaxDocument3 pagesCivic Ass JolaxEyob TeferaNo ratings yet

- 1270A544-032 Console v3.1Document304 pages1270A544-032 Console v3.1badr eddine100% (1)

- History of Operating SystemDocument16 pagesHistory of Operating SystemBryan John BerzabalNo ratings yet

- CSS 11 - Q1 DIAGNOSTIC TEST - No AnswerDocument4 pagesCSS 11 - Q1 DIAGNOSTIC TEST - No AnswerJanelkris PlazaNo ratings yet

- UK Patient Metronidazole Vaginal Gel Medication LeafletDocument4 pagesUK Patient Metronidazole Vaginal Gel Medication Leafletmarisa apriliaNo ratings yet

- Statistics II Week 6 HomeworkDocument3 pagesStatistics II Week 6 Homeworkteacher.theacestudNo ratings yet

- Product Sheet: AutoclaveDocument2 pagesProduct Sheet: AutoclaveISHA ARORANo ratings yet

- Structure Fires Caused by Hot Work: Marty AhrensDocument14 pagesStructure Fires Caused by Hot Work: Marty AhrensBurgosg ValeryNo ratings yet

- Easy Reeding!-August 2009Document8 pagesEasy Reeding!-August 2009yara20No ratings yet

- Forces and MotionDocument22 pagesForces and MotiongamahimeNo ratings yet