Professional Documents

Culture Documents

Marine Propulsion Engine: 1678 BKW (2250 BHP) at 1800 RPM

Uploaded by

Resul UygunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Propulsion Engine: 1678 BKW (2250 BHP) at 1800 RPM

Uploaded by

Resul UygunCopyright:

Available Formats

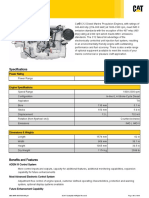

3512E

MARINE PROPULSION ENGINE

1678 bkW (2250 bhp) @ 1800 rpm

ENGINE SPECIFICATIONS

Configuration: Governor

Vee 12, 4-stroke-cycle diesel Electronic (A5 ECM)

Emissions Refill Capacity

U.S. EPA Tier 4 Final certified Lube Oil System w/ oil filter change:

IMO III emissions certified 613 L (162 gal)/1000 hrs pan

(SCR required) Oil Change Interval

IMO II-III switchable 1000 hrs

Rated Engine Speed Cooling

1800 rpm Heat exchanger or keel cooled

Bore x Stroke Flywheel Housing

170 mm x 215 mm / 6.69 in x 8.46 in SAE No. 00 with SAE No. 00 flywheel

Displacement (183 teeth)

58.6 Liter / 3574 cu in Rotation

3512E Marine Propulsion Engine Aspiration Counterclockwise from flywheel end

U.S. EPA Tier 4 Final / IMO III Turbocharged-aftercooled

aspiration

FEATURES AND BENEFITS OPTIONAL ATTACHMENTS

• Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations • Plate-type heat exchanger with integrated SCAC and JW Water expansion

compliance while lowering operational costs tanks

• Utilizes closed loop air assisted DEF dosing control strategy that delivers: • Special appearance packages with chrome covers

• Highest efficiency mixing and control to lower operational costs • Marine society certifications

• Extends emissions useful life • Power take-off

• Ensures compliance • Certified marine alarm and protection safety system

• Flexible to urea quality • Standard instrument panel with color touchscreen display

• Advanced engine combustion design process utilizing optimum • Mounting rails and trunnion mount options

configurations and cylinder geometry for maximum engine efficiency • Engine mounted fuel cooler (SCAC Water Cooled)

• Enhanced control of fuel injection optimized through crank timing and the • Sea water pump with 25% more capacity for cooling auxiliary vessel

latest A5 ECM technology equipment

• Optimal fuel injector nozzle geometry and electronic injection control for • Closed crank case ventilation

improved fuel delivery

• Strengthened cylinder heads and valves for increased durability and peak A RATING (UNRESTRICTED CONTINUOUS) DEFINITION

cylinder pressure capability resulting in higher engine duty cycle capability Typical applications: For vessels operating at rated load and rated speed up

• Industry-leading warranty coverage for factory packaged components to 100% of the time without interruption or cyclical load (80% to 100% load

• Global dealer network for service in any location factor). Typical operation ranges from 5000 to 8000 hours per year

STANDARD ENGINE EQUIPMENT

• Corrosion-resistant aftercooler core

• Dual A5 engine control modules with electronic unit injection and low

pressure fuel system

• Dual turbochargers with water-cooled bearings and heat shields

• Vibration damper and guard

• Meets SOLAS regulations

• Duplex Fuel and Oil Filtration

• Auxiliary fresh water pump

• Gear Driven, centrifugal jacket water pump with 40% more capacity

TECHNICAL DATA

3512E Marine Propulsion Engine

PROP DEMAND FUEL & DEF CONSUMPTION (A RATING)

Brake Specific Fuel Consumption DEF Consumption DEF Consumption

32.5 % Concentration 40 % Concentration

rpm bhp lb/bhp-hr bkW g/bkW-hr Gal/hr Liters/hr Gal/hr Liters/hr

1800 2250 0.333 1678 198.6 5.7 21.6 4.3 16.3

1600 1581 0.323 1179 192.5 4.4 16.8 3.4 12.7

1400 1059 0.333 790 198.6 2.4 9.2 1.8 6.9

1200 666 0.349 497 208.0 1.2 4.5 0.9 3.4 For Cat® dealers:

Please reference TMI

1000 386 0.357 288 213.0 0.5 1.9 0.4 1.5

Web for most current

800 197 0.370 147 221.0 0.0 0.0 0.0 0.0 information.

• ISO 3046/1 fluid consumption tolerance of -0/+5% Consult your local Cat® dealer to create a customized engine

• Reference 32.5% DEF density of 1.0895 kg/L TCO (Total Cost of Ownership) analysis specific to your vessel as

• Reference 40% DEF density of 1.1120 kg/L well as for IMO II optimized performance data.

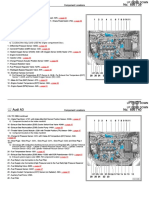

DIMENSIONS & WEIGHT

Length (1) Height (2) Width (3) Engine dry weight

min. 104.2 in/2646 mm 91.9 in/2335 mm 71.2 in/1808 mm 18,025 lb/8,176 kg

2

max. 81.9 in/2081 mm

Note: Do not use these dimensions for installation design.

See general dimension drawings for detail.

3 1

CLEAN EMISSIONS MODULE (CEM)

Clean Emissions Module (CEM)

Dimensions & Weight

Available in U-flow configurations (shown)

Model Length (1) Height (2) Width (3) Weight and Z-flow configurations.

12 Brick Z-Flow 3453.6 mm 1012.4 mm 1627.2 mm 1253.6 kg

135.97 in 39.86 in 64.06 in 2763.7 lb

2712.0 mm 1012.4 mm 1627.2 mm 1261.5 kg 2

12 Brick U-Flow

106.77 in 39.86 in 64.06 in 2783.3 lb

948.6 mm 534.5 mm 477.3 mm

Dosing Cabinet ---

37.35 in 21.05 in 18.79 in 3 1

The 3512E engine requires Selective Catalyst Reduction (SCR) technology.

The easy-to-install Cat® SCR System is an exhaust gas aftertreatment solution Dosing Cabinet

compliant with U.S. EPA Tier 4 Final / IMO III emission standards.

• Proven technology to meet U.S. EPA Tier 4 Final / IMO III emission standards

• IMO II-III switchable calibrations available

2

• Maintains engine efficiency, durability and reliability

• Easy to install with minimum impact to vessel design

• Compact package from one single source

3 1

• Available for new builds and retrofits

• For detailed dimensions and installation requirements, please refer to latest revision of A&I guide LEBM0023.

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow“ and the “Power Edge“ trade dress,

as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without ©2018 Caterpillar

permission. U.S. Sourced All rights reserved.

LEHM0263-02 Materials and specifications are subject to change without notice.

To find your nearest dealer, please visit: www.cat.com/marine The International System of Units (SI) is used in this publication.

You might also like

- Range Rover Classic Workshop ManualDocument767 pagesRange Rover Classic Workshop Manualrange-rover94% (18)

- (MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDocument500 pages(MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDaniel Reconco88% (8)

- 29 Yaris Verso / Echo Verso (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D) (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D)Document1 page29 Yaris Verso / Echo Verso (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D) (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D)Adanaque Villacorta Jd100% (2)

- Cummins QSB 5.9 SheetDocument2 pagesCummins QSB 5.9 SheetDaniel Perez100% (1)

- Caterpillar 3408Document5 pagesCaterpillar 3408Fernando Padilla100% (3)

- 4 5902085539233794318Document366 pages4 5902085539233794318Angel Jesús Agapito Cortez100% (6)

- Cummins 4BT3.3-G5 Parts ManualDocument130 pagesCummins 4BT3.3-G5 Parts Manualthaihung thep100% (1)

- 1206a-E70ttag3 PN3184 - 4Document4 pages1206a-E70ttag3 PN3184 - 4MohamedJaberKutkutMjkNo ratings yet

- C7.1 Gen Set Sales PresentationDocument43 pagesC7.1 Gen Set Sales PresentationSanchez JoseNo ratings yet

- C7 ACERT 205bkWDocument5 pagesC7 ACERT 205bkWsheronNo ratings yet

- Perkins 4012 46TAG2A PDFDocument5 pagesPerkins 4012 46TAG2A PDFAdriawan AnnesNo ratings yet

- DVZ BrochureDocument40 pagesDVZ BrochureResul UygunNo ratings yet

- Fuel Consumption of Construction EquipmentDocument8 pagesFuel Consumption of Construction EquipmentHiremath ShivaprasadNo ratings yet

- 1.4 ltr./132 KW TSI Petrol Engine: Self-Study ProgrammeDocument48 pages1.4 ltr./132 KW TSI Petrol Engine: Self-Study ProgrammeAndrei Baluse100% (3)

- CAT 3406 C Heavy Duty Truck EngineDocument5 pagesCAT 3406 C Heavy Duty Truck EngineAS_865025438100% (1)

- Paccar PX 8 Spec SheetDocument6 pagesPaccar PX 8 Spec SheetCarlos Alberto Gutierrez Lopez0% (1)

- Cat 3406 Fuel ConsumptionDocument5 pagesCat 3406 Fuel Consumptionayman akrab100% (2)

- Bluebird Workshop Manual PDFDocument214 pagesBluebird Workshop Manual PDFAnil RamsuranNo ratings yet

- Cat c15 Fuel ConsumptionDocument8 pagesCat c15 Fuel Consumptionayman akrabNo ratings yet

- Diesel Engine - Marine Gen Set PowerDocument2 pagesDiesel Engine - Marine Gen Set PowerTaufan ArifNo ratings yet

- Cat 3412e PDFDocument4 pagesCat 3412e PDFCristina CoceasuNo ratings yet

- Fundamentals of Gas Turbine Systems R1Document71 pagesFundamentals of Gas Turbine Systems R1hasnaNo ratings yet

- Kess Список Поддерживаемых АвтомобилейDocument276 pagesKess Список Поддерживаемых Автомобилейfreon48100% (1)

- c4.4 Marine Genset SpecsheetDocument4 pagesc4.4 Marine Genset SpecsheetBilel Ben SlamaNo ratings yet

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- Cat 798-AcDocument8 pagesCat 798-AcluischipaNo ratings yet

- C7 Acert EspecificaciónDocument5 pagesC7 Acert EspecificaciónFabrizio Jesus Morales Salirrosas100% (1)

- Marine Propulsion Engine (Imo Ii)Document2 pagesMarine Propulsion Engine (Imo Ii)avinash_1229No ratings yet

- Lehm20288-00 Marine AuxiliaryDocument4 pagesLehm20288-00 Marine AuxiliaryDedi MaryadiNo ratings yet

- High Performance Applications: Marine Propulsion EngineDocument2 pagesHigh Performance Applications: Marine Propulsion EngineRocco SilfieddiNo ratings yet

- CM20210209 E645b f7f51Document2 pagesCM20210209 E645b f7f51n.gawasNo ratings yet

- D13-MH (FE) - AUX 290a500HP MarinoDocument3 pagesD13-MH (FE) - AUX 290a500HP MarinoClaudioNo ratings yet

- Specifications: Ugarcane AndlerDocument4 pagesSpecifications: Ugarcane AndlercblancasNo ratings yet

- C93 310bkW Spec Sheet HEXDocument5 pagesC93 310bkW Spec Sheet HEXHammad AneesNo ratings yet

- Lehw0258 02Document4 pagesLehw0258 02Robel KebedeNo ratings yet

- Specifications: Ompact Heel OaderDocument4 pagesSpecifications: Ompact Heel OaderMego PlamoniaNo ratings yet

- Marine Auxiliary Engine (U.S. Epa Tier 3 / Imo Ii) : 208 BKW (280 BHP) at 2300 RPMDocument2 pagesMarine Auxiliary Engine (U.S. Epa Tier 3 / Imo Ii) : 208 BKW (280 BHP) at 2300 RPMtruong nguyenNo ratings yet

- CM20210223 Dcdec 95cf5Document2 pagesCM20210223 Dcdec 95cf5kumarraghuNo ratings yet

- 918M PDFDocument4 pages918M PDFYundi GaoNo ratings yet

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pages4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoNo ratings yet

- Marine Generator Set: 781 BKW (1047 BHP) at 1800 RPM / 994 BKW (1333 BHP) at 1800 RPMDocument2 pagesMarine Generator Set: 781 BKW (1047 BHP) at 1800 RPM / 994 BKW (1333 BHP) at 1800 RPMavinash_1229No ratings yet

- 2206C-E13TAG3 EngineDocument5 pages2206C-E13TAG3 EngineAnamta KhanNo ratings yet

- 4012 46twg2aDocument5 pages4012 46twg2aWgghggd FdqwqgvgNo ratings yet

- Specifications: Ompact Heel OaderDocument4 pagesSpecifications: Ompact Heel OadergoncaloNo ratings yet

- PDFDocument5 pagesPDFTaylorNo ratings yet

- MSS Mar 18349729 004 PDFDocument6 pagesMSS Mar 18349729 004 PDFTom BoeremaNo ratings yet

- C Series Marine 480 HP (343kW) : Engine SpecificationsDocument2 pagesC Series Marine 480 HP (343kW) : Engine SpecificationsFred WestlingNo ratings yet

- CAT-C15 ACERT-Ind - EngineDocument5 pagesCAT-C15 ACERT-Ind - EngineRakesh DoshiNo ratings yet

- PN3183 3Document4 pagesPN3183 3Osanebi Chukwudi LuckyNo ratings yet

- C4.4 ACERT Sales PresentationDocument39 pagesC4.4 ACERT Sales PresentationDjebali Mourad100% (1)

- 4.4TW2GM - Data (2) 28Document2 pages4.4TW2GM - Data (2) 28zahrahassanspecNo ratings yet

- CM20220311 36abd 47aa1Document7 pagesCM20220311 36abd 47aa1shinojNo ratings yet

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 pagesCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)avinash_1229100% (1)

- Cat 3508Document4 pagesCat 3508Sopian PianNo ratings yet

- Page: M-1 of M-5 © 2017 Caterpillar All Rights Reserved MSS-MAR-18409526-005 PDFDocument5 pagesPage: M-1 of M-5 © 2017 Caterpillar All Rights Reserved MSS-MAR-18409526-005 PDFVươngNo ratings yet

- C9 ACERT 224bkWDocument5 pagesC9 ACERT 224bkWAlief FadilNo ratings yet

- 4000 Series: 4012-46TAG2ADocument5 pages4000 Series: 4012-46TAG2Aherry tristantoNo ratings yet

- Petroleum Oil Well Service Engine: 1996 EPA and Carb Non-Road Emissions CertifiedDocument2 pagesPetroleum Oil Well Service Engine: 1996 EPA and Carb Non-Road Emissions Certifiedyamil ramirezNo ratings yet

- Slick Jute Elk ItDocument2 pagesSlick Jute Elk ItkrarNo ratings yet

- 2206a E13tag2Document5 pages2206a E13tag2Shahzad Ali0% (1)

- Catálogo Caterpillar C12Document4 pagesCatálogo Caterpillar C12José ArgüelloNo ratings yet

- Datashhet 4012-46tag2aDocument5 pagesDatashhet 4012-46tag2aacrotech100% (1)

- Small Catalog OHT CAT 773E PDFDocument4 pagesSmall Catalog OHT CAT 773E PDFSupriyono Abdullah100% (1)

- 4000 Series: 4008TAG2ADocument5 pages4000 Series: 4008TAG2ALopo LesmanaNo ratings yet

- STG FPT 65kvaDocument2 pagesSTG FPT 65kvamohamadNo ratings yet

- Industrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselDocument5 pagesIndustrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselLuis Eduardo Albarracin RugelesNo ratings yet

- Tad572ve enDocument2 pagesTad572ve enPakito-sanNo ratings yet

- MSS Mar 18499457 009Document5 pagesMSS Mar 18499457 009Steve HalvexNo ratings yet

- Brosur Baudouin - UVDocument9 pagesBrosur Baudouin - UVmarjukiNo ratings yet

- Hybrid PropulsionDocument9 pagesHybrid PropulsionPRANAV DEVNo ratings yet

- AdBlue Quality Sensor 74701 Fast FactsDocument1 pageAdBlue Quality Sensor 74701 Fast FactsResul UygunNo ratings yet

- Minera GMX - GMX100012579843M00Document2 pagesMinera GMX - GMX100012579843M00AliNo ratings yet

- DI13 072M. 441 KW (600 HP) : IMO Tier II, Us Tier 2, EU Stage IIIADocument2 pagesDI13 072M. 441 KW (600 HP) : IMO Tier II, Us Tier 2, EU Stage IIIAClaudio Enrique Troncoso ParedesNo ratings yet

- HLCP 05 BrochureDocument11 pagesHLCP 05 BrochureResul UygunNo ratings yet

- CA 500 Maintenance M500enDocument35 pagesCA 500 Maintenance M500enalexandreNo ratings yet

- Mk8-MM-Manual-19.05.2020 - ENG - 80-158Document79 pagesMk8-MM-Manual-19.05.2020 - ENG - 80-158Eduardo JoseNo ratings yet

- Mud Pumps: Triplex vs DuplexDocument16 pagesMud Pumps: Triplex vs DuplexAli Shan KakarNo ratings yet

- Department of Education: Republic of The PhilippinesDocument16 pagesDepartment of Education: Republic of The PhilippinesJheng Delos Reyes PantojaNo ratings yet

- Blink Code List For WP12 Diesel EnginesDocument12 pagesBlink Code List For WP12 Diesel Enginesmarsh2002No ratings yet

- Installation Procedure: D6T Track-Type Tractor Machine Systems (KENR5130)Document3 pagesInstallation Procedure: D6T Track-Type Tractor Machine Systems (KENR5130)Edwin juanito gamarra serranoNo ratings yet

- 2.0+TDI+component+locationsDocument18 pages2.0+TDI+component+locationsalmir karahodzicNo ratings yet

- Catalogue Perkins 1104C 44TAG2Document8 pagesCatalogue Perkins 1104C 44TAG2RobNo ratings yet

- Rotate-MD-80 - Tutorial FlightDocument47 pagesRotate-MD-80 - Tutorial FlightgochilindaNo ratings yet

- Seaspan 3rd Engineer OralsDocument7 pagesSeaspan 3rd Engineer OralsVihanga VithanageNo ratings yet

- Ships: High Speed Craft Dry Cargo Ships Fishing Vessels Passenger ShipsDocument1 pageShips: High Speed Craft Dry Cargo Ships Fishing Vessels Passenger Shipsreaz uddin100% (1)

- Engine ClasificationDocument13 pagesEngine Clasificationvasanth9046No ratings yet

- Practical Replacement AssignmentDocument8 pagesPractical Replacement AssignmentSThaneasMurNo ratings yet

- LMS Press Release 5-22-15Document2 pagesLMS Press Release 5-22-15Ricardo SoaresNo ratings yet

- Comparison Between Centrifugal Pump and Reciprocating PumpDocument3 pagesComparison Between Centrifugal Pump and Reciprocating PumpDanyal KhattakNo ratings yet

- User Guide C3R5 - DA - 20210325Document159 pagesUser Guide C3R5 - DA - 20210325jose francisNo ratings yet

- Grade 12: National Senior CertificateDocument19 pagesGrade 12: National Senior CertificateSanu Kaji MaharjanNo ratings yet

- Trial On Boiler To Determine Boiler Efficiency, Equivalent Evaporation and EnergyDocument7 pagesTrial On Boiler To Determine Boiler Efficiency, Equivalent Evaporation and EnergyRavi PatilNo ratings yet

- LUKOIL Marine Lubricants Product Info on NAVIGO TPEO ULTRA Engine OilsDocument2 pagesLUKOIL Marine Lubricants Product Info on NAVIGO TPEO ULTRA Engine OilsGabriel NogueiraNo ratings yet

- Bosch Ev6Document2 pagesBosch Ev6cumhur tasNo ratings yet