Professional Documents

Culture Documents

Project Work Instruction

Uploaded by

RAJU RAJPUTOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Work Instruction

Uploaded by

RAJU RAJPUTCopyright:

Available Formats

CIS INDUSTRIES

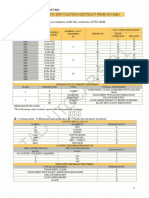

TITLE : WORK INSTRUCTION FOR Co2 WELDING

DOC. NO : WI/07 CL. NO. : 7.5.2 PG. NO. : 01 of 01

SR. NO. PARAMETER

PART A- Current Issue

Task/Activity: Date:

Tool/Equipment Required to complete the

task:

Personal Protective Equipment (PPE) Required (Comments in the box below for the required PPE):

Suitable Hearing Protective Cloth-

Hand Protection Face Masks Eye Protection Full face shield

Footwear Protection ing

REV NO : 00 REL DATE : 10/04/2023

CIS INDUSTRIES

TITLE : WORK INSTRUCTION FOR CLEANING OF PREMISES

DOC. NO : WI/02 CL. NO. : 6.4 PG. NO. : 01 of 01

SR. PARAMETER DOC/REC NO.

NO.

01 Clean the shop floor & office daily.

02 Ensure that nobody spits on the shop floor.

03 Ensure that drinking water system & toilet system is neat and clean.

04 Ensure that all-working tables, chairs, other furniture, fans, tube

lights etc. are neat and clean.

05 Keep waste, generated during the shift in bins.

06 Cotton waste / scrap paper lying on the shop floor should be thrown

in the dustbin.

07 Ensure that cutting oil, kerosene, machine oil etc. not spilled on shop

floor.

08 Cutting oil, kerosene, machine oil etc. spilled on shop floor should be

soaked immediately.

09 Pants, Shirts, aprons changed while on duty to be kept at dedicated

place only.

10 Do not keep loose papers, files etc. on tables after duty hours.

REV NO : 00 REL DT : 10/04/2023

CIS INDUSTRIES

TITLE : WORK INSTRUCTION FOR MILLING M/C

DOC. NO. : WI/03 CL. NO.: 7.5.1 PG. NO. : 01 of 01

SR. NO. PARAMETER

1. Keep the material near m/c.

2. Clean the Milling m/c before its use.

3. Lubricant all parts of Milling m/c.

4. Check m/c is properly working or not.

5. Select the cutting tool as per requirement.

6. Clamp the cutting tool tightly.

7. Produce one job and handover it to Q.A. I/c to check it. If component is OK as per Process

plan, then continue the production, if not then ask Prod I/c to set the M/c, to get job as per

requirement.

8. Remove all material to store or as per instruction.

9. After completion of production clean M/c & surrounding area.

REV NO : 00 REL DATE : 10/04/2023

CIS INDUSTRIES

TITLE: WORK INSTRUCTIONS FOR DRILLING M/C

DOC. NO : WI/06 CL. NO. : 7.5.1 PG. NO. : 01 of 01

SR. NO. PARAMETER

1. Check all electrical connection of machine for working condition.

2. Take required no of jobs as per Prod I/c instruction and put it on proper location so

that it will easy to operate the machine.

3. Insure that Process plan of the job is displayed near the machine. If not ask Prod.

I/c for Process plan.

4. Select the drill & fixture as per Process Plan.

5. Clamp the fixture & drill on machine & ensure that job rests correctly on the fixture.

6. Do not use hand gloves.

7. Drill the 1st job and offer to Prod. I/c.

8. If approved start production. If not get instruction from Prod I/c; make necessary

changes till next piece gets approved.

9. In continues production check jobs from Prod I/c as per Process plan.

10. Keep rejected material in Rejection Area so that it can't mix in OK jobs.

11. Do not mix conform material in nonconforming material.

12. Switch off the machine & then clean the machine & machine area after the use.

REV NO : 00 REL DATE : 10/04/2023

CIS INDUSTRIES

TITLE : WORK INSTRUCTION FOR Co2 WELDING

DOC. NO : WI/07 CL. NO. : 7.5.2 PG. NO. : 01 of 01

SR. NO. PARAMETER

1. Check & tight the nut & bolt of welding holder.

2. Take the instruction about job, which is to be welded.

3. Job's which are going to be welded must be clean.

4. Switch on the machine & set the machine parameter as per requirement.

5. Ensure that the drawing of the operation, which is carried, on machine is displayed

by the side of the machine.

6. Weld 1st piece & inspect it.

7. If job is conforming then continue production.

8. Apply anti spatter spray on gas nozzle & contact tip at regular interval to avoid

spatter on them.

9. Switch off the machine & then clean the machine & machine area after completion

of the work.

REV NO : 00 REL DATE : 10/04/2023

You might also like

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Works Instructions For Preparing The SampleDocument2 pagesWorks Instructions For Preparing The Sampleyadu kumar singhNo ratings yet

- DAQ1-0092Q Regulations Exterior Defects Management (17) en (1) 1Document43 pagesDAQ1-0092Q Regulations Exterior Defects Management (17) en (1) 1yeucongnghemoiNo ratings yet

- Electrolytic Zinc Coating PDFDocument2 pagesElectrolytic Zinc Coating PDFzoran100% (1)

- ASMEY14.5M Geometric Dimensioning and TolerancingDocument239 pagesASMEY14.5M Geometric Dimensioning and TolerancingVicente Pañol VNo ratings yet

- Die Maintenance. Die Repair.Document9 pagesDie Maintenance. Die Repair.zfrlNo ratings yet

- TS-0002074 Rev AfDocument9 pagesTS-0002074 Rev AfRaul GarciaNo ratings yet

- Form Tooling List Approval Tooling (002) Rev 4Document3 pagesForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNo ratings yet

- Battery Management Systems For Electric Vehicles: Bachelor of TechnologyDocument25 pagesBattery Management Systems For Electric Vehicles: Bachelor of TechnologyJatin YadavNo ratings yet

- Pneumatic Seal Catalogue 2022Document141 pagesPneumatic Seal Catalogue 2022Septyan kurnia ardiansyahNo ratings yet

- Die Material Spec FordDocument35 pagesDie Material Spec FordluisA1923No ratings yet

- Mold DesignDocument326 pagesMold DesignYoNo ratings yet

- PS 8956 NDocument7 pagesPS 8956 N林坤緯No ratings yet

- MS201 01Document20 pagesMS201 01mehmet ustunNo ratings yet

- Works Instructionsfor Belt GrinderDocument2 pagesWorks Instructionsfor Belt Grinderyadu kumar singhNo ratings yet

- GMW 14669 Table CDocument1 pageGMW 14669 Table CJOECOOL67No ratings yet

- STN - GMP Powertrain/Carbody Adaptation Interface Assembled Exhaust LineDocument42 pagesSTN - GMP Powertrain/Carbody Adaptation Interface Assembled Exhaust LineAlireza AameriNo ratings yet

- Esbm5a 1B310 S AaDocument28 pagesEsbm5a 1B310 S AaAlanevh AlanevhNo ratings yet

- Specifikations Moulds enDocument79 pagesSpecifikations Moulds enNuță AlinNo ratings yet

- MTTR - MTBFDocument4 pagesMTTR - MTBFChalapathi ReddyNo ratings yet

- 98-01 VFR800 Instruction Manual (Low Quality)Document21 pages98-01 VFR800 Instruction Manual (Low Quality)Walsky KoleNo ratings yet

- For Suppliers: IMDS Operation ManualDocument27 pagesFor Suppliers: IMDS Operation ManualKaran MalhiNo ratings yet

- RAS-3015T 1000W: Technical ProposalDocument15 pagesRAS-3015T 1000W: Technical ProposalAhmed ShafeekNo ratings yet

- Quality Manufacturing Today Magazine September 2008Document40 pagesQuality Manufacturing Today Magazine September 2008Pat Coyne100% (1)

- Quality Assurance Plan: Sheet MetalDocument2 pagesQuality Assurance Plan: Sheet Metalsabir hussain0% (1)

- Iocl-3030mg (U)Document1 pageIocl-3030mg (U)Vignesh SubramanianNo ratings yet

- Engineering Material SpecificationDocument9 pagesEngineering Material SpecificationReginaldo SantosNo ratings yet

- CSR Matrix For RefDocument4 pagesCSR Matrix For RefnormalNo ratings yet

- AdvancesDocument20 pagesAdvancesZeeshan MohamedNo ratings yet

- CBHF2-D 36V 25A Technical Manual US Version1Document4 pagesCBHF2-D 36V 25A Technical Manual US Version1Stefan CorjucNo ratings yet

- Automatic Portable Spot Welding MachineDocument24 pagesAutomatic Portable Spot Welding MachinekeerthanaNo ratings yet

- MFDP2 - L04 - Deep Drawing and Stretch Drawing - ENIM 2021-22Document43 pagesMFDP2 - L04 - Deep Drawing and Stretch Drawing - ENIM 2021-22Alaa RmidaNo ratings yet

- 2.declaration TypeDocument8 pages2.declaration TypeTauseef JuttNo ratings yet

- DU Sliding Material SpecificationsDocument55 pagesDU Sliding Material SpecificationsMichał AmborNo ratings yet

- Gauges and InstrumentsDocument14 pagesGauges and InstrumentsRatan Misra100% (1)

- Analysis of Structure of C Type Hydraulic PressDocument10 pagesAnalysis of Structure of C Type Hydraulic PressShubhamNo ratings yet

- Special Terms 2012: Mercedes-BenzDocument53 pagesSpecial Terms 2012: Mercedes-BenzMatija KovačičNo ratings yet

- ViseDocument4 pagesVisemichaelguzzi100% (1)

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Engineering Specification: ESFU5A-8079-AADocument5 pagesEngineering Specification: ESFU5A-8079-AAjavier ortizNo ratings yet

- Unit I Fundamentals of DesignDocument8 pagesUnit I Fundamentals of DesignChaitanya YengeNo ratings yet

- DFM LectureDocument46 pagesDFM LectureMuhammad Khairul BasarNo ratings yet

- Supply Specification DBL 5555: General ConditionsDocument17 pagesSupply Specification DBL 5555: General ConditionsMateo BanzanNo ratings yet

- DIN 17022-5 - Heat Treating of Ferrous Materials PDFDocument13 pagesDIN 17022-5 - Heat Treating of Ferrous Materials PDFFelipe FernandesNo ratings yet

- COUNTER MEASURE of Customer ComplaintDocument2 pagesCOUNTER MEASURE of Customer Complaintpreetam kumarNo ratings yet

- Various Forging ProcessesDocument24 pagesVarious Forging ProcessesHeetNo ratings yet

- Sop May, 2020Document26 pagesSop May, 2020Dheerendra GaikwadNo ratings yet

- A2 Tool Steel: CompositionDocument1 pageA2 Tool Steel: CompositionSama Umate100% (1)

- HIPF Catalog Issue No.12 Rev.1 2022 LDocument30 pagesHIPF Catalog Issue No.12 Rev.1 2022 LJorge Gerardo Riascos QuiñonesNo ratings yet

- V3I2IJERTV3IS21239Document5 pagesV3I2IJERTV3IS21239erwindNo ratings yet

- PIV Exhaust Generic V11Document18 pagesPIV Exhaust Generic V11Alireza AameriNo ratings yet

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- HVC Double Chamber Vacuum Packing Machine ManualDocument46 pagesHVC Double Chamber Vacuum Packing Machine ManualxtrahighgradeNo ratings yet

- CG3043 - GM C1YX-2 HUD - DV1 - PATAC - SignatureDocument160 pagesCG3043 - GM C1YX-2 HUD - DV1 - PATAC - SignatureUlises SalazarNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument14 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- FIVB Official Beach Volleyball Net: User's ManualDocument28 pagesFIVB Official Beach Volleyball Net: User's ManualGurupandi MariyappanNo ratings yet

- Surface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801Document4 pagesSurface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801anhthoNo ratings yet

- 023 147 Ind ReqDocument2 pages023 147 Ind ReqKishore KumarNo ratings yet

- Project Work Instruction BackupDocument4 pagesProject Work Instruction BackupRAJU RAJPUTNo ratings yet

- All Work InstructionsDocument7 pagesAll Work InstructionsAmine Chahi100% (1)