Professional Documents

Culture Documents

SCM 2022 14

Uploaded by

Jamal Mohamed RahamathullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCM 2022 14

Uploaded by

Jamal Mohamed RahamathullahCopyright:

Available Formats

OMS SALERI SAUDIA CO.

,

MINUTES OF MEETING 2ND INDS. CITY,

(MOM) DAMMAM

Title: Safety Communication Weekly Meeting MOM No.: SCM-2022-14

Topic: The Most Common Mechanical Industrial Date: 03-Apr-2022

Workshop Injuries.

Time: 08.45 AM

Venue: OMS Workshop

Attendees:

Sl. No. Name of Attendees Designation Signature

01 ABDUL HUQE PAINTER

02 MAHBOOB HASAN MAINTENANCE TECHNICIAN

03 DURAI RAJU MACHINIST

04 MAHADEV ASHOK PAINTER

05 MANOJ MERINO VALVE TECHNICIAN

06 ABDULLAH AL BUTI HR & ADMIN

07 ABDUL AZIZ STORE

08 ABDULLAH ALMODHAFAR PPC

09 RAHAMATHULLAH QC

All nominated attendees are responsible for attending on the time and date specified.

Sl. No. Details Responsibility Remarks

a) Safety Communication Weekly Meeting will be

conducted on every Sunday at 8.45 am and Toolbox

Talk will be conducted on week days at 8.35am. Staff’s, Valve

Technicians,

b) Production Engineer, Production Supervisor or foreman Maintenance

1.

should conduct the Toolbox Talk, even though, in Technician,

absence of Safety Officer. Record shall be submitted to Painters and

the Safety Officer on the next day. Helpers

Safety induction is basic requirement which must be

compiled without any negligence

Page 1 of 3 Doc. No.: SCM 01 Rev. 00

OMS SALERI SAUDIA CO.,

MINUTES OF MEETING 2ND INDS. CITY,

(MOM) DAMMAM

Staff’s, Valve

The Most Common Mechanical Industry Workshop Technicians,

Injuries: Maintenance

Technician,

There are different types of injuries that occurs in the Painters and

workshops. But some of injuries stand out more than other Helpers

2. injuries, because they occur more frequently and recur more

often than other types of injuries.

Any time injuries occur frequently and repetitively, it’s worth

a closer look.

Following are the most common injuries in mechanical

industry workshops, and safe work practices to prevent them.

1. Back Injuries

2. Hand Injuries and

3. Eye Injuries

1. Back Injuries:

Back Injuries are one of the most common injuries that occur

prefab shops. The injuries occur during the manual material

handling. The following to prevent these types of injuries.

a) Keep the material as close to your work place/station

as much as possible.

b) Use material Lifting/moving equipment such as forklift,

trolly/pallet jacks, gantry crane/EOT etc.,

c) When you need to move the materials manually, make

sure your muscles are warm and flexible, get help when

the materials are heavy and/or bulky, and use proper

techniques.

2. Hand Injuries:

Hand Injuries are another common injury that occur

prefab shops. Most of the hand injuries are cut from sharp

edges, gouges from the slipping hand tools and pinches from

moving materials.

Occasionally, someone gets a hand crushed by moving

materials, machines or other equipment’s.

The following to prevent these types of injuries.

a) Use Wear cut resistant gloves, that fit correctly and

allow you to grip materials.

Page 2 of 3 Doc. No.: SCM 01 Rev. 00

OMS SALERI SAUDIA CO.,

MINUTES OF MEETING 2ND INDS. CITY,

(MOM) DAMMAM

b) You must ne know where you place your hands, when

you are moving materials, especially stacked materials.

c) Before you use the power tools and equipment, make

sure the guards are in place and proper.

3. Eye Injuries:

Eye Injuries are also common injury in prefab shops. Most

of the time they take place when safety glass wasn’t used.

Or someone looked at a welding arc without proper eye

Protection.

The following to prevent these types of injuries.

a) Get in the habit of PPE including safety glasses before

you enter the workshop, and never remove them off

until you exit from the workshop.

Next Safety Meeting will be held on: 10-April-2022

MOM Prepared By: RAHAMATHULLAH JM

QCI

Management Representative General Manager

Page 3 of 3 Doc. No.: SCM 01 Rev. 00

You might also like

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 008 Machinery SafetyDocument6 pages008 Machinery Safetyimranul haqNo ratings yet

- Ingles Tecnico Trabajo FinalDocument7 pagesIngles Tecnico Trabajo FinalArturo Tapia SolisNo ratings yet

- CE06 Use of Power SawDocument3 pagesCE06 Use of Power SawTafireyi TeveraNo ratings yet

- Osha ReportDocument12 pagesOsha ReportHusain MohdNo ratings yet

- COREN Olatunde TanimolaDocument43 pagesCOREN Olatunde TanimolaAdeola JosephNo ratings yet

- HSE Alert 105-21 Welder Finger InjuryDocument2 pagesHSE Alert 105-21 Welder Finger InjuryAlecs NedeaNo ratings yet

- Project Work InstructionDocument5 pagesProject Work InstructionRAJU RAJPUTNo ratings yet

- Machine GuardingDocument10 pagesMachine GuardingYarenNo ratings yet

- Ambuja Cements Limited Unit-Rabriyawas: Work Instruction For ILC & SLC PH Cyclone Refractory Bricks Maintenance JobDocument3 pagesAmbuja Cements Limited Unit-Rabriyawas: Work Instruction For ILC & SLC PH Cyclone Refractory Bricks Maintenance JobSantanu PachhalNo ratings yet

- Machine Safety Standard Full VersionDocument229 pagesMachine Safety Standard Full VersionDiniy Yusof0% (1)

- Assignment HIRARCDocument11 pagesAssignment HIRARC2022467678No ratings yet

- Safety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09Document3 pagesSafety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09madhulikaNo ratings yet

- Unit - I Industrial SafetyDocument27 pagesUnit - I Industrial SafetyKanda SamyNo ratings yet

- Safe Working Procedure For Band SawDocument2 pagesSafe Working Procedure For Band SawsizweNo ratings yet

- 1 Hot Metal Tapping SOPDocument25 pages1 Hot Metal Tapping SOPSANJAY KUMAR PATINo ratings yet

- Nebosh Ra 2Document14 pagesNebosh Ra 2mustafa el refaey0% (1)

- Assignment (Ir)Document4 pagesAssignment (Ir)81C RICHIK MAITYNo ratings yet

- 007 Oper. Control - Injection Molding MachineDocument6 pages007 Oper. Control - Injection Molding MachineRobert UlatanNo ratings yet

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Machine Safety ProcedureDocument4 pagesMachine Safety ProcedureSaad Eddine IboudghacemNo ratings yet

- New Sop DemolitionDocument8 pagesNew Sop Demolitionabhishek narayan singhNo ratings yet

- CNC LatheDocument8 pagesCNC LatheHanif RafizanNo ratings yet

- Maintenance ManualDocument43 pagesMaintenance ManualAlan Jimenez Gonzalez100% (1)

- Amspl Ppe Policy FinalDocument4 pagesAmspl Ppe Policy Finalmool rajNo ratings yet

- Mechanical HazardsDocument57 pagesMechanical HazardsZainorin AliNo ratings yet

- Review Article: Machine Fault Signature AnalysisDocument11 pagesReview Article: Machine Fault Signature AnalysisEclipse ShuNo ratings yet

- Chapter 1 Introduction To Mechanical WorkshopDocument10 pagesChapter 1 Introduction To Mechanical WorkshopDipayan DasNo ratings yet

- Marine Hsse Final Assignment Chop SawDocument11 pagesMarine Hsse Final Assignment Chop SawMuhammad Mirza RaziqNo ratings yet

- Method Statement For DemolitionDocument7 pagesMethod Statement For DemolitionNikita KasyanovNo ratings yet

- TV712 IS CertificateDocument2 pagesTV712 IS CertificateZia UddinNo ratings yet

- 3. job-safety Sheet piling 钢板桩工作安全分析Document3 pages3. job-safety Sheet piling 钢板桩工作安全分析ADEN LIUNo ratings yet

- Autel BT608e Manual PDFDocument69 pagesAutel BT608e Manual PDFBATERÍAS MZNo ratings yet

- T-MEET001 CEE31 Basic OSH Group-3 Case StudyDocument9 pagesT-MEET001 CEE31 Basic OSH Group-3 Case StudyXam AcostaNo ratings yet

- Work Method Statements For Reed SelectDocument53 pagesWork Method Statements For Reed SelectInoe InaeNo ratings yet

- Die Casting SafetyDocument47 pagesDie Casting SafetyTrang Anh Toàn0% (1)

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile CapknabpshoNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Discuss Clearly About Two Inspection Methods For Checking of Machines and EquipmentDocument4 pagesDiscuss Clearly About Two Inspection Methods For Checking of Machines and Equipmentmuhaba muhamedNo ratings yet

- 250KVA Gen No1 Mantrac ServiceDocument3 pages250KVA Gen No1 Mantrac ServiceDarren OscarNo ratings yet

- Safety in The Process Industry: Chemical Engineering DepartmentDocument17 pagesSafety in The Process Industry: Chemical Engineering DepartmentDon Aries EidosNo ratings yet

- Workshop SafetyDocument53 pagesWorkshop SafetyMunir AhmedNo ratings yet

- New Holland G170 G190 G210 G240 Repair ManualDocument2,105 pagesNew Holland G170 G190 G210 G240 Repair ManualDing DangNo ratings yet

- Workshop Technology Notes B.EDocument58 pagesWorkshop Technology Notes B.EMonikandonNo ratings yet

- WSH Guidelines On Safe Use of Machinery PDFDocument72 pagesWSH Guidelines On Safe Use of Machinery PDFIoannisVourdounisNo ratings yet

- Mdx36Range: Installation, Use and Maintenance GearlessDocument36 pagesMdx36Range: Installation, Use and Maintenance GearlessANTONIO ROSARIO ESCUDERONo ratings yet

- 297967.1 - Safety - Manual (Es)Document78 pages297967.1 - Safety - Manual (Es)REINALDO ANTONIO NAVARRO BLANCONo ratings yet

- Internship Report: Value Added CourseDocument9 pagesInternship Report: Value Added CourseHarihar RathinakumaranNo ratings yet

- Instruction Manual TT1800SY PDFDocument244 pagesInstruction Manual TT1800SY PDFGriffin Armament SuppressorsNo ratings yet

- Jha Piping Insulation Installation and Dismantle Work p28Document12 pagesJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- SOP of Idler ChangeDocument9 pagesSOP of Idler ChangeDwitikrushna RoutNo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Talk On Requirements For EquipmentDocument1 pageTalk On Requirements For EquipmentNicolas LelorrainNo ratings yet

- Ford - New Holland Tractors 8670, 8670A, 8770, 8770A, 8870, 8870A, 8970, 8970A Service Manual - CompressedDocument2,105 pagesFord - New Holland Tractors 8670, 8670A, 8770, 8770A, 8870, 8870A, 8970, 8970A Service Manual - CompressednoshansNo ratings yet

- Sinumerik Sinumerik 808D Mechanical Installation ManualDocument34 pagesSinumerik Sinumerik 808D Mechanical Installation ManualRogério PereiraNo ratings yet

- User Manual Portable Mixer MachineDocument32 pagesUser Manual Portable Mixer MachineFadhli HashimNo ratings yet

- Management - U01 - C04.: Diploma in ME/EE/EP/EU/CH/PSDocument16 pagesManagement - U01 - C04.: Diploma in ME/EE/EP/EU/CH/PSAbhishek ChavanNo ratings yet

- SOP PARDIH (Epoxy Flooring) RevisedDocument6 pagesSOP PARDIH (Epoxy Flooring) RevisedNaman Kumar75% (4)

- SCSPlan KMDocument1 pageSCSPlan KMJamal Mohamed RahamathullahNo ratings yet

- W DM CertificateDocument1 pageW DM CertificateJamal Mohamed RahamathullahNo ratings yet

- Exp Jul 2022Document1 pageExp Jul 2022Jamal Mohamed RahamathullahNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Comp. A GRDocument10 pagesComp. A GRJamal Mohamed RahamathullahNo ratings yet

- VPC BD 2022Document1 pageVPC BD 2022Jamal Mohamed RahamathullahNo ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Coa D WaDocument1 pageCoa D WaJamal Mohamed RahamathullahNo ratings yet

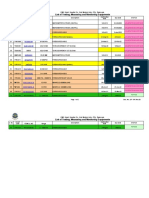

- List of Testing, Measuring and Monitoring Equipments 31st July 2022Document1 pageList of Testing, Measuring and Monitoring Equipments 31st July 2022Jamal Mohamed RahamathullahNo ratings yet

- Carboguard 890 FinishDocument1 pageCarboguard 890 FinishJamal Mohamed RahamathullahNo ratings yet

- List of Testing Measuring and Monitoring Equipments 31st July 2022Document2 pagesList of Testing Measuring and Monitoring Equipments 31st July 2022Jamal Mohamed RahamathullahNo ratings yet

- Rawae Al Amal Industrial Services: IndexDocument4 pagesRawae Al Amal Industrial Services: IndexJamal Mohamed RahamathullahNo ratings yet

- RAA - Procurement InchargeDocument3 pagesRAA - Procurement InchargeJamal Mohamed RahamathullahNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataJamal Mohamed RahamathullahNo ratings yet

- Carboline Thinner 33Document1 pageCarboline Thinner 33Jamal Mohamed RahamathullahNo ratings yet

- G - 1 AttachmentDocument12 pagesG - 1 AttachmentJamal Mohamed RahamathullahNo ratings yet

- Sepco Arabia: King Salman International Complex For Maritime Industries & Services ProjectDocument1 pageSepco Arabia: King Salman International Complex For Maritime Industries & Services ProjectJamal Mohamed RahamathullahNo ratings yet

- Date Isak/Day OT Guddu OT Munna OT Lunch Allowence Lunch AllowenceDocument24 pagesDate Isak/Day OT Guddu OT Munna OT Lunch Allowence Lunch AllowenceJamal Mohamed RahamathullahNo ratings yet

- QSP-010 Product Iden.&TraceabilityDocument5 pagesQSP-010 Product Iden.&TraceabilityJamal Mohamed Rahamathullah100% (1)

- Rawae Al Amal Industrial Services: Quality ManaulDocument1 pageRawae Al Amal Industrial Services: Quality ManaulJamal Mohamed RahamathullahNo ratings yet

- Rawae Al Amal Industrial Services: IndexDocument5 pagesRawae Al Amal Industrial Services: IndexJamal Mohamed RahamathullahNo ratings yet

- Sl. No Equipment List Model Sl. No Equipment List ModelDocument1 pageSl. No Equipment List Model Sl. No Equipment List ModelJamal Mohamed RahamathullahNo ratings yet

- Date Material Specification QuantityDocument4 pagesDate Material Specification QuantityJamal Mohamed RahamathullahNo ratings yet

- Rawae Al Amal Industrial Services: Work InstructionDocument3 pagesRawae Al Amal Industrial Services: Work InstructionJamal Mohamed RahamathullahNo ratings yet

- Material Summary: Project Client Drawing No. DescriptionDocument1 pageMaterial Summary: Project Client Drawing No. DescriptionJamal Mohamed RahamathullahNo ratings yet

- Customer Supplied Material ProcedureDocument2 pagesCustomer Supplied Material ProcedureJamal Mohamed RahamathullahNo ratings yet

- Sl. No Equipment List ModelDocument3 pagesSl. No Equipment List ModelJamal Mohamed RahamathullahNo ratings yet

- Aljeri Equipment ListDocument2 pagesAljeri Equipment ListJamal Mohamed RahamathullahNo ratings yet

- Rawae Al Amal Industrial Services: Quality System ProcedureDocument4 pagesRawae Al Amal Industrial Services: Quality System ProcedureJamal Mohamed RahamathullahNo ratings yet

- Job Sheet - Week 7 Level 5Document4 pagesJob Sheet - Week 7 Level 5Salman Muneer AhmedNo ratings yet

- Inspection PDFDocument27 pagesInspection PDFNagy Elrasheedy100% (2)

- Basic Metatrader 5 GuideDocument22 pagesBasic Metatrader 5 GuideDavid Al100% (1)

- Dynalog3.4 Update enDocument13 pagesDynalog3.4 Update enMirsad MurticNo ratings yet

- Chapter 1 FinanceDocument17 pagesChapter 1 FinanceRanin, Manilac Melissa SNo ratings yet

- 9i DBA Performance Tuning R2 V2 - D37163Document374 pages9i DBA Performance Tuning R2 V2 - D37163avk.oracleNo ratings yet

- Excel Wide Path Undercarriage REV2 English EDocument41 pagesExcel Wide Path Undercarriage REV2 English EPeter FrankNo ratings yet

- NRP5 Organization Review All - Optimization - 220224Document22 pagesNRP5 Organization Review All - Optimization - 220224trirat phonloedNo ratings yet

- 2 N 4036Document3 pages2 N 4036sas999333No ratings yet

- Project Report On BHELDocument47 pagesProject Report On BHELManju Tokas0% (1)

- Sybase AseDocument25 pagesSybase AseSudheer Koppala0% (1)

- Supplier Quality Development A Review of Literature and Industry PracticesDocument23 pagesSupplier Quality Development A Review of Literature and Industry PracticesAli ZulqarnainNo ratings yet

- Project Management AIO PDFDocument11 pagesProject Management AIO PDFEngr M Asad RiazNo ratings yet

- Cpa WorksheetDocument2 pagesCpa WorksheetAditi MishraNo ratings yet

- Reo Detailing HandbookDocument201 pagesReo Detailing HandbookYuki Gitara100% (5)

- Composite Properties of RTM370 Polyimide Fabricated by Vacuum Assisted Resin Transfer Molding (VARTMDocument10 pagesComposite Properties of RTM370 Polyimide Fabricated by Vacuum Assisted Resin Transfer Molding (VARTMnhackoloi93No ratings yet

- HorschDocument69 pagesHorschIonita SebastianNo ratings yet

- OSHA Ladder Safety Brochure - FinalDocument6 pagesOSHA Ladder Safety Brochure - FinalNaveed RabbaniNo ratings yet

- Using Diagnostic and Interactive Control SystemDocument20 pagesUsing Diagnostic and Interactive Control SystemNovi KusumaNo ratings yet

- L1 Adaptive ControlDocument139 pagesL1 Adaptive ControlDavid EstevesNo ratings yet

- Docu60239 Symmetrix VMAX and VMAXe Series Enginuity Operating Environment ReadMe For Enginuity Service Packs Release Level 5876.286.194Document23 pagesDocu60239 Symmetrix VMAX and VMAXe Series Enginuity Operating Environment ReadMe For Enginuity Service Packs Release Level 5876.286.194Dhananjay GuptaNo ratings yet

- Approved OilsDocument4 pagesApproved OilsmsiarovNo ratings yet

- XB 70 PDFDocument16 pagesXB 70 PDFKIRU SILVIUNo ratings yet

- GB 070614 Mod3 TGX Tgs ArgDocument79 pagesGB 070614 Mod3 TGX Tgs ArgCleverson Jose GodinhoNo ratings yet

- FloatDocument6 pagesFloataakash3978No ratings yet

- Letter of Introduction-SWORD ElevatorDocument2 pagesLetter of Introduction-SWORD ElevatorMohamad Ikhwan0% (1)

- TIC ContributorsDocument5 pagesTIC ContributorsPatrick SvitekNo ratings yet

- Container - Filling - Plants - Eng Kosan CrispanDocument2 pagesContainer - Filling - Plants - Eng Kosan CrispanNick DolsurenNo ratings yet