Professional Documents

Culture Documents

LV Motors Product Range Flyer

Uploaded by

PRABHU SHANKAR MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LV Motors Product Range Flyer

Uploaded by

PRABHU SHANKAR MCopyright:

Available Formats

A MOTOR FOR EVERY NEED

0.12kW to 1250kW

ENERGY SAVING RELIABILITY WIDE RANGE

January 2022

LV Motors Product Range

Motors Conform to relevant Indian Standards IS/IEC 60034 series Insula on: Class 'F' with temperature rise limited to Class 'B', Rota on: Bi-direc onal

Voltage: 415V +/- 10%, Frequency: 50 Hz +/- 5%, Combined Varia on: +/- 10% Cooling: IC411, Degree of Protec on: IP55, Al tude: upto 1000m above MSL

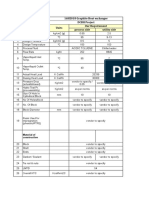

Motor Type Frame Power (kW) Polarity Standard Technical Specifica ons Op onal Features Applica ons

● Non Standard Voltage: upto 690V

● Higher Polarity on request ● High Temperature Grease: Suitable up to 200° C

IE2 Motors 56 to 355 0.12 to 355 2, 4, 6, 8 Pump, Fan, Compressor, Packing Machinery,

● Ambient: 50° C ● Insula on: Class H ● SS Hardware

Coiler/De-coiler, Agro Equipment,

● Ambient for DCCA: 40° C ● Space Heater: 90 Frame onwards ● Non standard sha diameter/extension*

Food Processing Equipment, Paper Machinery,

● Inverter Grade Winding: For IE3 and DCCA ● RTD & BTD: 250 Frame onwards ● Non Standard Paint

IE3 Motors 56 to 355 0.12 to 355 2, 4, 6, 8 Agitator, Dairy Equipment, Machine Tool,

● Duty: S1 ● PTC Thermistor: 80 to 355L ● Provision for Encoder Moun ng

Air Condi oning, Material Handling,

● RTD & BTD: For DCCA motors ● Sha Material: EN24* ● Low Vibra on as per IS or IEC

Plas c Machinery, Tex le Machinery,

● Moun ng: B3, B5, B35, V1, B14 upto 132 frame ● Enclosure: IP56 / 65 / 66 ● Insulated Bearing: 132 Frame onwards

Large LT Motors (DCCA) 355 to 450 250 to 1250 2, 4, 6, 8 Cooling Tower, Crusher, Material Handling

● Forced Cooling: 132 to 450 Frame ● SPM Nipples Provision: Frame 250 onwards

● Roller Bearing: 160 Frame onwards

● Insula on: Class H

● Ambient: 50° C

● Space Heater: 90 frame onwards ● Non standard sha diameter/extension*

● Inverter Duty Winding

● PTC Thermistor: 80 to 225 Frame ● Non Standard Paint

IE4 Motors 112 to 225 1.5 to 45 4 ● Duty: S1 Fans, HVAC, Pumps, Tex les, Hydraulic Press

● Sha Material: EN24* ● Provision for Encoder Moun ng

● VPI: With Class H solvent less Resin

● Enclosure: IP56 / 65 / 66 ● Low Vibra on as per IS or IEC

● Moun ng: B3, B5, B35, V1

● Roller Bearing: 160 Frame onwards

Standard Flame Proof Ex'd' Motors 80 to 315 0.37 to 200 2, 4, 6, 8 ● Non Standard Voltage: 220 to 690V ● Insulated Bearing: 132 Frame onwards

● Intermi ent Duty S3, S4: In 4, 6, 8 Pole* ● Non standard sha diameter/extension* Pump, Fan, Compressor,

● Ambient: 45° C ● Insula on: Class H ● Motors for inverter duty applica on ; offered with Material Handling, Agitator,

IE2 Flame Proof Ex'd' Motors 80 to 315 0.37 to 200 2, 4, 6, 8 ● Inverter Grade Winding: For IE3 Motors ● PTC Thermistor: 80 to 315 L ● Combined tes ng of motor and VFD or LPG Bo ling Plant,

● Duty: S1 ● Space Heater: 90 Frame onwards ● Motors fi ed with PTC Thermistor Pharma Machinery,

● Moun ng: B3, B5, B35, V1 ● Roller Bearing: 160 Frame onwards ● Test facility available for combined Tes ng with VFD Chemical Plant Machinery,

IE3 Flame Proof Ex'd' Motors 80 to 315 0.37 to 180 2, 4, 6, 8 ● Sha Material: EN24* ● Non Standard Paint Machinery for mines

● Enclosure: IP56 / 65 / 66 ● Low Vibra on as per IS or IEC

● Insulated Bearing: 132 Frame onwards

● Non standard sha diameter/extension*

IE2 Increased Safety Ex ec Motors 63 to 355 0.12 to 355 2, 4, 6, 8 ● Insula on: Class H

● Ambient: 50° C ● Motors for inverter duty applica on with combined tes ng Pump, Fan, Compressor,

● Sha Material: EN24*

● Duty: S1 of motor and VFD for temperature class cer fica on Material Handling, Agitator,

● Enclosure: IP56 / 65 / 66

● Moun ng: B3, B5, B35, V1 (B14 upto 132 Frame) ● Test facility available for combined tes ng with VFD Pharma Machinery

IE3 Increased Safety Ex ec Motors 63 to 355 0.12 to 355 2, 4, 6, 8 ● Roller Bearing: 160 Frame onwards

● Non Standard Paint

● Low Vibra on as per IS or IEC

● Duty: S2, S3 and S5

● Non Standard Voltage: 380 to 460V

● Insula on: Class H ● Motors for Inverter Duty

● Ambient: 45° C Crane, Hoist, Li ,

● Space Heater: 90 Frame onwards ● Insulated Bearing: 132 Frame onwards

● Duty: S4 Material Handling,

Crane & Hoist Duty Motors 71 to 355 0.37 to 400 4, 6, 8 ● BTD: 250 Frame & above ● Non standard sha diameter/extension*

● Offered in DOL & Converter Fed Supply Car Stacker,

● PTC Thermistor: 80 to 355 L ● Non Standard Paint

● Moun ng: B3, B5, B35, V1 (B14 upto 132 Frame) Door Opening

● Roller Bearing: 160 Frame onwards ● Low Vibra on as per IS or IEC

● Sha Material: EN24*

● Enclosure: IP56 / 65 / 66

● Duty: S2 and above

● Ambient: 50° C

● Non Standard Voltage: upto 460V

Brake Motors ● Duty: S1 ● Non standard sha diameter/extension* Crane, Hoist, Material Handling, Tex le,

71 to 132 0.25 to 9.3 2, 4, 6, 8 ● Motors for Inverter Duty

(With Integral DC Brake) ● Moun ng: B3, B5, B35 ● Non Standard Paint Pharma to name a few

● Manual Release Arrangement: For 90 to

● Integral DC Brake

132 Frame

● Ambient: 50° C ● Duty: S2 and above

Brake Motors ● Duty: S1 ● Non Standard Voltage: upto 460V ● Double Sha Extension for brake arrangement Crane, Hoist, Material Handling,

71 to 200 0.37 to 22 2, 4, 6, 8 ● Non Standard Paint

(With External Mounted Brake) ● Moun ng: B3, B5, B35 ● Motors for Inverter Duty Tex le, Pharma to name a few

● External Mounted DC Brake/Arrangement ● Manual Release Arrangement

● Ambient: 45° C

● Duty: S3, S4, S5 ● Moun ng: B35

Slip Ring Motors 100 to 160 1.1 to 10 4, 6 ● Non Standard Paint Crane, Hoist, Li , Material Handling

● Moun ng: B3 ● Non standard sha diameter & extension*

● Ambient: 50° C

● Motors for Inverter Duty

Tex le Motors 100 to 160 1.1 to 15 4, 6, 8 ● Duty: S1 ● Non Standard Voltage: upto 500V Ginning, Tex le Machinery

● Non Standard Paint

● Moun ng: B3, B5, B35 ● Insula on: Class H

● Low Vibra on as per IS

● Ambient: 45° C

● Start/Stop per Hour: upto 900

● Duty: S5, 50% CDF ● Insula on: Class H ● Insulated Bearing: 132 Frame onwards

Cane Unloader Motors 160 to 225 11 to 30 6 ● Thermostat Cane Loading-Unloading Machine

● PTC Thermistor ● Non Standard Paint

● Moun ng: B3, B5, B35

● Forced Cooling

● Sha Material: En24

* Subject to confirma on from Bharat Bijlee

ALL INDIA SERVICE NETWORK

Regional Offices

Works

Authorised Service Centre: Motors

Amritsar

Service Centre: Servo Motors

Ludhiana

Mohali

Saharanpur

Faridabad

Panipat

Rudrapur

Gurugram

New Delhi

Bhiwadi, Alwar

Noida Tinsukia

Jaipur

Ajmer Kanpur

Guwahati

Beawar Patna

Udaipur Rewa

Gandhidham Katni Purba Burdwan

Ahmedabad Bhopal Jabalpur Hooghly

Korba

Jamnagar Mandideep

Baroda Indore Bilaspur

Rajkot Ankleshwar Ramgarh

Bharuch Kolkata

Surat Nagpur Raipur Jamshedpur

Vapi Bhilai

Nashik Rourkela

Mumbai Ahmednagar Bhuvaneshwar

Pune

Visakhapatnam

Kolhapur

Vijaywada

REGIONAL OFFICES

Mumbai T: +91 22 6145 7200

Secunderabad

Guntur Pune T: 7410011272 / 7410011271

Goa

Ahmedabad T: +91 79 6604 9200

Belgaum

New Delhi T: +91 11 2581 6931 / 6932 / 6933

Hubli

Indore T: +91 731 2524 474 / 2514 486

Bengaluru Ludhiana T: +91 161 2775 692 / 93

Chennai

Salem Jaipur T: +91 141 2377 223

Veppadai Puducherry

Kolkata T: +91 33 24432383 / 2467 ; +91 33 4062 3076 / 3077

Calicut Erode

Coimbatore Bengaluru T: +91 80 2559 2646 / 2137 / 2681

Madurai Chennai T: +91 44 2815 4794 / 4793

Kochi Secunderabad T: +91 40 2780 1791 / 2781 4512

Coimbatore T: +91 422 4204314

For any enquiries please write to motorlvsales@bharatbijlee.com

+91 22 - 2763 7290 | serviceline@bharatbijlee.com

With effect from January 2022

Customer Service Helpdesk for Industrial Systems

REGISTERED OFFICE WORKS

Electric Mansion, 6th Floor, No. 2, MIDC Thane-Belapur Road, Airoli,

Appasaheb Marathe Marg, Navi Mumbai 400 708

Prabhadevi, Mumbai 400 025 T: +91 22 2763 7200 / +91 22 2760 0401

M/F/PRO/3/0122/2000

T: +91 22 2430 6237 / 6375

E: info@bharatbijlee.com

CIN: L31300MH1946PLC005017 www.bharatbijlee.com

Product improvement is a continuous process and technical information herein is subject to change.

You might also like

- Koel Engine, Ha Operation and Maintenance Manual (Ha - SR)Document89 pagesKoel Engine, Ha Operation and Maintenance Manual (Ha - SR)Karthik K Raja75% (12)

- User Manual SteadyControlDocument57 pagesUser Manual SteadyControlrobiny100% (2)

- Single Phase Two Wire, Split STS Prepaid/AMI Smart Meter: HighlightsDocument2 pagesSingle Phase Two Wire, Split STS Prepaid/AMI Smart Meter: HighlightsElisiö Dicälä Homem da LéiNo ratings yet

- Ed5lfs2 ST22V1Document24 pagesEd5lfs2 ST22V1Matheus BorgesNo ratings yet

- Nader NDW2 Series Products SpecificationDocument91 pagesNader NDW2 Series Products Specificationlitech technicalNo ratings yet

- 260 Postulates of The Dynamics of TimeDocument78 pages260 Postulates of The Dynamics of Timesmartjohnsmith10100% (2)

- Linear ProgrammingDocument6 pagesLinear ProgrammingabeerNo ratings yet

- ASTM Pumping TestDocument125 pagesASTM Pumping TestErnesto Heinze100% (1)

- Generic TWS600S Service ManualDocument113 pagesGeneric TWS600S Service ManualWise So100% (2)

- Document 1Document14 pagesDocument 1bismarckandresNo ratings yet

- 4 Ataxle PDFDocument22 pages4 Ataxle PDFAnonymous XTkln6H100% (1)

- Optical Fiber Communication 06EC7 2: Citstudents - inDocument4 pagesOptical Fiber Communication 06EC7 2: Citstudents - inShailaja UdtewarNo ratings yet

- HEM Product LeafletDocument2 pagesHEM Product LeafletAbhishek Kumar Pandey1No ratings yet

- Atten at 8502Document1 pageAtten at 8502Ngọc TrầnNo ratings yet

- Fluke Acess TemperatureDocument4 pagesFluke Acess TemperatureJuan José Villavicencio CantoNo ratings yet

- Marine Motors: Three-Phase Induction MotorsDocument20 pagesMarine Motors: Three-Phase Induction MotorsVenu Aravindh ThiyagarajanNo ratings yet

- 60KW Ricardo Open Diesel GensetDocument4 pages60KW Ricardo Open Diesel GensetnicolasNo ratings yet

- English Version Catalogue-2013-02-1Document27 pagesEnglish Version Catalogue-2013-02-1Arunee SombatjindaNo ratings yet

- Diesel PumpDocument16 pagesDiesel PumpSalman SaifuddinNo ratings yet

- Series Hr25: DynaparDocument4 pagesSeries Hr25: DynaparRicardo SanchezNo ratings yet

- MC1081 Ranger Selection GuideDocument2 pagesMC1081 Ranger Selection GuideMiguel AngelNo ratings yet

- Temperature Scanner/Pyrometer SWICHGAGE: Model TDX6Document2 pagesTemperature Scanner/Pyrometer SWICHGAGE: Model TDX6Erick Portela cruzNo ratings yet

- DC Motor CatalogueDocument12 pagesDC Motor CatalogueAbhishek KumarNo ratings yet

- Bro Dhg400 enDocument1 pageBro Dhg400 enAzkha EsaNo ratings yet

- Air-Cooled Scroll Modular Chiller: Technical Service ManualDocument169 pagesAir-Cooled Scroll Modular Chiller: Technical Service Manualyacinealg1No ratings yet

- Remote Torque Interface (Rtixe) : Distributed Processing UnitsDocument2 pagesRemote Torque Interface (Rtixe) : Distributed Processing UnitsАлександр ШевченкоNo ratings yet

- Rƒsco So2000dt: 2-In-1 Handler With Two Temperature ChambersDocument2 pagesRƒsco So2000dt: 2-In-1 Handler With Two Temperature ChambersmhafizanNo ratings yet

- Data Sheet of Cummins 500kva by IntranusaDocument9 pagesData Sheet of Cummins 500kva by IntranusaDeni DendenNo ratings yet

- Encoder WDG 40S: Wachendorff Automation ... Systems and EncodersDocument11 pagesEncoder WDG 40S: Wachendorff Automation ... Systems and EncodersPierre ClouNo ratings yet

- GDG 11000ec 60HZ enDocument1 pageGDG 11000ec 60HZ enEduardo VicoNo ratings yet

- CG Three Phase CatalogueDocument6 pagesCG Three Phase CatalogueJim MorrisonNo ratings yet

- Katalog ATBDocument120 pagesKatalog ATBvirgil guimanNo ratings yet

- 360v-200ah GTPDocument1 page360v-200ah GTPShanmuganathan ShanNo ratings yet

- Steel 33crmov12 GKH - GBDocument2 pagesSteel 33crmov12 GKH - GBAdnan ColoNo ratings yet

- 281 ITW GSE Hobart 140 180 GPU PDFDocument2 pages281 ITW GSE Hobart 140 180 GPU PDFDario GuerraNo ratings yet

- 1.5kW MotorDocument1 page1.5kW MotorTareq JildehNo ratings yet

- Catalog 75 061Document17 pagesCatalog 75 061Muhammad IskandarNo ratings yet

- PB Unimax English160604152107Document12 pagesPB Unimax English160604152107filipeNo ratings yet

- Crompton PumpDocument2 pagesCrompton PumpAbiNo ratings yet

- 현대 고압 모터 카다로그 영문Document132 pages현대 고압 모터 카다로그 영문RIZKY FIQRINo ratings yet

- Manual Encoder WDG 58ADocument14 pagesManual Encoder WDG 58APramono MuktiNo ratings yet

- AISI A2 DatasheetDocument2 pagesAISI A2 DatasheetShivuNo ratings yet

- Evap. KeeprideDocument44 pagesEvap. KeeprideAbdiel Kadir Martinez MendozaNo ratings yet

- DatasheetDocument13 pagesDatasheetJNo ratings yet

- Moulded Case Circuit Breakers: Standard Type (S) Higher Type (H)Document21 pagesMoulded Case Circuit Breakers: Standard Type (S) Higher Type (H)daalca26No ratings yet

- Ferguson IM-pAC E-UKDocument2 pagesFerguson IM-pAC E-UKSuhas KODRENo ratings yet

- Midea - Product BookletDocument4 pagesMidea - Product Bookletart ruszell castroNo ratings yet

- GPD SV2 eDocument13 pagesGPD SV2 eMuh ZakariaNo ratings yet

- GHT 2001 Chino 12 Point Temperature Recorder EH3127 001Document1 pageGHT 2001 Chino 12 Point Temperature Recorder EH3127 001gawaNo ratings yet

- Speedstar - Class Leading Led LightingDocument3 pagesSpeedstar - Class Leading Led Lightingsatria ghaniNo ratings yet

- 30MW TG DatasheetDocument3 pages30MW TG Datasheetmeenakshisundaram100% (1)

- PC8000-6 A4 InternetDocument8 pagesPC8000-6 A4 InternetAkhmad SebehNo ratings yet

- PC8000-6 A4 InternetDocument8 pagesPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Cotizacion Piller - Octubre - 2019Document26 pagesCotizacion Piller - Octubre - 2019liki pabonNo ratings yet

- Manual EncoderDocument7 pagesManual EncoderSyahrul FitriaNo ratings yet

- Ge 0Document7 pagesGe 0PhanNamNo ratings yet

- 5.0 - en-US - 2019-01 - TS - Flygt 3202Document60 pages5.0 - en-US - 2019-01 - TS - Flygt 3202FedeNo ratings yet

- DC Motor Type DMRDocument44 pagesDC Motor Type DMRmass72No ratings yet

- CGL Flame - Proof - MotorsDocument15 pagesCGL Flame - Proof - MotorspriteshNo ratings yet

- En Futura Max Data SheetDocument3 pagesEn Futura Max Data SheetGoran MladenovicNo ratings yet

- Product Information Installation and Maintenance: RAL 7035 IP66 IK08Document3 pagesProduct Information Installation and Maintenance: RAL 7035 IP66 IK08Abdulaziz AlrawiNo ratings yet

- GT200WDocument40 pagesGT200WRobel EvangelistaNo ratings yet

- Kongber TelegrDocument2 pagesKongber TelegrTamNo ratings yet

- (Control Biz.) 18 - Jan - PAHCMR000 - PAHCMS000 (SA)Document43 pages(Control Biz.) 18 - Jan - PAHCMR000 - PAHCMS000 (SA)Paulo Augusto GarayNo ratings yet

- Series: GBG 110te & GBG 120teDocument1 pageSeries: GBG 110te & GBG 120teEduardo VicoNo ratings yet

- Specifications: Table 1. DCM D9902 Chassis SpecificationsDocument1 pageSpecifications: Table 1. DCM D9902 Chassis SpecificationsReyes Saul Rodriguez EstradaNo ratings yet

- ATB - Explosition Proof Motors EEXDocument122 pagesATB - Explosition Proof Motors EEXSergey KrylatovNo ratings yet

- 8 Annexure 8 Technical Specification of VFD-2021-04-12-03 22 03Document12 pages8 Annexure 8 Technical Specification of VFD-2021-04-12-03 22 03PRABHU SHANKAR MNo ratings yet

- Data Sheet 1Document2 pagesData Sheet 1PRABHU SHANKAR MNo ratings yet

- LV Motors Ie2 Safe Area CatalougeDocument20 pagesLV Motors Ie2 Safe Area CatalougePRABHU SHANKAR MNo ratings yet

- Synchrovert CatalogueDocument12 pagesSynchrovert CataloguePRABHU SHANKAR MNo ratings yet

- Preparation of Transformer Specifications1Document56 pagesPreparation of Transformer Specifications1ahmaborashedNo ratings yet

- RFQ No. ASPA17.030 Supply & Delivery of VFDs For The Tafuna WWTP-Attachment B - VFD SpecificationDocument6 pagesRFQ No. ASPA17.030 Supply & Delivery of VFDs For The Tafuna WWTP-Attachment B - VFD SpecificationPRABHU SHANKAR MNo ratings yet

- LV Motors Ie3 Safe Area CatalougeDocument22 pagesLV Motors Ie3 Safe Area CatalougePRABHU SHANKAR MNo ratings yet

- Iss BrochureDocument6 pagesIss BrochurePRABHU SHANKAR MNo ratings yet

- ABB CAT SKY Ingles BAJADocument24 pagesABB CAT SKY Ingles BAJAPRABHU SHANKAR MNo ratings yet

- Designed To Ensure Maximum Protection and Comfort To Your HomeDocument1 pageDesigned To Ensure Maximum Protection and Comfort To Your HomePRABHU SHANKAR MNo ratings yet

- Concept BS: Naturally AestheticDocument24 pagesConcept BS: Naturally AestheticPRABHU SHANKAR MNo ratings yet

- Catalogue IPS 2021 English Rev GDocument192 pagesCatalogue IPS 2021 English Rev GPRABHU SHANKAR MNo ratings yet

- Sky Niessen - Catalogue - 2018 - ENDocument152 pagesSky Niessen - Catalogue - 2018 - ENPRABHU SHANKAR MNo ratings yet

- E Z Ground Types of ConnectorsDocument1 pageE Z Ground Types of ConnectorsPRABHU SHANKAR MNo ratings yet

- 200 A 600 V Polyphase pl27 SeriesDocument1 page200 A 600 V Polyphase pl27 SeriesPRABHU SHANKAR MNo ratings yet

- Bacnet From Abb Cylon®: Integrating and Optimising Building Control SystemsDocument8 pagesBacnet From Abb Cylon®: Integrating and Optimising Building Control SystemsPRABHU SHANKAR MNo ratings yet

- Schedule 40 PVC Rigid Nonmetallic ConduitsDocument3 pagesSchedule 40 PVC Rigid Nonmetallic ConduitsPRABHU SHANKAR MNo ratings yet

- Pole Line HardwareDocument10 pagesPole Line HardwarePRABHU SHANKAR MNo ratings yet

- 100 A 600 V King Size Be1 SeriesDocument1 page100 A 600 V King Size Be1 SeriesPRABHU SHANKAR MNo ratings yet

- E Z Ground Grounding SystemsDocument8 pagesE Z Ground Grounding SystemsPRABHU SHANKAR MNo ratings yet

- Service Entrance Masts and AccessoriesDocument11 pagesService Entrance Masts and AccessoriesPRABHU SHANKAR MNo ratings yet

- 200 A (Main Lugs) 600 V Multiple Position - 200 A Per PositionDocument4 pages200 A (Main Lugs) 600 V Multiple Position - 200 A Per PositionPRABHU SHANKAR MNo ratings yet

- 200 A 120/240 V Single-Phase Service A Solution For Meter Sockets Not Installed On The Side of A Residence or BuildingDocument1 page200 A 120/240 V Single-Phase Service A Solution For Meter Sockets Not Installed On The Side of A Residence or BuildingPRABHU SHANKAR MNo ratings yet

- 200 A 600 V Standard Enclosure: BQ2 SeriesDocument12 pages200 A 600 V Standard Enclosure: BQ2 SeriesPRABHU SHANKAR MNo ratings yet

- 9AKK10103A5108 Zenit Catalogue EN 12 21Document224 pages9AKK10103A5108 Zenit Catalogue EN 12 21PRABHU SHANKAR MNo ratings yet

- Maximum Freedom Thanks To The Most Modern Technology ContactsDocument2 pagesMaximum Freedom Thanks To The Most Modern Technology ContactsPRABHU SHANKAR MNo ratings yet

- 20 A 600 V Transformer Rated: CL SeriesDocument3 pages20 A 600 V Transformer Rated: CL SeriesPRABHU SHANKAR MNo ratings yet

- 100 A 600 V Ba3 SeriesDocument1 page100 A 600 V Ba3 SeriesPRABHU SHANKAR MNo ratings yet

- 9AKK107045A7243 - ABB Create Smarter Brochure RevF - 9 - 21Document48 pages9AKK107045A7243 - ABB Create Smarter Brochure RevF - 9 - 21PRABHU SHANKAR MNo ratings yet

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- Data Sheet - Cat Et (Nedg6015-06)Document2 pagesData Sheet - Cat Et (Nedg6015-06)victor.cipriani100% (1)

- CASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)Document3 pagesCASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)engrrahman3135No ratings yet

- Appendix 1: Lesson Plan (Template)Document4 pagesAppendix 1: Lesson Plan (Template)Anonymous X7u8sMNo ratings yet

- M6 L11 FinalDocument12 pagesM6 L11 FinalUrban EcoLab CurriculumNo ratings yet

- CPDS Notes Final Unit 1 PDFDocument25 pagesCPDS Notes Final Unit 1 PDFSai TejaNo ratings yet

- Baan ERP HistoryDocument18 pagesBaan ERP HistoryBalaji_SAPNo ratings yet

- Managerial EconomicsDocument219 pagesManagerial Economicsashishpandey1261100% (2)

- SFTP Certificate Handling in BISDocument18 pagesSFTP Certificate Handling in BISkemoT1990TM100% (1)

- Catalog07 PDFDocument13 pagesCatalog07 PDFdeig15050% (2)

- Est-Pergola Octogonal 21-03-2022Document1 pageEst-Pergola Octogonal 21-03-2022Victor MuñozNo ratings yet

- Chpt6 Taylor Made HONDocument23 pagesChpt6 Taylor Made HONManju MudakaviNo ratings yet

- Trane VAV Equipment SpecificationsDocument52 pagesTrane VAV Equipment Specificationsyu4212No ratings yet

- 2SK3377Document5 pages2SK3377Jheremy Sebastian TorresNo ratings yet

- Power GenerationDocument34 pagesPower GenerationTaufiq AkbarNo ratings yet

- Etic HackDocument31 pagesEtic HackJOrdi CrespoNo ratings yet

- Tutorial 9Document4 pagesTutorial 9fawwazfauzi2004No ratings yet

- AS9104 2A Form-CDocument3 pagesAS9104 2A Form-C44abcNo ratings yet

- Creation of Customer From Business PartnerDocument9 pagesCreation of Customer From Business PartnerParag SoniNo ratings yet

- AMAZONE ZA-F 604 Uputstvo Za Koristenje I OdrzavanjeDocument32 pagesAMAZONE ZA-F 604 Uputstvo Za Koristenje I OdrzavanjeIvonaLepir100% (1)

- Design of Staircase by Limit State Method UNIT-5: C.risers Minus OneDocument5 pagesDesign of Staircase by Limit State Method UNIT-5: C.risers Minus OneVAIJAYANTHI PNo ratings yet