Professional Documents

Culture Documents

56 - Isijint 2015 691

Uploaded by

H. LEOCADIOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

56 - Isijint 2015 691

Uploaded by

H. LEOCADIOCopyright:

Available Formats

ISIJ International,

ISIJ International, Vol. 56 (2016), No. 7 Vol. 56 (2016), No. 7, pp. 1210–1218

Experimental Investigation of High-temperature Steel Plate

Cooled by Multiple Nozzle Arrays

Qian XIE, Bingxing WANG,* Yu WANG, Zhaodong WANG and Guodong WANG

The State Key Laboratory Rolling and Automation (RAL), Northeastern University, Shenyang, 110819 China.

(Received on December 7, 2015; accepted on March 24, 2016; J-STAGE Advance published date: May

26, 2016)

Thermo-mechanical controlled process (TMCP) technology has been widely used to improve controlled

cooling technology during the hot rolled plate manufacturing process. Multiple impinging jets are the main

cooling form used in plate cooling process of the steel mills. In this work, we mainly focused on the sur-

face flow field and heat transfer of high-temperature plate (700°C) cooled by nine-nozzle arrays with dif-

ferent Reynolds numbers. The distribution of turbulent kinetic energy and water velocity vector were

numerically studied. By analyzing the simulation results and measuring temperature data, the maximum

heat flux, the corresponding surface temperature and time at each measurement point were found to be

dependent on the distance from the impinging point and the jet velocity. No obvious maximum heat flux

elevation for the locations between jets was observed, where the wetting speed was also slow with Reyn-

olds numbers lower than 8 278. These results are valuable in interpreting the heat transfer mechanism

under jet arrays and predicting the cooling rate, and forecasting the microstructure of the steel product.

KEY WORDS: multiple impinging jets; nozzle arrays; heat transfer; flow structure; steel plate cooling.

the flow patterns and the heat transfer distribution during

1. Introduction

the cooling process by impinging on the stainless cylinder

The hot rolled steel plate has been extensively employed specimen of 900°C with different jet velocities, and their

in the field of construction engineering, machinery manu- conclusions about heat flux distribution and surface flow

facturing, container manufacturing and shipbuilding. During field were valuable. Meanwhile, their results also revealed

the plate manufacturing process, the thermo-mechanical that the effect of jet velocity on heat transfer at stagnation

controlled process (TMCP) technology can effectively region was comparably low.

improve plate mechanical properties without adding extra The maximum heat flux of a single jet is attained in the

elements. One important part of TMCP technology is to let stagnation region, and the heat flux decreases rapidly with

the plate rapid cooling to a certain temperature at an ultra- the increasing distance from the impinging point. In order to

fast cooling rate, which will have a strong effect on the achieve uniform cooling in industrial application, multiple

microstructure and phase distribution of the plate. Although, jets have been widely used. Tie Peng6) studied submerged

laminar cooling has been the most common cooling method cooling with jet arrays; they wanted to cool down the

in commercial steel mills in nowadays. The disadvantages overheated CPU chips from 75.7°C, more efficiently. In

of laminar cooling still need to be fixed, such as the laminar this case, 7 mm nozzle spacing, and 5.0 mm jet-to-target

cooling water accumulates on the plate, the surface flow distance were set by optimizing the cooling parameters.

field interferes cooling capacity and uniformity, most of Many studies7–9) had been focused on the flow field and

the cooling water slides and falls from the plate instead of heat transfer of multiple air jet arrays, of which the pressure

directly contacting the plate for the presence of Leidenfrost and velocity distribution characteristics are similar to the

phenomenon.1,2) water cooling condition. The flow pattern includes stagna-

The cooling regions in impinging cooling are classified as tion region, decelerated flow, recirculating flow and vortex.

the wetted region and the unwetted region. At the imping- Kwon and his coworkers10,11) numerically studied the cool-

ing point, the temperature drops quickly, and the surface ing process of a steel plate in a run out table (ROT). The

appears to be a dark circle, which keeps expanding as the thickness of residual water increased with flow rate. The

cooling goes on. The maximum heat flux is believed to cooling efficiency decreased with the density of the nozzle

occur at the position a little behind the wetting front, where arrangement, and the average heat flux did not increase

the transition from transient boiling to nucleate boiling hap- monotonously with the increased flow rate. Therefore, a

pens.3) Nitin Karwa and his coworkers4,5) mainly focused on proper flow density was required to achieve the optimum

cooling effect.

* Corresponding author: E-mail: wbxang@126.com Flows of multiple jets are complicated, they interact

DOI: http://dx.doi.org/10.2355/isijinternational.ISIJINT-2015-691 with each other, and the boiling and heat transfer states

© 2016 ISIJ 1210

ISIJ International, Vol. 56 (2016), No. 7

are affected by the decelerated flow and recirculating point 4 is at the outer impinging point. The temperature

flow. Moreover, the cooling performance of multiple jets data in the area between the jets and outside the jets were

impingements on the high-temperature steel plate has been recorded simultaneously.

rarely reported. In this work, we aimed at extending the The accurate temperature detection position located at the

understanding of heat transfer features on high-temperature head of the thermocouple. The measuring component inside

steel plate during the cooling process of multiple jet arrays. the thermocouple was attached to the sheath to make sure a

Based on the flow field features, the experiments of transient fast temperature response. The distance between the center

cooling were carried out by cooling 700°C stainless steel of the hole and the impinged surface was 2.5 mm, with the

with multiple nozzles arrays to analyze the temperature data inserted depth of 30 mm. In order to keep the thermocouples

at different locations. contact closely with the plate, the paste of high temperature

thermal conductive (λ = 9.1 W·m − 1 K − 1) was utilized

to fulfill the inside of holes. The temperature data were

2. Experimental Set-up and Procedure

recorded by a moveable dependent device (midi LOGGER

2.1. Measurement Apparatuses GL220) at a frequency of 10 Hz. Before every experiment,

The experiment was carried out on the specially designed the steel was polished to eliminate the influence of surface

cooling platform as shown in Fig. 1. The water flow rate and roughness, and its surface roughness was about 0.4 μm.

air pressure were set to the target value before the cooling.

The specimen was heated to 700°C by two ceramic heating 2.2. Nozzle Structure

panels. Then it was transferred to the trestle table, which Velocity uniformity of jet arrays is an important factor in

was above the water tank. The heat losses during the trans- the study. As shown in Fig. 3, to guarantee the good velocity

portation were ~25°C. uniformity, a flow-equalizing device was designed and built

AISI 304 stainless steel specimen was chosen for its up from the polylactic acid by 3D Printers (Wiiboox) tech-

stable austenitic structure and the excellent oxidization nology. The machining accuracy is 0.1 mm. The diameter of

resistance at high temperature. As shown in Fig. 2, the entrances is 24.4 mm with M35 screw thread; A clapboard

size of the specimen is 150 × 80 × 20 mm (Length, Width, achieves damping effectiveness with four 10 mm holes, so

Thickness), nine K-type sheathed thermocouples with a inlet water cannot directly impinge on the bottom position.

temperature range of 0–900°C of 3 mm diameter were cus- The lower chamber can maintain a uniform pressure distri-

tomized to obtain the temperature data. The arrangement of bution, which is helpful to obtain the same jet velocity at the

thermocouples was aimed to get the temperature data at the outlet of each nozzle. The length, diameter, and interval of

center line of the impinging region. The measurement point nozzles are 20, 3, and 25 mm, respectively. The deviation

9 was at the center impinging point and the measurement of outlet jet speed is within 5%.

Fig. 1. The flow diagram of the specially designed cooling plat- Fig. 2. The schematic of plate with distribution of thermocouples

form. and jet arrays.

Fig. 3. The structure and digital graph of the flow-equalizing device.

1211 © 2016 ISIJ

ISIJ International, Vol. 56 (2016), No. 7

2.3. Numerical Model Where T is temperature, t is time, τ is the time interval,

The calculation domain and the associated boundary λ is heat conductivity, C is specific heat, ρ is density. The

conditions of the cooling process are presented in Fig. 4. third boundary condition is adopted, and the initial and

The purpose of the numerical study focused on the flow boundary conditions are written as follows:15)

field under multiple jets. Considering the lack of the reli-

Tk B

able boundary data and fundamental mechanisms about the T ( x, y, 0 ) = φ ( T ) , t = 0, 0 ≤ x ≤ , 0 ≤ y ≤ ... (2)

high-temperature cooling process, the numerical study of 2 2

heat transfer process was not implemented here.

∂T Tk

The numerical calculation is based on the ANSYS CFX −λ ( tTk ) = qx , x = , t > 0 ................ (3)

software (version 15.0). The volume of fluid (VOF) model ∂x 2

is adopted to calculate the steady states flow field, and the

∂T B

reliable k-ε model is used to calculate the turbulence. Each −λ ( t B ) = q y , y = , t > 0 ................. (4)

nozzle entrance is set to the velocity input condition with ∂y 2

water fraction of 1, which means the nozzle is full of water. ∂T ∂T

Non-nozzle portions of the top surface are set to the opening = = 0, (t > 0, x = 0, y = 0) ................ (5)

∂x ∂y

boundary conditions without the water back flow. The aver-

age grid size in the calculation domain is 1.5 mm, and the Where, Tk is thickness of the plate, B is width, ϕ is heat

grids near cooling surface are refined to 0.5 mm. The con- capacity of steel plate. The Crank-Nicolson difference

vection and diffusion terms of the governing equation are method is employed for thickness and width direction, the

discretized by using the second-order upwind scheme. The computing time step is 0.1 s, the grid size is 1 mm2. The

simple algorithm is employed to calculate the pressure.12) strand diameter of thermocouples is 3 mm and the tempera-

ture responsiveness is less than 0.1 s. In each time step, the

2.4. Data Reduction difference between the measured and calculated values is

During the impinging cooling process, standard tempera- used as the criterion for a new heat flux. The calculation was

ture measurement techniques such as infrared thermography implemented in commercial software MATLAB. The detail

cannot be used for the disturbance of surface-water and of the calculation can be found in Wang’s work.16)

vapor. As a result, the surface temperature and heat flux are The local convective heat transfer coefficient, h, between

obtained by inverse heat transfer method based on thermal the jet flow and plate surface, is defined as follows:

conduction differential equation and temperature curves q

readings from the inside of the plate.13,14) h= ............................... (6)

The two-dimension unsteady thermal conduction differ- (Ts − Tw )

ential equation is written as: The major uncertainty of temperature fluctuations can

be ascribed to the positional deviation of thermocouples.

∂T λ (T ) ∂ 2T ∂ 2T Therefore, all the measurements were repeated twice, the

= + .................... (1)

∂τ C ( T ) ρ ∂x 2 ∂y 2 maximum uncertainty of the average data was about 5%.

The uncertainty of steel thermal properties was assumed to

within 10% in the temperature range of 200–700°C. The

water temperature was controlled within ± 0.5°C at the point

of cooling. The jet velocity was controlled within a toler-

ance of ± 0.2 m/s. The experimental parameters are listed as

follow: the plate initial temperature is 700°C, ΔTsub = 82°C,

D = 3 mm, H = 90 mm, V is 1.9, 2.6, and 3.9 m/s and the

corresponding Re is 6 367, 8 278, and 13 087, respectively.

3. Results and Discussion

3.1. Analysis of Flow States

As indicated in Fig. 5(a), at the beginning of the impinge-

ment (0.034 s after the water impingement on the surface),

the small black circle zone appearing in the stagnant zone

is called wetted region, which indicates that the cooling

water contacts the surface directly.17) With increasing boil-

ing frequency, the very high heat flux is achieved within a

short period with a significant drop in surface temperature.

The sputtered water drops collided with each other, and no

obvious boiling bubbles were observed.

Figures 5(b)–5(c) shows the expanding of the wetted

region. The dark zone spread radially as soon as the cool-

ing began, and the intermediate region between jets did not

Fig. 4. The calculation domain and position of the visualization wetted yet. The volume of accumulated water on the plate

planes. increased with time. The sputtered water drops started to

© 2016 ISIJ 1212

ISIJ International, Vol. 56 (2016), No. 7

Fig. 5. Digital graphs of the variation of flow fields and the growth of wetted region in experiment C2 after water

impinging on the plate, (a) 0.034 s, (b) 0.34 s, (c) 0.67 s, (d) 1.00 s, (e) 2.00 s and (f) 3.00 s.

merge into a flow between the jets and drained off through

the gaps among jets.

In Figs. 5(d)–5(f), the wetted regions kept expanding and

connected with each other at the time of 1 s. The accumu-

lated water maintained a relatively stable status and corre-

sponding with the expansion of the wetted region, where the

water did not slip on the vapor film at a fast speed anymore.

Abundant bubbles, which derived from the boiling on the

plate surface and the doped air during the interaction of

upwash flow, were mixed into the accumulated water.

The simulated flow states are shown in Figs. 6(a)–6(b), Fig. 6. The distribution of velocity vector in the volume that the

where the thin flow layers were distributed around each water fraction is above 0.05, Re = 8 278, (a) standard view,

(b) top view.

impinging point. With high horizontal velocity, the thin

flow layers collided with each other and formed the upwash

flows, which located at the interval of the impinging points.

The kinetic energy of upwash flow decreased with height, between adjacent jets can be observed, the upwash flow was

and the speed vector at the top layer flow reached the mini- closer to the outside jets. The height of accumulated water

mum. decreased along the outward direction. The region with

The position of visualization plane is shown in Fig. 4. higher k was corresponding with the collision of parallel

The k and projection of the velocity vector for the vertical flow at the normal direction of plane 2. At the horizontal

plane 1 at the center jet and its neighbors are presented in plane exhibited in Fig. 7(d), the higher k region was distrib-

Figs. 7(a) and 7(c). The k was relatively high in the vertical uted at the peripheral area of the jets, where the overflowing

region that closed to the jets. The height of upwash water, water fell and collided with the parallel flow.

determined by the collisions among the adjacent jet flows,

can reach ~50 mm. Part of upwash water entered into the 3.2. Analysis of Surface Temperature Curves

adjacent jet regions and re-impinged on the plate surface. For the disturbance of surface-water and vapor on the

The other part of upwash water was drained by flowing surface of the plate, the surface temperature was evaluated

to the adjacent and ambient jets. Moreover, Matsumoto18) by the inverse heat conduction method. Figure 8 shows the

had reported both of the drained mechanisms. In the gaps corresponding transient surface temperature curves. In the

between jets, the formed vortexes in accumulated water, period before the cooling start, the temperature on the plate

which resulted from the interaction of the upwash flow and was uniform, which indicated the proper heating process.

falling water, showed higher k value. In Fig. 7(b), the vortex The cooling curves herein were similar to the previous

1213 © 2016 ISIJ

ISIJ International, Vol. 56 (2016), No. 7

Fig. 7. The distribution of k and velocity vector of each plane, (a) plane 1, (b) plane 2, (c) plane 3, (d) plane 4, horizontal

plane at height 3 mm.

reports about the single impinging cooling.19,20) Since the of Re, the temperature dropped at a slow speed, which can

jet impinged on the surface (0.0 s), a sharp temperature be accounted for the less volume and momentum of the

decrease was observed at the stagnant points in the wetted splashed water, as well as the decreased wetting speed.

states regardless of the variation of Reynolds number (Re), Meanwhile, these areas kept unwetted for a longer time and

as shown in Figs. 8(a)–8(c). The wetting process initiated film boiling was the dominant form of heat transfer.

in 0.034 s after the beginning of impingement, as shown in Figure 9 presents the variation of surface temperature

Fig. 5(a). The Fig. 5 indicated that it took a certain time for with cooling time for the different Reynolds numbers. With

the wetted region to reach the periphery of the stagnation Reynolds number increasing from 6 367 to 13 087, the sur-

points. When the wetting front arrived at a particular spatial face cooling rate was further enhanced, particularly in the

location on the surface, a sharp drop in surface temperature radial locations which were away from the stagnation point.

can be observed.5,21) The surface cooling rate at different At 0.5 s, the temperature at impinging points showed an

spatial locations varied with the jet Reynolds number. extreme decrease, and the moment when temperature curves

At Re of 13 087, it took 5.8 s for the surface temperature begin decrease was related to the expanding of the wet-

cooling down from 650°C to 150°C at point 1, which was ted region. The lowest temperature region located at each

15 mm away from the point 4. This time was nearly 2 times impinging point were found to increase with the distance

higher than the time interval at the stagnation point 4 (3.0 s). from the impinging point. At 1.0 s, the temperature at point

With the decrease of Re, the time interval at the stagnation 6 and 7 were lower than at point 2, which proved the wet-

point did not change prominently, just increased to 3.9 s ting speed of the parallel flow collision region was slightly

(Re = 6 367). However, the difference between surface tem- faster than the relative outer region, where the distances

perature curves can be discovered at the point 1, 6, 7, which between measurement points 2, 6, 7, and the nearest imping-

were away from the impinging points. With the decrease ing points are 10 mm. However, the lowered temperature at

© 2016 ISIJ 1214

ISIJ International, Vol. 56 (2016), No. 7

point 6 than at point 7 in all the experimental cases can be

attributed to the upwash flow was much closer to point 6.

The vortex at point 6 with higher k can effectively take away

the bubbles that attached to the surface. This behavior was

helpful to increase boiling frequency and heat extraction

quantity, and the lower surface temperature was the critical

factor that drive the movement of wetting front.17) Addition-

ally, more water was accumulated at point 6 than point 7,

and the increase of water volume was also beneficial for the

acceleration of the wetting process.22)

The temperature difference between measurement points

reached the maximum at 1 s after the cooling start in all the

experimental conditions. At Re of 13 087, the temperature

difference between point 7 and 9 was 280.8°C and then

drastically dropped to 95.1°C after another 1 s cooling. It

can conclude that the heat transfer efficiency at a certain

position decreased with extending the impinging cooling

time.

3.3. Analysis of Heat Transfer Coefficients

The heat transfer coefficient (HTC, h) curves at various

locations are shown in Fig. 10. The HTC behaved nonlin-

early as a function of surface temperature. The different

cooling trends were presented at various places. Figure

10(a) shows the curves at impinging points, where the

HTC increased shapely when the temperature dropped from

650°C to 500°C. With further decreasing the temperature,

the slope of HTC curve flattened gradually. After reach-

ing the maximum of HTC around 150–180°C, the HTC

decreased sharply, and the heat transfer mechanism eventu-

ally changed into the forced convection heat transfer at low

surface temperatures, which was confirmed in Nallathambi’s

study.23) However, at point 9, the maximum of HTC ranged

from 13 275.8 to 14 232.1 with different Reynolds numbers.

The HTC curves at locations that are 5 mm away from

impinging points are shown in Fig. 10(b), these curves were

similar to the curves at impinging points, but both of the

HTC increasing speed and the maximum HTC were lower

than those at the impinging point. At Re of 13 087, the HTC

of point 8 at 500°C was ~30% lower than it at point 9. The

maximum of HTC was in the range 200–220°C, which

was slightly higher than the corresponding temperature at

Fig. 8. The variation of surface temperature curves with cooling point 9.

time and Re.

The measurement points of 6, 7, and 2 are 10 mm to the

nearest impinging points, and the corresponding HTC curves

are shown in Fig. 10(c). The increase of HTC were sluggish

at the initial cooling process (temperature above 600°C) for

the film boiling dominated the heat transfer. Although the

cooling water accumulated at the position between the jets,

the surface kept unwetted until the wetting front expanded to

here from the impinging position. The points 6 and 7 located

at the interval of the jets while the point 2 located at the

outside of jets. Therefore, their temperatures along with the

maximum HTCs behaved differently. The temperature of

the maximum HTC at the inner location was about 300°C,

while at the outer location was about 200°C.

In order to further clarify the featured HTC, the com-

parison of the data herein with the previous data from

Leocadio24) and Wang16) are shown in Fig. 11. Although

Fig. 9. The variation of surface temperature of entire cooling area the experimental conditions were not the same, these curves

with cooling time and Re. behaved similarly. All curves monotonously increased with

1215 © 2016 ISIJ

ISIJ International, Vol. 56 (2016), No. 7

the temperature decreased from 800 to 200°C except the

obvious difference in the value of HTC. The increasing

speed and maximum of HTC herein were higher than the

previous results because the gathered data in this study were

much closer to the real ones. The main possible reason for

the difference was due to the deviation of data recording

process. For one reason was that the temperature dropped

abruptly at the initial cooling stage, the rapid response

of temperature detector and the accurate temperature of

specimens were critical for recording the temperature. As a

result, the tight junction between thermocouples and plate,

as well as the fast response speed of thermocouple were

required. Otherwise, the recorded temperature data and HTC

would be lower than the real values. Another reason can be

attributed to the different surface roughness and physical

property of specimens. The nucleation process of boiling

bubbles25) were affected by the roughness of the surface,

so as to the HTC, which mainly depend on the boiling heat

transfer process.

3.4. Effect of Jet Velocity on the Maximum Heat Flux,

TMax, and Wetting Trend

The maximum heat flux varies with the position, as

shown in Fig. 12. The higher maximum heat flux was found

to be along with shorter cooling time and higher surface

temperature. During the transient cooling process, heat flux

increased sharply due to the high boiling driving force under

high surface superheat. As a result, it reached the maximum

quickly and followed by a slow decrease.26) During the

Fig. 10. The variation of HTC with surface temperature at differ-

ent locations and Re.

Fig. 11. The comparisons of HTC results with the previous litera- Fig. 12. The maximum heat flux and TMax at different locations

ture. and Reynolds numbers.

© 2016 ISIJ 1216

ISIJ International, Vol. 56 (2016), No. 7

initial cooling process, the dominant boiling mechanism is

transient boiling. Once heat flux reached the maximum heat

flux, the boiling mechanism changed from transient boiling

into nucleate boiling.5,26) What’s more, the higher maximum

heat flux indicated the faster boiling frequency and shorter

bubble detach time.27,28)

The highest maximum heat flux was at point 9 where

was the center impinging point, and the maximum heat flux

decreased with the increasing spatial distance to the nearest

impinging point without the influence of Re. At impinging

point 9, the fluctuation of maximum heat flux was within

0.29 MW/m2 (or 6.7%) when the Re ranged from 6 034 to

13 087. From the above results, it can be concluded that

the Re had little effect on the maximum heat flux at the

impinging point, and this tendency agreed well with the

previous studies of single impinging jet.5,26) It is worthy Fig. 13. The t* and tMax at different locations and Reynolds num-

to note that the variation of water flow rate only resulted bers.

in small changes in contact pressure and saturation tem-

perature. Such minor change could not cause a significant

change in heat flux. However, a reverse trend between maximum heat flux and

At measurement points of 3, 5, and 8, which spatial loca- t* was found at each location when Fig. 10(a) was taken

tion is 5 mm away from the nearest impinging point. The into consideration, where a higher maximum heat flux cor-

maximum heat flux results here were lower than those at responded with a shorter t* and tMax.

the impinging points. At Re of 13 087, the average maxi- At measurement points 4 and 9, the surface wetted imme-

mum heat flux at these points was 3.68 MW/m2, which was diately after the impingement regardless of the variation in

~18.9% lower than that at the impinging points. At Re of Re. In the inner region, the biggest t* and tMax existed at the

6 034, the lowest maximum heat flux was at point 5. How- points 7 and apparently higher than those at points 6, and

ever, with the increase of Re, the maximum heat flux did not the distances of point 6, 7 to the nearest impinging point

increase proportionally. At Re of 13 087, the measurement were both 10 mm. The observed time differences can be

points of 2, 6 and 7, where spatial location are 10 mm away attributed to the center of upwash flow was much closer to

from the nearest impinging point, displayed the average point 6. The upwash flow accompanied with much cooling

maximum heat flux of 3.73 MW/m2, which was ~17.7% water and stronger kinetic energy, as shown in Fig. 6(b).

lower than that at the impinging points. Meanwhile, the flow At Re of 13 087, the measurement points of 3, 5, and 8,

states at point 2 and 6 were parallel flow and vortex flow, which were 5 mm to the nearest impinging points, became

respectively. The similarity of maximum heat flux at these wetted as soon as the impingement started. It took an extra

locations indicated the boiling process was unaffected by the 0.3 s for these points to reach the maximum heat flux when

complex flow structure. compared with the impinging point. The points located 5

Combining with the analysis of HTC, it concluded that mm away from impinging points were in the stable paral-

the boiling process did not fundamentally alter in the pres- lel flow (as shown in Figs. 6 and 7) in spite of collision of

ence of multiple jets. For the strongest cooling location was multiple jets were involved in. Therefore, the wetting trend

still at the impinging point, and the vortex flows between patterns were similar in these regions.

jets had little effect on the maximum heat flux. At Re of 13 087, the differences between t* and tMax

In the industrial application, the impinging time at a cer- ranged from 0.47 s to 0.8 s at all the measurement points.

tain position is momentary for the plate always moving at These differences increased to 0.87 s and 1.0 s when the

a fast speed. The influenced factors such as the jet velocity Re decreased to 8 326 at points 6 and 7, which were in

and water temperature, both help to enlarge the total heat upwash region between nozzles. However, the time differ-

removal quantity by expanding the effective cooling area ences at points 1, 2, and 3 kept constant with decreasing Re.

rather than substantially elevating the cooling intensity of A possible explanation was the insufficient cooling water

impinging region.5,26) Therefore, the faster-wetted region in the region between jets. Moreover, the volume of cool-

expanding speed and less wetting delay time were crucial ing water was an important factor that affected the wetting

for the elevation of the cooling ability under moving cool- process.29,30) Part of cooling water discharge to the outside

ing condition.29) The wetting delay time, t*, which also region (points 1, 2, and 3) driven by the vortex flow at the

named resident time,30) was defined as the period between inner area, this behavior was supported by the characteristic

the beginning of jet impinginged on the surface and the of t* for points 1, 2, and 3. For the observed t* which did

moment wetting front began moving31) in the present study. not decrease with the increase of Re in the outer region

Moreover, the tMax represented the cooling time when a was different from the findings in single jet experiments,

location reach its maximum heat flux (s). The relationship where the Re and flow rate dramatically affected the move-

between t*, tMax, and Re can be seen in Fig. 13, in which the ment of wetting front.29,30) The discovered time differences

patterns of t* and tMax as a function of measurement points21) evidenced the drained water would increase the flow rate in

were similar. This similarity can be attributed to that the the outer region and reduce the impact of Re on flow rate.

maximum heat flux lay in the wetting front region.17,30,32)

1217 © 2016 ISIJ

ISIJ International, Vol. 56 (2016), No. 7

tMax: cooling time when a location reach its maximum

4. Conclusions

heat flux (s)

(1) The flow structure and heat transfer of high- TMax: surface temperature when a location reach its maxi-

temperature plate cooled by nine-nozzle arrays were studied mum heat flux (°C)

experimentally and numerically. The results revealed that H: distance between the nozzle exit and the impinge-

the water accumulated in the area between adjacent jets, part ment surface (mm)

of accumulated water re-impinged on the surface and part of D: nozzle diameter (mm)

it drained off from the jets gaps with a low speed. V: nozzle impinging speed (m/s)

(2) The temperature differences between measurement

points reached the maximum 1 s after the cooling started REFERENCES

at Re 13 087. The heat transfer efficiency decreased with 1) B. S. Gottfried, C. J. Lee and K. J. Bell: Int. J. Heat Mass Transf., 9

extending the cooling time when impinged at a certain (1966), 1167.

position. 2) J. J. Carbajo: Nucl. Eng. Des., 84 (1985), 21.

3) D. H. Wolf, F. P. Incropera and R. Viskanta: Int. J. Heat Mass

(3) At impinging points, increasing Re from 6 034 to Transf., 39 (1996), 1395.

13 087 would have a significant effect on the wetted region 4) N. Karwa, L. Schmidt and P. Stephan: Int. J. Heat Mass Transf., 55

(2012), 3677.

expanding speed rather than on the maximum heat flux and 5) N. Karwa, G. R. Tatiana, P. Stephan and T. Cameron: Exp. Therm.

the corresponding temperature. The faster-wetted region Fluid Sci., 7 (2011), 1435.

expanding speed is necessary to increase the heat transfer 6) P. Tie, Q. Li and Y. Xuan: Appl. Therm. Eng., 31 (2011), 2757.

7) J. Y. San and M. D. Lai: Int. J. Heat Mass Transf., 44 (2001), 3997.

ability in industrial application. 8) L. F. G. Geers, K. Hanjalic and M. J. Tummers: J. Fluid Mech., 546

(4) The wetted region started expanding from the cen- (2005), 255.

9) L. F. G. Geers, M. J. Tummers and K. Hanjalic: Exp. Fluids, 36

ters of each impinging point, and the maximum heat flux at (2004), 946.

each measurement point decreased with the distance to the 10) M. J. Kwon and I. S. Park: ISIJ Int., 53 (2013), 1042.

11) M. J. Kwon and I. S. Park: ISIJ Int., 53 (2013), 2192.

impinging point, both of which were similar to the single 12) M. J. Cho, B. G. Thomas and P. J. Lee: Metall. Mater. Trans. B, 39

impinging jet. The parallel flow collision region had little (2008), 593.

effect on maximum heat flux, but had a more obvious effect 13) J. P. Holman: Heat Transfer, McGraw-Hill, New York, (1972), 391.

14) M. N. Ozisik and H. R. B. Orlande: Inverse Heat Transfer Funda-

on the t*, the t* at point 6 was less than it at point 7 because mentals and Applications, Taylor&Francis, New York, (2000), 49.

the center of inside upwash flow was closer to point 6. 15) S. C. Chapra and R. P. Canale: Numerical Methods for Engineers,

McGraw-Hill, New York, (2015), 832.

The experimental data can be utilized to interpret the 16) H. Wang, W. Yu and Q. Cai: J. Mater. Process Technol., 212 (2012),

heat transfer process under jet arrays, predict the cooling 1825.

rate, and forecasting the microstructure of the steel product. 17) A. K. Mozumder, M. Monde and P. L. Woodfield: Int. J. Heat Mass

Transf., 48 (2005), 5395.

However, these results were subjected to the experimental 18) R. Matsumoto, I. Ishihara, T. Yabe, K. Ikeda, S. Kikkawa and M.

condition, in which the linearly arranged nine-nozzle arrays Senda: Proc 5th ASME-JSME Thermal Engineering Joint Conf., New

York, NY, (1999), 1.

were equidistance of 25 mm. The effect of nozzle distance 19) I. Filipovic, F. P. Incropera and R. Viskanta: Exp. Heat Transf., 8

on the flow field and heat transfer and optimum nozzle (1995), 97.

arrangement parameters still need to be further studied, 20) M. Monde: J. Heat Transfer., 109 (1987), 991.

21) A. K. Mozumder, M. Monde, P. L. Woodfield and M. A. Islam: Int.

additionally, the plate moving speed, jet diameter, jet speed J. Heat Mass Transf., 49 (2006), 2877.

should also be taken into consideration. 22) C. Agrawal, R. Kumar, A. Gupta and B. Chatterjee: Exp. Therm.

Fluid Sci., 42 (2012), 25.

23) A. K. Nallathambi and E. Specht: J. Mater. Process Technol., 209

Acknowledgement (2009), 5325.

24) H. Leocadio, J. Cesar, A. Fabio and C. Silva: Mech. Eng., 5 (2009), 3.

This work was supported by the National Science Foun- 25) B. J. Jones, J. P. McHale and S. V. Garimella: J. Heat Transf., 131

dation of China (Grant No. 51404058 and 51234002). (2009), 315.

26) C. Agrawal, R. Kumar, A. Gupta and B. Chatterjee: Int. J. Heat Mass

Transf., 55 (2012), 4772.

Nomenclature 27) S. G. Kandlikar, V. R. Mizo, M. D. Cartwright and M. D. Ikenze:

Ts: surface temperature (°C) ASME Proc. 32nd National Heat Transfer Conf., Baltimore, (1997), 11.

28) D. P. Rini, R. H. Chenand and L. C. Chow: J. Heat Transf., 124

Tw: water temperature (°C) (2002), 63.

ΔTsub: liquid subcooling (°C) 29) K. H. M. Abdalrahman, U. Alam and E. Specht: 14th Int. Heat Trans-

q: surface heat flux (W/m2) fer Conf., ASME, New York, NY, (2010), 475.

30) J. Hammad, Y. Mitsutake and M. Monde: Int. J. Therm. Sci., 43

h: heat transfer coefficient (HTC) (W/m2°C) (2005), 743.

k: turbulence kinetic energy (m2/s2) 31) B. D. G. Piggott, E. P. White and R. B. Duffey: Nucl. Eng. Des., 36

(1976), 169.

t*: wetting delay time, the interval between the 32) J. Hammad, M. Monde and Y. Mitsutake: Therm. Sci. Eng., 12

beginning of jet impinging on the surface and the (2004), 19.

moment wetting front begins moving (s)

© 2016 ISIJ 1218

You might also like

- Ammonia Plant DescriptionDocument41 pagesAmmonia Plant Descriptionhussainbeds75% (4)

- Effect of Controlling Parameters On Heat Transfer During Spray Impingement Cooling of Steel PlateDocument9 pagesEffect of Controlling Parameters On Heat Transfer During Spray Impingement Cooling of Steel PlateAJER JOURNALNo ratings yet

- A Foaming Bath Method For Direct Heat Treatment SystemsDocument9 pagesA Foaming Bath Method For Direct Heat Treatment Systemsceyhun kilicNo ratings yet

- Characteristics of Transient Heat Transfer and Wetting Pheno - 2015 - Procedia EDocument11 pagesCharacteristics of Transient Heat Transfer and Wetting Pheno - 2015 - Procedia Eyirga shitahunNo ratings yet

- Development of Hard Secondary Cooling by High-Pressure Water Spray in Continuous CastingDocument7 pagesDevelopment of Hard Secondary Cooling by High-Pressure Water Spray in Continuous CastingaNo ratings yet

- Air-side heat transfer characteristics of finned-tube heat exchangers under frost conditionsDocument7 pagesAir-side heat transfer characteristics of finned-tube heat exchangers under frost conditionsUalisson FerreiraNo ratings yet

- Boiling Curves in Relation To QuenchingDocument11 pagesBoiling Curves in Relation To QuenchingfabioNo ratings yet

- Thermal-Hydraulic Analysis For Aluminawater Nanofluid Inside A Mini-Channel Heat Sink With Latent Heat Cooling Ceiling An Experimental StudyDocument13 pagesThermal-Hydraulic Analysis For Aluminawater Nanofluid Inside A Mini-Channel Heat Sink With Latent Heat Cooling Ceiling An Experimental StudyFurkan GülerNo ratings yet

- A Perforated Plate Stacked Siglass Heat ExchangerDocument5 pagesA Perforated Plate Stacked Siglass Heat ExchangerTapasvi BhattNo ratings yet

- Heat Transfer Analysis of A Cold PlateDocument13 pagesHeat Transfer Analysis of A Cold PlateManisha Hitesh BansalNo ratings yet

- Preprints202206 0249 v1Document29 pagesPreprints202206 0249 v1MarkNo ratings yet

- Heat Transfer of Mist Flow Jet Impingement for Glass TemperingDocument11 pagesHeat Transfer of Mist Flow Jet Impingement for Glass TemperingANNAS TOHURI 190513631617No ratings yet

- Phase Change Phenomena in Silicon Microchannels: Lian Zhang, Evelyn N. Wang, Kenneth E. Goodson, Thomas W. KennyDocument11 pagesPhase Change Phenomena in Silicon Microchannels: Lian Zhang, Evelyn N. Wang, Kenneth E. Goodson, Thomas W. KennyRavi Sankar BNo ratings yet

- Heat Transfer From A Hot Moving CylinderDocument13 pagesHeat Transfer From A Hot Moving CylinderfabioNo ratings yet

- Experimental Investigation of Circular Free-Surface Jet Impingement QuenchingDocument9 pagesExperimental Investigation of Circular Free-Surface Jet Impingement Quenchingmalik aijazNo ratings yet

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDocument7 pagesHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysEmmanuel Ber SNo ratings yet

- Effect of Dimple Protrusion Shape On The Cooling Performance of The Turbine Blade Using CFDDocument8 pagesEffect of Dimple Protrusion Shape On The Cooling Performance of The Turbine Blade Using CFDEditor IJTSRDNo ratings yet

- Rewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceDocument21 pagesRewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceH. LEOCADIONo ratings yet

- Multiple Jet Air Cooling Relating With Reynolds Number and Nusselt NumberDocument10 pagesMultiple Jet Air Cooling Relating With Reynolds Number and Nusselt NumberTJPRC PublicationsNo ratings yet

- Numerical Analysis of Temperature and Residual Stresses in Hot-Rolled Steel Strip During Cooling in CoilsDocument10 pagesNumerical Analysis of Temperature and Residual Stresses in Hot-Rolled Steel Strip During Cooling in CoilsFahrgerusteNo ratings yet

- IJIRSTV1I12040Document4 pagesIJIRSTV1I12040Vincent RobinsonNo ratings yet

- Effects of Cooling Water Velocity On Temperature Field of Hot Billet Conveyor RollerDocument5 pagesEffects of Cooling Water Velocity On Temperature Field of Hot Billet Conveyor Roller조기현No ratings yet

- Fabricating A Heat Pipe Structure Within A Radiating Plate For Electronics Fan-Less CoolingDocument5 pagesFabricating A Heat Pipe Structure Within A Radiating Plate For Electronics Fan-Less CoolingRahul RakhadeNo ratings yet

- 23 Roshan KumarDocument5 pages23 Roshan Kumarzoom_999No ratings yet

- First Paper To IeDocument6 pagesFirst Paper To Iepankajkhatak8069No ratings yet

- Thongwik 2008Document5 pagesThongwik 2008João Paulo VissottoNo ratings yet

- Experimental study of frost formationDocument8 pagesExperimental study of frost formationDeyaeNo ratings yet

- Thermal Stress Evolution of The Roll During Rolling and Idling in Hot Strip Rolling ProcessDocument22 pagesThermal Stress Evolution of The Roll During Rolling and Idling in Hot Strip Rolling ProcessHarshalNo ratings yet

- Heat Transfer Conference Paper - Beijing Institute of Technology - MD Aliya Rain PDFDocument5 pagesHeat Transfer Conference Paper - Beijing Institute of Technology - MD Aliya Rain PDFReby RoyNo ratings yet

- 1 s2.0 S2214157X23010948 MainDocument17 pages1 s2.0 S2214157X23010948 MainASIST MechNo ratings yet

- Influence The Nozzle Shape On Local Heat Transfer in Impinging JetDocument8 pagesInfluence The Nozzle Shape On Local Heat Transfer in Impinging JetmhNo ratings yet

- Experimental Study of Convective Heat Transfer by Using Aluminum Pin-Fin With Metal Matrix CompositesDocument5 pagesExperimental Study of Convective Heat Transfer by Using Aluminum Pin-Fin With Metal Matrix CompositesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A New Horizon With Enhance Heat Transfer Rate Using Heat Pipe For Compact Thermal System - A ReviewDocument9 pagesA New Horizon With Enhance Heat Transfer Rate Using Heat Pipe For Compact Thermal System - A ReviewRaj RathvaNo ratings yet

- Experimental Investigation of The Performance CharacteristicsDocument8 pagesExperimental Investigation of The Performance CharacteristicsFernandoNo ratings yet

- Icmax Thermal Analysis of Perforated Fin Arrays Applying Taguchi MethodDocument7 pagesIcmax Thermal Analysis of Perforated Fin Arrays Applying Taguchi MethodDHANAWADE HanamantNo ratings yet

- Rossette 等。 - 2009 - The effect of start-up cycle in ceramic coating usDocument10 pagesRossette 等。 - 2009 - The effect of start-up cycle in ceramic coating usXin LiNo ratings yet

- Computational Analysis of Thermal Behavior Within A Scraped Surface Heat Exchanger SSHEDocument9 pagesComputational Analysis of Thermal Behavior Within A Scraped Surface Heat Exchanger SSHEEditor IJTSRDNo ratings yet

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDocument6 pagesHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysSwati KarNo ratings yet

- Heat Transfer Analysis of Blast Furnace StaveDocument10 pagesHeat Transfer Analysis of Blast Furnace StavemetalmasaNo ratings yet

- Semi-Therm50369 2020 9142831Document7 pagesSemi-Therm50369 2020 9142831ramvineethkasireddyNo ratings yet

- Effect of Chevron Angle and Surface Roughness On Thermal Performance of Single Phase Water Flow in A Plate Heat ExchangerDocument9 pagesEffect of Chevron Angle and Surface Roughness On Thermal Performance of Single Phase Water Flow in A Plate Heat ExchangerAkash AhmedNo ratings yet

- Effect of Spray Inclination on Cooling Hot Steel PlateDocument15 pagesEffect of Spray Inclination on Cooling Hot Steel PlateAvadhesh SharmaNo ratings yet

- IJERT CFD Analysis of Double Pipe Counte (Lab 11)Document13 pagesIJERT CFD Analysis of Double Pipe Counte (Lab 11)bjuanlunabNo ratings yet

- Spe 176089 MS PDFDocument11 pagesSpe 176089 MS PDFatilio martinezNo ratings yet

- J Ijheatmasstransfer 2016 12 014Document12 pagesJ Ijheatmasstransfer 2016 12 014Long ZeNo ratings yet

- Joshi 2017Document24 pagesJoshi 2017Pabitra MandalNo ratings yet

- 1-s2.0-S0017931013004493-mainDocument9 pages1-s2.0-S0017931013004493-mainsoroushNo ratings yet

- CFD Analysis and OptimizationDocument6 pagesCFD Analysis and OptimizationTHE SEZARNo ratings yet

- Effect of Tool Temperature On The Reduction of The Springback of Aluminum SheetsDocument4 pagesEffect of Tool Temperature On The Reduction of The Springback of Aluminum SheetsJabbar AljanabyNo ratings yet

- Morphological Change of Plain and Nano-Porous Surfaces During Boiling and Its Effect On Nucleate Pool Boiling Heat TransferDocument9 pagesMorphological Change of Plain and Nano-Porous Surfaces During Boiling and Its Effect On Nucleate Pool Boiling Heat TransferHany Elsawy AbdelrahmanNo ratings yet

- 152 ISPJE Vol. 2640Document9 pages152 ISPJE Vol. 2640Mostafa AbdelalimNo ratings yet

- 1 s2.0 S0017931022002472 MainDocument12 pages1 s2.0 S0017931022002472 MainAhmadHamdyNo ratings yet

- IJCRT2106379Document9 pagesIJCRT2106379Dinesh YadavNo ratings yet

- Stable and Uniform Heat Dissipation Using Nucleate-Catalytic NanowiresDocument10 pagesStable and Uniform Heat Dissipation Using Nucleate-Catalytic NanowiresAbhijit PalNo ratings yet

- Experimental Study of Air-Cooled Parallel Plate Fin Heat Sinks With and Without Circular Pin Fins Between The Plate FinsDocument6 pagesExperimental Study of Air-Cooled Parallel Plate Fin Heat Sinks With and Without Circular Pin Fins Between The Plate FinssuhasNo ratings yet

- Nuclear Engineering and Design: Thermal Striping Limits For Components of Sodium Cooled Fast Spectrum ReactorsDocument12 pagesNuclear Engineering and Design: Thermal Striping Limits For Components of Sodium Cooled Fast Spectrum ReactorsjofredjosephNo ratings yet

- Sdarticle 3Document9 pagesSdarticle 3mahdixyzNo ratings yet

- Smoothing Effect of The Thermal Interface Material On The Temperature Distribution in A Stepwise Varying Width Microchannel Cooling DeviceDocument11 pagesSmoothing Effect of The Thermal Interface Material On The Temperature Distribution in A Stepwise Varying Width Microchannel Cooling DeviceMohamednjahi OmriNo ratings yet

- Thermo AcousticDocument6 pagesThermo AcousticAshwin VargheseNo ratings yet

- Design and Analysis of Liquid Cooled Cold Plates Using CAD ModelingDocument5 pagesDesign and Analysis of Liquid Cooled Cold Plates Using CAD ModelingEditor IJTSRDNo ratings yet

- Heating Still in JetsDocument7 pagesHeating Still in JetsHotnCrispy CrispyNo ratings yet

- 57 - Isijint 2016 679Document8 pages57 - Isijint 2016 679H. LEOCADIONo ratings yet

- 2010 Ubc Prodanovic Et Al - Experimental Investigation of Submerged Jets During Accelerated Cooling of PlatesDocument6 pages2010 Ubc Prodanovic Et Al - Experimental Investigation of Submerged Jets During Accelerated Cooling of PlatesH. LEOCADIONo ratings yet

- 2011 Accelerated and Controlled Cooling Process 2011Document8 pages2011 Accelerated and Controlled Cooling Process 2011H. LEOCADIONo ratings yet

- Heat Transfer Characteristics Jet Impingement Cooling of A High Temperature SteelDocument15 pagesHeat Transfer Characteristics Jet Impingement Cooling of A High Temperature SteelH. LEOCADIONo ratings yet

- Degassing, Boiling and Rewetting in Free Surface Jet QuenchingDocument12 pagesDegassing, Boiling and Rewetting in Free Surface Jet QuenchingH. LEOCADIONo ratings yet

- ABM Week 2018 Sao PauloDocument13 pagesABM Week 2018 Sao PauloH. LEOCADIONo ratings yet

- Heat Transfer Coefficient During Water Jet Cooling of High-Temperature SteelDocument11 pagesHeat Transfer Coefficient During Water Jet Cooling of High-Temperature SteelH. LEOCADIONo ratings yet

- Interfaces and Heat Transfer in Jet Impingement On A High Temperature SurfaceDocument131 pagesInterfaces and Heat Transfer in Jet Impingement On A High Temperature SurfaceH. LEOCADIONo ratings yet

- ABM Week 2018 Sao PauloDocument13 pagesABM Week 2018 Sao PauloH. LEOCADIONo ratings yet

- Rewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceDocument21 pagesRewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceH. LEOCADIONo ratings yet

- 30 Lesson 30 - Boiling Heat Transfer - ProblemsDocument11 pages30 Lesson 30 - Boiling Heat Transfer - ProblemsAkshat RastogiNo ratings yet

- Understanding Fluid Mechanics FundamentalsDocument8 pagesUnderstanding Fluid Mechanics FundamentalsKrishnaChaitanyaNo ratings yet

- Avg Pitot Tubes - 6 Steps InstallDocument9 pagesAvg Pitot Tubes - 6 Steps InstallBhaskar Shankar ChowdhuryNo ratings yet

- Chapter Glossary: Properties of Pure SubstancesDocument6 pagesChapter Glossary: Properties of Pure SubstancesyusufNo ratings yet

- Assignment 2 (334421)Document5 pagesAssignment 2 (334421)AB RehmanNo ratings yet

- Week 1Document115 pagesWeek 1Haziq YussofNo ratings yet

- Haggis Exercise - Prosper - Updated 2007Document11 pagesHaggis Exercise - Prosper - Updated 2007Anonymous 3TyM2U3U4eNo ratings yet

- Understanding Lobe Blowers Roots Blower PDFDocument9 pagesUnderstanding Lobe Blowers Roots Blower PDFEduardoPomarMakthonNo ratings yet

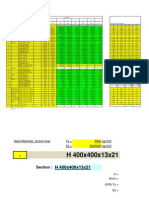

- Steel Column - Beams CalcDocument21 pagesSteel Column - Beams CalctmssorinNo ratings yet

- Ventilare Si Desfumare Parcaje - ModelDocument220 pagesVentilare Si Desfumare Parcaje - ModelalanatoraNo ratings yet

- DC Cook PORV - SD-070123-001Document179 pagesDC Cook PORV - SD-070123-001Wilhelm ThorleyNo ratings yet

- Brochure Dwsub 9.2021Document2 pagesBrochure Dwsub 9.2021Lynn MailNo ratings yet

- Agar50series MPFM SpecDocument4 pagesAgar50series MPFM SpecJADNo ratings yet

- STP Review Benitez - June 10 2013 Brahms PDFDocument2 pagesSTP Review Benitez - June 10 2013 Brahms PDFcoolth2No ratings yet

- EBARA泵FSA系列Document28 pagesEBARA泵FSA系列hermanNo ratings yet

- Final DissertationDocument162 pagesFinal Dissertation3444900809No ratings yet

- ME 422 Experiment No 4Document15 pagesME 422 Experiment No 4Tousif SadmanNo ratings yet

- Gas Dynamics and Jet Propulsion - P. MurugaperumalDocument224 pagesGas Dynamics and Jet Propulsion - P. MurugaperumalVickraman S100% (1)

- 09 - Assembled ValvesDocument2 pages09 - Assembled ValvesDesign V-Tork ControlsNo ratings yet

- Shallow Water Approach To The Circular Hydraulic JumpDocument14 pagesShallow Water Approach To The Circular Hydraulic Jump杨家宁No ratings yet

- EVAPORATION AND DEHYDRATION TECHNIQUESDocument23 pagesEVAPORATION AND DEHYDRATION TECHNIQUESRogelyn JosolNo ratings yet

- Aphron Fluids Study2 Ramzi AljadiDocument14 pagesAphron Fluids Study2 Ramzi AljadiMunsef AL-juroshyNo ratings yet

- Gas Lift Pittman - para Revisar PDFDocument8 pagesGas Lift Pittman - para Revisar PDFedi agurto carrascoNo ratings yet

- Oxidation Ponds & LagoonsDocument31 pagesOxidation Ponds & LagoonsDevendra Sharma100% (1)

- Extreme Negative Pressures and Cavitation Tendency On Steeply Sloping Stepped SpillwaysDocument7 pagesExtreme Negative Pressures and Cavitation Tendency On Steeply Sloping Stepped SpillwaysMarcelo ProtzNo ratings yet

- Chem 2 Instructional Video Pairs TopicsDocument2 pagesChem 2 Instructional Video Pairs TopicsJudel LozadaNo ratings yet

- Wall Thickness Calculation Followed B31.8 PDFDocument3 pagesWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- CFD Analysis of ODAF Power Transformer CoolingDocument10 pagesCFD Analysis of ODAF Power Transformer CoolingdgtzagaNo ratings yet

- Joule Thomson EffectDocument2 pagesJoule Thomson EffectElliott100% (1)