0% found this document useful (0 votes)

1K views14 pagesGeneral Ordering Procedure Spare Parts

This document is an operations and maintenance manual chapter on spare parts. It discusses Vanderlande Industries' spare parts philosophy, including classifying parts by priority level based on their impact on system performance if failed. It provides guidance on determining which spare parts to purchase and store. The document also explains how to read the spare parts list, including part numbering conventions, and provides instructions for properly storing and maintaining spare parts.

Uploaded by

surya agungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views14 pagesGeneral Ordering Procedure Spare Parts

This document is an operations and maintenance manual chapter on spare parts. It discusses Vanderlande Industries' spare parts philosophy, including classifying parts by priority level based on their impact on system performance if failed. It provides guidance on determining which spare parts to purchase and store. The document also explains how to read the spare parts list, including part numbering conventions, and provides instructions for properly storing and maintaining spare parts.

Uploaded by

surya agungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- SPARE PARTS

- Explanation of the Spare Parts List

- DASH VARIANTS

- General Instructions for the Maintenance and Storage of Spare Parts

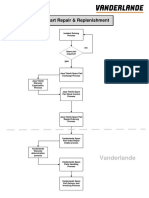

- How to Find the Right Parts

- Order Spare Parts

- Returning Materials to Vanderlande Industries